无机材料学报 ›› 2024, Vol. 39 ›› Issue (12): 1325-1330.DOI: 10.15541/jim20240156 CSTR: 32189.14.10.15541/jim20240156

所属专题: 【信息功能】柔性材料(202506); 【能源环境】热电材料(202506)

收稿日期:2024-04-01

修回日期:2024-05-27

出版日期:2024-06-24

网络出版日期:2024-06-24

通讯作者:

孙婷婷, 讲师. E-mail: Tingtingsun@dhu.edu.cn;作者简介:张波涛(1997-), 男, 硕士研究生. E-mail: zbtfsy@163.com

基金资助:

ZHANG Botao1( ), SUN Tingting3(

), SUN Tingting3( ), WANG Lianjun1(

), WANG Lianjun1( ), JIANG Wan1,2

), JIANG Wan1,2

Received:2024-04-01

Revised:2024-05-27

Published:2024-06-24

Online:2024-06-24

Contact:

SUN Tingting, lecturer. E-mail: Tingtingsun@dhu.edu.cn;About author:ZHANG Botao (1997-), male, Master candidate. E-mail: zbtfsy@163.com

Supported by:摘要:

柔性热电器件可以利用人体与环境之间的微小温差发电, 在可穿戴设备的持续供电领域展现出巨大的潜力, 但较低的热电性能限制了柔性热电器件的广泛应用。本研究报道了一种利用喷墨打印制备高性能柔性热电薄膜的方法。将利用化学转移法制备的AgCuTe纳米线分散在乙醇溶剂中, 得到的墨水无明显沉降, 能稳定持续喷射, 将其喷印在聚酰亚胺衬底上得到p型热电薄膜。随后利用放电等离子烧结炉进行热处理, 得到了致密的热电薄膜, 并研究了烧结温度对热电性能的影响。结果表明, 在10 MPa、400 ℃下烧结15 min后, 室温下薄膜功率因子为432 µW·m-1·K-2, 比现有文献报道的喷墨打印p型Bi2Te3薄膜的室温功率因子(153 µW·m-1·K-2)提高了182%。本研究进一步拓宽了喷墨打印在柔性热电器件领域的应用, 同时也为制备新一代高性能柔性热电器件提供了更多可能。

中图分类号:

张波涛, 孙婷婷, 王连军, 江莞. 喷墨打印制备AgCuTe热电薄膜[J]. 无机材料学报, 2024, 39(12): 1325-1330.

ZHANG Botao, SUN Tingting, WANG Lianjun, JIANG Wan. Inkjet Printing Preparation of AgCuTe Thermoelectric Thin Films[J]. Journal of Inorganic Materials, 2024, 39(12): 1325-1330.

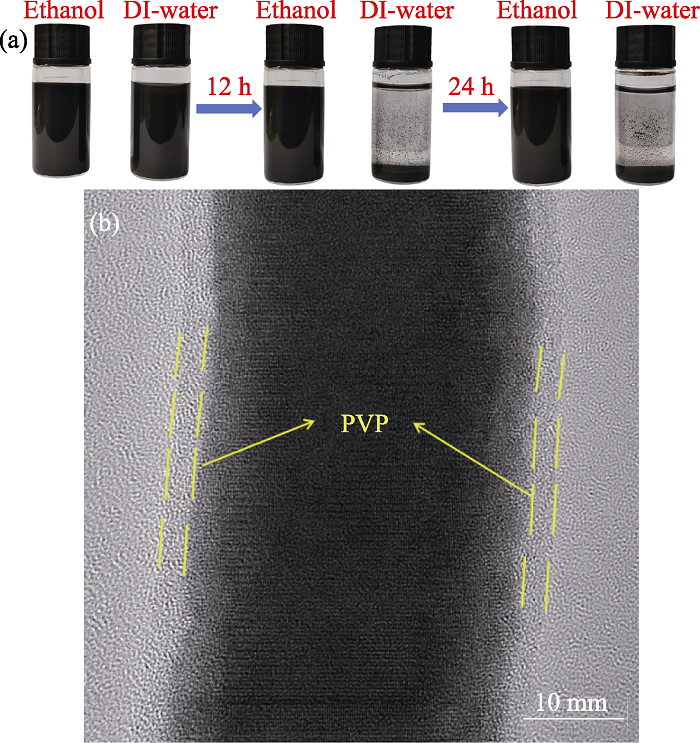

图3 (a) AgCuTe粉体在去离子水和乙醇中的分散性和稳定性; (b) AgCuTe纳米线的TEM照片

Fig. 3 (a) Dispersibility and stability of AgCuTe powders in deionized water and ethanol, and (b) TEM image of AgCuTe nanowire

图5 不同墨滴间距条件下打印的薄膜显微照片

Fig. 5 Micrographs of films printed at different droplet spacings (a) 5 μm; (b) 10 μm; (c) 20 μm; (d) 30 μm; (e) 40 μm; (f) Size of a single droplet

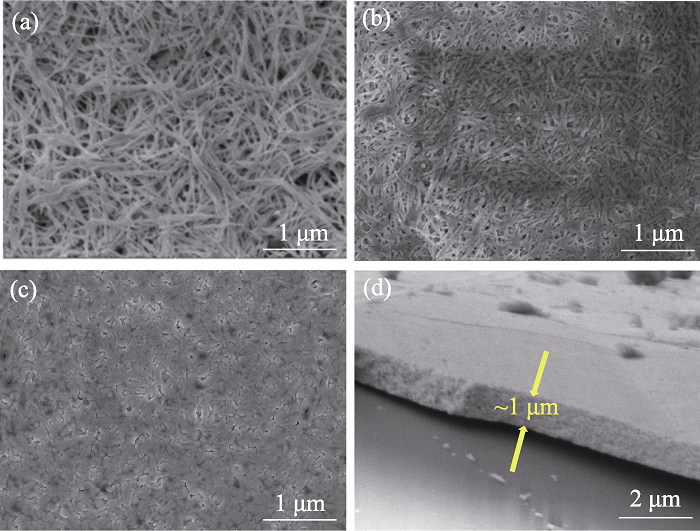

图7 (a) 300, (b) 350和(c) 400 ℃烧结后薄膜的表面SEM照片和(d) 400 ℃烧结后薄膜的断面SEM照片

Fig. 7 Surface SEM images of films sintered at (a) 300, (b) 350 and (c) 400 ℃, and (d) cross-sectional SEM image of film sintered at 400 ℃

| Sintering temperature/℃ | σ/(S·cm-1) | S/(μV·K-1) | PF/(μW·m-1·K-2) |

|---|---|---|---|

| 300 | 80 | 108 | 93 |

| 350 | 168 | 126 | 266 |

| 400 | 227 | 138 | 432 |

表1 不同温度烧结后薄膜的热电性能

Table 1 Thermoelectric properties of films sintered at different temperatures

| Sintering temperature/℃ | σ/(S·cm-1) | S/(μV·K-1) | PF/(μW·m-1·K-2) |

|---|---|---|---|

| 300 | 80 | 108 | 93 |

| 350 | 168 | 126 | 266 |

| 400 | 227 | 138 | 432 |

| Material | σ/ (S·cm-1) | S/ (μV·K-1) | PF/ (μW·m-1·K-2) | Ref. |

|---|---|---|---|---|

| PEDOT | 267 | 21.5 | 12.3 | [ |

| PEDOT | 300 | 10 | 3 | [ |

| Graphene | 41 | 12 | 18.7 | [ |

| Bi0.5Sb1.5Te3 | 135 | 21 | 61 | [ |

| Bi0.5Sb1.5Te3 | 338 | 67.3 | 153 | [ |

| AgCuTe | 227 | 138 | 432 | This work |

表2 本工作与已报道的喷墨打印p型热电材料的性能

Table 2 Performance of inkjet printed p-type thermoelectric materials in this work and reported literatures

| Material | σ/ (S·cm-1) | S/ (μV·K-1) | PF/ (μW·m-1·K-2) | Ref. |

|---|---|---|---|---|

| PEDOT | 267 | 21.5 | 12.3 | [ |

| PEDOT | 300 | 10 | 3 | [ |

| Graphene | 41 | 12 | 18.7 | [ |

| Bi0.5Sb1.5Te3 | 135 | 21 | 61 | [ |

| Bi0.5Sb1.5Te3 | 338 | 67.3 | 153 | [ |

| AgCuTe | 227 | 138 | 432 | This work |

| [1] | PEI J, CAI B, ZHUANG H L, et al. Bi2Te3-based applied thermoelectric materials: research advances and new challenges. National Science Review, 2020, 7(12): 1856. |

| [2] | JIA B, HUANG Y, WANG Y, et al. Realizing high thermoelectric performance in non-nanostructured n-type PbTe. Energy & Environmental Science, 2022, 15(5): 1920. |

| [3] | HU Z, FU Y, JIANG M, et al. Thermal stability of Nb/Mg3SbBi interface. Journal of Inorganic Materials, 2023, 38(8):931. |

| [4] | HONG M, ZOU J, CHEN Z, et al. Thermoelectric GeTe with diverse degrees of freedom having secured superhigh performance. Advanced Materials, 2019, 31(14):1807071. |

| [5] | XU S, SHI X L, DARGUSCH M, et al. Conducting polymer-based flexible thermoelectric materials and devices: from mechanisms to applications. Progress in Materials Science, 2021, 121: 100840. |

| [6] | JIN H, LI J, IOCOZZIA J, et al. Hybride organisch- anorganische thermoelektrische materialien und baueinheiten. Angewandte Chemie International Edition, 2019, 131(43):15348. |

| [7] | ZHANG L, SHI X L, YANG Y L, et al. Flexible thermoelectric materials and devices: from materials to applications. Materials Today, 2021, 46: 62. |

| [8] | BURTON M, HOWELLS G, ATOYO J, et al. Printed thermoelectrics. Advanced Materials, 2022, 34(18):2108183. |

| [9] | LIN Z, HOLLAR C, KANG J S, et al. A solution processable high- performance thermoelectric copper selenide thin film. Advanced Materials, 2017, 29(21):1606662. |

| [10] | XU Y, WU B, HOU C, et al. High thermoelectric performance in Ti3C2Tx MXene/Sb2Te3 composite film for highly flexible thermoelectric devices. Global Challenges, 2024, 8(2):2300032. |

| [11] | NEWBROOK D W, RICHARDS S P, GREENACRE V K, et al. Selective chemical vapor deposition approach for Sb2Te3 thin film micro-thermoelectric generators. ACS Applied Energy Materials, 2020, 3(6):5840. |

| [12] | ZHENG Z H, SHI X L, AO D W, et al. Harvesting waste heat with flexible Bi2Te3 thermoelectric thin film. Nature Sustainability, 2022, 6(2):180. |

| [13] | SHI J, WU X, GENG X, et al. Anisotropy engineering in solution- derived nanostructured Bi2Te3 thin films for high-performance flexible thermoelectric devices. Chemical Engineering Journal, 2023, 458: 141450. |

| [14] |

LIU Y, ZHU H, XING L, et al. Recent advances in inkjet-printing technologies for flexible/wearable electronics. Nanoscale, 2023, 15(13):6025.

DOI PMID |

| [15] | ZENG M, DU Y, JIANG Q, et al. High-throughput printing of combinatorial materials from aerosols. Nature, 2023, 617(7960):292. |

| [16] | ZHANG D, LIM X J G, LI X, et al. 3D-Printed porous thermoelectrics for in situ energy harvesting. ACS Energy Letters, 2023, 8(1):332. |

| [17] | BERETTA D, BARKER A J, MAQUEIRA-ALBO I, et al. Thermoelectric properties of highly conductive poly(3,4- ethylenedioxythiophene) polystyrene sulfonate printed thin films. ACS Applied Materials & Interfaces, 2017, 9(21):18151. |

| [18] | JING J, CHOPPLET L, BATTAGLINI N, et al. The role of substrates and electrodes in inkjet-printed PEDOT: PSS thermoelectric generators. Journal of Materials Chemistry C, 2024, 12(17):6185. |

| [19] | JUNTUNEN T, JUSSILA H, RUOHO M, et al. Inkjet printed large-area flexible few-layer graphene thermoelectrics. Advanced Functional Materials, 2018, 28(22):1800480. |

| [20] | FERHAT S, DOMAIN C, VIDAL J, et al. Flexible thermoelectric device based on TiS2HAx n-type nanocomposite printed on paper. Organic Electronics, 2019, 68: 256. |

| [21] | HORIKE S, FUKUSHIMA T, SAITO T, et al. Highly stable n-type thermoelectric materials fabricated via electron doping into inkjet-printed carbon nanotubes using oxygen-abundant simple polymers. Molecular Systems Design & Engineering, 2017, 2(5):616. |

| [22] | DU J, ZHANG B, JIANG M, et al. Inkjet printing flexible thermoelectric devices using metal chalcogenide nanowires. Advanced Functional Materials, 2023, 33(26):2213564. |

| [23] |

LU Z, LAYANI M, ZHAO X, et al. Fabrication of flexible thermoelectric thin film devices by inkjet printing. Small, 2014, 10(17):3551.

PMID |

| [24] | CHEN B, DAS S R, ZHENG W, et al. Inkjet printing of single- crystalline Bi2Te3 thermoelectric nanowire networks. Advanced Electronic Materials, 2017, 3(4):1600524. |

| [25] |

CHEN B, KRUSE M, XU B, et al. Flexible thermoelectric generators with inkjet-printed bismuth telluride nanowires and liquid metal contacts. Nanoscale, 2019, 11(12):5222.

DOI PMID |

| [26] |

ZHANG K, ZHENG Q, WANG L, et al. Preparation and characterization of Ag2Se-based ink used for inkjet printing. Journal of Inorganic Materials, 2022, 37(10):1109.

DOI |

| [27] | LIU Y, ZHANG Q, HUANG A, et al. Fully inkjet-printed Ag2Se flexible thermoelectric devices for sustainable power generation. Nature Communications, 2024, 15(1): 2141. |

| [28] | WANG S, JIANG M, WANG L, et al. n-Type Pb-free AgBiSe2 based thermoelectric materials with stable cubic phase structure. Journal of Inorganic Materials, 2023, 38(7):807. |

| [29] | LI L, ZHAI W, WANG C, et al. Maximizing phonon scattering efficiency by Cu2Se alloying in AgCuTe thermoelectric materials. Journal of Materials Chemistry A, 2022, 10(12):6701. |

| [30] | WEI T, QIU P, ZHAO K, et al. Ag2Q-Based (Q = S, Se, Te) silver chalcogenide thermoelectric materials. Advanced Materials, 2023, 35(1):2110236. |

| [31] | WU R, LI Z, LI Y, et al. Synergistic optimization of thermoelectric performance in p-type Ag2Te through Cu substitution. Journal of Materiomics, 2019, 5(3):489. |

| [32] | LIU W, YANG L, CHEN Z, et al. Promising and eco-friendly Cu2X-based thermoelectric materials: progress and applications. Advanced Materials, 2020, 32(8):1905703. |

| [33] | DENG S, JIANG X, CHEN L, et al. Ultralow thermal conductivity and high thermoelectric performance in AgCuTe1-xSex through isoelectronic substitution. ACS Applied Materials & Interfaces, 2021, 13(1):868. |

| [34] | JIANG J, ZHU H, NIU Y, et al. Achieving high room-temperature thermoelectric performance in cubic AgCuTe. Journal of Materials Chemistry A, 2020, 8(9):4790. |

| [35] | NIU Y, LI S, MAO J, et al. Suppressed phase transition and enhanced thermoelectric performance in iodine-doped AgCuTe. Nano Energy, 2020, 77: 105297. |

| [36] |

YANG Q, YANG S, QIU P, et al. Flexible thermoelectrics based on ductile semiconductors. Science, 2022, 377(6608):854.

DOI PMID |

| [37] | LI J, LYU J, YANG W, et al. The remarkable role of indium in synergistically optimizing carrier concentration and phase distribution of AgCuTe-based materials. Small, 2024, 20(28):2311340. |

| [38] | LYU J, LI J, YANG W, et al. Enhancing thermoelectric performance in GeTe through Ge enrichment regulation and AgCuTe alloying. Chemical Engineering Journal, 2024, 485: 149695. |

| [39] | MA Z, XU T, LI W, et al. High thermoelectric performance SnTe with a segregated and percolated structure. ACS Applied Materials & Interfaces, 2022, 14(7):9192. |

| [40] | ROYCHOWDHURY S, JANA M K, PAN J, et al. Soft phonon modes leading to ultralow thermal conductivity and high thermoelectric performance in AgCuTe. Angewandte Chemie International Edition, 2018, 57(15):4043. |

| [41] | LUAN X, LI J, WU S, et al. A nanoscale perspective of the coexistence of multidimensional defects in the AgCuTe system. Nano Energy, 2024, 124: 109505. |

| [42] | ZENG M, ZAVANELLI D, CHEN J, et al. Printing thermoelectric inks toward next-generation energy and thermal devices. Chemical Society Reviews, 2022, 51(2):485. |

| [43] |

HU G, ALBROW-OWEN T, JIN X, et al. Black phosphorus ink formulation for inkjet printing of optoelectronics and photonics. Nature Communications, 2017, 8(1):278.

DOI PMID |

| [1] | 张哲, 孙婷婷, 王连军, 江莞. 不同维度Ag2Se构筑柔性热电薄膜的性能优化与器件集成研究[J]. 无机材料学报, 2024, 39(11): 1221-1227. |

| [2] | 张国庆, 秦鹏, 黄富强. 空间限域铅离子与钙钛矿纳米晶间的可逆转换与信息存储应用[J]. 无机材料学报, 2022, 37(4): 445-451. |

| [3] | 张可忆, 郑琦, 王连军, 江莞. 用于喷墨打印的Ag2Se墨水的制备及表征[J]. 无机材料学报, 2022, 37(10): 1109-1115. |

| [4] | 王 卓,李永祥,杨群保. 无机材料喷墨制备新方法的进展[J]. 无机材料学报, 2009, 24(6): 1090-1096. |

| [5] | 施建章,汪宏,Werner Jillek,姚熹. BZN陶瓷墨水的制备及其性质研究[J]. 无机材料学报, 2008, 23(2): 257-261. |

| [6] | 袁峰,王红洁,金志浩. 碳毡中SiC纳米线的制备[J]. 无机材料学报, 2007, 22(3): 418-422. |

| [7] | 郭瑞松,齐海涛,李金有,李鸿祥,陈玉如,杨正方. 提高AEO9/醇/烷/水体系反相微乳液陶瓷墨水浓度的研究[J]. 无机材料学报, 2003, 18(4): 955-959. |

| [8] | 郭瑞松,齐海涛,李金有,陈玉如,杨正方,袁启明. AEO9/醇/烷/水系反相微乳液陶瓷墨水制备与性能研究[J]. 无机材料学报, 2003, 18(3): 645-652. |

| [9] | 郭瑞松,齐海涛,郭多力,吕晓娟,陈玉如,杨正方. 喷射打印成型用陶瓷墨水制备方法[J]. 无机材料学报, 2001, 16(6): 1049-1054. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||