Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (8): 931-937.DOI: 10.15541/jim20230006

• RESEARCH ARTICLE • Previous Articles Next Articles

HU Zhongliang1( ), FU Yuntian1, JIANG Meng1, WANG Lianjun1, JIANG Wan1,2(

), FU Yuntian1, JIANG Meng1, WANG Lianjun1, JIANG Wan1,2( )

)

Received:2023-01-04

Revised:2023-03-03

Published:2023-08-20

Online:2023-03-17

Contact:

JIANG Wan, professor. E-mail: wanjiang@dhu.edu.cnAbout author:HU Zhongliang (1997-), male, Master candidate. E-mail: hu676789989@163.com

Supported by:CLC Number:

HU Zhongliang, FU Yuntian, JIANG Meng, WANG Lianjun, JIANG Wan. Thermal Stability of Nb/Mg3SbBi Interface[J]. Journal of Inorganic Materials, 2023, 38(8): 931-937.

Fig. 3 Thermoelectric properties of hot-pressed 750 ℃ sintered samples with various holding time as a function of test temperature (a) Electrical conductivity; (b) Seebeck coefficient; (c) Lattice thermal conductivity; (d) ZT

| Point | Mg/% | Sb/% | Bi/% | Nb/% |

|---|---|---|---|---|

| 1 | 59.75 | 9.25 | 29.64 | 1.36 |

| 2 | 51.88 | 8.35 | 25.57 | 14.20 |

| 3 | 1.19 | 0.14 | 0.13 | 98.54 |

| 4 | 58.78 | 19.85 | 20.22 | 1.15 |

Table 1 EDS point analysis results of the points in Fig.4(c) (in atomic)

| Point | Mg/% | Sb/% | Bi/% | Nb/% |

|---|---|---|---|---|

| 1 | 59.75 | 9.25 | 29.64 | 1.36 |

| 2 | 51.88 | 8.35 | 25.57 | 14.20 |

| 3 | 1.19 | 0.14 | 0.13 | 98.54 |

| 4 | 58.78 | 19.85 | 20.22 | 1.15 |

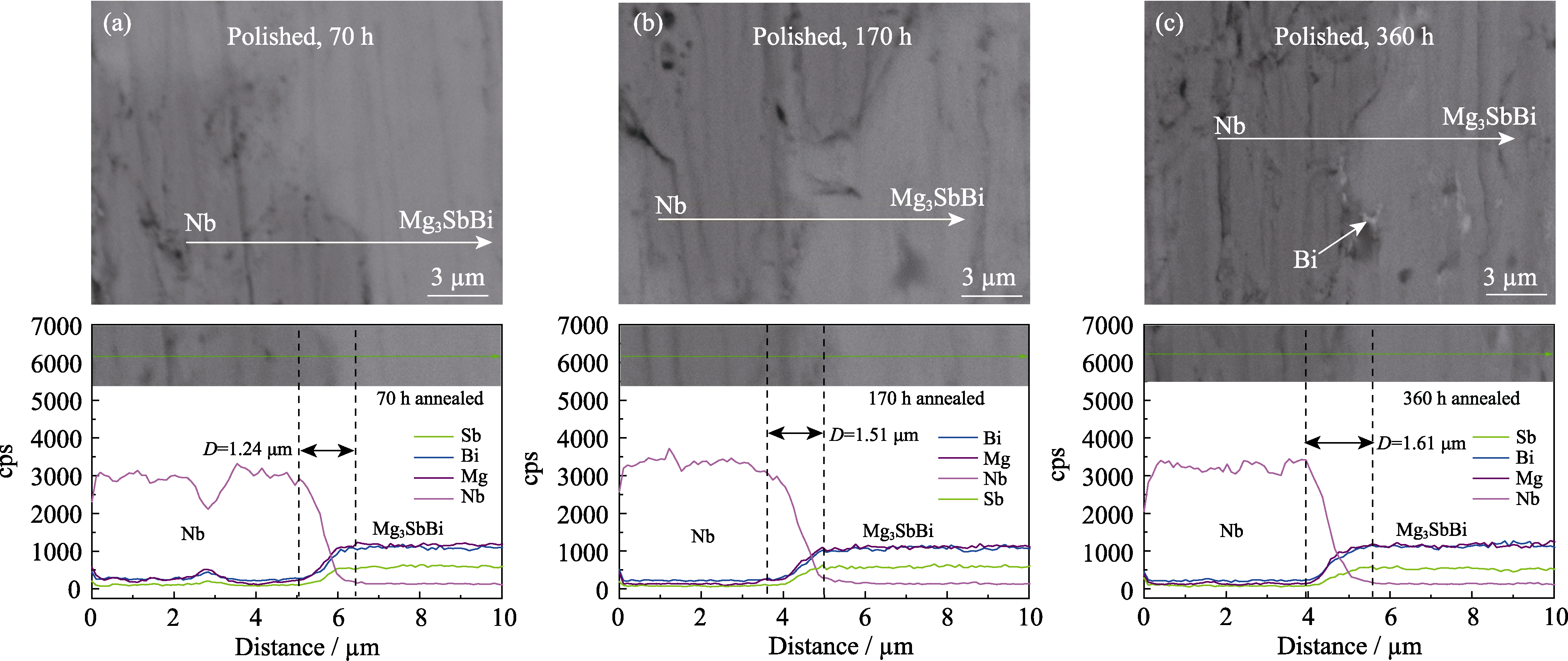

Fig. 6 Backscatter (up) and line sweep (down) results of Nb /Mg3SbBi interface aged at 525℃for different time (a) 70; (b) 170 h; (c) 360 h; Colorful figures are available on website

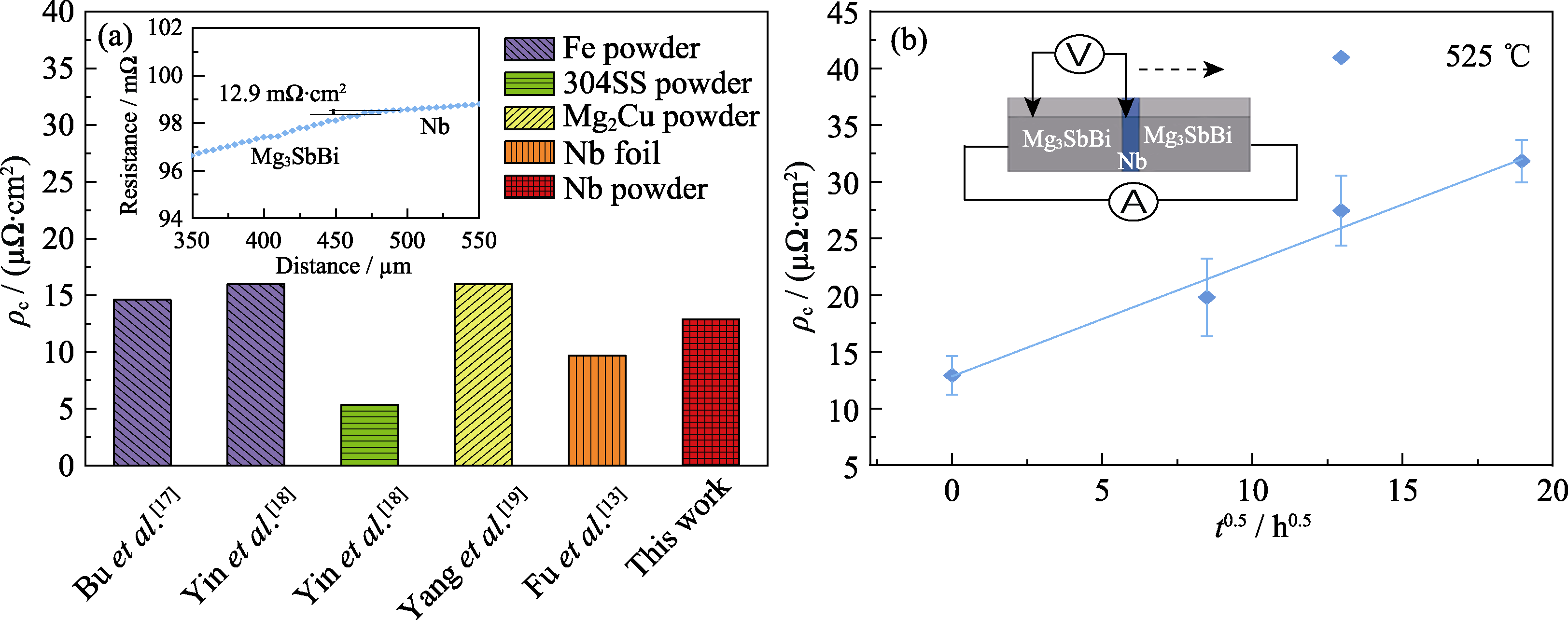

Fig. 7 Interface resistivities of Nb/Mg3SbBi (a) Comparison with literature [13,17⇓-19]; (b) Relationship of interface resistivity with thermal aging time

| [1] |

ZHANG K Y, ZHENG Q, WANG L J, et al. Preparation and characterization of Ag2Se-based ink used for inkjet printing. Journal of Inorganic Materials, 2022, 37(10): 1109.

DOI URL |

| [2] |

FAN S J, SUN T T, JIANG M, et al. In-situ growth of carbon nanotubes on ZnO to enhance thermoelectric and mechanical properties. Journal of Advanced Ceramics, 2022, 11(12): 1932.

DOI |

| [3] |

JAYACHANDRAN B, GOPALAN R, DASGUPTA T, et al. Elevated temperature behavior of CuPb18SbTe20/nano-Ag/Cu joints for thermoelectric devices. Journal of Electronic Materials, 2018, 48(2): 1276.

DOI |

| [4] |

LI C C, DRYMIOTIS F, LIAO L L, et al. Interfacial reactions between PbTe-based thermoelectric materials and Cu and Ag bonding materials. Journal of Materials Chemistry C, 2015, 3(40): 10590.

DOI URL |

| [5] | ZHANG Q H, LIAO J C, TANG Y S, et al. Realizing a thermoelectric conversion efficiency of 12% in bismuth telluride/skutterudite segmented modules through full-parameter optimization and energy-loss minimized integration. Energy & Environmental Science, 2017, 10(4): 956. |

| [6] | LIU W S, BAI S Q. Thermoelectric interface materials: a perspective to the challenge of thermoelectric power generation module. Journal of Materiomics, 2019, 5(3): 3216. |

| [7] |

ZHANG Q H, BAI S Q, CHEN L D. Technologies and applications of thermoelectric devices: current status, challenges and prospects. Journal of Inorganic Materials, 2019, 34(3): 279.

DOI URL |

| [8] |

HU X K, ZHANG S M, ZHAO F, et al. Thermoelectric device: contact interface and interface materials. Journal of Inorganic Materials, 2019, 34(3): 269.

DOI URL |

| [9] |

TAMAKI H, SATO H K, KANNO T. Isotropic conduction network and defect chemistry in Mg3+δSb2-based layered Zintl compounds with high thermoelectric performance. Advanced Materials, 2016, 28(46): 10182.

DOI URL |

| [10] |

ZHANG J W, SONG L, PEDERSEN S H, et al. Discovery of high-performance low-cost n-type Mg3Sb2-based thermoelectric materials with multi-valley conduction bands. Nature Communications, 2017, 8: 13901.

DOI |

| [11] |

LIN S Q, LI A R, FU C G, et al. Research progress on crystal growth and the thermoelectric properties of Zintl phase Mg3X2(X=Sb, Bi) based materials. Journal of Inorganic Materials, 2023, 38(3): 270.

DOI URL |

| [12] |

YANG Q Y, QIU P F, SHI X, et al. Application of entropy engineering in thermoelectrics. Journal of Inorganic Materials, 2021, 36(4): 347.

DOI URL |

| [13] | FU Y T, ZHANG Q H, HU Z L, et al. Mg3(Bi,Sb)2-based thermoelectric modules for efficient and reliable waste-heat utilization up to 750 K. Energy & Environmental Science, 2022, 15(8): 3265. |

| [14] | WANG Y C, CHEN J, JIANG Y, et al. Suppression of interfacial diffusion in Mg3Sb2 thermoelectric materials through an Mg4.3Sb3Ni/Mg3.2Sb2Y0.05/Mg4.3Sb3Ni-graded structure. ACS Applied Materials & Interfaces, 2022, 14(29): 33419. |

| [15] |

ZHU Q, SONG S W, ZHU H T, et al. Realizing high conversion efficiency of Mg3Sb2-based thermoelectric materials. Journal of Power Sources, 2019, 414: 393.

DOI URL |

| [16] | LIANG Z, XU C, SHANG H, et al. High thermoelectric energy conversion efficiency of a unicouple of n-type Mg3Bi2 and p-type Bi2Te3. Materials Today Physics, 2021, 19: 100413. |

| [17] | BU Z, ZHANG X, HU Y, et al. An over 10% module efficiency obtained using non-Bi2Te3 thermoelectric materials for recovering heat of <600 K. Energy & Environmental Science, 2021, 14(12): 6506. |

| [18] |

YIN L, CHEN C, ZHANG F, et al. Reliable N-type Mg3.2Sb1.5Bi0.49Te0.01/304 stainless steel junction for thermoelectric applications. Acta Materialia, 2020, 198: 25.

DOI URL |

| [19] |

YANG J W, LI G D, ZHU H T, et al. Next-generation thermoelectric cooling modules based on high-performance Mg3(Bi,Sb)2 material. Joule, 2022, 6(1): 193.

DOI URL |

| [20] | CHU J, GU M, LIU R H, et al. Interfacial behaviors of p-type CeyFexCo4-xSb12/Nb thermoelectric joints. Functional Materials Letters, 2020, 13(5): 2051020. |

| [21] | SHAO X, LIU R H, WANG L, et al. Interfacial stress analysis on skutterudite-based thermoelectric joints under service conditions. Journal of Inorganic Materials, 2020, 35(2): 30. |

| [22] |

AGNE M T, IMASATO K, ANAND S, et al. Heat capacity of Mg3Sb2, Mg3Bi2, and their alloys at high temperature. Materials Today Physics, 2018, 6: 83.

DOI URL |

| [23] |

THIMONT Y, LOGNONÉ Q, GOUPIL C, et al. Design of apparatus for Ni/Mg2Si and Ni/MnSi1.75 contact resistance determination for thermoelectric legs. Journal of Electronic Materials, 2014, 43(6): 2023.

DOI URL |

| [24] | KUO J J, KANG S D, IMASATO K, et al. Grain boundary dominated charge transport in Mg3Sb2-based compounds. Energy & Environmental Science, 2018, 11(2): 429. |

| [25] | WOOD M, KUO J J, IMASATO K, et al. Improvement of low-temperature ZT in a Mg3Sb2-Mg3Bi2 solid solution via Mg-vapor annealing. Advanced Materials, 2019, 31(35): 1902337. |

| [26] |

CHU J, HUANG J, LIU R H, et al. Electrode interface optimization advances conversion efficiency and stability of thermoelectric devices. Nature Communications, 2020, 11(1): 2723.

DOI |

| [1] | SHAO Xiao,LIU Rui-Heng,WANG Liang,CHU Jing,BAI Guang-Hui,BAI Sheng-Qiang,GU Ming,ZHANG Li-Na,MA Wei,CHEN Li-Dong. Interfacial Stress Analysis on Skutterudite-based Thermoelectric Joints under Service Conditions [J]. Journal of Inorganic Materials, 2020, 35(2): 224-230. |

| [2] | ZHANG Qi-Hao, LIAO Jin-Cheng, TANG Yun-Shan, GU Ming, LIU Rui-Heng, BAI Sheng-Qiang, CHEN Li-Dong. Interface Stability of Skutterudite Thermoelectric Materials/Ti88Al12 [J]. Journal of Inorganic Materials, 2018, 33(8): 889-894. |

| [3] | ZHANG Xiao-Fang, LIU Tao, JIN Hong-Bin, YU Jing-Kun, GAO Xiang, WANG Cheng, WANG Xiang-Nan. La0.8Sr0.2(Ga0.8Mg0.2)0.1Fe0.9O3-δ Dense Diffusion Barrier Limiting Current Oxygen Sensor Prepared by Co-pressing and Co-sintering Method [J]. Journal of Inorganic Materials, 2017, 32(10): 1089-1094. |

| [4] | TANG Wen-Ming,ZHENG Zhi-Xiang,DING Hou-Fu,JIN Zhi-Hao. Oxidation of SiC and Its Effect on the Interface Stability of SiC/Fe [J]. Journal of Inorganic Materials, 2001, 16(2): 289-296. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||