无机材料学报 ›› 2017, Vol. 32 ›› Issue (12): 1257-1263.DOI: 10.15541/jim20160699 CSTR: 32189.14.10.15541/jim20160699

贾营坤1,2, 陈培1, 张青红1, 孙静2

收稿日期:2016-12-27

修回日期:2017-07-18

出版日期:2017-12-20

网络出版日期:2017-11-21

作者简介:贾营坤(1991-), 女, 硕士研究生. E-mail: jykun8909@163.com

基金资助:JIA Ying-Kun1,2, CHEN Pei1, ZHANG Qing-Hong1, SUN Jing2

Received:2016-12-27

Revised:2017-07-18

Published:2017-12-20

Online:2017-11-21

摘要:

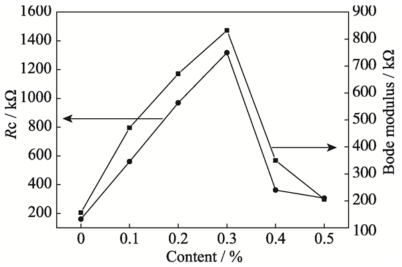

将高温热还原氧化石墨烯(TRGO)作为二维纳米填料添加到聚酰亚胺(PI)聚合物基质中, 制备了不同质量分数的TRGO/PI纳米复合耐蚀涂层, 采用交流阻抗谱和动电位极化曲线评估了涂层在模拟海水(3.5wt%NaCl溶液)中的电化学腐蚀行为。结果表明: 与纯PI涂层相比, 添加TRGO可以显著提高涂层的电阻和腐蚀防护效率; 当TRGO的添加量为0.3wt%时, 对涂层耐蚀性能的增强效果最好, 最大涂层电阻为1.3176×106 Ω, 最高腐蚀防护效率可达到99.65%, 其防蚀增益与片层结构TRGO的物理阻隔性能有关。

中图分类号:

贾营坤, 陈培, 张青红, 孙静. 高温热还原氧化石墨烯/聚酰亚胺复合涂层的制备及防腐蚀性能研究[J]. 无机材料学报, 2017, 32(12): 1257-1263.

JIA Ying-Kun, CHEN Pei, ZHANG Qing-Hong, SUN Jing. Thermal Reduced Graphene Oxide/Polyimide Nanocomposite Coating: Fabrication and Anticorrosive Property[J]. Journal of Inorganic Materials, 2017, 32(12): 1257-1263.

图3 不同浓度的TRGO分散液的照片

Fig. 3 Pictures of TRGO dispersions with varying concentrations^(a) 0.17 mg/mL; (b) 0.33 mg/mL; (c) 0.50 mg/mL; (d) 0.66 mg/mL; (e) 0.83 mg/mL

| Samples | Rs/Ω | CPEdl-T/F | CPEdl-P/F | Rc/Ω |

|---|---|---|---|---|

| Pure PI | 1279 | 2.7060×10-6 | 0.7721 | 1.6081×105 |

| TRGO0.1/PI | 1290 | 1.6952×10-6 | 0.6325 | 5.6110×105 |

| TRGO0.2/PI | 1064 | 6.2072×10-7 | 0.7235 | 9.6912×105 |

| TRGO0.3/PI | 1136 | 6.0883×10-7 | 0.7442 | 1.3176×106 |

| TRGO0.4/PI | 1249 | 2.3677×10-6 | 0.7022 | 3.6245×105 |

| TRGO0.5/PI | 1002 | 3.9181×10-6 | 0.6605 | 3.0603×105 |

表1 不同样品涂层的等效电路拟合结果

Table 1 Fitting results for pure PI and TRGO/PI coatings

| Samples | Rs/Ω | CPEdl-T/F | CPEdl-P/F | Rc/Ω |

|---|---|---|---|---|

| Pure PI | 1279 | 2.7060×10-6 | 0.7721 | 1.6081×105 |

| TRGO0.1/PI | 1290 | 1.6952×10-6 | 0.6325 | 5.6110×105 |

| TRGO0.2/PI | 1064 | 6.2072×10-7 | 0.7235 | 9.6912×105 |

| TRGO0.3/PI | 1136 | 6.0883×10-7 | 0.7442 | 1.3176×106 |

| TRGO0.4/PI | 1249 | 2.3677×10-6 | 0.7022 | 3.6245×105 |

| TRGO0.5/PI | 1002 | 3.9181×10-6 | 0.6605 | 3.0603×105 |

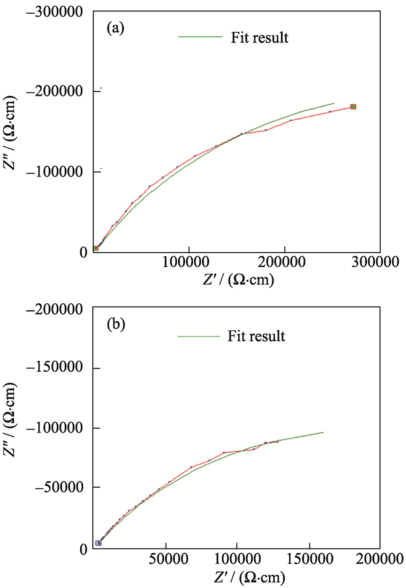

图7 (a)TRGO0.1/PI和(b)TRGO0.4/PI两种涂层的拟合结果示意图

Fig. 7 Comparison of experimental data and fitting curves for (a) TRGO0.1/PI, (b) TRGO0.4/PI composite coatings

图8 TRGO/PI的涂层电阻和0.1 Hz处对应的阻抗模值对TRGO含量的变化

Fig. 8 Coating resistance and Bode modulus at 0.1 Hz as a function of the SRGO content in TRGO/PI composite coating

| Sample | Ecorr/V | Icorr/(A·cm-1) | ba/(mV·dec-1) | bc/(mV·dec-1) | Rp/(kΩ·cm2) | Thickness/μm | PEF/% |

|---|---|---|---|---|---|---|---|

| Bare steel | -0.53 | 1.319×10-4 | 11 | 4423 | 0.744 | - | - |

| Pure PI | -0.40 | 1.490×10-6 | 1408 | 5960 | 36.931 | 1.30 | 98.87 |

| TRGO0.1/PI | -0.31 | 8.513×10-7 | 4312 | 5946 | 49.785 | 1.30 | 99.35 |

| TRGO0.2/PI | -0.28 | 6.199×10-7 | 1145 | 7123 | 108.823 | 1.30 | 99.53 |

| TRGO0.3/PI | -0.24 | 4.616×10-7 | 3036 | 8532 | 158.105 | 1.30 | 99.65 |

| TRGO0.4/PI | -0.34 | 5.865×10-7 | 2800 | 5227 | 96.969 | 1.30 | 99.56 |

| TRGO0.5/PI | -0.36 | 1.070×10-6 | 3463 | 5388 | 44.839 | 1.30 | 99.19 |

表2 不同样品涂层的电化学腐蚀参数

Table 2 Corrosion parameters of bare 304SS, pure PI, TRGO/PI-coated 304SS electrodes immersed in 3.5 wt% NaCl solution after 6 h

| Sample | Ecorr/V | Icorr/(A·cm-1) | ba/(mV·dec-1) | bc/(mV·dec-1) | Rp/(kΩ·cm2) | Thickness/μm | PEF/% |

|---|---|---|---|---|---|---|---|

| Bare steel | -0.53 | 1.319×10-4 | 11 | 4423 | 0.744 | - | - |

| Pure PI | -0.40 | 1.490×10-6 | 1408 | 5960 | 36.931 | 1.30 | 98.87 |

| TRGO0.1/PI | -0.31 | 8.513×10-7 | 4312 | 5946 | 49.785 | 1.30 | 99.35 |

| TRGO0.2/PI | -0.28 | 6.199×10-7 | 1145 | 7123 | 108.823 | 1.30 | 99.53 |

| TRGO0.3/PI | -0.24 | 4.616×10-7 | 3036 | 8532 | 158.105 | 1.30 | 99.65 |

| TRGO0.4/PI | -0.34 | 5.865×10-7 | 2800 | 5227 | 96.969 | 1.30 | 99.56 |

| TRGO0.5/PI | -0.36 | 1.070×10-6 | 3463 | 5388 | 44.839 | 1.30 | 99.19 |

| [1] | NINE M J, COLE M A, TRAN O N H, et al. Graphene: a multipurpose material for protective coatings. J. Mater. Chem. A, 2015, 3(24): 12580-12602. |

| [2] | KUANG D, HU W.Research progress of graphene composites. J. Inorg. Mater., 2013, 28(3): 235-246. |

| [3] | ZHU Y, MURALI S, CAI W, et al.Graphene and graphene oxide: synthesis, properties, and applications. Adv. Mater., 2010, 22(35): 3906-3924. |

| [4] | LEENAERTS O, PARTOENS B, PEETERS F M. Graphene: a perfect nanoballoon. Appl. Phys. Lett., 2008, 93(19): 193107-1-4. |

| [5] | BUNCH J S, VERBRIDGE S S, ALDEN J S, et al.Impermeable atomic membranes from graphene sheets. Nano Lett., 2008, 8(8): 2458-2462. |

| [6] | NAIR R R, WU H A, JAYARAM P N, et al.Unimpeded permeation of water through helium-leak-tight graphene-based membranes. Science, 2012, 335(6067): 442-444. |

| [7] | CHEN S, BROWN L, LEVENDORF M, et al.Oxidation resistance of graphene-coated Cu and Cu/Ni alloy. ACS Nano, 2011, 5(2): 1321-1327. |

| [8] | PRASAI D, TUBERQUIA J C, HARL R R, et al.Graphene: corrosion-inhibiting coating. ACS Nano, 2012, 6(2): 1102-1108. |

| [9] | SCHRIVER M, REGAN W, W J GANNETT, et al. Graphene as a long-term metal oxidation barrier: worse than nothing. ACS Nano, 2013, 7(7): 5763-5768. |

| [10] | COMPTON O C, KIM S, PIERRE C, et al.Crumpled graphene nanosheets as highly effective barrier property enhancers. Adv. Mater., 2010, 22(42): 4759-4763. |

| [11] | YANG Y H, BOLLING L, MORGAN A, et al.Super gas barrier and selectivity of graphene oxide-polymer multilayer thin films. Adv. Mater., 2013, 25(4): 503-508. |

| [12] | KIM H, MIURA Y, MACOSKO C W.Graphene/polyurethane nanocomposites for improved gas barrier and electrical conductivity.Chem. Mater., 2010, 22(11): 3441-3450. |

| [13] | YOUSEFI N, GUDARZI M M, ZHENG Q, et al.Highly aligned, ultralarge-size reduced graphene oxide/polyurethane nanocomposites: mechanical properties and moisture permeability. Compos. Part A-Appl. S., 2013, 49(6): 42-50. |

| [14] | 李雅雅. 石墨烯增强水性聚氨酯复合涂层及其对钢铁表面的腐蚀防护. 上海: 上海理工大学硕士学位论文, 2013. |

| [15] | LI Y, YANG Z, QIU H, et al.Self-aligned graphene as anticorrosive barrier in waterborne polyurethane composite coatings. J. Mater. Chem. A, 2014, 2(34): 14139. |

| [16] | CHANG C H, HUANG T C, PENG C W, et al.Novel anticorrosion coatings prepared from polyaniline/graphene composites. Carbon, 2012, 50(14): 5044-5051. |

| [17] | YU Y H, LIN Y Y, LIN C H, et al.High-performance polystyrene/ graphene-based nanocomposites with excellent anti-corrosion properties. Poly. Chem., 2014, 5(2): 535-550. |

| [18] | CHEN S, ZHU J, WU X, et al.Graphene oxide MnO2 nanocomposites for supercapacitors. ACS Nano, 2010, 4(11): 2822-2830. |

| [19] | SU C Y, XU Y, ZHANG W, et al.Electrical and spectroscopic characterizations of ultra-large reduced graphene oxide monolayers. Chem. Mater., 2009, 21(23): 5674-5680. |

| [20] | LI M X, ZHU J E, ZHANG L L, et al.Facile synthesis of NiAl-layered double hydroxide/graphene hybrid with enhanced electrochemical properties for detection of dopamine. Nanoscale, 2011, 3(10): 4240-4246. |

| [21] | LI H, ZHU G, LIU Z H, et al.Fabrication of a hybrid graphene/layered double hydroxide material. Carbon, 2010, 48(15): 4391-4396. |

| [22] | LUO D, ZHANG G, LIU J, et al.Evaluation criteria for reduced graphene oxide. J. Phys. Chem. C, 2011, 115(23): 11327-11335. |

| [23] | TAI Z, YAN X, XUE Q.Shape-alterable and -recoverable graphene/ polyurethane bi-layered composite film for supercapacitor electrode. J. Power Source, 2012, 213: 350-357. |

| [24] | JI Z Y, SHEN X P, ZHU G X, et al.Reduced graphene oxide/nickel nanocomposites: facile synthesis, magnetic and catalytic properties. J. Mater. Chem., 2012, 22(8): 3471-3477. |

| [25] | 曹楚南; 张鉴清. 电化学阻抗谱导论. 北京: 科学出版社, 2002. |

| [26] | CHI M, LI F, ZHOU M, et al.Synthesis and anticorrosive properties of a novel electroactive polyurea containing oligoaniline pendants. Colloid Polym. Sci., 2015, 293(8): 2217-2227. |

| [27] | SCULLY J R.Electrochemical impedance of organic-coated steel: correlation of impedance parameters with long-term coating deterioration. J. Electro. Chem. Soc., 1989, 136(4): 979-990. |

| [28] | GU L, LIU S, ZHAO H, et al.Facile preparation of water¬dispersible graphene sheets stabilized by carboxylated oligoanilines and their anticorrosion coatings. ACS Appl. Mater. Interfaces, 2015, 7(32): 17641-17648. |

| [29] | AMIRUDIN A, THIENY D.Application of electrochemical impedance spectroscopy to study the degradation of polymer-coated metals. Prog. Org. Coat., 1995, 26(1): 1-28. |

| [30] | LIU J, GONG G, YAN C, et al.EIS study of corrosion behaviour of organic coating/Dacromet composite systems. Electrochim. Acta, 2005, 50(16): 3320-3332. |

| [31] | CHANG K C, HSU C H, LU H I, et al.Advanced anticorrosive coatings prepared from electroactive polyimide/graphene nanocomposites with synergistic effects of redox catalytic capability and gas barrier properties. Express Polym. Lett., 2014, 8: 243-255. |

| [1] | 杨茗凯, 黄泽皑, 周芸霄, 刘彤, 张魁魁, 谭浩, 刘梦颖, 詹俊杰, 陈国星, 周莹. 基于Cu与金属氧化物-KCl熔融介质的甲烷热解制备少层石墨烯与氢气联产研究[J]. 无机材料学报, 2025, 40(5): 473-480. |

| [2] | 高晨光, 孙晓亮, 陈君, 李达鑫, 陈庆庆, 贾德昌, 周玉. 基于湿法纺丝技术的SiBCN-rGO陶瓷纤维的组织结构、力学和吸波性能[J]. 无机材料学报, 2025, 40(3): 290-296. |

| [3] | 王悦, 王欣, 于显利. 室温铁磁性还原氧化石墨烯基全碳膜[J]. 无机材料学报, 2025, 40(3): 305-313. |

| [4] | 李红兰, 张俊苗, 宋二红, 杨兴林. Mo/S共掺杂的石墨烯用于合成氨: 密度泛函理论研究[J]. 无机材料学报, 2024, 39(5): 561-568. |

| [5] | 孙川, 何鹏飞, 胡振峰, 王荣, 邢悦, 张志彬, 李竞龙, 万春磊, 梁秀兵. 含有石墨烯阵列的SiC基陶瓷材料的制备与力学性能[J]. 无机材料学报, 2024, 39(3): 267-273. |

| [6] | 王艳莉, 钱心怡, 沈春银, 詹亮. 石墨烯基介孔锰铈氧化物催化剂: 制备和低温催化还原NO[J]. 无机材料学报, 2024, 39(1): 81-89. |

| [7] | 杨平军, 李铁虎, 李昊, 党阿磊. 石墨烯对环氧树脂泡沫炭石墨化、电导率和力学性能的影响[J]. 无机材料学报, 2024, 39(1): 107-112. |

| [8] | 董怡曼, 谭占鳌. 宽带隙钙钛矿基二端叠层太阳电池复合层的研究进展[J]. 无机材料学报, 2023, 38(9): 1031-1043. |

| [9] | 蔡佳, 赵芳霞, 范栋, 黄利平, 牛亚然, 郑学斌, 张振忠. 聚碳硅烷基复合涂层PCS裂解行为及其抗激光烧蚀性能[J]. 无机材料学报, 2023, 38(11): 1271-1280. |

| [10] | 陈赛赛, 庞雅莉, 王娇娜, 龚䶮, 王锐, 栾筱婉, 李昕. 绿-黄可逆电热致变色织物的制备及其性能[J]. 无机材料学报, 2022, 37(9): 954-960. |

| [11] | 孙铭, 邵溥真, 孙凯, 黄建华, 张强, 修子扬, 肖海英, 武高辉. RGO/Al复合材料界面性质第一性原理研究[J]. 无机材料学报, 2022, 37(6): 651-659. |

| [12] | 洪督, 牛亚然, 李红, 钟鑫, 郑学斌. 等离子喷涂TiC-Graphite复合涂层摩擦磨损性能[J]. 无机材料学报, 2022, 37(6): 643-650. |

| [13] | 安琳, 吴淏, 韩鑫, 李耀刚, 王宏志, 张青红. 非贵金属Co5.47N/N-rGO助催化剂增强TiO2光催化制氢性能[J]. 无机材料学报, 2022, 37(5): 534-540. |

| [14] | 王虹力, 王男, 王丽莹, 宋二红, 赵占奎. 功能化石墨烯担载型AuPd纳米催化剂增强甲酸制氢反应[J]. 无机材料学报, 2022, 37(5): 547-553. |

| [15] | 董淑蕊, 赵笛, 赵静, 金万勤. 离子化氨基酸对氧化石墨烯膜渗透汽化过程中水选择性渗透的影响[J]. 无机材料学报, 2022, 37(4): 387-394. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||