Journal of Inorganic Materials ›› 2016, Vol. 31 ›› Issue (9): 961-968.DOI: 10.15541/jim20150628

• Orginal Article • Previous Articles Next Articles

XU Guo-Zhong1,2, JIN Wen-Wu1, ZENG Xie-Rong2, ZOU Ji-Zhao2, XIONG Xin-Bai2, HUANG Lin2, ZHAO Zhen-Ning1

Received:2015-12-14

Revised:2016-01-27

Published:2016-09-20

Online:2016-08-29

About author:XU Guo-Zhong. E-mail: gz_xu@163.com

Supported by:CLC Number:

XU Guo-Zhong, JIN Wen-Wu, ZENG Xie-Rong, ZOU Ji-Zhao, XIONG Xin-Bai, HUANG Lin, ZHAO Zhen-Ning. Tailoring of Pore Structure of Coal-based Carbon Foam[J]. Journal of Inorganic Materials, 2016, 31(9): 961-968.

| precursors | Proximate analysis /wt% | Ultimate anasysis/wt% | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Mad | Ad | Vdaf | C | H | O | N | S | ||

| Fat coal | 1.6 | 8.52 | 38.29 | 88.16 | 4.92 | 4.84 | 1.46 | 0.62 | |

| Vitrinite | 1.7 | 3.50 | 43.80 | 86.45 | 5.73 | 5.65 | 1.53 | 0.64 | |

Table 1 Proximate analysis and ultimate analysis of the fat coal and its vitrinite-concentration

| precursors | Proximate analysis /wt% | Ultimate anasysis/wt% | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Mad | Ad | Vdaf | C | H | O | N | S | ||

| Fat coal | 1.6 | 8.52 | 38.29 | 88.16 | 4.92 | 4.84 | 1.46 | 0.62 | |

| Vitrinite | 1.7 | 3.50 | 43.80 | 86.45 | 5.73 | 5.65 | 1.53 | 0.64 | |

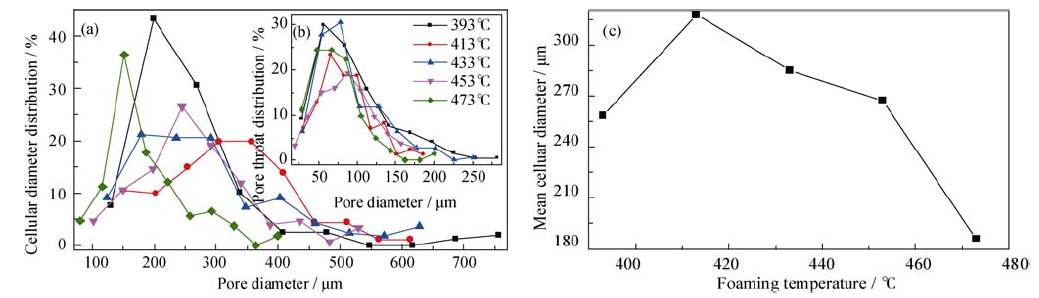

Fig. 9 Influence of foaming temperature on pore cell diameter distribution (a), pore throat distribution (b) and mean cell diameter (c) of carbon foams

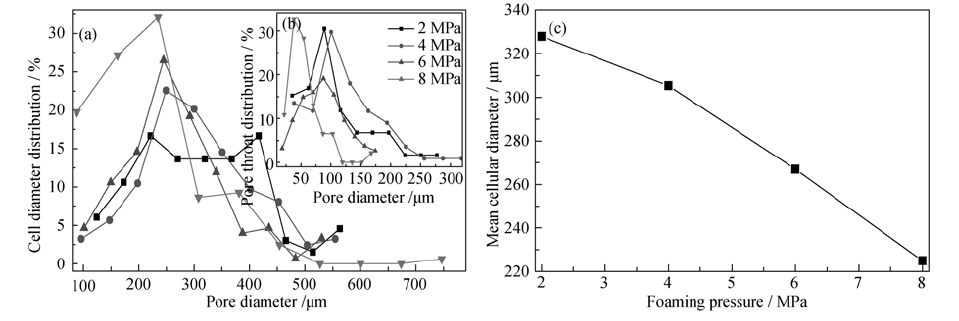

Fig. 12 Effect of foaming pressure on pore cell diameter distribution (a), pore throat distribution diameter (b) and mean cell diameter (c) of carbon foams

| [1] | MICHIO INAGAKI, QIU JIESHAN, GUO QUANGUI.Carbon foam: Preparation and application.Carbon, 2015, 87: 128-152. |

| [2] | KLETT JAMES, HARDY ROMMIE, ROMINE ERNIE, et al.High-thermal-conductivity, mesophase-pitch-derived carbon foams: effect of precursor on structure and properties. Carbon, 2000, 38(7): 953-973. |

| [3] | BAO YING, WANG CHUN-XIAO,LING lI-CHENG, et al. Effect mechanisms of carbon nanotubes on the supercritical foaming behaviors and mechanical performance of carbon foam. Journal of Inorganic Materials, 2011, 26(10): 1020-1024. |

| [4] | KUMAR R, SINGH A P, CHAND M.et al.Improved microwave absorption in lightweight resin-based carbon foam by decorating with magnetic and dielectric nanoparticles.RSC ADV., 2014, (4): 23476. |

| [5] | GALLEGO N C, KLETT J W.Carbon foams for thermal management. Carbon, 2003, 41(7): 1461-1466. |

| [6] | NORAKI SANO, HIROSHI AKAZAWA, TAKEYUKI KIKUCHI, et al.Separated synthesis of iron-included carbon nanocapsules and nanotubes by pyrolysis of ferrocene in pure hydrogen.Carbon, 2003, 41(11): 2159-2179. |

| [7] | BRUNETON E, TALLARON C, GRASS-NAULIN N, et al.Evolution of the structure and mechanical behaviour of a carbon foam at very high temperatures.Carbon, 2002, 40(11): 1919-1927. |

| [8] | CHEN FEN, ZHANG HONG-BO, XIONG XIANG, et al.Microstructure and properties of carbon foams reinforced by CVD Pc.Journal of Inorganic Materials, 2008, 26(6): 1184-1188. |

| [9] | STILLER ALFRED H, STANSHERRY PETER G, ZONDLO JOHN W. Method of making a Carbon Foam Material and Resultant Product.US,5888469A.1999-3-30. |

| [10] | ROGERS D K. Cellular Coal Products and Pocesses.US,75886082009-09-15. |

| [11] | CALVO MONTSERRAT, GARCIA ROBERTO.Carbon foams from coals. A preliminary study. Fuel, 2005, 84(17): 2184-2189. |

| [12] | CALVO MONTSERRAT, GARCIA ROBERTO, SABINO R MOINELO.Carbon foams from different coals.Energy & Fuels, 2008, 22(5): 3376-3383. |

| [13] | MATVIYA T M, ROCKS M P A. Production of Carbon Foam from Coals. US,7767183.2010-08-03. |

| [14] | 徐国忠, 钟祥云, 赵振宁, 等. 利用预处理烟煤制备煤基炭泡沫的方法. 中国,C,ZL 201210364642.6, 2014-07-16. |

| [15] | BOGUMILA NAGEL, SLAWOMIRA PUSZ, BARBARA TRZEBICKA.Review: tailoring the properties of macroporous carbon foams. J Mater Sci., 2014, 49: 1-17. |

| [16] | COLTON J S, SUH N P.Nucleation of microcellular thermoplastic foam with additives part I: Theoretical considerations.Polymer Engineering and Science, 1987, 27(7): 485-492. |

| [17] | 吴舜英, 徐敬一. 泡沫塑料成型, 2版. 北京: 化学工业出版社, 1999: 1-90. |

| [18] | 徐晓. 对塑料发泡中应用的经典成核理论. 广州: 华南理工大学博士学位论文, 2000: 14-23. |

| [19] | LEE D, HANSEN V, WALLACE MCCARLIE.From foam rubber to volcanoes: the physical chemistry of foam formation.Journal of Chemical Education, 2004, 81(11): 1581-1583. |

| [1] | GUO Ziyu, ZHU Yunzhou, WANG Li, CHEN Jian, LI Hong, HUANG Zhengren. Effect of Zn2+ Catalyst on Microporous Structure of Porous Carbon Prepared from Phenolic Resin/Ethylene Glycol [J]. Journal of Inorganic Materials, 2025, 40(5): 466-472. |

| [2] | YANG Pingjun, LI Tiehu, LI Hao, DANG Alei. Effect of Graphene on Graphitization, Electrical and Mechanical Properties of Epoxy Resin Carbon Foam [J]. Journal of Inorganic Materials, 2024, 39(1): 107-112. |

| [3] | LING Jie, ZHOU Anning, WANG Wenzhen, JIA Xinyu, MA Mengdan. Effect of Cu/Mg Ratio on CO2 Adsorption Performance of Cu/Mg-MOF-74 [J]. Journal of Inorganic Materials, 2023, 38(12): 1379-1386. |

| [4] | ZHANG Junmin, CHEN Xiaowu, LIAO Chunjin, GUO Feiyu, YANG Jinshan, ZHANG Xiangyu, DONG Shaoming. Optimizing Microstructure and Properties of SiCf/SiC Composites Prepared by Reactive Melt Infiltration [J]. Journal of Inorganic Materials, 2021, 36(10): 1103-1110. |

| [5] | NIE Lan-Jian, GU Zhen-An, WANG Yu-Fen, XIANG Zai-Kui, ZHANG Chen-Yang, RAO Chuan-Dong. SiO2 Soot Body at Vacuum Sintering Process: Densification and Transparency Mechanism [J]. Journal of Inorganic Materials, 2019, 34(10): 1060-1066. |

| [6] | XU Jian-Xin, SHAN Ying-Chun, WANG Guang, XU Jiu-Jun, WANG Liang, LI Jiang-Tao. Nucleation Density on the Synthesis of AlON Powder and Preparation of Transparent Ceramics [J]. Journal of Inorganic Materials, 2018, 33(4): 373-379. |

| [7] | LI Jun, CAO Ya-Li, WANG Lu-Xiang, JIA Dian-Zeng. Performance of Coal-derived Spherical Porous Carbon as Anode Materials for Lithium Ion Batterie [J]. Journal of Inorganic Materials, 2017, 32(9): 909-915. |

| [8] | ZHAI Li-Li, ZHANG Jiang, LI Xuan-Ke, CONG Ye, DONG Zhi-Jun, YUAN Guan-Ming. F127 Template on Pore Structure and Electrochemical Performances of Mesoporous SnO2 [J]. Journal of Inorganic Materials, 2016, 31(6): 588-596. |

| [9] | LI Jin-Hong, ZHOU Qi-Xiong, MI Hong-Yu, LI Xian, LI Hui-Ping. Preparation and Capacitive Properties of Graphite-like Porous Carbon Based on Coal Extracts [J]. Journal of Inorganic Materials, 2016, 31(1): 39-46. |

| [10] | YANG Liu, LIU Xiu-Jun, LI Tong-Qi, HAN Rui-Lian, FENG Zhi-Hai. Effect of Plating Solution Flow Pattern on Preparation of Electroless Copper- Plated Carbon Foam under Vacuum and Ultrasonic Conditions [J]. Journal of Inorganic Materials, 2016, 31(1): 69-74. |

| [11] | YI Shang-Qi, LIU Hong-Bo, XIA Xiao-Hong, HUANG Gui-Rong, MA Qian, CHEN Yu-Xi. Preparation and Electrochemical Performance of Graphene/Carbon Aerogels [J]. Journal of Inorganic Materials, 2015, 30(7): 757-762. |

| [12] | XIE Xiao-Ling, CAO Qing, GUO Liang-Chen, ZHONG Cun-Gui. Preparation and Electrochemical Properties of Ordered Needle Coke with Graphene as an Inoculating Seed [J]. Journal of Inorganic Materials, 2014, 29(9): 979-984. |

| [13] | LI Yu-Ping, WANG Tie-Jun, MA Long-Long, WU Chuang-Zhi, DING Ming-Yue. Hβ Modified Co/SiO2 Catalysts for Fischer-Tropsch Synthesis of Jet Fuel-range Hydrocarbons [J]. Journal of Inorganic Materials, 2014, 29(6): 599-604. |

| [14] | MENG Fan-Ning, WANG Chun-Lei, WU Ming-Xing, LIN Xiao, WANG Tong-Hua, MA Ting-Li. Preparation of FTO-free and Coal Based Carbon Counter Electrodes for Dye Sensitized Solar Cells [J]. Journal of Inorganic Materials, 2013, 28(3): 273-277. |

| [15] | SONG Cheng-Wen, TAO Ping, SONG Xue-Kai, WU Shuai-Hua, SHAO Mi-Hua, GAO Guang-Rui, FENG Yi-Ning, WANG Tong-Hua. Removal of Microalgae in Ballast Water by Coal-based Porous Carbon Membrane [J]. Journal of Inorganic Materials, 2013, 28(10): 1067-1071. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||