Journal of Inorganic Materials ›› 2020, Vol. 35 ›› Issue (2): 224-230.DOI: 10.15541/jim20190112

Special Issue: 2020年能源材料论文精选(三) :太阳能电池、热电材料及其他

• RESEARCH LETTERS • Previous Articles Next Articles

SHAO Xiao1,2,LIU Rui-Heng1,3( ),WANG Liang1,CHU Jing1,2,BAI Guang-Hui4,BAI Sheng-Qiang1,3,GU Ming1,ZHANG Li-Na4,MA Wei4,CHEN Li-Dong1,3

),WANG Liang1,CHU Jing1,2,BAI Guang-Hui4,BAI Sheng-Qiang1,3,GU Ming1,ZHANG Li-Na4,MA Wei4,CHEN Li-Dong1,3

Received:2019-03-18

Revised:2019-04-30

Published:2020-02-20

Online:2019-05-29

Supported by:CLC Number:

SHAO Xiao,LIU Rui-Heng,WANG Liang,CHU Jing,BAI Guang-Hui,BAI Sheng-Qiang,GU Ming,ZHANG Li-Na,MA Wei,CHEN Li-Dong. Interfacial Stress Analysis on Skutterudite-based Thermoelectric Joints under Service Conditions[J]. Journal of Inorganic Materials, 2020, 35(2): 224-230.

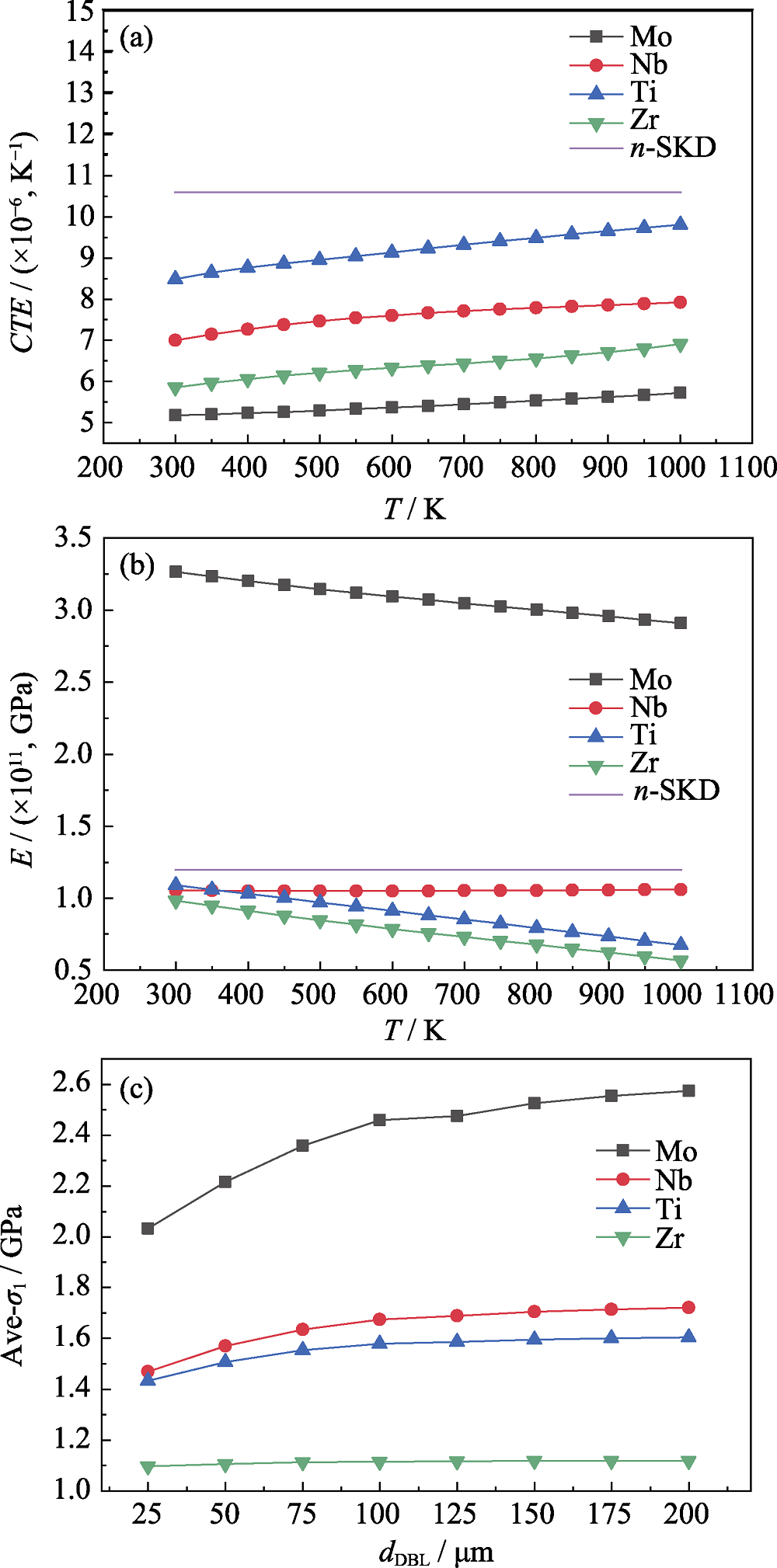

Fig. 1 (a) CTE, (b) Young’s modulus (E), and (c) variations of average first principle stresses with thicknesses of different DBL candidates (purple lines: CTE and E of SKD)

| Layer | SKD | Nb/Zr | CoSb2 | NbSb2/ ZrSb2 | Difference |

|---|---|---|---|---|---|

| Relative volume change (SKD/Nb) | -2.75 | -0.27 | +1.78 | +1 | -0.24 |

| Relative volume change (SKD/Zr) | -2.48 | -0.32 | +1.65 | +1 | -0.15 |

| Layer | SKD | Nb/Zr | CoSb2 | NbSb2/ ZrSb2 | Difference |

|---|---|---|---|---|---|

| Relative volume change (SKD/Nb) | -2.75 | -0.27 | +1.78 | +1 | -0.24 |

| Relative volume change (SKD/Zr) | -2.48 | -0.32 | +1.65 | +1 | -0.15 |

| Joints | dNbSb2/μm | c/μm | n | Ave-σ1/GPa | σt/MPa | Fracture position | Fracture composition |

|---|---|---|---|---|---|---|---|

| 0 d | 0 | 0 | 0 | 1.46 | (9.68±1.70) | Nb/ SKD | (Nb+ NbSb2)/(3%CoSb2+97% SKD) |

| 600-5 d | 2 | 2.02 | 3 | 2.72 | (4.63±2.12) | CoSb2/NbSb2 | NbSb2/(36%CoSb2+64% SKD) |

| 600-10 d | 3 | 2.21 | 3 | 2.80 | (3.39±1.44) | CoSb2/NbSb2 | NbSb2/(47%CoSb2+53% SKD) |

| 650-5 d | 7 | 4.13 | 1 | 3.07 | (4.44±1.50) | CoSb2/NbSb2 | NbSb2/(80%CoSb2+20% SKD) |

| 650-10 d | 12 | 5.20 | 1 | 3.42 | (1.46±0.38) | CoSb2/NbSb2 | NbSb2/(97%CoSb2+3% SKD) |

| Joints | dNbSb2/μm | c/μm | n | Ave-σ1/GPa | σt/MPa | Fracture position | Fracture composition |

|---|---|---|---|---|---|---|---|

| 0 d | 0 | 0 | 0 | 1.46 | (9.68±1.70) | Nb/ SKD | (Nb+ NbSb2)/(3%CoSb2+97% SKD) |

| 600-5 d | 2 | 2.02 | 3 | 2.72 | (4.63±2.12) | CoSb2/NbSb2 | NbSb2/(36%CoSb2+64% SKD) |

| 600-10 d | 3 | 2.21 | 3 | 2.80 | (3.39±1.44) | CoSb2/NbSb2 | NbSb2/(47%CoSb2+53% SKD) |

| 650-5 d | 7 | 4.13 | 1 | 3.07 | (4.44±1.50) | CoSb2/NbSb2 | NbSb2/(80%CoSb2+20% SKD) |

| 650-10 d | 12 | 5.20 | 1 | 3.42 | (1.46±0.38) | CoSb2/NbSb2 | NbSb2/(97%CoSb2+3% SKD) |

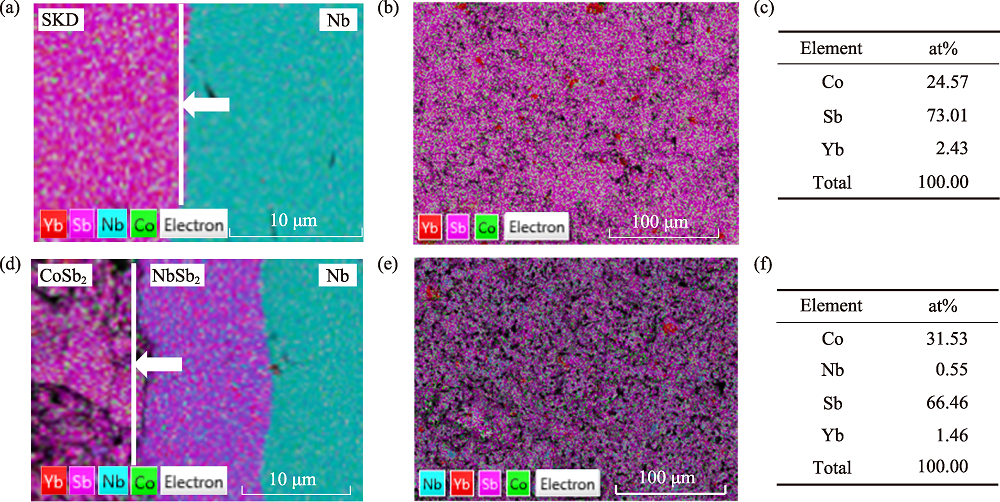

Fig. 4 EDS mappings of (a, d) interfaces and (b, e) fracture surfaces of (a-b) unaged joint and (d-e) sample 650-10d (White line indicating the fracture surface, and white arrow indicating direction of observation in (b) or (d)); Total element data were shown in table (c) for figure (b) and in table (f) for figure (e)

| Material | SKD | CoSb2 | NbSb2[ | ZrSb2[ | Nb | Zr |

|---|---|---|---|---|---|---|

| Molar Mass/(g·mol-1) | 424.21 | 302.45 | 336.43 | 334.82 | 92.91 | 91.22 |

| Density/(g·cm-3) | 7.80* | 8.36 | 8.29 | 7.62 | 8.57-8.45 | 6.5-6.4 |

| Young’s modulus/GPa | 120* | 160 | 186.1 | 135.7 | 104.8-105.7 | 97-57 |

| Poisson’s ratio | 0.21[ | 0.23 | 0.21 | 0.243 | 0.382-0.394 | 0.34 |

| Thermal conductivity/(W·m-1·K-1) | 3.04-4.05* | 6.8-12.5[ | 24 | 10 | 55-65 | 20-25 |

| Thermal expansion/(×10-6, K-1) | 10-11[ | 14-23[ | 8.4 | 9.7 | 7-7.8 | 5.9-6.9 |

| Heat capacity/(J·g-1·K-1) | 0.22-0.23* | 0.247 | 0.222 | 0.223 | 0.27-0.45 | 0.28-0.34 |

| Material | SKD | CoSb2 | NbSb2[ | ZrSb2[ | Nb | Zr |

|---|---|---|---|---|---|---|

| Molar Mass/(g·mol-1) | 424.21 | 302.45 | 336.43 | 334.82 | 92.91 | 91.22 |

| Density/(g·cm-3) | 7.80* | 8.36 | 8.29 | 7.62 | 8.57-8.45 | 6.5-6.4 |

| Young’s modulus/GPa | 120* | 160 | 186.1 | 135.7 | 104.8-105.7 | 97-57 |

| Poisson’s ratio | 0.21[ | 0.23 | 0.21 | 0.243 | 0.382-0.394 | 0.34 |

| Thermal conductivity/(W·m-1·K-1) | 3.04-4.05* | 6.8-12.5[ | 24 | 10 | 55-65 | 20-25 |

| Thermal expansion/(×10-6, K-1) | 10-11[ | 14-23[ | 8.4 | 9.7 | 7-7.8 | 5.9-6.9 |

| Heat capacity/(J·g-1·K-1) | 0.22-0.23* | 0.247 | 0.222 | 0.223 | 0.27-0.45 | 0.28-0.34 |

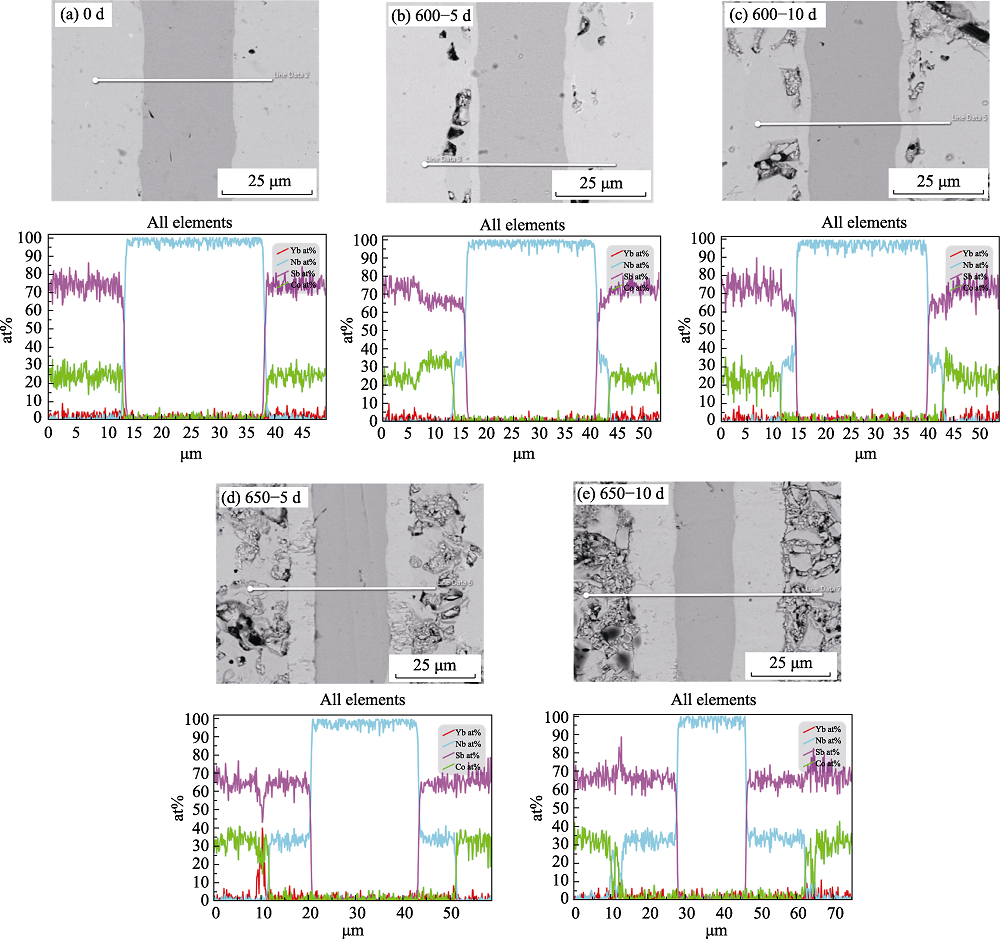

Fig. A2 Interface structures and line scans of joints (a) As-prepared; (b) Aged at 600 ℃ for 5 d; (c) Aged at 600 ℃ for 10 d; (d) Aged at 650 ℃ for 5 d; (e) Aged at 650 ℃ for 10 d

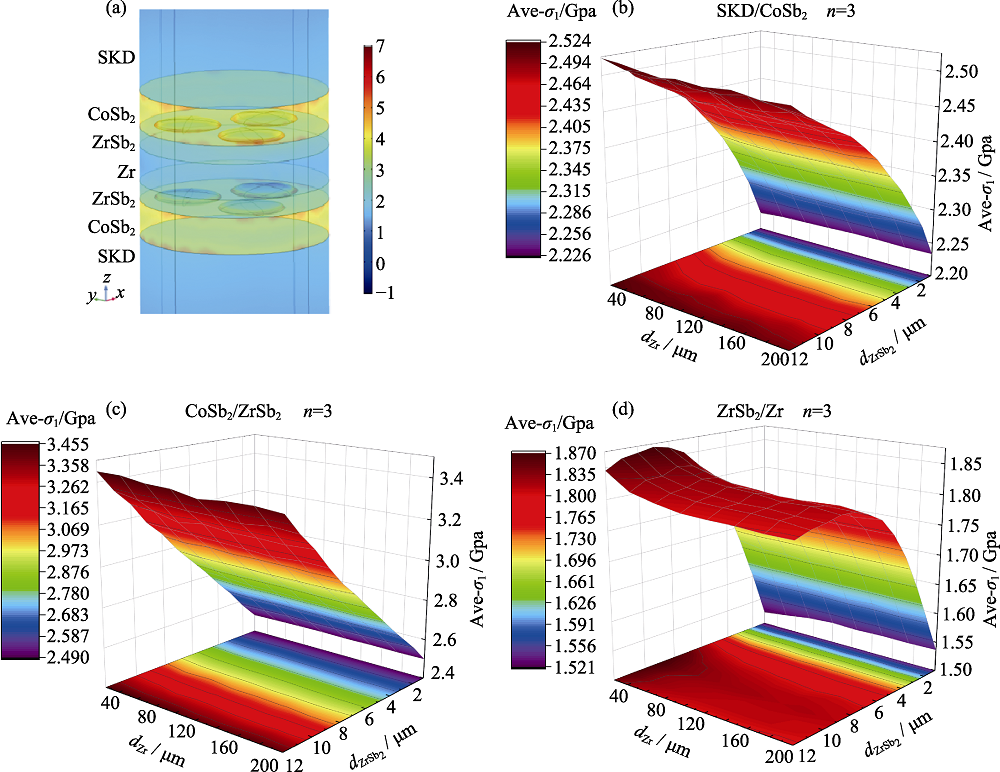

Fig. A4 (a) Calculated stress state of SKD/Zr joint with the Zr layer of 25 μm and the micropores number n of 3; (b) Variation of average σ1 on SKD/CoSb2 interface with thickness of ZrSb2 and Zr (n=3); (c) Variation of average σ1 on CoSb2/ZrSb2 interface with thickness of ZrSb2 and Zr (n=3); (d) Variation of average σ1 on ZrSb2/Zr interface with thickness of ZrSb2 and Zr (n=3)

| [1] | BELL L E . Cooling, heating, generating power and recovering waste heat with thermoelectric systems. Science, 2008,321(5895):1457-1461. |

| [2] | CHAMPIER D . Thermoelectric generators: a review of applications. Energy Conversion and Management, 2017,140:167-181. |

| [3] | CHEN L, BAI S, ZHANG Q . Technologies and applications of thermoelectric devices: current status, challenges and prospects. Journal of Inorganic Materials, 2019,34(3):279. |

| [4] | SALES B C, MANDRUS D, WILLIAMS R K . Filled skutterudite antimonides: a new class of thermoelectric materials. Science, 1996,272:1325-1328. |

| [5] | LIU H, SHI X, XU F , et al. Copper ion liquid-like thermoelectrics. Nature Materials, 2012,11(5):422-425. |

| [6] | ZHAO L D, LO S H, ZHANG Y , et al. Ultralow thermal conductivity and high thermoelectric figure of merit in SnSe crystals. Nature, 2014,508(7496):373-377. |

| [7] | ZHANG Q H, HUANG X Y, BAI S Q , et al. Thermoelectric devices for power generation: recent progress and future challenges. Advanced Engineering Materials, 2016,18(2):194-213. |

| [8] | HE R, SCHIERNING G, NIELSCH K . Thermoelectric devices: a review of devices, architectures, and contact optimization. Advanced Materials Technologies, 2018,3(4):1700256. |

| [9] | ZHANG Q, LIAO J, TANG Y , et al. Realizing a thermoelectric conversion efficiency of 12% in bismuth telluride/skutterudite segmented modules through full-parameter optimization and energy- loss minimized integration. Energy Environ. Sci., 2017,10(4):956-963. |

| [10] | YAO Z, QIU P, LI X , et al. Investigation on quick fabrication of n-type filled skutterudites. Journal of Inorganic Materials, 2016,31(12):1375-1382. |

| [11] | RAVI V, FIRDOSY S, CAILLAT T , et al. Mechanical properties of thermoelectric skutterudites. AIP Conference Proceedings, 2008,969:656-662. |

| [12] | SALVADOR J R, YANG J, SHI X , et al. Transport and mechanical properties of Yb-filled skutterudites. Philosophical Magazine, 2009,89(19):1517-1534. |

| [13] | DAHAL T, KIM H S, GAHLAWAT S , et al. Transport and mechanical properties of the double-filled p-type skutterudites La0.68Ce0.22Fe4-xCoxSb12. Acta Materialia, 2016,117:13-22. |

| [14] | RUAN Z, LIU L, ZHAI P , et al. Residual strength degradation of CoSb3 skutterudite compounds under low-cycle fatigue loading. Journal of Electronic Materials, 2012,41(6):1487-1492. |

| [15] | WEN P, ZHU Y, CHEN J , et al. The microstructure and thermoelectric properties of Yb-filled skutterudite Yb0.1Co4Sb12 under cyclic thermal loading. Journal of Materials Engineering and Performance, 2016,25(11):4764-4768. |

| [16] | ZHAO D, LI X, HE L , et al. Interfacial evolution behavior and reliability evaluation of CoSb(3)/Ti/Mo-Cu thermoelectric joints during accelerated thermal aging. Journal of Alloys and Compounds, 2009,477(1/2):425-431. |

| [17] | SHI L, HUANG X, GU M , et al. Interfacial structure and stability in Ni/SKD/Ti/Ni skutterudite thermoelements. Surface and Coatings Technology, 2016,285:312-317. |

| [18] | FAN X C, GU M, SHI X , et al. Fabrication and reliability evaluation of Yb0.3Co4Sb12/Mo-Ti/Mo-Cu/Ni thermoelectric joints. Ceramics International, 2015,41(6):7590-7595. |

| [19] | WOJCIECHOWSKI K T, ZYBALA R, MANIA R . High temperature CoSb3-Cu junctions. Microelectronics Reliability, 2011,51(7):1198-1202. |

| [20] | GU M, XIA X, LI X , et al. Microstructural evolution of the interfacial layer in the Ti-Al/Yb0.6Co4Sb12 thermoelectric joints at high temperature. Journal of Alloys and Compounds, 2014,610:665-670. |

| [21] | TANG Y S, BAI S Q, REN D D , et al. Interface structure and electrical property of Yb0.3Co4Sb12/Mo-Cu element prepared by welding using Ag-Cu-Zn solder. Journal of Inorganic Materials, 2015,30(3):256-260. |

| [22] | GU M, BAI S, WU J , et al. A high throughput strategy to screen interfacial diffusion barrier materials for thermoelectric modules. Journal of Materials Research, 2019,34(7):1179-1187. |

| [23] | CHEN L, BAI S, LIU R , et al. Interface stability of skutterudite thermoelectric materials/Ti88Al12. Journal of Inorganic Materials, 2018,33(8):889-894. |

| [24] | EL-GENK M S, SABER H H, CAILLAT T , et al. Tests results and performance comparisons of coated and un-coated skutterudite based segmented unicouples. Energy Conversion and Management, 2006,47(2):174-200. |

| [25] | HSUEH C H . Thermal stresses in elastic multilayer systems. Thin Solid Films, 2002,418:182-188. |

| [26] | HAN M, HUANG J, CHEN S . The influence of interface morphology on the stress distribution in double-ceramic-layer thermal barrier coatings. Ceramics International, 2015,41(3):4312-4325. |

| [27] | LI Y, YANG X Q, ZHAI P C , et al. Thermal stress simulation and optimum design of CoSb3/Bi2Te3 thermoelectric unicouples with graded interlayers. AIP Conference Proceedings, 2008,973:297-302. |

| [28] | JIA X, GAO Y . Estimation of thermoelectric and mechanical performances of segmented thermoelectric generators under optimal operating conditions. Applied Thermal Engineering, 2014,73(1):335-342. |

| [29] | GU M, XIA X, HUANG X , et al. Study on the interfacial stability of p-type Ti/CeyFexCo4-xSb12 thermoelectric joints at high temperature. Journal of Alloys and Compounds, 2016,671:238-244. |

| [1] | LI Guangyu, YUE Yifan, WANG Bo, ZHANG Chengyu, SUO Tao, LI Yulong. Damage of 2D-SiC/SiC Composites under Projectile Impact and Tensile Properties after Impact [J]. Journal of Inorganic Materials, 2024, 39(5): 494-500. |

| [2] | HU Zhongliang, FU Yuntian, JIANG Meng, WANG Lianjun, JIANG Wan. Thermal Stability of Nb/Mg3SbBi Interface [J]. Journal of Inorganic Materials, 2023, 38(8): 931-937. |

| [3] | WU Shuang, GOU Yanzi, WANG Yongshou, SONG Quzhi, ZHANG Qingyu, WANG Yingde. Effect of Heat Treatment on Composition, Microstructure and Mechanical Property of Domestic KD-SA SiC Fibers [J]. Journal of Inorganic Materials, 2023, 38(5): 569-576. |

| [4] | PI Huilong, ZHANG Baopeng, YU Xinmin, LIU Wei, JIN Xin. Damage Characteristics of 2D C/SiC-ZrC Composites under Low Velocity Impact [J]. Journal of Inorganic Materials, 2020, 35(12): 1327-1332. |

| [5] | ZHENG Jin-Huang, LI He-Jun, CUI Hong, WANG Yi, DENG Hai-Liang, YIN Zhong-Yi, YAO Dong-Mei, SU Hong. Relations between Needling Processing Parameters and Tensile Strength of C/C Composites [J]. Journal of Inorganic Materials, 2017, 32(11): 1147-1153. |

| [6] | ZHANG Xiao-Fang, LIU Tao, JIN Hong-Bin, YU Jing-Kun, GAO Xiang, WANG Cheng, WANG Xiang-Nan. La0.8Sr0.2(Ga0.8Mg0.2)0.1Fe0.9O3-δ Dense Diffusion Barrier Limiting Current Oxygen Sensor Prepared by Co-pressing and Co-sintering Method [J]. Journal of Inorganic Materials, 2017, 32(10): 1089-1094. |

| [7] | ZOU Yang, ZHAO Li-Li, YOU Li-Jun, CHEN Xiao-Ying, SONG Li-Xin. Preparation and Numerical Simulation Investigation of High Reflectance Anti-laser-ablation Coating [J]. Journal of Inorganic Materials, 2016, 31(8): 869-875. |

| [8] | JI A-Lin, LI He-Jun, CUI Hong, CHENG Wen. Axial Thermodynamic Performance Analysis of the Different Preform C/C Composites [J]. Journal of Inorganic Materials, 2010, 25(9): 994-998. |

| [9] | ZHANG Rong-Jun, YANG Yan-Qing, SHEN Wen-Tao. Preparation and Tensile Test of SiC Fiber Fabricated by Three-stage Chemical Vapor Deposition [J]. Journal of Inorganic Materials, 2010, 25(8): 840-844. |

| [10] | YANG Cheng-Peng,JIAO Gui-Qiong,WANG Bo. Effects of Interface Properties on Tensile Strength of Ceramic Matrix Composites [J]. Journal of Inorganic Materials, 2009, 24(5): 919-923. |

| [11] | LIU Guo-Qin,LAI Qi,LI Yu-Feng. Size Effect of Expanded Graphite [J]. Journal of Inorganic Materials, 2007, 22(5): 985-990. |

| [12] | HE Yan-Fei,GONG Rong-Zhou,LI Xiang-Cheng,WANG Xian,HE Hua-Hui. Preparation and Microwave Absorbing Properties of Multi-layered Radar(Microwave) Absorbing Materials Composites [J]. Journal of Inorganic Materials, 2006, 21(6): 1449-1453. |

| [13] | WU Yao,LI Hu,DENG Chun-Lin,YANG Bang-Cheng,ZHANG Xing-Dong. Biomechanical Properties of Porous Titanium with Different Surface Characteristics Used for Soft-tissue Anchorage [J]. Journal of Inorganic Materials, 2005, 20(1): 112-118. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||