Journal of Inorganic Materials ›› 2019, Vol. 34 ›› Issue (9): 918-924.DOI: 10.15541/jim20180557

Special Issue: 陶瓷基复合材料

• RESEARCH PAPER • Previous Articles Next Articles

ZHANG Zhao-Fu1,SHA Jian-Jun1,2( ),ZU Yu-Fei1,DAI Ji-Xiang1

),ZU Yu-Fei1,DAI Ji-Xiang1

Received:2018-11-28

Revised:2019-01-22

Published:2019-09-20

Online:2019-05-22

Supported by:CLC Number:

ZHANG Zhao-Fu,SHA Jian-Jun,ZU Yu-Fei,DAI Ji-Xiang. ZrB2-SiC Composites Toughened by Interlocking Microstructure and Chopped Carbon Fiber[J]. Journal of Inorganic Materials, 2019, 34(9): 918-924.

| Sample | Theoretical density/ (g?cm-3) | Bulk density/ (g?cm-3) | Open porosity/ % | Closed porosity/ % | Relative density/ % |

|---|---|---|---|---|---|

| ZS | 4.52 | 4.41 | 1.72 | 0.68 | 97.6 |

| Csf/ZS | 3.97 | 3.79 | 3.27 | 1.13 | 95.6 |

Table 1 Density, porosity and relative density of ZS and Csf/ZS composites

| Sample | Theoretical density/ (g?cm-3) | Bulk density/ (g?cm-3) | Open porosity/ % | Closed porosity/ % | Relative density/ % |

|---|---|---|---|---|---|

| ZS | 4.52 | 4.41 | 1.72 | 0.68 | 97.6 |

| Csf/ZS | 3.97 | 3.79 | 3.27 | 1.13 | 95.6 |

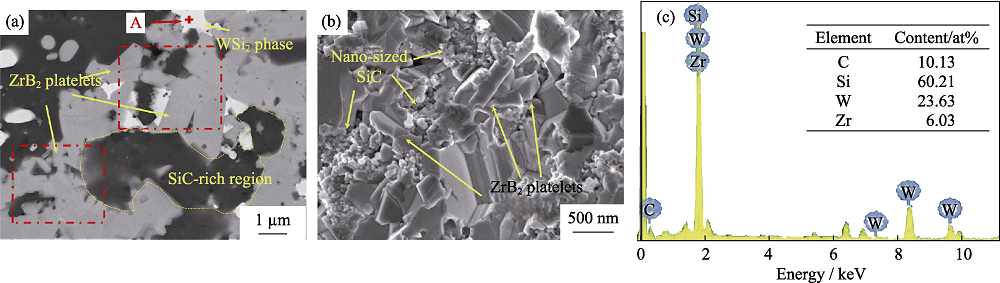

Fig. 3 (a) Backscattered electron micrograph taken from polished surface of ZS sample, (b) secondary electron micrograph taken from fracture surface of ZS sample, and (c) EDS analysis taken from the point A in (a)

| Sample | Vickers hardness /GPa | Flexural strength, σ/MPa | Fracture toughness, KIC/ (MPa?m1/2) | KIC/σ | Work of fracture/ (J?m-2) |

|---|---|---|---|---|---|

| ZS | (17.1±0.7) | (655±21) | 6.08±0.17 | 0.009 | 149.40 |

| Csf/ZS | (13.8±0.2) | (368±27) | (5.41±0.25) | 0.015 | 264.06 |

Table 2 Mechanical properties of ZS and Csf/ZS composites

| Sample | Vickers hardness /GPa | Flexural strength, σ/MPa | Fracture toughness, KIC/ (MPa?m1/2) | KIC/σ | Work of fracture/ (J?m-2) |

|---|---|---|---|---|---|

| ZS | (17.1±0.7) | (655±21) | 6.08±0.17 | 0.009 | 149.40 |

| Csf/ZS | (13.8±0.2) | (368±27) | (5.41±0.25) | 0.015 | 264.06 |

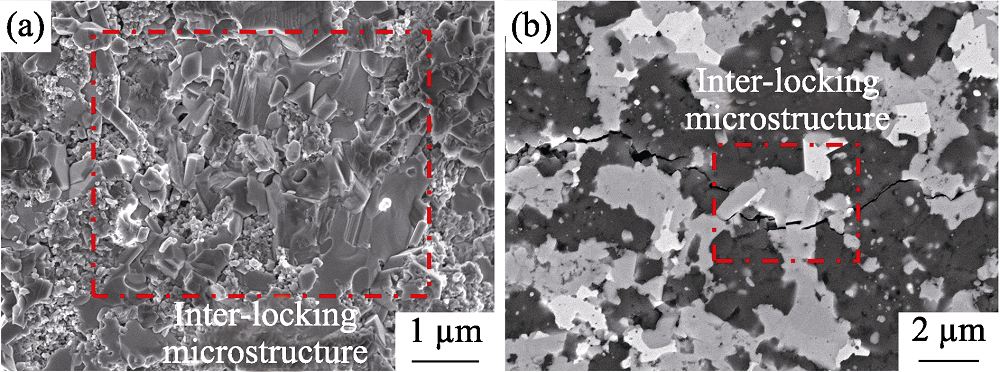

Fig. 6 (a) Secondary electron micrograph taken from fracture surface of ZS sample, and (b) backscattered electron micrograph of indentation crack propagation on polished surface of ZS sample

| [1] | FAHRENHOLTZ W G, HILMAS G E, TALMY I G ,et al. Refractory diborides of zirconium and hafnium. Journal of the American Ceramic Society, 2007,90(5):1347-1364. |

| [2] | CHAMBERLAIN A L, FAHRENHOLTZ W G, HILMAS G E ,et al. High-strength zirconium diboride-based ceramics. Journal of the American Ceramic Society, 2004,87(6):1170-1172. |

| [3] | GUO S Q . Densification of ZrB2-based composites and their mechanical and physical properties: a review. Journal of the European Ceramic Society, 2009,29(6):995-1011. |

| [4] | ZHENG H Y, MENG C X, HU D L ,et al. EBSD Analysis for orientation relationship of textured ZrB2-SiC ultra-high temperature ceramics. Journal of Inorganic Materials, 2018,33(4):380-384. |

| [5] | ZHANG G J, NI D W, ZOU J ,et al. Inherent anisotropy in transition metal diborides and microstructure/property tailoring in ultra- high temperature ceramics-a review. Journal of the European Ceramic Society, 2017,38(2):371-389. |

| [6] | WU W W, WANG Z, ZHANG G J ,et al. ZrB2-MoSi2 composites toughened by elongated ZrB2 grains via reactive hot pressing. Scripta Materialia, 2009,61(3):316-319. |

| [7] | SHAHEDI ASL M, FARAHBAKHSH I, NAYEBI B . Characteristics of multi-walled carbon nanotube toughened ZrB2-SiC ceramic composite prepared by hot pressing. Ceramics International, 2016,42(1):1950-1958. |

| [8] | ZHU T, XU L, ZHANG X H ,et al. Densification, microstructure and mechanical properties of ZrB2-SiCw ceramic composites. Journal of the European Ceramic Society, 2009,29(13):2893-2901. |

| [9] | HU P, GUI K X, HONG W H ,et al. High-performance ZrB2-SiC-Cf composite prepared by low-temperature hot pressing using nanosized ZrB2 powder. Journal of the European Ceramic Society, 2017,37(6):2317-2324. |

| [10] | GUI K X, LIU F Y, WANG G ,et al. Inhibited degradation of carbon fibers in ZrB2-SiC-Csf ultra-high temperature ceramic composites. Journal of Synthetic Crystals, 2018,47(2):418-423. |

| [11] | HE P G, JIA D C, LI Y T ,et al. Preparation and mechanical performance of ductile Csf/Al2O3-BN composites-Part 2: Effects of fiber contents and ablation properties. Ceramics International, 2016,42(9):11063-11069. |

| [12] | BAI Y L, HE X D, ZHU C C ,et al. Microstructures, electrical, thermal, and mechanical properties of bulk Ti2AlC synthesized by self-propagating high-temperature combustion synthesis with pseudo hot isostatic pressing. Journal of the American Ceramic Society, 2012,95(1):358-364. |

| [13] | WANG M C, ZHANG Z G, SUN Z J ,et al. Effect of fiber type on mechanical properties of short carbon fiber reinforced B4C composites. Ceramics International, 2009,35(4):1461-1466. |

| [14] | ZU Y F, SHA J J, LI J ,et al. Effect of multi-walled carbon nanotubes on microstructure and fracture properties of carbon fiber- reinforced ZrB2-based ceramic composite. Ceramics International, 2017,43(10):7454-7460. |

| [15] | SHA J J, ZHANG Z F, DI S X ,et al. Microstructure and mechanical properties of ZrB2-based ceramic composites with nano-sized SiC particles synthesized by in-situ reaction. Materials Science and Engineering A, 2017,693:145-150. |

| [16] | SILVESTRONI L, MERIGGI G, SCITI D . Oxidation behavior of ZrB2 composites doped with various transition metal silicides. Corrosion Science, 2014,83:281-291. |

| [17] | LIU H L, LIU J X, LIU H T ,et al. Changed oxidation behavior of ZrB2-SiC ceramics with the addition of ZrC. Ceramics International, 2015,41(6):8247-8251. |

| [18] | HU C F, ZOU J, HUANG Q ,et al. Synthesis of plate-Like ZrB2 Grains. Journal of the American Ceramic Society, 2012,95(1):85-88. |

| [19] | ZOU J, ZHANG G J, KAN Y M . Formation of tough interlocking microstructure in ZrB2-SiC-based ultrahigh-temperature ceramics by pressureless sintering. Journal of Materials Research, 2009,24(7):2428-2434. |

| [20] | XU L, HUANG C Z, LIU H L ,et al. In situ synthesis of ZrB2 -ZrCx ceramic tool materials toughened by elongated ZrB2 grains. Materials & Design, 2013,49:226-233. |

| [21] | ZHANG S C, HILMAS G E, FAHRENHOLTZ W G . Mechanical properties of sintered ZrB2-SiC ceramics. Journal of the European Ceramic Society, 2011,31(5):893-901. |

| [22] | YANG F Y, ZHANG X H, HAN J C ,et al. Analysis of the mechanical properties in short carbon fiber-toughened ZrB2-SiC ultra- high temperature ceramic. Journal of Composite Materials, 2010,44(8):953-961. |

| [23] | VINCI A, ZOLI L, SCITI D ,et al. Understanding the mechanical properties of novel UHTCMCs through random forest and regression tree analysis. Materials & Design, 2018,145:97-107. |

| [24] | TAYLOR D, CORNETTI P, PUGNO N . The fracture mechanics of finite crack extension. Engineering Fracture Mechanics, 2005,72(7):1021-1038. |

| [1] | ZHOU Fan, TIAN Zhilin, LI Bin. Research Progress on Carbide Ultra-high Temperature Ceramic Anti-ablation Coatings for Thermal Protection System [J]. Journal of Inorganic Materials, 2025, 40(1): 1-16. |

| [2] | TAN Min, CHEN Xiaowu, YANG Jinshan, ZHANG Xiangyu, KAN Yanmei, ZHOU Haijun, XUE Yudong, DONG Shaoming. Microstructure and Oxidation Behavior of ZrB2-SiC Ceramics Fabricated by Tape Casting and Reactive Melt Infiltration [J]. Journal of Inorganic Materials, 2024, 39(8): 955-964. |

| [3] | ZHANG Xinghong, WANG Yiming, CHENG Yuan, DONG Shun, HU Ping. Research Progress on Ultra-high Temperature Ceramic Composites [J]. Journal of Inorganic Materials, 2024, 39(6): 571-590. |

| [4] | CAI Feiyan, NI Dewei, DONG Shaoming. Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 591-608. |

| [5] | ZHANG Yuyu, WU Yicheng, SUN Jia, FU Qiangang. Preparation and Wave-absorbing Properties of Polymer-derived SiHfCN Ceramics [J]. Journal of Inorganic Materials, 2024, 39(6): 681-690. |

| [6] | ZHENG Hai-Ya, MENG Chen-Xi, HU Dong-Li, GU Hui, LIU Hai-Tao, ZHANG Guo-Jun. EBSD Analysis for Orientation Relationship of Textured ZrB2-SiC Ultra-high Temperature Ceramics [J]. Journal of Inorganic Materials, 2018, 33(4): 380-384. |

| [7] | ZHENG Qiang, WANG Xian-Hao, XING Juan-Juan, GU Hui, ZHANG Guo-Jun. Quantitative Analysis for Phase Compositions of ZrB2-SiC-ZrC Ultra-High Temperature Ceramic Composites [J]. Journal of Inorganic Materials, 2013, 28(4): 358-362. |

| [8] | ZHOU Hai-Jun, ZHANG Xiang-Yu, GAO Le, HU Jian-Bao, WU Bin, DONG Shao-Ming. Ablation Properties of ZrB2-SiC Ultra-high Temperature Ceramic Coatings [J]. Journal of Inorganic Materials, 2013, 28(3): 256-260. |

| [9] | WANG Xin-Gang,LIU Ji-Xuan,KAN Yan-Mei,ZHANG Guo-Jun,WANG Pei-Ling. Slip Casting and Pressureless Sintering of ZrB2-SiC Ceramics [J]. Journal of Inorganic Materials, 2009, 24(4): 831-835. |

| [10] | YAN Yong-Jie,ZHANG Hui,HUANG Zheng-Ren,LIU Xue-Jian. Oxidation Behaviors of the Pressureless Sintered ZrB2-SiC Composites [J]. Journal of Inorganic Materials, 2009, 24(3): 631-635. |

| [11] | YANG Fei-Yu,ZHANG Xing-Hong,HAN Jie-Cai,DU Shan-Yi. Ablation Mechanism of ZrB2-SiC and Csf/ZrB2-SiC Ultra-high Temperature Ceramic Composites [J]. Journal of Inorganic Materials, 2008, 23(4): 734-738. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||