无机材料学报 ›› 2025, Vol. 40 ›› Issue (1): 31-38.DOI: 10.15541/jim20240352 CSTR: 32189.14.10.15541/jim20240352

所属专题: 【信息功能】MAX、MXene及其他二维材料(202506)

王文婷1,2( ), 徐敬军1(

), 徐敬军1( ), 马科1, 李美栓1, 李兴超3, 李同起3

), 马科1, 李美栓1, 李兴超3, 李同起3

收稿日期:2024-07-27

修回日期:2024-09-23

出版日期:2025-01-20

网络出版日期:2024-09-27

通讯作者:

徐敬军, 副研究员. E-mail: jjxu@imr.ac.cn作者简介:王文婷(1992-), 女, 博士研究生. E-mail: wtwang16s@imr.ac.cn

基金资助:

WANG Wenting1,2( ), XU Jingjun1(

), XU Jingjun1( ), MA Ke1, LI Meishuan1, LI Xingchao3, LI Tongqi3

), MA Ke1, LI Meishuan1, LI Xingchao3, LI Tongqi3

Received:2024-07-27

Revised:2024-09-23

Published:2025-01-20

Online:2024-09-27

Contact:

XU Jingjun, associate professor. E-mail: jjxu@imr.ac.cnAbout author:WANG Wenting (1992-), female, PhD candidate. E-mail: wtwang16s@imr.ac.cn

Supported by:摘要:

Ti2AlC是MAX相材料中抗氧化性能最好的化合物之一, 在高温结构材料和高温抗氧化防护涂层领域具有潜在的应用前景, 然而其强度和硬度不足, 在高温领域的应用受到限制。为了提升Ti2AlC的性能, 本研究采用原位固-液相反应/热压方法成功合成了Ti2AlC-20%TiB2(体积分数)复合材料(简称Ti2AlC-20TiB2), 分析了其在1000~1300 ℃的高温氧化行为, 揭示了其高温抗氧化机理。结果表明: Ti2AlC-20TiB2复合材料的氧化动力学符合自然对数规律, 比单相Ti2AlC具有更优异的抗氧化性能。1200 ℃以下, 氧化膜主要由Al2O3(内层)和TiO2(外层)组成, 而在1300 ℃时, 氧化膜的外层则是TiO2与Al2TiO5混合物。复合材料形成的Al2O3保护层比单相Ti2AlC形成的更为致密, 这是抗氧化性能优异的关键。引入的TiB2颗粒减小了材料的晶粒尺寸, 增加了短路扩散的晶界数量, 有利于Al的选择性氧化, 从而加速了Al2O3保护层的形成。TiB2氧化过程中生成的B2O3能够填充微孔并修复微裂纹, 有效阻止了O的内扩散, 进一步提高了复合材料的抗氧化性能。

中图分类号:

王文婷, 徐敬军, 马科, 李美栓, 李兴超, 李同起. 原位反应/热压合成Ti2AlC-20TiB2复合材料在1000~1300 ℃空气中的高温氧化行为[J]. 无机材料学报, 2025, 40(1): 31-38.

WANG Wenting, XU Jingjun, MA Ke, LI Meishuan, LI Xingchao, LI Tongqi. Oxidation Behavior at 1000-1300 ℃ in air of Ti2AlC-20TiB2 Synthesized by in-situ Reaction/Hot Pressing[J]. Journal of Inorganic Materials, 2025, 40(1): 31-38.

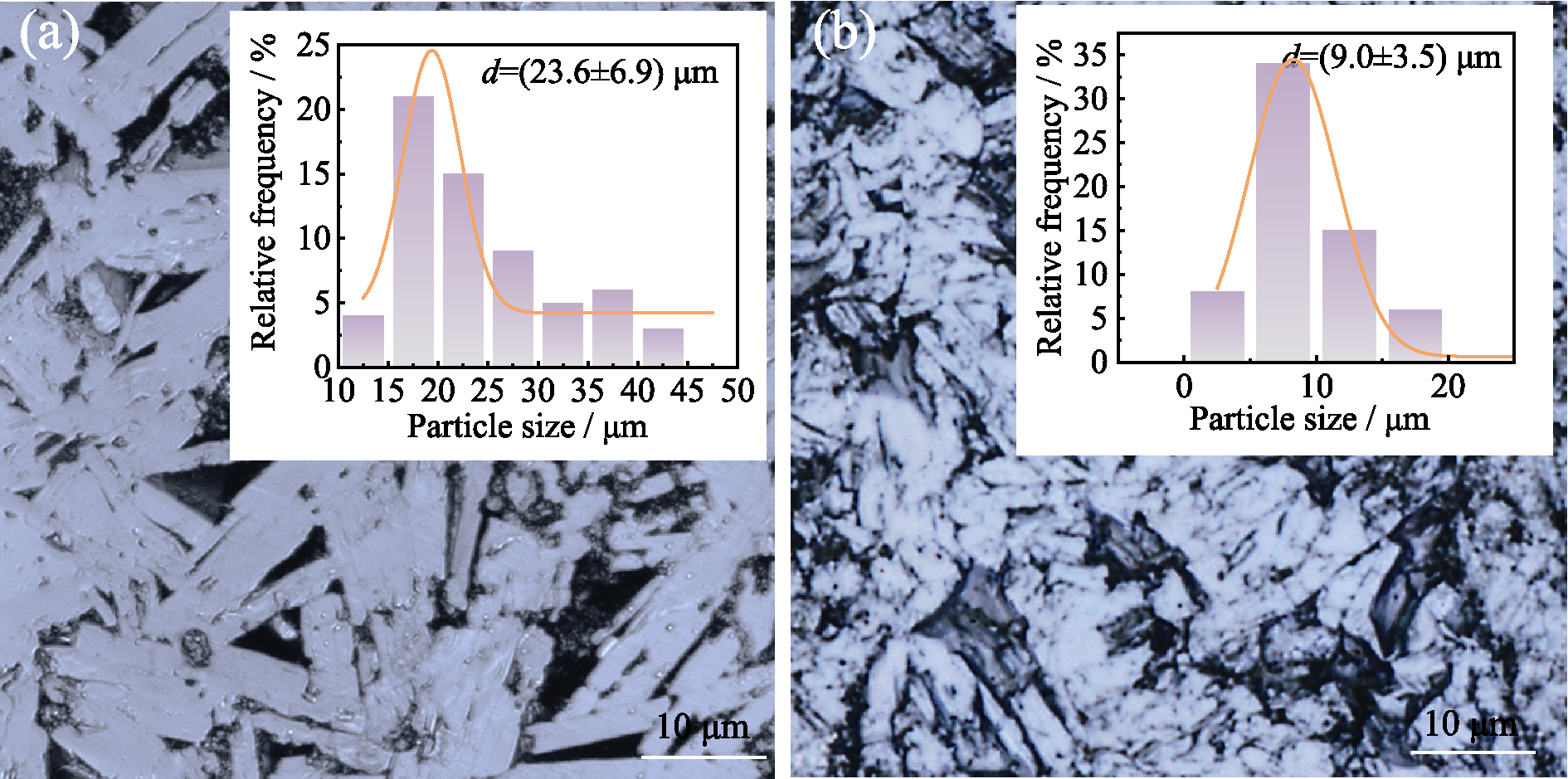

图2 材料的蚀刻表面形貌(内插图为粒径统计分布图)

Fig. 2 Morphologies of the etched surface with inserts showing the statistical distribution of particle size (a) Ti2AlC; (b) Ti2AlC-20TiB2

图3 Ti2AlC-20TiB2在1000~1300 ℃空气中的氧化动力学曲线

Fig. 3 Oxidation kinetics of Ti2AlC-20TiB2 composite at 1000-1300 ℃ in air (a) Δm/A vs. t; (b) Δm/A vs. ln(t/t0+1)

| Temperature | 1000 ℃ | 1100 ℃ | 1200 ℃ | 1300 ℃ | |

|---|---|---|---|---|---|

| Ti2AlC- 20TiB2 | k | 0.0656 | 0.1355 | 0.0920 | 0.2849 |

| t0 | 0.0918 | 0.0488 | 0.1313 | 0.6860 | |

| R2 | 99.50 | 99.47 | 99.72 | 99.77 | |

| Ti2AlC | kc | 2.38×10-12 | 1.54×10-11 | 1.12×10-10 | 2.13×10-10 |

表1 图3(a)氧化动力学曲线拟合得到的k、t0和R2, 以及Ti2AlC[8]的kc

Table 1 k, t0, R2 by fitting the oxidation kinetics curves in Fig. 3(a) and kc of Ti2AlC[8]

| Temperature | 1000 ℃ | 1100 ℃ | 1200 ℃ | 1300 ℃ | |

|---|---|---|---|---|---|

| Ti2AlC- 20TiB2 | k | 0.0656 | 0.1355 | 0.0920 | 0.2849 |

| t0 | 0.0918 | 0.0488 | 0.1313 | 0.6860 | |

| R2 | 99.50 | 99.47 | 99.72 | 99.77 | |

| Ti2AlC | kc | 2.38×10-12 | 1.54×10-11 | 1.12×10-10 | 2.13×10-10 |

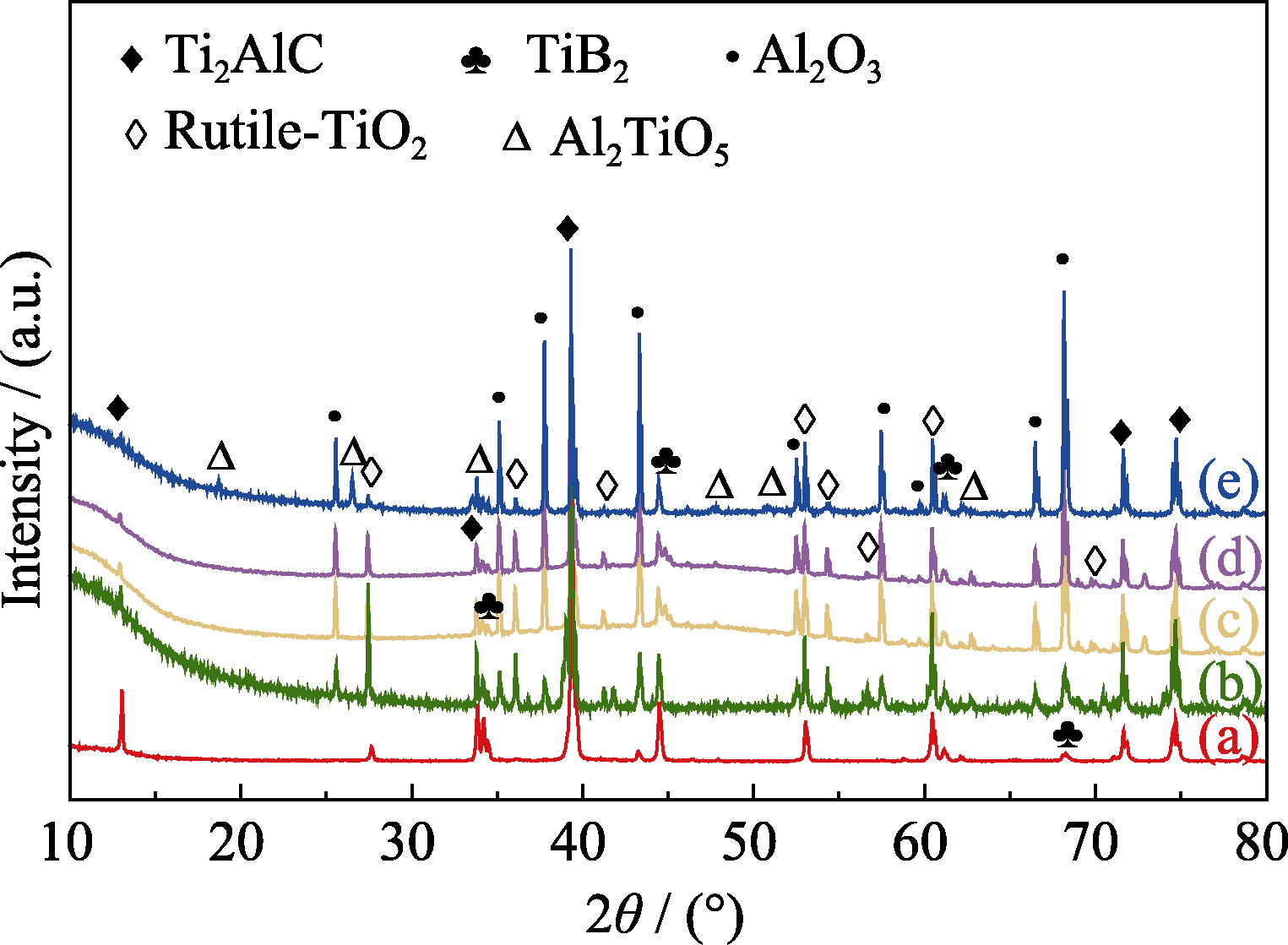

图4 Ti2AlC-20TiB2氧化前和在1000~1300 ℃空气中氧化10 h后的XRD图谱

Fig. 4 XRD patterns of Ti2AlC-20TiB2 composite before and after oxidation at 1000-1300 ℃ in air for 10 h (a) Before oxidation; (b) 1000 ℃; (c) 1100 ℃; (d) 1200 ℃; (e) 1300 ℃

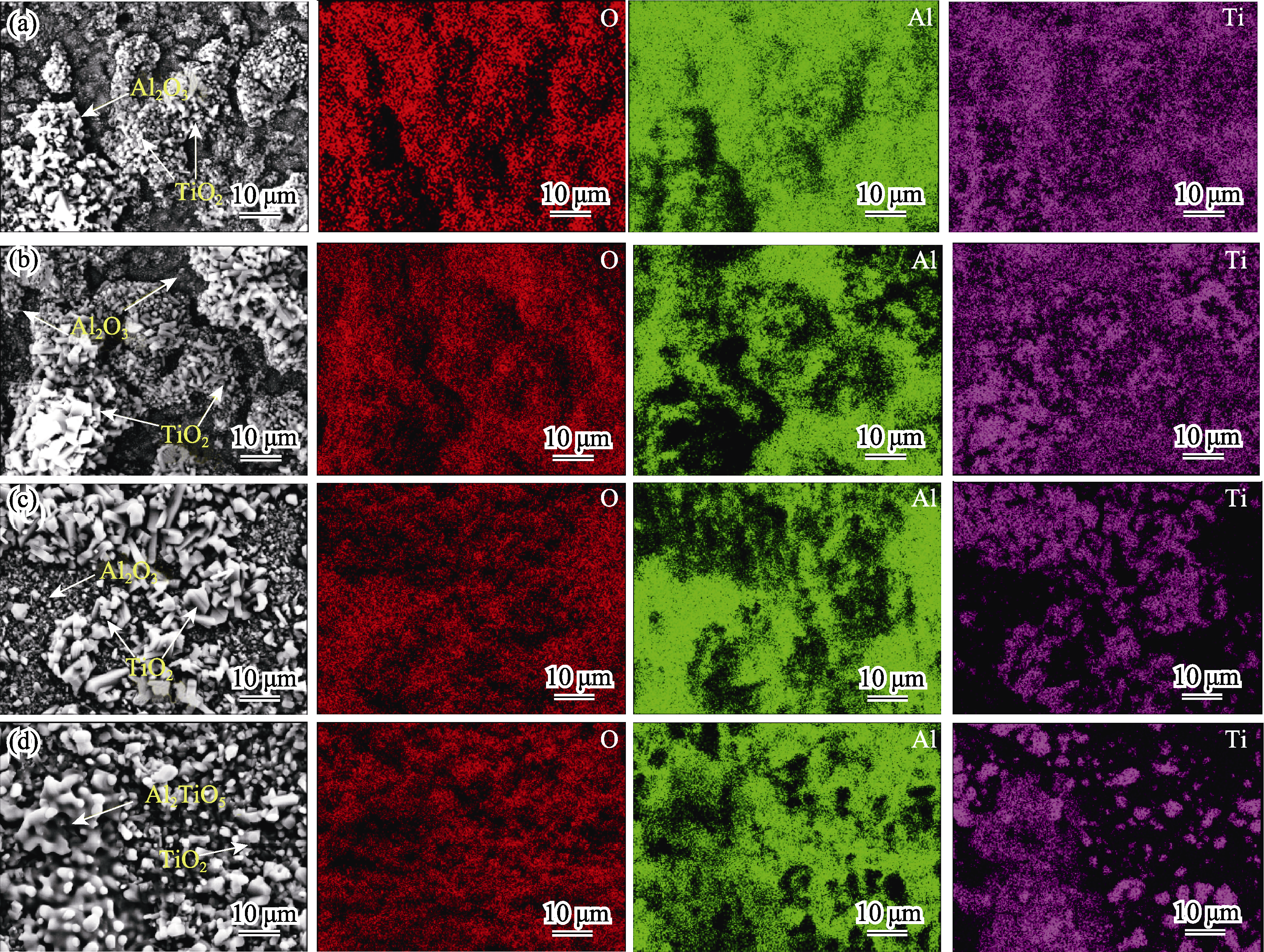

图5 Ti2AlC-20TiB2复合材料在1000~1300 ℃空气中氧化10 h后的表面形貌以及O、Al、Ti元素的EDS面扫描结果

Fig. 5 Surface morphologies of Ti2AlC-20TiB2 composite oxidized at 1000-1300 ℃ in air for 10 h and EDS element mappings of O, Al, and Ti (a) 1000 ℃; (b) 1100 ℃; (c) 1200 ℃; (d) 1300 ℃

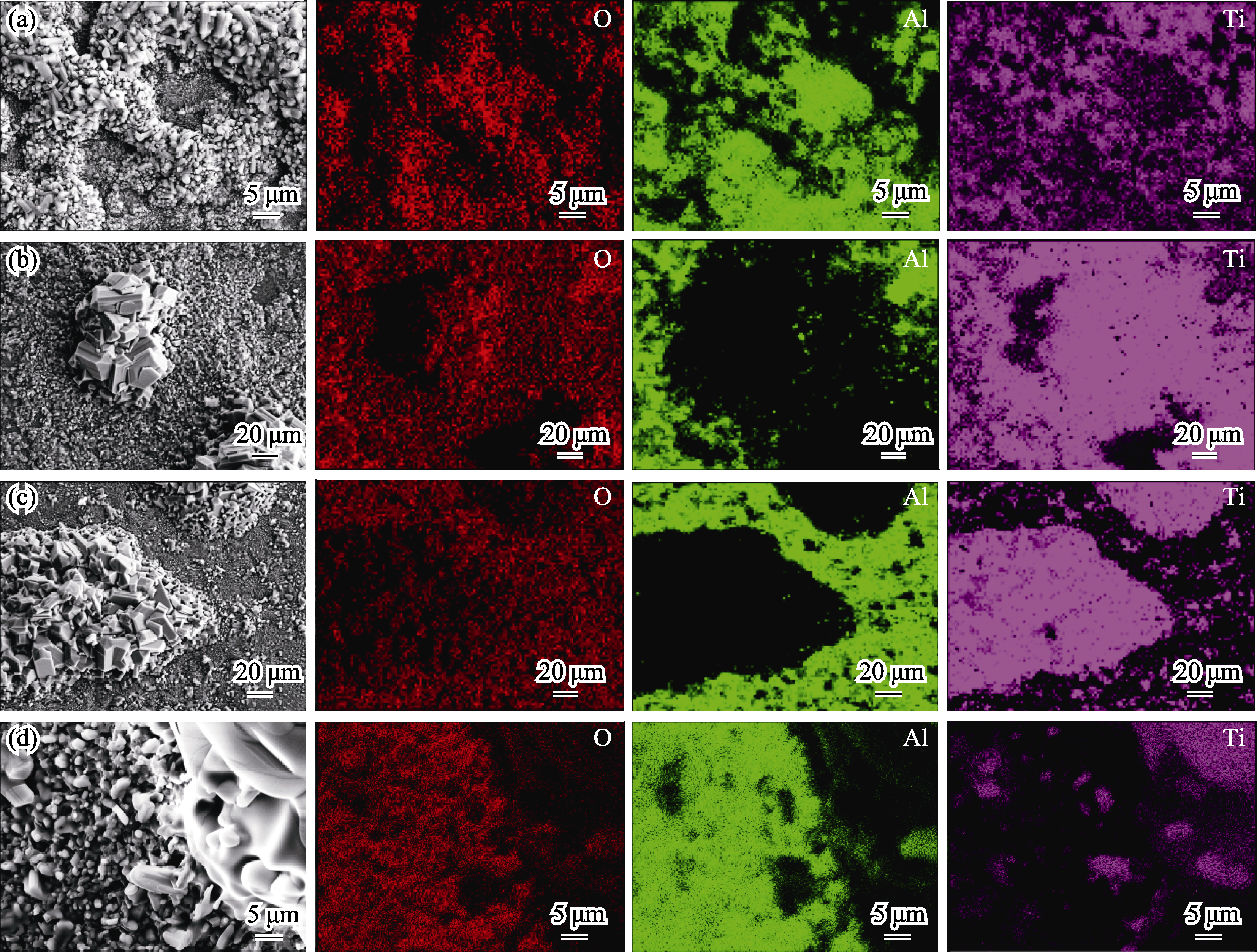

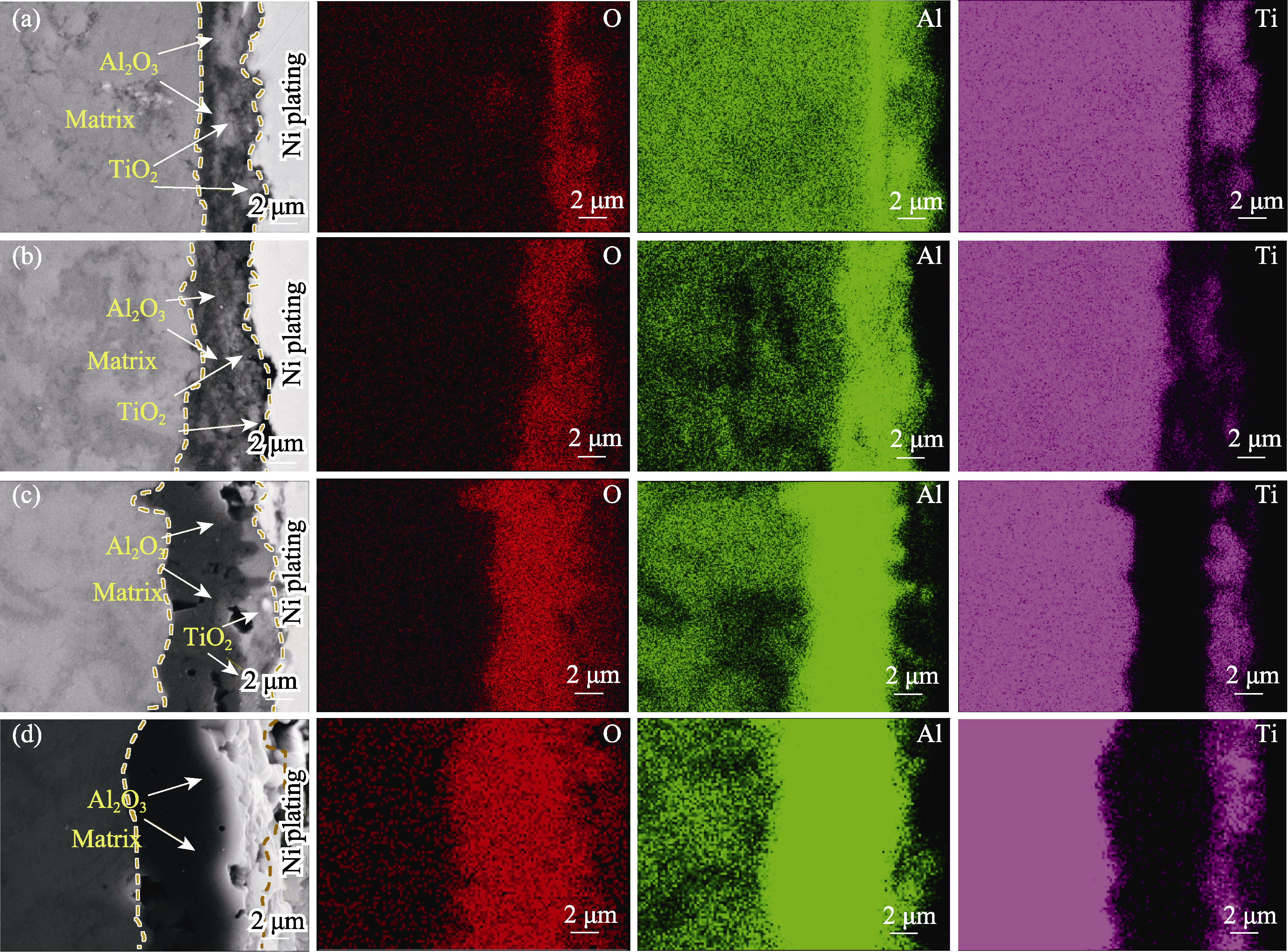

图6 Ti2AlC在1000~1300 ℃空气中氧化10 h后的表面形貌以及O、Al、Ti元素的EDS面扫描结果

Fig. 6 Surface morphologies of Ti2AlC oxidized at 1000-1300 ℃ in air for 10 h and EDS element mappings of O, Al, and Ti (a) 1000 ℃; (b) 1100 ℃; (c) 1200 ℃; (d) 1300 ℃

图7 Ti2AlC-20TiB2复合材料在1000~1300 ℃空气中氧化10 h后的截面形貌以及O、Al、Ti元素的EDS面扫描结果

Fig. 7 Cross-sectional morphologies of Ti2AlC-20TiB2 composite oxidized at 1000-1300 ℃ in air for 10 h and EDS element mappings of O, Al, and Ti (a) 1000 ℃; (b) 1100 ℃; (c) 1200 ℃; (d) 1300 ℃

图8 Ti2AlC在1000~1300 ℃空气中氧化10 h后的截面形貌以及O、Al、Ti元素的EDS面扫描结果

Fig. 8 Cross-sectional morphologies of Ti2AlC oxidized at 1000-1300 ℃ in air for 10 h and EDS element mappings of O, Al, and Ti (a) 1000 ℃; (b) 1100 ℃; (c) 1200 ℃; (d) 1300 ℃

| [1] | BARSOUM M W. The Mn+1AXn phases: a new class of solids: thermodynamically stable nanolaminates. Progress in Solid State Chemistry, 2000, 28: 201. |

| [2] | LIN Z J, ZHUO M J, ZHOU Y C, et al. Microstructural characterization of layered ternary Ti2AlC. Acta Materialia, 2006, 54(4): 1009. |

| [3] | WANG X H, ZHOU Y C. Layered machinable and electrically conductive Ti2AlC and Ti3AlC2 ceramics: a review. Journal of Materials Science & Technology, 2010, 26(5): 385. |

| [4] | ZHOU Y C, SUN Z M. Electronic structure and bonding properties of layered machinable Ti2AlC and Ti2AlN ceramics. Physical Review B, 2000, 61(19): 12570. |

| [5] |

PADTURE N P, GELL M, JORDAN E H. Thermal barrier coatings for gas-turbine engine applications. Science, 2002, 296(5566): 280.

PMID |

| [6] | FRODELIUS J, SONESTED M, BJORKLUND S, et al. Ti2AlC coatings deposited by high velocity oxy-fuel spraying. Surface and Coatings Technology, 2008, 202(24): 5976. |

| [7] | TALLMAN D J, ANASORI B, BARSOUM M W. A critical review of the oxidation of Ti2AlC, Ti3AlC2 and Cr2AlC in air. Materials Research Letters, 2013, 115(3): 115. |

| [8] | WANG X H, ZHOU Y C. High-temperature oxidation behavior of Ti2AlC in air. Oxidation of Metals, 2002, 59(3): 303. |

| [9] | ZHANG X H, WANG Y M, CHENG Y, et al. Research progress on ultra-high temperature ceramic composites. Journal of Inorganic Materials, 2024, 39(6): 571. |

| [10] | LI C, QIAN Y H, MA C L, et al. Suppressing the anomalous rapid oxidation of Ti3AlC2 by incorporating TiB2. Journal of Materials Science & Technology, 2019, 35(3): 432. |

| [11] | LI C, LI M S, ZHOU Y C, et al. In situ synthesis and properties of Ti3AlC2/TiB2 composites. Journal of the American Ceramic Society, 2007, 90(11): 3615. |

| [12] | LI M S, LI C, LI J J, et al. Oxidation behavior of a Ti3AlC2/TiB2 composite at 1000-1400 ℃ in air. Journal of the American Ceramic Society, 2010, 93(2): 554. |

| [13] | 赵芳, 王明远, 唐香珺, 等. Ti2AlC/TiB2/TiC复相陶瓷的制备及性能研究. 宇航材料工艺, 2016, 46(5): 4. |

| [14] | WANG W T, XU J J, ZUO J, et al. Oxidation resistance of in situ reaction/hot pressing synthesized Ti2AlC-20%TiB2 composite at 600-900 ℃ in air. Acta Metallurgica Sinica (English Letters), 2024, 37(4): 739. |

| [15] | SUNDBERG M, MALMQVIST G, MAGNUSSON A. Alumina forming high temperature silicides and carbides. Ceramics International, 2004, 30(7): 1899. |

| [16] | FU G D, GUI J, WANG Z G, et al. High temperature cyclic oxidation behavior of Ti2AlC/Al2O3 composites at 1100-1300 ℃ in air. China Ceramics, 2014, 50(3): 16. |

| [17] | WANG X H, ZHOU Y C. Oxidation behavior of Ti3AlC2 at 1000- 1400 ℃ in air. Corrosion Science, 2003, 45(5): 891. |

| [18] | SHEN Y, RUAN Y Z, YU Y. Study on the in-situ synthesis of aluminum titanate sintered by waste aluminum slag. Chinese Journal of Structural Chemistry, 2009, 28(1): 61. |

| [19] | LI X Q, XIE X, GONZALEZ-JULIAN J, et al. Mechanical and oxidation behavior of textured Ti2AlC and Ti3AlC2 MAX phase materials. Journal of the European Ceramic Society, 2020, 40(15): 5258. |

| [20] | WAGNER C. Beitrag zur theorie des anlaufvorgangs. Zeitschrift für Physikalische Chemie, 1933, 21B(1): 25. |

| [21] | LANGENSIEPEN R A, TRESSLER R E, HOWELL P R. A preliminary study of precipitation in Ti4+-doped polycrystalline alumina. Journal of Materials Science, 1983, 18(9): 2771. |

| [22] | WANG J Y, ZHOU Y C, LIAO T, et al. A first-principles investigation of the phase stability of Ti2AlC with Al vacancies. Scripta Materialia, 2008, 58(3): 227. |

| [23] | LEE D B, PARK S W. High-temperature oxidation of Ti3AlC2 between 1173 and 1473 K in air. Materials Science and Engineering: A, 2006, 434(1/2): 147. |

| [24] | SONG Q, ZHANG Z H. Microstructure and self-healing mechanism of B4C-TiB2-SiC composite ceramic after pre-oxidation behaviour. Ceramics International, 2022, 48(17): 25458. |

| [25] | YU W B, VALLET M, LEVRAUT B, et al. Oxidation mechanisms in bulk Ti2AlC: influence of the grain size. Journal of the European Ceramic Society, 2004, 40(5): 1820. |

| [26] | XU L D, ZHU D G, LIU Y L, et al. Effect of texture on oxidation resistance of Ti3AlC2. Journal of the European Ceramic Society, 2018, 38(10): 3417. |

| [1] | 李筱暄, 付前刚, 文子豪, 杨金山, 倪德伟, 张洁, 程源, 刘昱轩, 褚衍辉, 蔡飞燕, 王京阳, 张幸红. 极端环境用超高温陶瓷结构材料研究进展[J]. 无机材料学报, 2025, 40(10): 1045-1078. |

| [2] | 陈斌, 任科, 王一光. Mini-SiCf/SiC复合材料长时间高温下的力学性能演变[J]. 无机材料学报, 2025, 40(9): 971-980. |

| [3] | 魏志帆, 陈国清, 祖宇飞, 刘渊, 李明浩, 付雪松, 周文龙. ZrB2-HfSi2复相陶瓷显微组织及其核-周结构形成机制[J]. 无机材料学报, 2025, 40(7): 817-825. |

| [4] | 洪培萍, 梁龙, 吴炼, 马颖康, 庞浩. ZIF-67结构调控及其对盐酸金霉素的吸附性能研究[J]. 无机材料学报, 2025, 40(4): 388-396. |

| [5] | 李建军, 陈芳明, 张梨梨, 王磊, 张丽亭, 陈慧雯, 薛长国, 徐良骥. CoFe2O4/MgAl-LDH催化剂活化过氧一硫酸盐促进抗生素降解[J]. 无机材料学报, 2025, 40(4): 440-448. |

| [6] | 侯佳琪, 陈睿聪, 曾耀莹, 周磊, 张佳平, 付前刚. 气相渗硅法修复SiC涂层及其抗热震和烧蚀性能[J]. 无机材料学报, 2025, 40(2): 168-176. |

| [7] | 栾新刚, 何典蔚, 涂建勇, 成来飞. 2D平纹和3D针刺C/SiC复合材料的低速冲击破坏行为和失效机理[J]. 无机材料学报, 2025, 40(2): 205-214. |

| [8] | 张立, 管皞阳, 郑琪宁, 洪智亮, 王佳璇, 邢宁, 李玫, 刘永胜, 张程煜. MI SiCf/SiC-SiYBC复合材料的蠕变性能及损伤机理[J]. 无机材料学报, 2025, 40(1): 23-30. |

| [9] | 文志朋, 韦毅, 侯向华, 郭佳文, 黎渠, 朱满庆, 张家浩, 潘凯, 吴炼. 膨润土基功能材料在电化学储能中的研究进展[J]. 无机材料学报, 2024, 39(12): 1301-1315. |

| [10] | 马永杰, 刘永胜, 关康, 曾庆丰. CH4+C2H5OH+Ar体系热解的气相动力学研究[J]. 无机材料学报, 2024, 39(11): 1235-1244. |

| [11] | 丁宁宁, 孙建华, 韦旭, 孙丽霞. 对氨基苯磺酸修饰MoO3/PPy复合材料室温下对氨气的监测[J]. 无机材料学报, 2024, 39(11): 1245-1253. |

| [12] | 周云凯, 刁亚琪, 王明磊, 张宴会, 王利民. 聚苯胺改性Ti3C2(OH)2抗氧化性的第一性原理计算研究[J]. 无机材料学报, 2024, 39(10): 1151-1158. |

| [13] | 魏相霞, 张晓飞, 徐凯龙, 陈张伟. 增材制造柔性压电材料的现状与展望[J]. 无机材料学报, 2024, 39(9): 965-978. |

| [14] | 全文心, 余艺平, 方冰, 李伟, 王松. 管状C/SiC复合材料高温空气氧化行为与宏细观建模研究[J]. 无机材料学报, 2024, 39(8): 920-928. |

| [15] | 马彬彬, 钟婉菱, 韩涧, 陈椋煜, 孙婧婧, 雷彩霞. ZIF-8/TiO2复合介观晶体的制备及光催化活性[J]. 无机材料学报, 2024, 39(8): 937-944. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||