Journal of Inorganic Materials ›› 2018, Vol. 33 ›› Issue (8): 866-872.DOI: 10.15541/jim20170519

• Orginal Article • Previous Articles Next Articles

ZHAO Hai-Lei1, 2, SUN Zhen-Chuan1, 2, CHEN Kui1, 2, WANG Hong-Zhi3, YANG Yan-Dong1, 2, ZHOU Jian-Jun1, 2, LI Feng-Yuan1, 2, ZHANG Bing1, 2, SONG Fa-Liang2

Received:2017-11-03

Revised:2017-12-12

Published:2018-08-28

Online:2018-07-17

About author:ZHAO Hai-Lei. E-mail: 478339242@qq.com

CLC Number:

ZHAO Hai-Lei, SUN Zhen-Chuan, CHEN Kui, WANG Hong-Zhi, YANG Yan-Dong, ZHOU Jian-Jun, LI Feng-Yuan, ZHANG Bing, SONG Fa-Liang. Synthesis, Property and Wear Detection of Disc Cutter for Shield Tunneling Machine of Nanobelt Ca0.68Si9Al3(ON)16 : Eu2+ Luminescence Fibers[J]. Journal of Inorganic Materials, 2018, 33(8): 866-872.

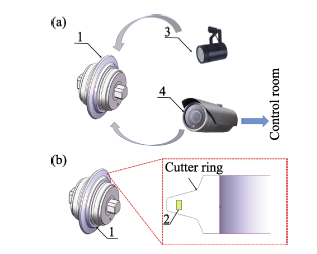

Fig. 13 Schematic diagram of fluorescence detection system for disc cutter wear (a) and detail structural drawing of disc cutter combined with fluorescent fiber film (b)1-Disc cutter; 2-Fluorescent fiber film; 3-LED chip; 4-Monitoring system

| [1] | LIU Y Q, ZHANG X P, XIA Y N,et al. Magnetic field assisted electrospinning of aligned straight and wavy polymeric nanofibers.Advanced Materials, 2010, 22(22): 2454-2457. |

| [2] | WU H, SUN Y, LIN D,et al. GaN nanofibers based on electrospinning: facile synthesis, controlled assembly, precise doping, and application as high performance photodetector.Advanced Materials, 2009, 21(2): 227-231. |

| [3] | AGARWAL S, GREINER A, WENDORFF J H,et al. Electrospinning of manmade and biopolyner nanofibers-progress in techniques, materials, and applications.Advanced Functional Materials, 2009, 19(18): 2863-2879. |

| [4] | WANG X F, DING B, SUN G,et al. Electro-spinning/netting: a strategy for the fabrication of three-dimensional polymer nano- fiber/nets.Progress in Materials Science, 2013, 58(8): 1173-1243. |

| [5] | HU J P, DING B, WANG X F, et al. One-step electro- spinning/netting technique for controllably preparing polyurethane nano-fiber/net. Macromolecular Rapid Communications, 2011, 32(21): 1729-1734. |

| [6] | SONG H W, YU H Q, PAN G H,et al. Electrospinning preparation, structure, and photoluminescence properties of YBO3 : Eu3+ nanotubes and nanowires.Chemistry of Materials, 2008, 20(18): 4762-4767. |

| [7] | HOU Z Y, LI C X, YANG J,et al. One-dimensional CaWO4 and CaWO4 : Tb3+ nanowires and nanotubes: electrospinning preparation and luminescent properties.Journal of Materials Chemistry, 2009, 19(18): 2737-2746. |

| [8] | DONG G P, XIAO X D, LIU X F,et al.Intense red and yellow emissions from Sr2SiO4 : Eu3+ (Eu2+) electrospun nanofibers.Journal of The Electrochemical Society, 2009, 156(11): J347-J350. |

| [9] | LI G G, HOU Z Y, PENG C,et al.Electrospinning derived one-dimensional LaOCl : Ln3+(Ln=Eu/Sm, Tb) nanofibers, nanotubes and microbelts with multicolor-tunable emission properties.Advanced Functional Materials, 2010, 20(20): 3446-3456. |

| [10] | XIE R J, HIROSAKI N, MITOMO M,et al. Photoluminescence of rare-earth-doped Ca-α-SiAlON phosphors: composition and concentration dependence.Journal of the American Ceramic Society, 2005, 88(10): 2883-2888. |

| [11] | CAO G Z, METSELAAR R.α°-Sialon ceramics: a review. Chemistry of Materials, 1991, 3(2): 242-252. |

| [12] | ZHANG H, HORIKAWA T, HANZAWA H,et al.Photoluminescence properties of α-SiAlON : Eu2+ prepared by carbothermal reduction and nitridation method. Journal of the Electrochemical Society, 2007, 154(2): J59-J61. |

| [13] | LI H L, XIE R J, HIROSAKI N,et al.Phase purity and luminescence properties of fine Ca-α-SiAlON: Eu phosphors synthesized by gas reduction nitridation method Journal of The Electrochemical Society, 2008, 155(6): J175-J179. |

| [14] | YANG Y Y, HUANG H W.Application of rock mass classification in cutter life prediction of TBM.Chinese Journal of Underground Space & Engineering, 2005, 1(5): 721-724. |

| [15] | MICHALAKOPOULOS T N, ANAGNOSTOU V G, BASSANOU M E,et al. The influence of steel styli hardness on the Cerchar abrasiveness index value.International Journal of Rock Mechanics & Mining Sciences, 2006, 43(2): 321-327. |

| [16] | ZHAO W, LIU M, DU Y,et al. Abnormal cutter wear recognition of full face tunnel boring machine (TBM).China Mechanical Engineering, 2007, 18(2): 150-153. |

| [1] | LIU Cheng, ZHAO Qian, MOU Zhiwei, LEI Jiehong, DUAN Tao. Adsorption Properties of Novel Bismuth-based SiOCNF Composite Membrane for Radioactive Gaseous Iodine [J]. Journal of Inorganic Materials, 2022, 37(10): 1043-1050. |

| [2] | ZHANG Xiaoshan, WANG Bing, WU Nan, HAN Cheng, LIU Haiyan, WANG Yingde. Infrared Radiation Shielded SiZrOC Nanofiber Membranes: Preparation and High-temperature Thermal Insulation Performance [J]. Journal of Inorganic Materials, 2022, 37(1): 93-100. |

| [3] | MA Lingling, CHANG Jiang. Nd-doped Calcium Silicate: Photothermal Effect, Fluorescence Performance, and Biological Properties of Its Composite Electrospun Membrane [J]. Journal of Inorganic Materials, 2021, 36(9): 974-980. |

| [4] | LI Tingting, ZHANG Zhiming, HAN Zhengbo. Research Progress in Polymer-based Metal-organic Framework Nanofibrous Membranes Based on Electrospinning [J]. Journal of Inorganic Materials, 2021, 36(6): 592-600. |

| [5] | ZHU Zhengwang,FENG Rui,LIU Yang,ZHANG Yang,XIE Wenhan,DONG Lijie. Preparation and Property of CoFe2O4 Nanofibers with Fishbone-like Structure [J]. Journal of Inorganic Materials, 2020, 35(9): 1011-1016. |

| [6] | SUN Xiao-Lu,SONG Xiao-Fei,LIU Yan-Hua,WU Yue,CAI Yi-Bing,ZHAO Hong-Mei. Electrospun FeMnO3 Nanofibrous Mats: Preparation and Electrochemical Property [J]. Journal of Inorganic Materials, 2019, 34(7): 709-714. |

| [7] | CUI Bo, JIA Wei, CHEN Zheng-Hua, LI Yao-Gang, ZHANG Qing-Hong, WANG Hong-Zhi. Synthesis and Property of CaSi2O2N2:Ce/Tb, Eu Stacking Luminescence Fibers [J]. Journal of Inorganic Materials, 2018, 33(4): 403-408. |

| [8] | DU Hai-Ying, YAO Peng-Jun, WANG Jing, SUN Yan-Hui, YU Nai-Sen, ZHANG Tao, DONG Liang. Preparation and Gas Sensing Property of SnO2/ZnO Composite Hetero-nanofibers Using Two-step Method [J]. Journal of Inorganic Materials, 2018, 33(4): 453-461. |

| [9] | CAI Jian-Xin, LI Zhi-Peng, LI Wei, ZHAO Peng-Fei, YANG Zhen-Yu, YU Ji. Synthesis and Electrochemical Performance of Fe2O3 Nanofibers as Anode Materials for LIBs [J]. Journal of Inorganic Materials, 2018, 33(3): 301-306. |

| [10] | WU Nan, WAN Lynn Yuqin, WANG Ying-De, FRANK KO. Electrospun Silicon Oxycarbide Ultrafine Fibers Derived from Polycarbosilane [J]. Journal of Inorganic Materials, 2018, 33(3): 357-362. |

| [11] | ZHANG Xue-Ke, XIANG Jun, WU Zhi-Peng, LIU Min, SHEN Xiang-Qian. Co Content on Absorption Property of C/Co Nanofibers as a Lightweight Microwave Absorber [J]. Journal of Inorganic Materials, 2017, 32(12): 1299-1307. |

| [12] | ZHAO Hai-Lei, CUI Bo, WANG Hong-Zhi, LI Yao-Gang, ZHANG Qing-Hong. Synthesis and Properties of Nanobelt CaSi2O2N2: Eu0.052+ Fluorescence Fibers [J]. Journal of Inorganic Materials, 2016, 31(1): 21-26. |

| [13] | ZHANG SHU-XIAN, CUI BO, WANG HONG-ZHI, LI YAO-GANG, ZHANG QING-HONG. Preparation and Luminescence Properties of Flexible Eu3+ Doped SiO2 Fibrous Membranes [J]. Journal of Inorganic Materials, 2015, 30(7): 719-724. |

| [14] | LI Jia-Le, XIANG Jun, YE Qin, LIU Min, SHEN Xiang-Qian. Microwave Absorption Properties of Double-layer Absorbing Coatings Based on Ni0.4Co0.2Zn0.4Fe2O4 and BaTiO3 Nanofibers [J]. Journal of Inorganic Materials, 2015, 30(5): 479-486. |

| [15] | GUO Li-Ping, BAI Jie, LIANG Hai-Ou, LI Chun-Ping, SUN Wei-Yan, MENG Qing-Run. Preparation and Application of Carbon Nanofibers-supported Palladium Nanoparticles Catalysts Based on Electrospinning [J]. Journal of Inorganic Materials, 2014, 29(8): 814-820. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||