Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (4): 425-432.DOI: 10.15541/jim20240411

Special Issue: 【结构材料】热障与环境障涂层(202506)

• RESEARCH ARTICLE • Previous Articles Next Articles

LIANG Ruihui( ), ZHONG Xin(

), ZHONG Xin( ), HONG Du, HUANG Liping, NIU Yaran, ZHENG Xuebin

), HONG Du, HUANG Liping, NIU Yaran, ZHENG Xuebin

Received:2024-09-14

Revised:2024-11-07

Published:2025-04-20

Online:2024-11-15

Contact:

ZHONG Xin, associate professor. E-mail: zhongxin@mail.sic.ac.cnAbout author:LIANG Ruihui (1998-), male, Master. E-mail: liangrh98@126.com

Supported by:CLC Number:

LIANG Ruihui, ZHONG Xin, HONG Du, HUANG Liping, NIU Yaran, ZHENG Xuebin. High-temperature Water Vapor Corrosion Behaviors of Environmental Barrier Coatings with Yb2O3-modified Silicon Bond Layer[J]. Journal of Inorganic Materials, 2025, 40(4): 425-432.

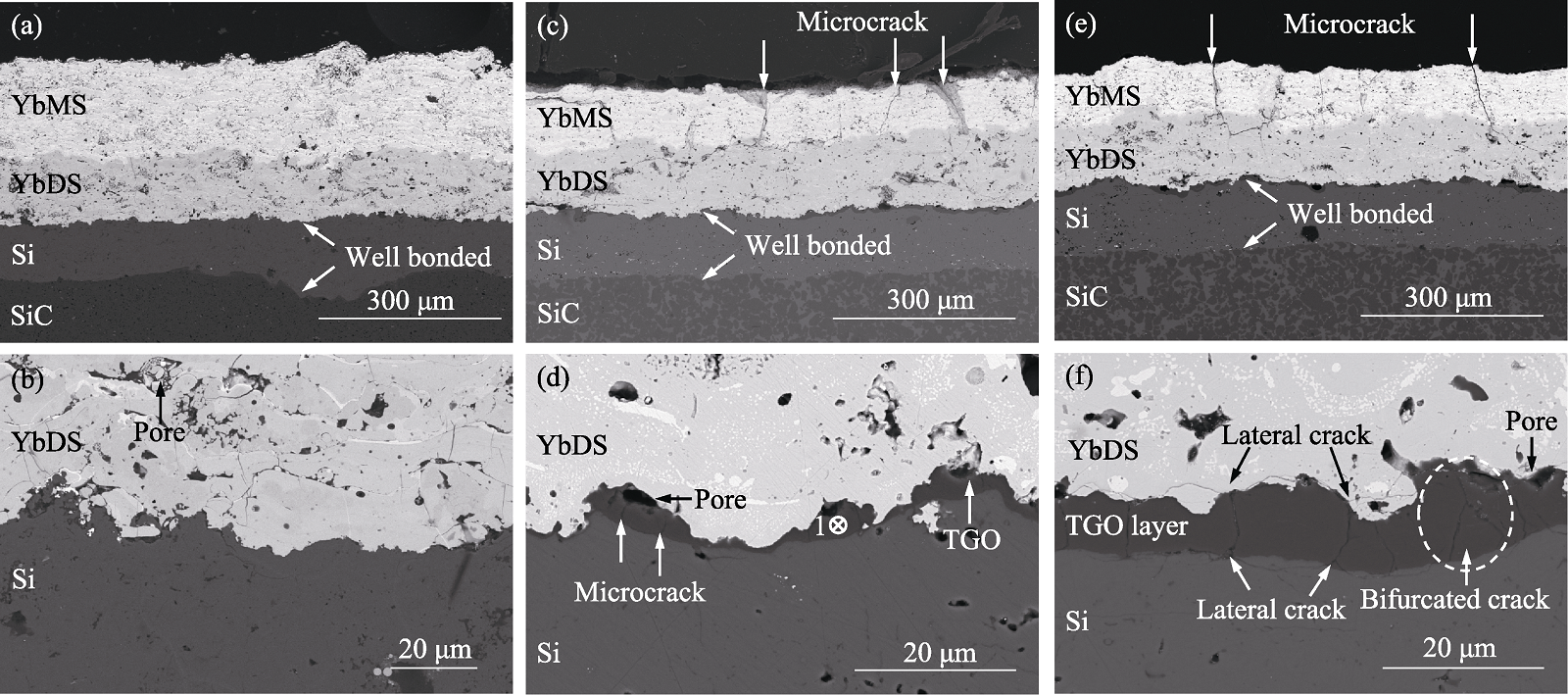

Fig. 3 Cross-sectional micromorphologies of Si/YbDS/YbMS EBCs before and after water vapor corrosion at 1350 ℃ (a, b) As-sprayed; (c, d) 100 h; (e, f) 200 h

| Sample site | Si | Yb | O |

|---|---|---|---|

| Point 1 | 40.30 | \ | 59.70 |

| Point 2 | 18.47 | 15.54 | 65.99 |

| Point 3 | 30.95 | 11.28 | 57.77 |

| Point 4 | 24.00 | 17.80 | 58.20 |

| Point 5 | 100.00 | \ | \ |

Table 1 EDS element analysis results (%, in atom) for different contrast regions in Fig. 3-Fig. 5

| Sample site | Si | Yb | O |

|---|---|---|---|

| Point 1 | 40.30 | \ | 59.70 |

| Point 2 | 18.47 | 15.54 | 65.99 |

| Point 3 | 30.95 | 11.28 | 57.77 |

| Point 4 | 24.00 | 17.80 | 58.20 |

| Point 5 | 100.00 | \ | \ |

Fig. 4 Cross-sectional micromorphologies of S5Yb/YbDS/YbMS EBCs after water vapor corrosion at 1350 ℃ with inserts in (c) showing corresponding EDS element analysis (a-c) 100 h; (d, e) 200 h

| [1] |

PADTURE N P. Advanced structural ceramics in aerospace propulsion. Nature Materials, 2016, 15(8):804.

DOI PMID |

| [2] | RAJ R. Fundamental research in structural ceramics for service near 2000 ℃. Journal of the American Ceramic Society, 1993, 76(9): 2147. |

| [3] | LUTHRA K L. Some new perspectives on oxidation of silicon carbide and silicon nitride. Journal of the American Ceramic Society, 1991, 74(5):1095. |

| [4] | COSTELLO J A, TRESSLER R E. Oxidation kinetics of silicon carbide crystals and ceramics: Ⅰ, in dry oxygen. Journal of the American Ceramic Society, 1986, 69(9):674. |

| [5] | EATON H E, LINSEY G D. Accelerated oxidation of SiC CMC's by water vapor and protection via environmental barrier coating approach. Journal of the European Ceramic Society, 2002, 22(14/15):2741. |

| [6] | WANG Y W, NIU Y R, ZHONG X, et al. Water vapor corrosion behaviors of plasma sprayed RE2SiO5 (RE = Gd, Y, Er) coatings. Corrosion Science, 2020, 167: 108529. |

| [7] |

LIU P P, ZHONG X, ZHANG L, et al. Molten salt corrosion behaviors and mechanisms of ytterbium silicate environmental barrier coating. Journal of Inorganic Materials, 2022, 37(12):1267.

DOI |

| [8] | ZHONG X, WANG Y W, NIU Y R, et al. Corrosion behaviors and mechanisms of ytterbium silicate environmental barrier coatings by molten calcium-magnesium-alumino-silicate melts. Corrosion Science, 2021, 191: 109718. |

| [9] | RICHARDS B T, SEHR S, FRANQUEVILLE F D, et al. Fracture mechanisms of ytterbium monosilicate environmental barrier coatings during cyclic thermal exposure. Acta Materialia, 2016, 103: 448. |

| [10] | LEE K N, FOX D S, BANSAL N P. Rare earth silicate environmental barrier coatings for SiC/SiC composites and Si3N4 ceramics. Journal of the European Ceramic Society, 2005, 25(10):1705. |

| [11] | LEE K N, JACOBSON N S MILLER R A. Refractory oxide coatings on SiC ceramics. MRS Bulletin, 1994, 19(10):35. |

| [12] | RICHARDS B T, YOUNG K A, FRANCQUEILLE F D, et al. Response of ytterbium disilicate-silicon environmental barrier coatings to thermal cycling in water vapor. Acta Materialia, 2016, 106: 1. |

| [13] | LAMKIN M A, RILEY F L. Oxygen mobility in silicon dioxide and silicate glasses: a review. Journal of the European Ceramic Society, 1992, 10(5):347. |

| [14] | HATCH D M, GHOSE S. The α-β phase transition in cristobalite, SiO2. Physics and Chemistry of Minerals, 1991, 17(6):554. |

| [15] | LU Y H, LUO L, LIU J, et al. Failure mechanism associated with the thermally grown silica scale in environmental barrier coated C/SiC composites. Journal of the American Ceramic Society, 2016, 99(8):2713. |

| [16] | ZHU D M, HADER B, HURST J B, et al. Development of advanced environmental barrier coatings for SiC/SiC ceramic matrix composites: path toward 2700 oF temperature capability and beyond. 41st Annual Conference on Composites, Materials, and Structures, Cocoa Beach, 2017: 20170005218. |

| [17] | ZHU D M. Environmental barrier coating development for SiC/SiC ceramic matrix composites: recent advances and future directions. Conference and Expo on Advanced Ceramics and Composites, Daytona Beach, 2016: 20160010286. |

| [18] | ZHU D M. Development and performance evaluations of HfO2-Si and rare earth-Si based environment barrier bond coat systems for SiC/SiC ceramic matrix composites. 41st International Conference on Metallurgical Coatings and Thin Films, San Diego, 2014: 20140008956. |

| [19] | ZHONG X, LIANG R H, HONG D, et al. Corrosion behavior and mechanism of ytterbium silicates environmental barrier coatings subjected to thermal cycling in water vapor. Journal of the American Ceramic Society, 2024, 107(1):387. |

| [20] | ANTON R, LEISNER V, WATERMEYER P, et al. Hafnia-doped silicon bond coats manufactured by PVD for SiC/SiC CMCs. Acta Materialia, 2020, 183: 471. |

| [21] | HARDER B J. Oxidation performance of Si-HfO2 environmental barrier coating bond coats deposited via plasma spray-physical vapor deposition. Surface and Coatings Technology, 2020, 384: 125311. |

| [22] | CHEN W B, HAN Q Z, HE J, et al. Effect of HfO2 framework on steam oxidation behavior of HfO2 doped Si coating at high temperatures. Ceramics International, 2022, 48(14):20201. |

| [23] | FERNÁDER-CARRIÓN A J, ALLIX M, BECERRO A I. Thermal expansion of rare-earth pyrosilicates. Journal of the American Ceramic Society, 2013, 96(7):2298. |

| [24] | AL NASIRI N, PATRA N, HORLAIT D, et al. Thermal properties of rare-earth monosilicates for EBC on Si-based ceramic composites. Journal of the American Ceramic Society, 2016, 99(2):589. |

| [25] | ZHONG X, NIU Y R, LI H, et al. Microstructure and thermomechanical properties of atmospheric plasma-sprayed Yb2O3 coating. Journal of Thermal Spray Technology, 2018, 27(6):959. |

| [26] | MAO F Q, NIU Y R, ZHONG X, et al. Oxidation behaviors and mechanisms of Yb2O3-doped silicon coatings fabricated by vacuum plasma spray. Ceramics International, 2021, 47(14):19906. |

| [27] | FAN D, ZHONG X, MAO F Q, et al. High temperature performances of tri-layer environmental barrier coating with Si bond layer modified by Yb2O3. Ceramics International, 2023, 49(8):11837. |

| [1] | FANG Guangwu, XIE Haoyuan, ZHANG Huajun, GAO Xiguang, SONG Yingdong. Progress of Damage Coupling Mechanism and Integrated Design Method for CMC-EBC [J]. Journal of Inorganic Materials, 2024, 39(6): 647-661. |

| [2] | LI Jie, LUO Zhixin, CUI Yang, ZHANG Guangheng, SUN Luchao, WANG Jingyang. CMAS Corrosion Resistance of Y3Al5O12/Al2O3 Ceramic Coating Deposited by Atmospheric Plasma Spraying [J]. Journal of Inorganic Materials, 2024, 39(6): 671-680. |

| [3] | TAO Shunyan, YANG Jiasheng, SHAO Fang, WU Yingchen, ZHAO Huayu, DONG Shaoming, ZHANG Xiangyu, XIONG Ying. Thermal Spray Coatings for Aircraft CMC Hot-end Components: Opportunities and Challenges [J]. Journal of Inorganic Materials, 2024, 39(10): 1077-1083. |

| [4] | FAN Dong, ZHONG Xin, WANG Yawen, ZHANG Zhenzhong, NIU Yaran, LI Qilian, ZHANG Le, ZHENG Xuebin. Corrosion Behavior and Mechanism of Aluminum-rich CMAS on Rare-earth Silicate Environmental Barrier Coatings: [J]. Journal of Inorganic Materials, 2023, 38(5): 544-552. |

| [5] | LIU Pingping, ZHONG Xin, ZHANG Le, LI Hong, NIU Yaran, ZHANG Xiangyu, LI Qilian, ZHENG Xuebin. Molten Salt Corrosion Behaviors and Mechanisms of Ytterbium Silicate Environmental Barrier Coating [J]. Journal of Inorganic Materials, 2022, 37(12): 1267-1274. |

| [6] | SUN Luchao, REN Xiaomin, DU Tiefeng, LUO Yixiu, ZHANG Jie, WANG Jingyang. High Entropy Engineering: New Strategy for the Critical Property Optimizations of Rare Earth Silicates [J]. Journal of Inorganic Materials, 2021, 36(4): 339-346. |

| [7] | ZHANG Xiao-Feng, ZHOU Ke-Song, LIU Min, DENG Chun-Ming, NIU Shao-Peng, XU Shi-Ming. Preparation of Si/Mullite/Yb2SiO5 Environment Barrier Coating (EBC) by Plasma Spray-Physical Vapor Deposition (PS-PVD) [J]. Journal of Inorganic Materials, 2018, 33(3): 325-330. |

| [8] | LIN Chu-Cheng, KONG Ming-Guang, ZHU Hui-Ying, HUANG Li-Ping, ZHENG Xue-Bin, ZENG Yi. Tribological Behavior of Vacuum Plasma Sprayed B4C-Mo Composite Coating [J]. Journal of Inorganic Materials, 2016, 31(1): 100-106. |

| [9] | YI De-Liang, WU Cheng-Tie, MA Xu-Bing, JI Heng, ZHENG Xue-Bin, CHANG Jiang. A Comparative Study of Vacuum and Air Plasma Sprayed Bioactive Akermanite Coating [J]. Journal of Inorganic Materials, 2014, 29(2): 172-178. |

| [10] | LU Lin-Jing, CHENG Lai-Fei, HONG Zhi-Liang, WANG Yi-Guang, ZHANG Li-Tong. Fabrication and Water-vapor Corrosion Resistance of Ba0.25Sr0.75Al2Si2O8 Environmental Barrier Coating [J]. Journal of Inorganic Materials, 2011, 26(7): 701-706. |

| [11] | WU Jiang,LIN Hong,LI Jian-Bao,LI Jun-Feng. Corrosion Behavior of AlNbO4/Mullite Composite as Environmental Barrier Coating in Water Vapor Environment [J]. Journal of Inorganic Materials, 2010, 25(4): 445-448. |

| [12] | HONG Zhi-Liang,CHENG Lai-Fei,LU Lin-Jing,ZHANG Li-Tong,WANG Yi-Guang. Corrosion Behavior of Lu-Si-O System in Water Vapor [J]. Journal of Inorganic Materials, 2010, 15(2): 186-190. |

| [13] | CHEN Xian-Hong,CHENG Lai-Fei,WANG Yi-Guang,ZHANG Li-Tong,HONG Zhi-Liang,WU Ya-Hui. Corrosion Behavior of AlPO4 as Environmental Barrier Coating in Water Vapor Enviroment [J]. Journal of Inorganic Materials, 2009, 24(2): 397-401. |

| [14] | ZHENG Xue-Bin,JI Heng,HUANG JING-Qi,DING CHUAN-Xian ZHU Zi-Yuan,ZHANG Fu-Qiang. Plasma Sprayed Antibacterial HA Coatings [J]. Journal of Inorganic Materials, 2006, 21(3): 764-768. |

| [15] | ZHENG Xue-Bin,JI Heng,HUANG Jing-Qi,ZENG Yi,DING Chuan-Xian. Preparation and Laser Ablation Test of Vacuum Plasma Sprayed Boron Carbide Coatings [J]. Journal of Inorganic Materials, 2005, 20(6): 1509-1514. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||