无机材料学报 ›› 2021, Vol. 36 ›› Issue (10): 1111-1117.DOI: 10.15541/jim20210045 CSTR: 32189.14.10.15541/jim20210045

李陇彬1,2( ), 薛玉冬1,2, 胡建宝1,2, 杨金山1,2, 张翔宇1,2, 董绍明1,2(

), 薛玉冬1,2, 胡建宝1,2, 杨金山1,2, 张翔宇1,2, 董绍明1,2( )

)

收稿日期:2021-01-27

修回日期:2021-04-15

出版日期:2021-10-20

网络出版日期:2021-05-10

通讯作者:

董绍明, 研究员. E-mail: smdong@mail.sic.ac.cn

作者简介:李陇彬(1997–), 男, 硕士研究生. E-mail: medolia97@student.sic.ac.cn

LI Longbin1,2( ), XUE Yudong1,2, HU Jianbao1,2, YANG Jinshan1,2, ZHANG Xiangyu1,2, DONG Shaoming1,2(

), XUE Yudong1,2, HU Jianbao1,2, YANG Jinshan1,2, ZHANG Xiangyu1,2, DONG Shaoming1,2( )

)

Received:2021-01-27

Revised:2021-04-15

Published:2021-10-20

Online:2021-05-10

Contact:

DONG Shaoming, professor. E-mail: smdong@mail.sic.ac.cn

About author:LI Longbin(1997–), male, Master candidate. Email: medolia97@student.sic.ac.cn

Supported by:摘要:

通过在碳化硅纤维表面原位生长纳米线得到具有多级增强结构的碳化硅复合材料, 对复合材料引入纳米线后的微观结构、弯曲强度以及损伤的变化过程进行了研究。研究结果表明, 相较于原始的碳化硅纤维增强碳化硅复合材料, 碳化硅纳米线可以明显提高基体沉积效率并改善材料的弯曲力学性能。从声发射技术和维氏硬度压痕测试结果可以看出, 纳米线通过抑制微裂纹的产生和在微裂纹之间发生桥联来抑制早期损伤的发展。此外, 在纳米线表面沉积一层氮化硼界面相, 纳米线与基体之间的结合力变弱, 复合材料对微裂纹的抑制和偏转得到进一步增强, 弯曲性能大幅提升。

中图分类号:

李陇彬, 薛玉冬, 胡建宝, 杨金山, 张翔宇, 董绍明. 碳化硅纳米线增韧碳化硅纤维/碳化硅基体损伤行为研究[J]. 无机材料学报, 2021, 36(10): 1111-1117.

LI Longbin, XUE Yudong, HU Jianbao, YANG Jinshan, ZHANG Xiangyu, DONG Shaoming. Influence of SiC Nanowires on the Damage Evolution of SiCf/SiC Composites[J]. Journal of Inorganic Materials, 2021, 36(10): 1111-1117.

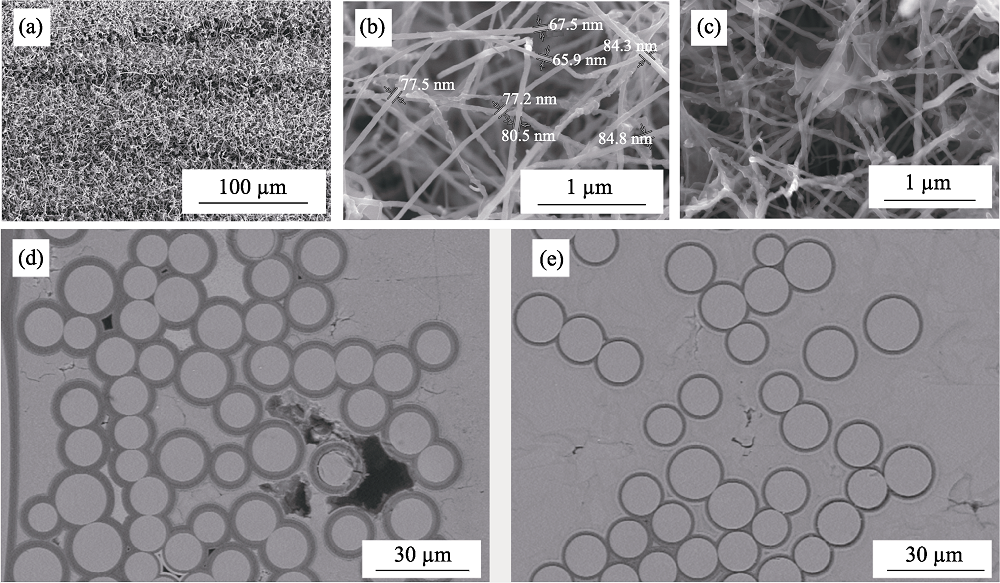

Fig. 2 Typical SEM images of (a, b) as-grown SiCnw, (c) BN-coated SiCnw, and typical SEM images demonstrating the pore size of (d) SiCf/SiC and (e) SiCf/SiC-SiCnw composites

| Composite | SiCf/SiC | SiCf/SiC- SiCnw/BN | SiCf/ SiC-SiCnw |

|---|---|---|---|

| Bulk density/(g·cm-3) | (1.98±0.03) | (2.02±0.04) | (2.08±0.03) |

| Open porosity/% | (17.64±1.08) | (14.39±0.60) | (11.58±1.35) |

Table 1 Density and porosity of different composites

| Composite | SiCf/SiC | SiCf/SiC- SiCnw/BN | SiCf/ SiC-SiCnw |

|---|---|---|---|

| Bulk density/(g·cm-3) | (1.98±0.03) | (2.02±0.04) | (2.08±0.03) |

| Open porosity/% | (17.64±1.08) | (14.39±0.60) | (11.58±1.35) |

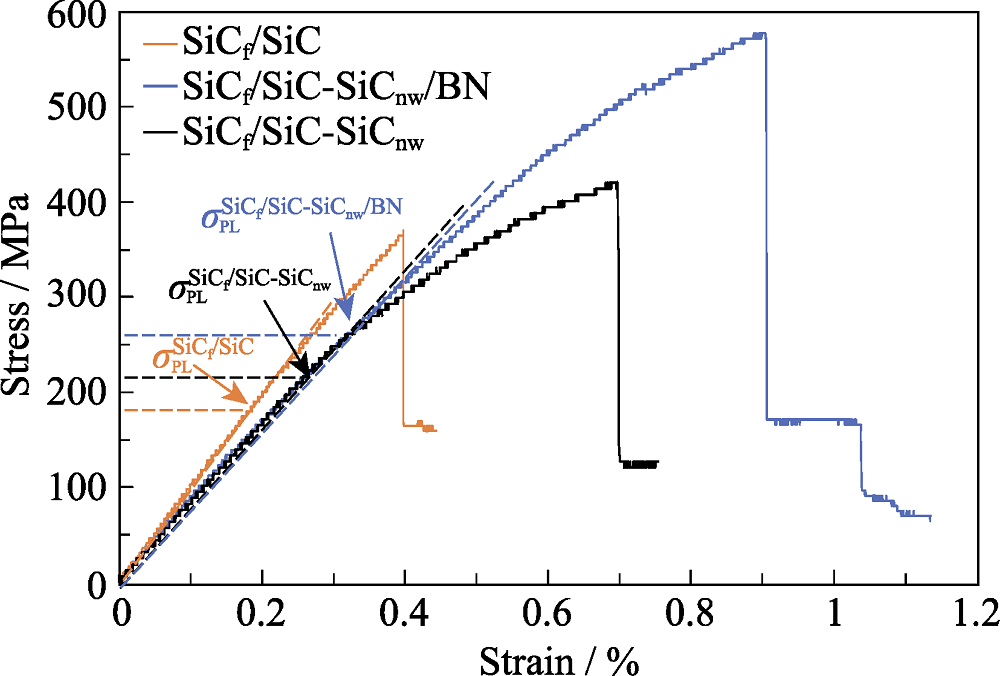

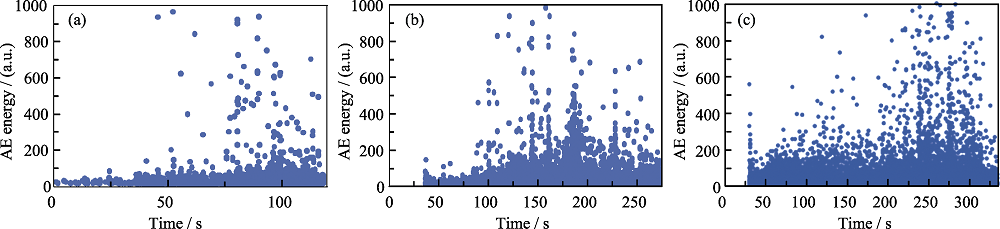

| Composite | SiCnw content / wt% | Flexural strength, σu/MPa | Proportional limit stress, σPL/MPa | Strain at flexural strength, εu/% | First AE stress, σmin/MPa | AE onset stress, σonset/MPa |

|---|---|---|---|---|---|---|

| SiCf/SiC | 0 | (356.7±16.2) | (153.9±6.4) | (0.39±0.05) | (58.8±7.5) | (116.1±8.9) |

| SiCf/SiC-SiCnw | 2.0 | (412.6±22.4) | (185.1±7.7) | (0.63±0.06) | (66.1±6.2) | (155.8±7.7) |

| SiCf/SiC-SiCnw/BN | 2.0 | (506.4±28.3) | (247.7±8.6) | (0.88±0.12) | (78.5±5.2) | (171.6±15.9) |

Table 2 Properties of original composites, as-grown and BN-coated hierarchical composites

| Composite | SiCnw content / wt% | Flexural strength, σu/MPa | Proportional limit stress, σPL/MPa | Strain at flexural strength, εu/% | First AE stress, σmin/MPa | AE onset stress, σonset/MPa |

|---|---|---|---|---|---|---|

| SiCf/SiC | 0 | (356.7±16.2) | (153.9±6.4) | (0.39±0.05) | (58.8±7.5) | (116.1±8.9) |

| SiCf/SiC-SiCnw | 2.0 | (412.6±22.4) | (185.1±7.7) | (0.63±0.06) | (66.1±6.2) | (155.8±7.7) |

| SiCf/SiC-SiCnw/BN | 2.0 | (506.4±28.3) | (247.7±8.6) | (0.88±0.12) | (78.5±5.2) | (171.6±15.9) |

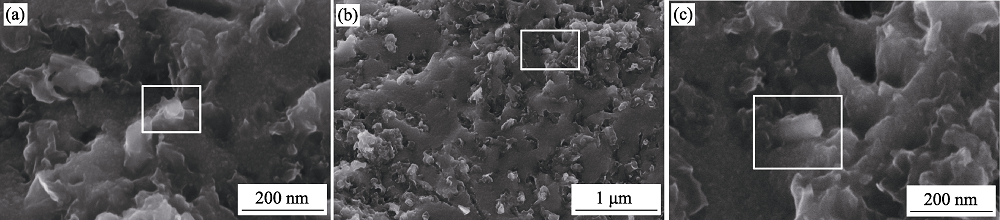

Fig. 3 SEM fractural morphologies of (a) as-grown SiCnw, (b, c) BN-coated SiCnw in composites Local parts marked by white rectangular borders demonstrating that SiCnw tends to break (a) or pull out (b, c)

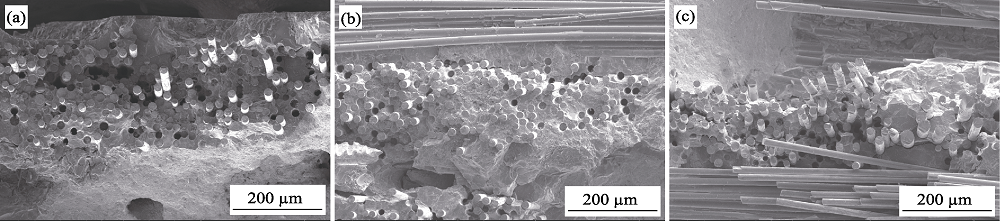

Fig. 4 Fracture morphologies of composite (a) SiCf/SiC, (b) SiCf/SiC-SiCnw and (c) SiCf/SiC-SiCnw/BN The images demonstrating the pull-out length of fibers

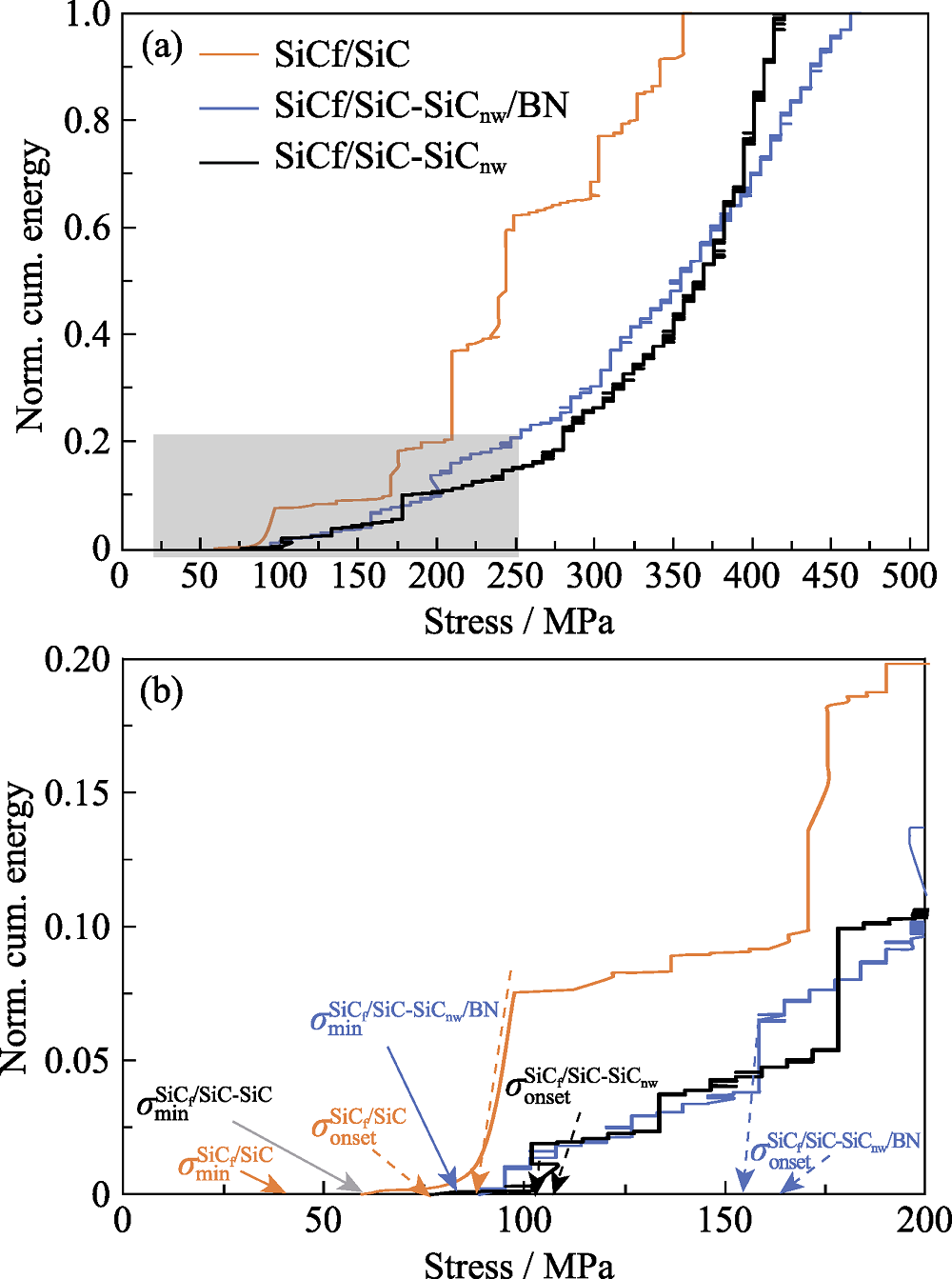

Fig. 5 Representative normalized cumulative AE energy curves as a function of stress (a) for composite SiCf/SiC (orange), SiCf/SiC-SiCnw (black) and SiCf/SiC-SiCnw/BN (blue) To clarify the difference of damage threshold among these three groups, initial key part (grey area) in (a) is magnified in (b). Colorful figures are available on website

Fig. 6 Typical stress-strain curves of SiCf/SiC(orange), SiCf/SiC-SiCnw (black) and SiCf/SiC-SiCnw/BN (blue) The proportional limit is pointed out in the picture. Colorful figures are available on website

Fig. 7 Scatter diagrams of the energy of individual AE events as a function of time in composites (a) SiCf/SiC, (b) SiCf/SiC-SiCnw, and (c) SiCf/SiC-SiCnw/BN Considering the massive amount of data, diagrams are depicted after compression

| [1] |

NASLAIN R. Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: an overview. Composites Science and Technology, 2004, 64(2):155-170.

DOI URL |

| [2] | DICARLO J A, van ROODE M. Ceramic Composite Development for Gas Turbine Engine Hot Section Components. Proceedings of the ASME Turbo Expo 2006: Power for Land, Sea, and Air, F, 2006. Volume 2: Aircraft Engine; Ceramics; Coal, Biomass and Alternative Fuels; Controls, Diagnostics and Instrumentation; Environmental and Regulatory Affairs. Barcelona, Spain. May 8-11, 2006: 221-231. |

| [3] |

NASLAIN R R. Processing of non-oxide ceramic matrix composites: an overview. Advances in Science and Technology, 2006, 50:64-74.

DOI URL |

| [4] |

YIN X, CHENG L, ZHANG L, et al. Fibre-reinforced multifunctional SiC matrix composite materials. International Materials Reviews, 2017, 62(3):117-172.

DOI URL |

| [5] |

YANG W, ARAKI H, TANG C, et al. Single-crystal SiC nanowires with a thin carbon coating for stronger and tougher ceramic composites. Advanced Materials, 2005, 17(12):1519-1523.

DOI URL |

| [6] |

HU J, DONG S, FENG Q, et al. Tailoring carbon nanotube/matrix interface to optimize mechanical properties of multiscale composites. Carbon, 2014, 69:621-625.

DOI URL |

| [7] |

ZHU G, XUE Y, HU J, et al. Influence of boron nitride nanotubes on the damage evolution of SiCf/SiC composites. Journal of the European Ceramic Society, 2018, 38(14):4614-4622.

DOI URL |

| [8] |

HE F, LIU Y, TIAN Z, et al. Carbon fiber/SiC composites modified SiC nanowires with improved strength and toughness. Materials Science and Engineering: A, 2018, 734:374-384.

DOI URL |

| [9] |

CHU Y, LI H, FU Q, et al. Oxidation protection and behavior of C/C composites with an in situ SiC nanowire-SiC-Si/SiC-Si coating. Corrosion Science, 2013, 70:285-289.

DOI URL |

| [10] |

ZHAO K, LI K, WANG Y. Rapid densification of C/SiC composite by incorporating SiC nanowires. Composites Part B: Engineering, 2013, 45(1):1583-1586.

DOI URL |

| [11] | DONG R, YANG W, WU P, et al. Effect of reinforcement shape on the stress-strain behavior of aluminum reinforced with SiC nanowire. Materials & Design, 2015, 88:1015-1020. |

| [12] |

THOULESS M D, EVANS A G. Effects of pull-out on the mechanical properties of ceramic-matrix composites. Acta Metallurgica, 1988, 36(3):517-522.

DOI URL |

| [13] |

DE GREEF N, GORBATIKH L, GODARA A, et al. The effect of carbon nanotubes on the damage development in carbon fiber/epoxy composites. Carbon, 2011, 49(14):4650-4664.

DOI URL |

| [14] |

KANG S M, KIM W J, YOON S G, et al. Effects of the PyC interface coating on SiC nanowires of SiCf/SiC composite. Journal of Nuclear Materials, 2011, 417(1/2/3):367-370.

DOI URL |

| [15] |

MORSCHER G N, SINGH M, KISER J D, et al. Modeling stress-dependent matrix cracking and stress-strain behavior in 2D woven SiC fiber reinforced CVI SiC composites. Composites Science and Technology, 2007, 67(6):1009-1017.

DOI URL |

| [16] |

WHITLOW T, JONES E, PRZYBYLA C. In-sit damage monitoring of a SiC/SiC ceramic matrix composite using acoustic emission and digital image correlation. Composite Structures, 2016, 158:245-251.

DOI URL |

| [17] |

MORSCHER G N. Stress-dependent matrix cracking in 2D woven SiC-fiber reinforced melt-infiltrated SiC matrix composites. Composites Science and Technology, 2004, 64(9):1311-1319.

DOI URL |

| [18] | ARGON A S. Fracture of composites. Treatise on Materials Science and Technology, 1972, 1:79-114. |

| [1] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [2] | 崔宁, 张玉新, 王鲁杰, 李彤阳, 于源, 汤华国, 乔竹辉. (TiVNbMoW)Cx高熵陶瓷的单相形成过程与碳空位调控[J]. 无机材料学报, 2025, 40(5): 511-520. |

| [3] | 李紫薇, 弓伟露, 崔海峰, 叶丽, 韩伟健, 赵彤. 前驱体法制备(Zr, Hf, Nb, Ta, W)C-SiC复相陶瓷及性能研究[J]. 无机材料学报, 2025, 40(3): 271-280. |

| [4] | 高晨光, 孙晓亮, 陈君, 李达鑫, 陈庆庆, 贾德昌, 周玉. 基于湿法纺丝技术的SiBCN-rGO陶瓷纤维的组织结构、力学和吸波性能[J]. 无机材料学报, 2025, 40(3): 290-296. |

| [5] | 穆浩洁, 张源江, 喻彬, 付秀梅, 周世斌, 李晓东. ZrO2掺杂Y2O3-MgO纳米复相陶瓷的制备及性能研究[J]. 无机材料学报, 2025, 40(3): 281-289. |

| [6] | 李伟, 许志明, 苟燕子, 尹森虎, 余艺平, 王松. SiC纤维烧结陶瓷的制备及其性能研究[J]. 无机材料学报, 2025, 40(2): 177-183. |

| [7] | 范武刚, 曹雄, 周响, 李玲, 赵冠楠, 张兆泉. 8YSZ陶瓷在模拟压水堆水环境中的耐腐蚀性能[J]. 无机材料学报, 2024, 39(7): 803-809. |

| [8] | 王伟明, 王为得, 粟毅, 马青松, 姚冬旭, 曾宇平. 以非氧化物为烧结助剂制备高导热氮化硅陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 634-646. |

| [9] | 孙海洋, 季伟, 王为民, 傅正义. TiB-Ti周期序构复合材料设计、制备及性能研究[J]. 无机材料学报, 2024, 39(6): 662-670. |

| [10] | 蔡飞燕, 倪德伟, 董绍明. 高熵碳化物超高温陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 591-608. |

| [11] | 刘国昂, 王海龙, 方成, 黄飞龙, 杨欢. B4C含量对(Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C陶瓷力学性能及抗氧化性能的影响[J]. 无机材料学报, 2024, 39(6): 697-706. |

| [12] | 吴晓晨, 郑瑞晓, 李露, 马浩林, 赵培航, 马朝利. SiCf/SiC陶瓷基复合材料高温环境损伤原位监测研究进展[J]. 无机材料学报, 2024, 39(6): 609-622. |

| [13] | 粟毅, 史扬帆, 贾成兰, 迟蓬涛, 高扬, 马青松, 陈思安. 浆料浸渍辅助PIP工艺制备C/HfC-SiC复合材料的微观结构及性能研究[J]. 无机材料学报, 2024, 39(6): 726-732. |

| [14] | 李雷, 程群峰. 高性能MXenes纳米复合材料研究进展[J]. 无机材料学报, 2024, 39(2): 153-161. |

| [15] | 刘艳艳, 谢曦, 刘增乾, 张哲峰. MAX相陶瓷增强金属基复合材料: 制备、性能与仿生设计[J]. 无机材料学报, 2024, 39(2): 145-152. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||