无机材料学报 ›› 2020, Vol. 35 ›› Issue (10): 1099-1104.DOI: 10.15541/jim20190646 CSTR: 32189.14.10.15541/jim20190646

所属专题: 结构陶瓷论文精选(2020)

吕晓旭1( ),姜卓钰1,周怡然1,齐哲1,赵文青1,2,焦健1

),姜卓钰1,周怡然1,齐哲1,赵文青1,2,焦健1

收稿日期:2019-12-23

修回日期:2020-02-01

出版日期:2020-10-20

网络出版日期:2020-03-06

作者简介:吕晓旭(1988-), 男, 博士. E-mail:xiaoxul@126.com.

基金资助:

LÜ Xiaoxu1( ),JIANG Zhuyu1,ZHOU Yiran1,QI Zhe1,ZHAO Wenqing1,2,JIAO Jian1

),JIANG Zhuyu1,ZHOU Yiran1,QI Zhe1,ZHAO Wenqing1,2,JIAO Jian1

Received:2019-12-23

Revised:2020-02-01

Published:2020-10-20

Online:2020-03-06

About author:Lü Xiaoxu(1988-), male, PhD. E-mail:xiaoxul@126.com

摘要:

采用化学气相渗透(CVI)工艺, 在SiC纤维表面沉积BN和BN/SiC复合界面层, 对沉积界面层前后纤维的力学性能进行了评价。采用聚合物浸渍裂解(PIP)工艺进行致密化, 制得以原纤维、BN界面层和BN/SiC界面层纤维增强的三种Mini-SiCf/SiC复合材料, 研究其微观结构和拉伸性能。结果表明: 采用CVI工艺制得的界面层厚度均匀、结构致密, 其中BN界面层中存在六方相, 晶体尺寸为1.76 nm; SiC界面层结晶性较好, 晶粒尺寸为18.73 nm; 沉积界面层后SiC纤维的弹性模量基本保持不变, 拉伸强度降低。与SiCf/SiC相比, PIP工艺制备的SiCf/BN/SiC和SiCf/(BN/SiC)/SiC-Mini复合材料所能承受的最大拉伸载荷和断裂应变明显提升, BN界面层起主要作用。由断面形貌分析可以看出, SiCf/BN/SiC和SiCf/(BN/SiC)/SiC复合材料的纤维拔出明显, 说明在断裂时消耗的能量增加, 可承受的最大载荷增大。

中图分类号:

吕晓旭, 姜卓钰, 周怡然, 齐哲, 赵文青, 焦健. BN/SiC复合界面层对SiC纤维和PIP-Mini复合材料力学性能的影响[J]. 无机材料学报, 2020, 35(10): 1099-1104.

LÜ Xiaoxu, JIANG Zhuyu, ZHOU Yiran, QI Zhe, ZHAO Wenqing, JIAO Jian. Effect of BN/SiC Multilayered Interphases on Mechanical Properties of SiC Fibers and Minicomposites by PIP[J]. Journal of Inorganic Materials, 2020, 35(10): 1099-1104.

| Linear density (g·m-1) Sample | PIP cycle | |||||

|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | |

| SiCf/SiC | (0.303±0.028) | (1.26±0.11) | (1.30±0.14) | (1.32±0.17) | (1.33±0.12) | (1.33±0.13) |

| SiCf/BN/SiC | (0.330±0.023) | (1.31±0.10) | (1.34±0.11) | (1.35±0.15) | (1.36±0.10) | (1.36±0.13) |

| SiCf/(BN/SiC)/SiC | (0.346±0.035) | (1.25±0.08) | (1.28±0.11) | (1.30±0.15) | (1.30±0.14) | (1.31±0.10) |

表1 浸渍不同次数后Mini复合材料的线密度

Table 1 The linear density of Mini-composites after different PIP cycles

| Linear density (g·m-1) Sample | PIP cycle | |||||

|---|---|---|---|---|---|---|

| 0 | 1 | 2 | 3 | 4 | 5 | |

| SiCf/SiC | (0.303±0.028) | (1.26±0.11) | (1.30±0.14) | (1.32±0.17) | (1.33±0.12) | (1.33±0.13) |

| SiCf/BN/SiC | (0.330±0.023) | (1.31±0.10) | (1.34±0.11) | (1.35±0.15) | (1.36±0.10) | (1.36±0.13) |

| SiCf/(BN/SiC)/SiC | (0.346±0.035) | (1.25±0.08) | (1.28±0.11) | (1.30±0.15) | (1.30±0.14) | (1.31±0.10) |

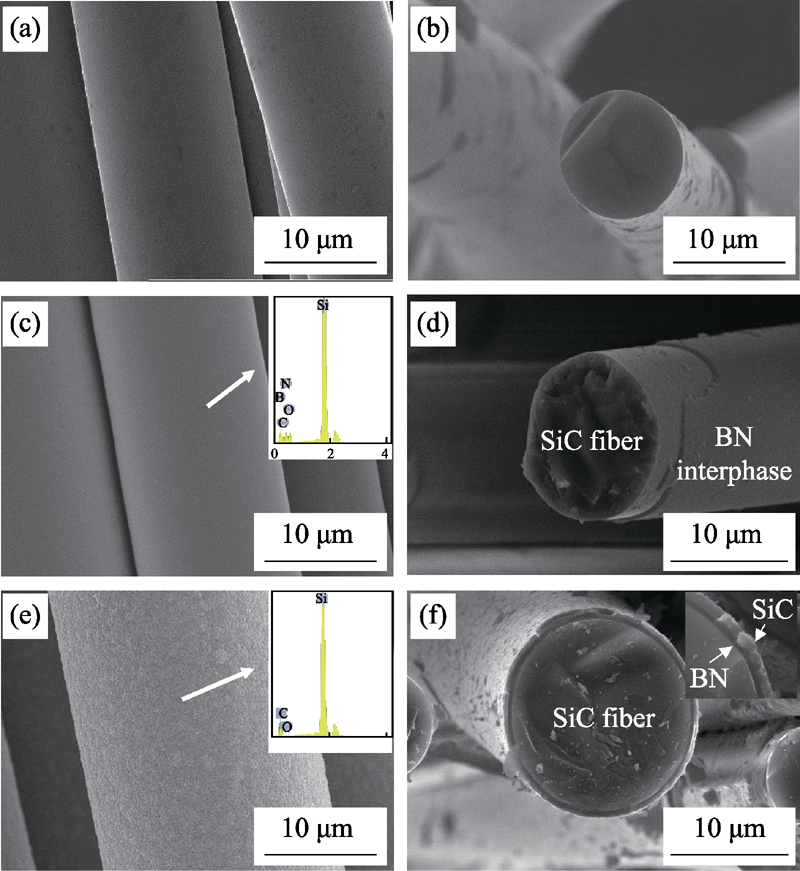

图1 不同种类界面层纤维的SEM照片及EDS分析结果

Fig. 1 SEM and EDS microstructures of fibers with different interphases (a, b) As-received; (c, d) BN-coated; (e, f) BN/SiC-coated

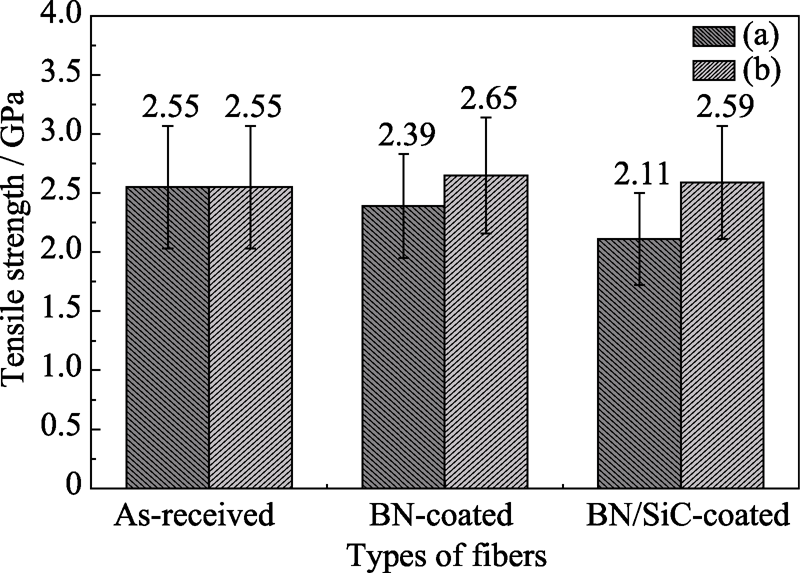

图4 不同种类界面层纤维的拉伸强度

Fig. 4 Tensile strength of SiC fibers with different interphases (a) Tested strength value; (b) Calculated strength value after deducting the thickness of interphases

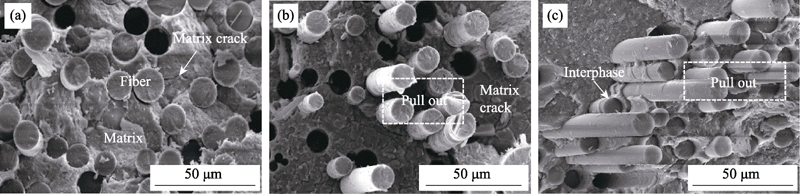

图7 不同界面层复合材料断口的SEM照片

Fig. 7 Cross-section morphologies of mini-SiCf/SiC composites with different interphases (a) No interphase, (b) BN interphase, (c) BN/SiC interphase

| [1] |

NASIRI N A, PATRA N, NI N , et al. Oxidation behaviour of SiC/SiC ceramic matrix composites in air. Journal of the European Ceramic Society, 2016,36(14):3293-3302.

DOI URL |

| [2] | 刘虎, 杨金华, 周怡然 , 等. 国外航空发动机用SiCf/SiC复合材料的材料级性能测试研究进展. 材料工程, 2018,46(11):1-12. |

| [3] |

STAEHLER J M, ZAWADA L P . Performance of four ceramic-matrix composite divergent flap inserts following ground testing on an F110 turbofan engine. Journal of the American Ceramic Society, 2000,83(7):1727-1738.

DOI URL |

| [4] | 焦健, 陈明伟 . 新一代发动机高温材料-陶瓷基复合材料的制备、性能及应用. 航空制造技术, 2014,451(7):62-69. |

| [5] |

CHARLES H, HENAGER J, KURTZ R J . Low-activation joining of SiC/SiC composites for fusion applications. Journal of Nuclear Materials, 2011,417(1/2/3):375-378.

DOI URL |

| [6] |

LAMON J . A micromechanics-based approach to the mechanical behavior of brittle matrix composites. Composites Science Technology, 2001,61(15):2259-2272.

DOI URL |

| [7] |

REBILLAT F, LAMON J, NASLAIN R , et al. Interfacial bond strength in SiC/C/SiC composite materials, as studied by single-fibre push-out tests. Journal of American Ceramic Society , 1998,81(4):965-978.

DOI URL |

|

SREEJITH K, VIPIN V, SUBRAMANIA S , et al. A comparative study on Cf/PyC/SiC minicomposites prepared via CVI process for hypersonic engine application. International Journal of Applied Ceramic Technology, 2018,15(5):1110-1123.

DOI URL |

|

| [8] |

WINDISCH C F, HENAGER C, SPRINGER G D , et al. Oxidation of the carbon interface in Nicalon fiber reinforced silicon carbide composite. Journal of the American Ceramic Society , 1997,80(3):569-574.

DOI URL |

| [9] | SHI YING, ARAKI HIROSHI, YANG WEN , et al. Influence of fiber pre-coating on mechanical properties and interfacial structures of SiC(f)/SiC composites. Journal of Inorganic Materials , 2001,16(5):883-888. |

| [10] |

OPILA E J, VERRILLI M J . Borosilicate glass-induced fiber degradation of SiC/BN/SiC composites exposed in combustion environments. International Journal of Applied Ceramic Technology, 2016,13(3):434-442.

DOI URL |

| [11] |

WING B L, HALLORAN J W . Subsurface oxidation of boron nitride coatings on silicon carbide fibers in SiC/SiC ceramic matrix composites. Ceramics International, 2018,44(14):17499-17505.

DOI URL |

| [12] |

NASLAIN R R, PAILLER R J F, LAMON J L. Single and multilayered interphases in SiC/SiC composites exposed to severe environmental conditions: an overview. International Journal of Applied Ceramic Technology, 2010,7(3):263-275.

DOI URL |

| [13] |

BERTRAND S, FORIO P, PAILLER R , et al. Hi-Nicalon/SiC minicomposites with (pyrocarbon/SiC)n nanoscale multilayered interphases. Journal of the American Ceramic Society, 1999,82(9):2465-2473.

DOI URL |

| [14] |

BERTRAND S, PAILLER R, LAMON J . SiC/SiC minicomposites with nanoscale multilayered fibre coatings. Composites Science and Technology, 2001,61(3):363-367.

DOI URL |

| [15] |

YU HAIJIAO, ZHOU XINGUI, ZHANG WEI , et al. Mechanical behavior of SiCf/SiC composites with alternating PyC/SiC multilayer interphases. Materials and Design, 2013,44:320-324.

DOI URL |

| [16] |

YANG M, ZHOU W C, LUO F , et al. Effects of BN/SiC dual-layer interphase on mechanical and dielectric properties of SiCf/SiC composites. Ceramic International, 2014,40(2):3411-3418.

DOI URL |

| [17] | BERTRAND S, BOISRON O, PAILLER R , et al. (PyC-SiC)n and(BN-SiC) n nano-scale multilayered interphases by pressure pulsed-CVI. Key Engineering Materials, 1999, 164-165:357-360. |

| [18] |

AMJAD A, EMMANUEL M, SIVAKUMAR R , et al. Effect of fiber content on single tow SiC minicomposite mechanical and damage properties using acoustic emission. Journal of the European Ceramic Society, 2015,35(13):3389-3399.

DOI URL |

| [19] | LV X X, QI Z, JIANG Z Y , et al. The Microstructure and Mechanical Properties of Silicon Carbide Fibers with Boron Nitride Interphase. IOP Conf. Series: Materials Science and Engineering, 2019,678, 012061. |

| [20] |

WANG GUODONG, SONG YONGCAI . Enhancing mechanical property of SiC fiber by decreasing fiber diameter through a modified melt-spinning process. Journal of Inorganic Materials, 2018,33(7):721-727.

DOI URL |

|

MU Y, ZHOU W C, WANG C , et al. Mechanical and electromagnetic shielding properties of SiCf/SiC composites fabricated by combined CVI and PIP process. Ceramics International, 2014,40(7):10037-10041.

DOI URL |

| [1] | 魏志帆, 陈国清, 祖宇飞, 刘渊, 李明浩, 付雪松, 周文龙. ZrB2-HfSi2复相陶瓷显微组织及其核-周结构形成机制[J]. 无机材料学报, 2025, 40(7): 817-825. |

| [2] | 洪培萍, 梁龙, 吴炼, 马颖康, 庞浩. ZIF-67结构调控及其对盐酸金霉素的吸附性能研究[J]. 无机材料学报, 2025, 40(4): 388-396. |

| [3] | 李建军, 陈芳明, 张梨梨, 王磊, 张丽亭, 陈慧雯, 薛长国, 徐良骥. CoFe2O4/MgAl-LDH催化剂活化过氧一硫酸盐促进抗生素降解[J]. 无机材料学报, 2025, 40(4): 440-448. |

| [4] | 侯佳琪, 陈睿聪, 曾耀莹, 周磊, 张佳平, 付前刚. 气相渗硅法修复SiC涂层及其抗热震和烧蚀性能[J]. 无机材料学报, 2025, 40(2): 168-176. |

| [5] | 栾新刚, 何典蔚, 涂建勇, 成来飞. 2D平纹和3D针刺C/SiC复合材料的低速冲击破坏行为和失效机理[J]. 无机材料学报, 2025, 40(2): 205-214. |

| [6] | 王文婷, 徐敬军, 马科, 李美栓, 李兴超, 李同起. 原位反应/热压合成Ti2AlC-20TiB2复合材料在1000~1300 ℃空气中的高温氧化行为[J]. 无机材料学报, 2025, 40(1): 31-38. |

| [7] | 张立, 管皞阳, 郑琪宁, 洪智亮, 王佳璇, 邢宁, 李玫, 刘永胜, 张程煜. MI SiCf/SiC-SiYBC复合材料的蠕变性能及损伤机理[J]. 无机材料学报, 2025, 40(1): 23-30. |

| [8] | 文志朋, 韦毅, 侯向华, 郭佳文, 黎渠, 朱满庆, 张家浩, 潘凯, 吴炼. 膨润土基功能材料在电化学储能中的研究进展[J]. 无机材料学报, 2024, 39(12): 1301-1315. |

| [9] | 马永杰, 刘永胜, 关康, 曾庆丰. CH4+C2H5OH+Ar体系热解的气相动力学研究[J]. 无机材料学报, 2024, 39(11): 1235-1244. |

| [10] | 丁宁宁, 孙建华, 韦旭, 孙丽霞. 对氨基苯磺酸修饰MoO3/PPy复合材料室温下对氨气的监测[J]. 无机材料学报, 2024, 39(11): 1245-1253. |

| [11] | 周云凯, 刁亚琪, 王明磊, 张宴会, 王利民. 聚苯胺改性Ti3C2(OH)2抗氧化性的第一性原理计算研究[J]. 无机材料学报, 2024, 39(10): 1151-1158. |

| [12] | 魏相霞, 张晓飞, 徐凯龙, 陈张伟. 增材制造柔性压电材料的现状与展望[J]. 无机材料学报, 2024, 39(9): 965-978. |

| [13] | 全文心, 余艺平, 方冰, 李伟, 王松. 管状C/SiC复合材料高温空气氧化行为与宏细观建模研究[J]. 无机材料学报, 2024, 39(8): 920-928. |

| [14] | 马彬彬, 钟婉菱, 韩涧, 陈椋煜, 孙婧婧, 雷彩霞. ZIF-8/TiO2复合介观晶体的制备及光催化活性[J]. 无机材料学报, 2024, 39(8): 937-944. |

| [15] | 由博杰, 李博, 李旭勤, 马雪寒, 张毅, 成来飞. 2D SiCf/SiC中温热冲击损伤与面内剪切性能退化规律[J]. 无机材料学报, 2024, 39(12): 1367-1376. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||