Journal of Inorganic Materials ›› 2014, Vol. 29 ›› Issue (3): 294-300.DOI: 10.3724/SP.J.1077.2014.13342

• Orginal Article • Previous Articles Next Articles

ZHANG Xiao-Feng1, 2, ZHOU Ke-Song1, 2, ZHANG Ji-Fu2, HAN Tao2, Song Jin-Bing2, LIU-Min2

Received:2013-07-01

Revised:2013-08-15

Published:2014-03-20

Online:2014-02-18

About author:ZHANG Xiao-Feng. E-mail:zxf200808@126.com

CLC Number:

ZHANG Xiao-Feng, ZHOU Ke-Song, ZHANG Ji-Fu, HAN Tao, Song Jin-Bing, LIU-Min. Erosion Failure Mechanism and Model Establishment of Thermal Barrier Coatings Based on Roughness[J]. Journal of Inorganic Materials, 2014, 29(3): 294-300.

Add to citation manager EndNote|Ris|BibTeX

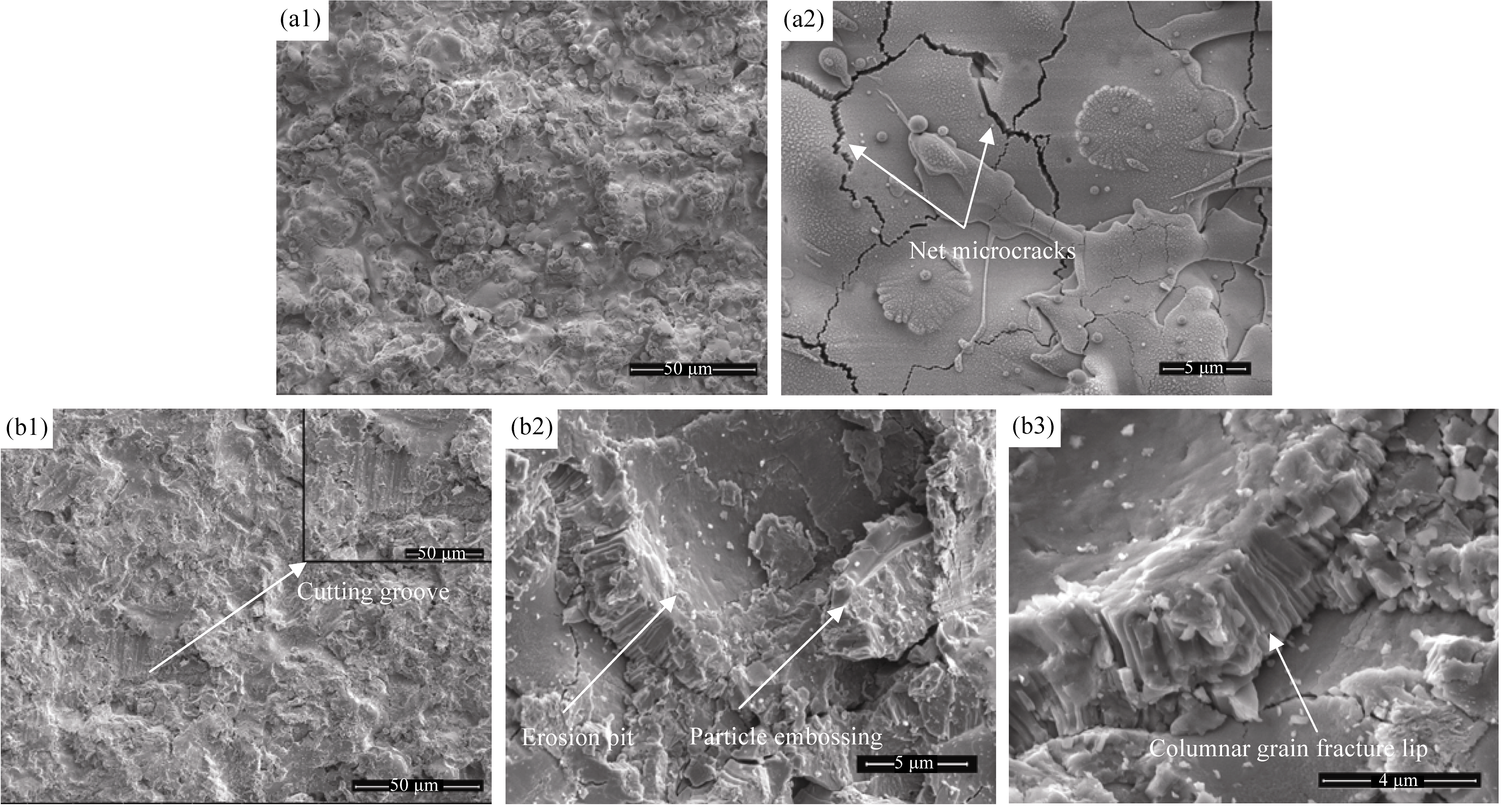

Fig. 6 Different magnification surface microstructures of ceramic coating Protection district, (a1, a2); Erosion district after erosion for 120 s, (b1, b2, b3)

Fig. 7 Cross-sectional microstructures of protection district and erosion district Whole district (a), protection district (b), erosion district (c-f) after erosion for 120 s

| [1] | HUA JIA-JIE, ZHANG LI-PENG, LIU ZI-WEi, et al. Progress of research on mechanism of thermal barrier coatings. Journal of Inorganic Materials, 2012, 27(7): 680-685. |

| [2] | GONG WEN-BIAO, LI YU-PENG, LIU WEI, et al. Preparation and high-temperature properties of nanostructured CeO2/ZrO2- Y2O3 thermal barrier coating. Journal of Inorganic Materials, 2010, 25(8): 860-864. |

| [3] | GUO HONG-BO, GONG SHENG-KAI, XU HUI-BIN. Progress in thermal barrier coatings for advanced aeroengines. Materials China, 2009, 28(9/10): 18-26. |

| [4] | YANG LI, ZHOU YI-CHUN, QI SHA-SHA. Research progress in erosion mechanisms of thermal barrier coatings. Advances in Mechanics, 2012, 25(6): 704-719. |

| [5] | CHEN X, HE M Y, SPITSBERG I, et al. Mechanisms governing the high temperature erosion of thermal barrier coatings. Wear, 2004, 256(7/8): 735-746. |

| [6] | WATANABE M, XU T, LEVI C G, et al. Shear band formation in columnar thermal oxides. Acta Materialia, 2005, 53(13): 3765-3773. |

| [7] | SUN JIA-SHU, WANG XIAO-TONG, GUO DA-ZHAN. Impact- erosion wear characteristics and mathematic model of plasma spray ceramic coatings by solid particles. Tribology, 1994, 14(1): 57-64. |

| [8] | WANG HAI-JUN, CAI JIANG, HAN ZHI-HAI. Study on erosion wearof WC-Co coatings prepared by supersonic plasma spray and HVOF spray. Journal of Materials Engineering, 2005, 49(4): 50-54. |

| [9] | LI YANG, LI SHU, LIU YANG, et al. Effect of porosity and laminar structure on erosion resistance of WC-Co-Cr Coatings. Tribology, 2011, 31(3): 228-234. |

| [10] | ZHANG C L, ZOU X Y, GONG J R, et al. Aerodynamic roughness of cultivated soil and its influences on soil erosion by wind in a wind tunnel. Soil & Tillage Research, 2004, 75(1): 53-59. |

| [11] | WANG REN-ZHI. Overview on the shot peening principle and its strengthening mechanisms for metallic materials. China Surface Engineering, 2012, 25(6): 1-9. |

| [12] | WELLMAN R G, NICHOLLS J R. A review of the erosion of thermal barrier coatings. J. Phys. D: Appl. Phys., 2007, 40(16): 293-305. |

| [13] | POHL M, STELLA J. Quantitative CLSM roughness study on early cavitation-erosion damage. Wear, 2002, 252(5/6): 501-511. |

| [14] | RAUPACH M R. The effect of roughness elements on wind erosion threshold. Journal of Geophysical Research, 1993, 98(2): 3023-3029. |

| [15] | CHEN X, WANG R, YAO N, et al. Foreign object damage in a thermal barrier system: mechanisms and simulations. Materials Science and Engineering A, 2003, 352(1): 221-231. |

| [16] | LI C J, LI Y, YANG G J, et al. A novel plasma-sprayed durable thermal barrier coating with a well bonded YSZ interlayer between porous YSZ and bond coat. Journal of Thermal Spray Technology, 2012, 21(3/4): 383-389. |

| [17] | EVANS A G, FLECK N A, FAULHABER S, et al. Scaling laws governing the erosion and impact resistance of thermal barrier coatings. Wear, 2006, 260(7/8): 886-894 |

| [18] | RAMANUJAM N, NAKAMURA T. Erosion mechanisms of thermally sprayed coatings with multiple phases. Surface and Coatings Technology, 2009, 204(1/2): 42-53. |

| [19] | CHEN X, HUTCHINSON J W. Particle impact on metal substrates with application to foreign object damage to aircraft engines. Journal of the Mechanics and Physics of Solids, 2002, 50(12): 2669-2690. |

| [1] | AN Wenran, HUANG Jingqi, LU Xiangrong, JIANG Jianing, DENG Longhui, CAO Xueqiang. Effect of Heat-treatment Temperature on Thermal and Mechanical Properties of LaMgAl11O19 Coating [J]. Journal of Inorganic Materials, 2022, 37(9): 925-932. |

| [2] | LI Qiaolei, GU Yue, YU Xuehua, ZHANG Chaowei, ZOU Mingke, LIANG Jingjing, LI Jinguo. Effect of Sintering Temperature on Surface Morphology and Roughness of 3D-printed Silicon Ceramic Cores [J]. Journal of Inorganic Materials, 2022, 37(3): 325-332. |

| [3] | WEI Hailang, CAO Xueqiang, DENG Longhui, JIANG Jianing. Thermodynamic Properties and Thermal Cycling Lifetimes of LaMeAl11O19/YSZ Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2022, 37(12): 1259-1266. |

| [4] | ZHU Jiatong, LOU Zhihao, ZHANG Ping, ZHAO Jia, MENG Xuanyu, XU Jie, GAO Feng. Preparation and Thermal Properties of Rare Earth Tantalates (RETaO4) High-Entropy Ceramics [J]. Journal of Inorganic Materials, 2021, 36(4): 411-417. |

| [5] | JI Xiaojuan,YU Yueguang,LU Xiaoliang. Effects of Impurities on Properties of YSZ Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2020, 35(6): 669-674. |

| [6] | Bo-Le MA, Wen MA, Wei HUANG, Yu BAI, Rui-Ling JIA, Hong-Ying DONG. Thermophysical Property of Single-phase Strontium Zirconate Co-doped with Double Rare-earth Oxides as a Thermal Barrier Coating Material [J]. Journal of Inorganic Materials, 2019, 34(4): 394-400. |

| [7] | WANG Lin, DING Kun-Ying, LIN Xiao-Ping, LI Ze, ZHENG Run-Guo, YANG Lian-Wei. Defect Evolution and Microcracks of 8YSZ Double-layer Thermal Barrier Coatings by Water Immersion Ultrasound Macroscopic Detection [J]. Journal of Inorganic Materials, 2019, 34(12): 1265-1271. |

| [8] | ZHANG Xiao-Feng, ZHOU Ke-Song, LIU Min, DENG Chun-Ming, DENG Chang-Guang, CHEN Huan-Tao. Thermal Shock Analysis of Surface Al-modified 7YSZ Nano-thermal Barrier Coatin [J]. Journal of Inorganic Materials, 2017, 32(9): 973-979. |

| [9] | LI Da-Chuan, ZHAO Hua-Yu, ZHONG Xing-Hua, TAO Shun-Yan. Research Progresses of Atmospheric Plasma Sprayed Splat [J]. Journal of Inorganic Materials, 2017, 32(6): 571-580. |

| [10] | SUN Xu-Xuan, CHEN Hong-Fei, YANG Guang, LIU Bin, GAO Yan-Feng. YSZ- Ti3AlC2 Thermal Barrier Coating and Its Self-healing Behavior under High Temperatures [J]. Journal of Inorganic Materials, 2017, 32(12): 1269-1274. |

| [11] | MA Rong-Bin, CHENG Xu-Dong, ZOU Jun, LI Qing-Yu, HUANG Xia. Toughness and Thermal Shock of SiC Fiber/Yttria-stabilized-zirconia Composite Thick Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2016, 31(2): 190-194. |

| [12] | YANG Bin, LI Lin-Yan, FAN Min-Guang, LI Bin, XU Sheng-Ming, WANG Jian-Long, LIN Xu-Ping. Synthesis and Thermophysical Properties of (La1-xMgx)2Ce2O7-x [J]. Journal of Inorganic Materials, 2014, 29(12): 1301-1305. |

| [13] | HOU Wei-Min, YU Yun, HU Xue-Bing, YU Yang, MI Le, SONG Li-Xin. Study on Superhydrophobic Modification of Al2O3 Microfiltration Membrane [J]. Journal of Inorganic Materials, 2013, 28(8): 864-868. |

| [14] | YANG Jia-Sheng, YU Jian-Hua, ZHONG Xing-Hua, ZHAO Hua-Yu, ZHOU Xia-Ming, TAO Shun-Yan, DING Chuan-Xian. Experimental and Numerical Investigation of Residual Stresses in Plasma-sprayed Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2013, 28(12): 1381-1386. |

| [15] | HUA Jia-Jie, ZHANG Li-PENG, LIU Zi-Wei, WANG Yong-Zhe, LIN Chu-Cheng, ZENG Yi, ZHENG Xue-Bing. Progress of Research on the Failure Mechanism of Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2012, 27(7): 680-686. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||