Journal of Inorganic Materials ›› 2019, Vol. 34 ›› Issue (12): 1279-1284.DOI: 10.15541/jim20190102

Previous Articles Next Articles

LUO Zhi-Yong,LIAO Chu-Jian,CAI Chuan-Bing,LIU Zhi-Yong,LI Min-Juan,LU Yu-Ming( )

)

Received:2019-03-04

Revised:2019-04-28

Published:2019-12-20

Online:2019-06-17

Supported by:CLC Number:

LUO Zhi-Yong, LIAO Chu-Jian, CAI Chuan-Bing, LIU Zhi-Yong, LI Min-Juan, LU Yu-Ming. Argon Ion Etching on Property of YBa2Cu3O7-x Thin Films Prepared by TFA-MOD Process[J]. Journal of Inorganic Materials, 2019, 34(12): 1279-1284.

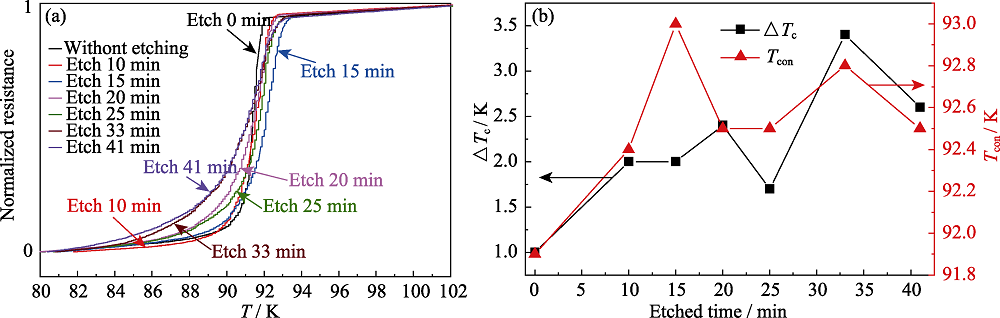

Fig. 5 Superconducting transition characteristics of samples with different etching time (a) T-R curves; (b) Transition width and initial transition temperature as a function of etching time

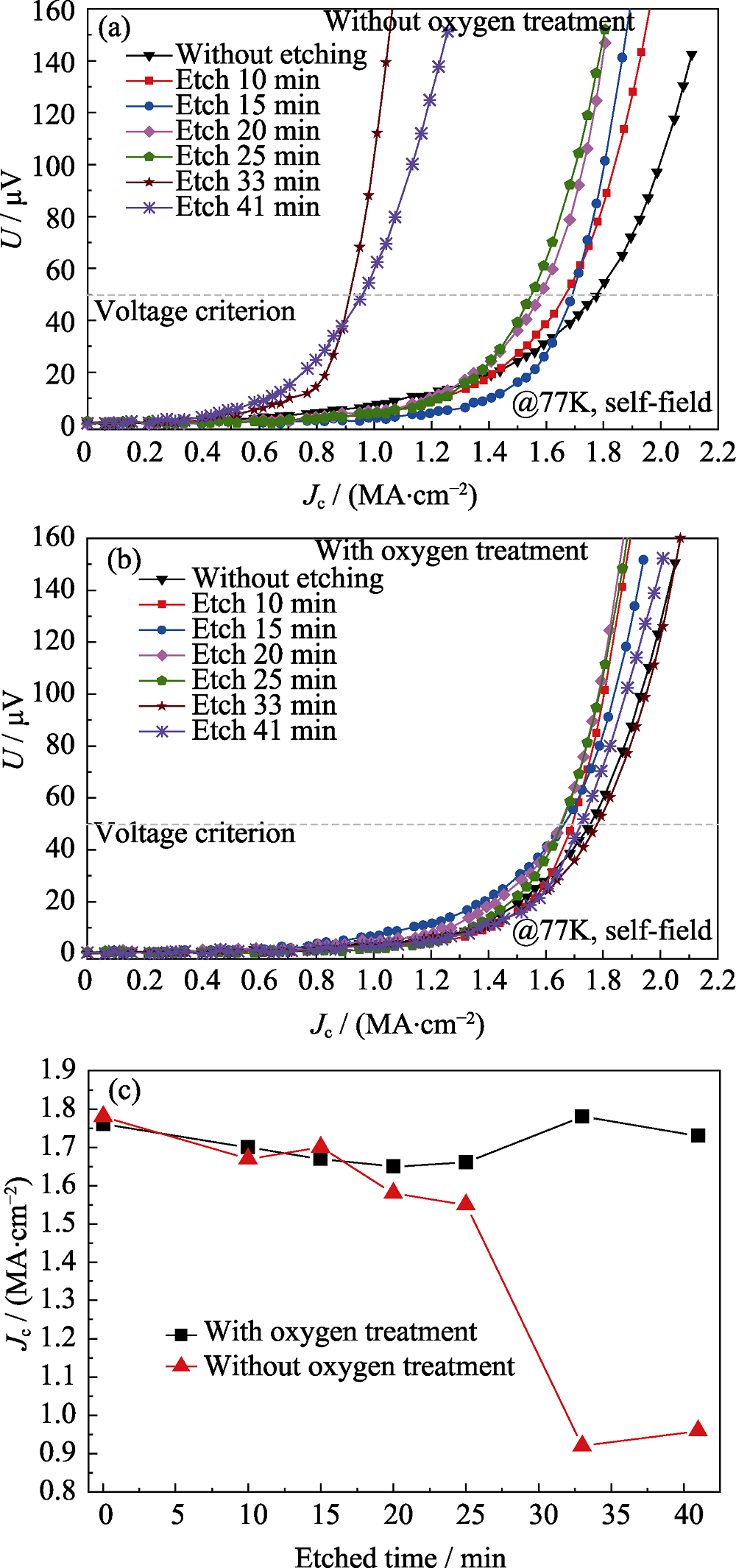

Fig. 6 The Jc curves of samples with different etching time were measured by induction method (a) No oxygen treatment was carried out after etching; (b) Oxygen treatment was carried out after etching; (c) Comparison image of Jc variation trend of oxygen-absorbing and non-oxygen-absorbing samples after etching for different time

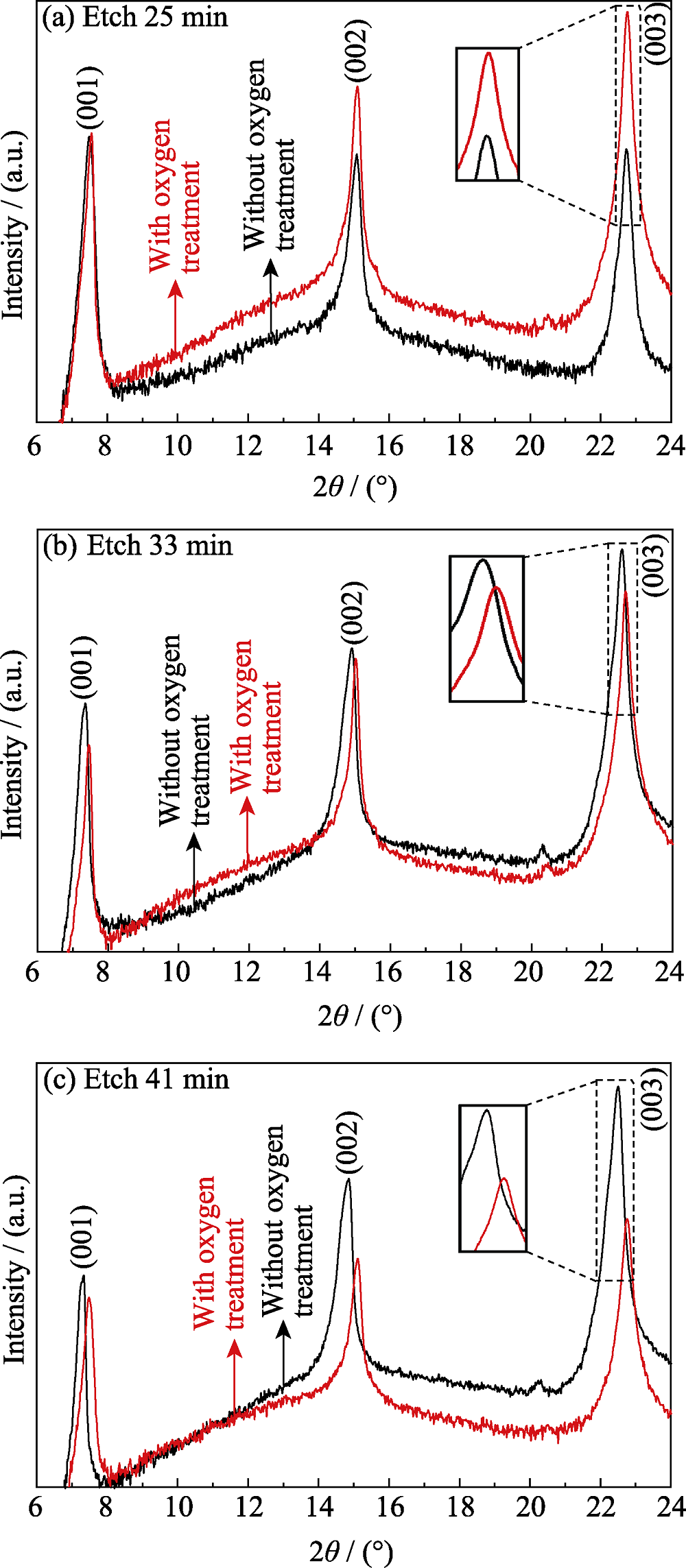

Fig. 7 XRD (00l) peak position comparison image of oxygen- absorbing treatment and no oxygen-absorbing treatment samples after etched for different time (a) 25 min; (b) 33 min; (c) 41 min

| [1] | DAVID L, ALEX G, FELDMANN M D , et al. High-Tc superconducting materials for electric power applications. Nature, 2001,414(11):368-377. |

| [2] | RUPICH M W, SCHOOP U, VEREBELYI D T , et al. YBCO coated conductors by an MOD/RABiTS process. IEEE Transactions on Applied Superconductivity, 2003,13(2):2458-2461. |

| [3] | WANG S S, ZHANG Z L, WANG L , et al. High quality uniform YBCO film growth by the metalorganic deposition using trifluoroacetates. Physica C: Superconductivity and Its Applications, 2017,534:68-72. |

| [4] | YAMANE H, KUROSAWA H, HIRAI T . Preparation of YBCO superconducting nano-composite films by MOCVD. Journal of the Japan Society of Powder & Powder Metallurgy, 2009,41(4):370-376. |

| [5] | JIANG P, ZHANG S, FAN Z , et al. Development of multipass MOCVD process for fabricating (Gd,Y)Ba2Cu3O7-δ coated conductors. IEEE Transactions on Applied Superconductivity, 2017,27(4):1-5. |

| [6] | STADEL O, SCHMIDT J, WAHL G , et al. Continuous YBCO deposition by MOCVD for coated conductors. Physica C: Superconductivity & Its Applications, 2002,372(372):751-754. |

| [7] | MATIAS V, HAMMOND R H . YBCO superconductor wire based on IBAD-textured templates and RCE of YBCO:process economics. Physics Procedia, 2012,36:1440-1444. |

| [8] | CHOI S M, LEE J W, SHIN G H , et al. Characteristics of high-Jc GdBCO coated conductors fabricated by the RCE-DR process. IEEE Transactions on Applied Superconductivity, 2013,23(3):8001004. |

| [9] | SHIN H, DEDICATORIA M J, KIM H . Measurement of electromechanical property in thick-film EDDC-SmBCO coated conductors with high critical current. IEEE Transactions on Applied Superconductivity, 2012,22(1):8400506. |

| [10] | ZHANG H, YANG J, LI T , et al. Film thickness dependence of microstructure and superconductive property of PLD prepared YBCO layers. Physica C: Superconductivity & Its Applications, 2014,499(4):54-56. |

| [11] | BUSBEE J, BIGGERS R, KOZLOWSKI G , et al. Investigation of in situ Raman spectra for the control of PLD of YBCO thin film superconductors. Engineering Applications of Artificial Intelligence, 2000,13(5):589-596. |

| [12] | OHKI K, NAGAISHI T, KATO T , et al. Fabrication, microstructure and persistent current measurement of an intermediate grown superconducting (iGS) joint between REBCO-coated conductors. Superconductor Science and Technology, 2017, 30(11): 115017-1-7. |

| [13] | PARK Y, LEE M, ANN H , et al. A superconducting joint for GdBa2Cu3O7-x-coated conductors. NPG Asia Materials, 2014,6(5):e98. |

| [14] | JEE Y A, LI M, MA B , et al. Comparison of texture development and superconducting properties of YBCO thin films prepared by TFA and PLD processes. Physica C, 2001,356(4):297-303. |

| [15] | NIKOLAY N, BALASHOY, PAVEL N , et al. Low-resistance soldered joints of commercial 2G HTS wire prepared at various values of applied pressure. IEEE Transactions on Appiled Superconductivity, 2018,28(4):6602604. |

| [16] | SUNGHO L, WOO I Y, HO S J , et al. The efects of Gd-free impurity phase on the aging behavior for the microwave surface resistance of Ag-coated GdBa2Cu3O7-δ at cryogenic temperatures. Electronic Materials Letters, 2018,14(5):646-654. |

| [17] | JORGENSEN J D, VEAL B W, PAULIKAS A P , et al. Structural properties of oxygen-deficient YBa2Cu3O7-δ. Physical Review B Condensed Matter, 1990,41(4):1863-1877. |

| [18] | HABERKORN N, GUIMPEL J, SUAREZ S , et al. Strong influence of the oxygen stoichiometry on the vortex bundle size and critical current densities Jc of GdBa2Cu3Ox-coated conductors grown by co-evaporation. Superconductor Science Technology, 2017,30(9):095009. |

| [1] | MA Wen, SHEN Zhe, LIU Qi, GAO Yuanming, BAI Yu, LI Rongxing. Preparation of Y2O3 Coating by Suspension Plasma Spraying and Its Resistance to Plasma Etching [J]. Journal of Inorganic Materials, 2024, 39(8): 929-936. |

| [2] | WANG Huajin, KOU Huamin, WANG Yongzhe, JIANG Dapeng, ZHANG Bo, QIAN Xiaobo, WANG Jingya, ZHU Linling, ZENG Aijun, YANG Qiuhong, SU Liangbi. Irradiation Damage of CaF2 with Different Yttrium Concentrations under 193 nm Laser [J]. Journal of Inorganic Materials, 2023, 38(2): 219-224. |

| [3] | WU Xiaowei, LI Jiayan. Texturing Technology on Multicrystalline Silicon Wafer by Metal-catalyzed Chemical Etching: a Review [J]. Journal of Inorganic Materials, 2021, 36(6): 570-578. |

| [4] | CHEN Lichi, WANG Yaogong, WANG Wenjiang, MA Xiaoqin, YANG Jingyuan, ZHANG Xiaoning. Preparation of Silicon Nanowires and Porous Silicon Composite Structure by Electrocatalytic Metal Assisted Chemical Etching [J]. Journal of Inorganic Materials, 2021, 36(6): 608-614. |

| [5] | JI Xiaojuan,YU Yueguang,LU Xiaoliang. Effects of Impurities on Properties of YSZ Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2020, 35(6): 669-674. |

| [6] | ZHENG Xue, JIANG Rui, LI Qian, WANG Weizhe, XU Zhimou, PENG Jing. Research on Anodic Aluminum Oxide Nanostructured LEDs [J]. Journal of Inorganic Materials, 2020, 35(5): 561-566. |

| [7] | MA Ya-Nan, LIU Yu-Fei, YU Chen-Xu, ZHANG Chuan-Kun, LUO Shi-Jun, GAO Yi-Hua. Monolayer Ti3C2Tx Nanosheets with Different Lateral Dimension: Preparation and Electrochemical Property [J]. Journal of Inorganic Materials, 2020, 35(1): 93-98. |

| [8] | WANG Ya, SUO Hong-Li, MAO Lei, LIU Min, MA Lin, WANG Yi, KAUSAR Shaheen, ZHOU Yu-Qi. Flux Pinning Mechanism of Nb-doped YBCO Film [J]. Journal of Inorganic Materials, 2019, 34(10): 1055-1059. |

| [9] | LI Jia-Ke, HAN Xiao-Qi, LIU Xin, WANG Yan-Xiang, GUO Ping-Chun, YANG Zhi-Sheng. Preparation of High Specific Surface Area Micro/Meso-porous SiOC Ceramics by the Low Temperature Phase Separation Method [J]. Journal of Inorganic Materials, 2018, 33(12): 1360-1364. |

| [10] | ZHANG Jian-Feng, CAO Hui-Yang, WANG Hong-Bing. Research Progress of Novel Two-dimensional Material MXene [J]. Journal of Inorganic Materials, 2017, 32(6): 561-570. |

| [11] | CHEN Hai-Tao, HUANG Xue-Fei, HUANG Wei-Gang. Influence of N Doping on the Electronic Structure and Absorption Spectrum of Ca2SiO4: Eu2+ Phosphor [J]. Journal of Inorganic Materials, 2017, 32(4): 443-448. |

| [12] |

SUN Li-Li, YAN Kai, LUO Wen, ZHOU Jian.

Hollow ZSM-5 Zeolite Microspheres with Improved Adsorption and Catalytic Properties [J]. Journal of Inorganic Materials, 2016, 31(8): 834-840. |

| [13] | BAO Xiao-Hui, MING Ping-Mei, BI Xiang-Yang. Preparation of Superhydrophobic Surface Based on SiC Particulate Reinforced Composite [J]. Journal of Inorganic Materials, 2016, 31(4): 383-387. |

| [14] | HUANG Yan-Hua, HAN Xiang, CHEN Hui-Xin, CHEN Song-Yan, YANG Yong. Investigation of Porous Silicon/Carbon Composite as Anodes for Lithium Ion Batteries [J]. Journal of Inorganic Materials, 2015, 30(4): 351-356. |

| [15] | MAO Lei, SUO Hong-Li, LIU Min, ZHANG Zi-Li, YE Shuai, MA Lin. Effect of Nb5+ -doped YBCO Film Synthesized by Low-fluorine MOD Method [J]. Journal of Inorganic Materials, 2013, 28(9): 956-960. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||