无机材料学报 ›› 2023, Vol. 38 ›› Issue (4): 461-468.DOI: 10.15541/jim20220469 CSTR: 32189.14.10.15541/jim20220469

刘文龙1,2( ), 赵瑾1,2(

), 赵瑾1,2( ), 刘娟1,2, 毛小建1,2, 章健1,2, 王士维1,2(

), 刘娟1,2, 毛小建1,2, 章健1,2, 王士维1,2( )

)

收稿日期:2022-08-09

修回日期:2022-11-25

出版日期:2023-04-20

网络出版日期:2022-12-09

通讯作者:

赵瑾, 助理研究员. E-mail: zhaojin@mail.sic.ac.cn;作者简介:刘文龙(1997-), 男, 硕士研究生. E-mail: liuwenlong20@mails.ucas.ac.cn

LIU Wenlong1,2( ), ZHAO Jin1,2(

), ZHAO Jin1,2( ), LIU Juan1,2, MAO Xiaojian1,2, ZHANG Jian1,2, WANG Shiwei1,2(

), LIU Juan1,2, MAO Xiaojian1,2, ZHANG Jian1,2, WANG Shiwei1,2( )

)

Received:2022-08-09

Revised:2022-11-25

Published:2023-04-20

Online:2022-12-09

Contact:

ZHAO Jin, lecturer. E-mail: zhaojin@mail.sic.ac.cn;About author:LIU Wenlong (1997-), male, Master candidate. E-mail: liuwenlong20@mails.ucas.ac.cn

Supported by:摘要:

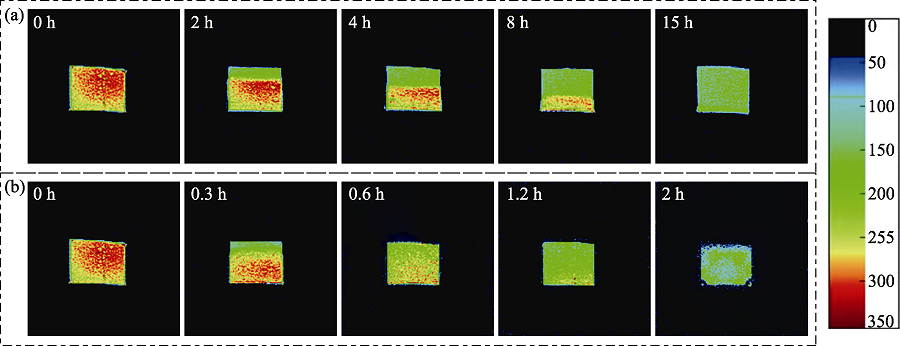

为了解决常规干燥(控温控湿)过程中坯体出现水分梯度问题, 利用微波干燥法来干燥湿坯。通过对比常规干燥(温度: 40 ℃; 湿度: 60%)和微波干燥的方式, 研究了湿坯的重量损失、线性收缩、表面温度和水分分布。与常规干燥相比, 采用微波干燥(功率250 W)时, 干燥结束时间和停止收缩时间分别缩短至1/6.8和1/6。在微波干燥过程中, 样品表面温度随时间延长先升高后降低, 与体内水分密切相关。而在常规干燥过程中, 温度保持恒定在40 ℃。采用低场核磁共振(NMR)成像技术表征湿坯内部的水分分布情况发现: 在微波干燥过程中, 水分分布更均匀, 表明微波干燥时湿坯的干燥应力更低。在1550 ℃下烧结6 h后, 微波干燥制备得到的氧化铝陶瓷具有更高的抗弯强度, 且标准差更小。

中图分类号:

刘文龙, 赵瑾, 刘娟, 毛小建, 章健, 王士维. 微波干燥自发凝固成型氧化铝湿坯[J]. 无机材料学报, 2023, 38(4): 461-468.

LIU Wenlong, ZHAO Jin, LIU Juan, MAO Xiaojian, ZHANG Jian, WANG Shiwei. Microwave Drying of Spontaneous-Coagulation-Cast Wet Alumina Green Body[J]. Journal of Inorganic Materials, 2023, 38(4): 461-468.

| Drying method | Microwave power/W | CRP/ h | Residual water after CRP/% (in vol.) | Residual water after drying/% (in vol.) |

|---|---|---|---|---|

| Conventional | — | 10 | (20.4±1.5) | 0.8 |

| Microwave | 250 | 1.8 | (11.2±1.4) | 0.6 |

| 400 | 1.3 | (9.4±1.4) | 0.5 | |

| 550 | 1.0 | (7.7±0.7) | 0.4 |

Table 1 CRP and residual water (after CRP and drying) of samples

| Drying method | Microwave power/W | CRP/ h | Residual water after CRP/% (in vol.) | Residual water after drying/% (in vol.) |

|---|---|---|---|---|

| Conventional | — | 10 | (20.4±1.5) | 0.8 |

| Microwave | 250 | 1.8 | (11.2±1.4) | 0.6 |

| 400 | 1.3 | (9.4±1.4) | 0.5 | |

| 550 | 1.0 | (7.7±0.7) | 0.4 |

| Drying method | Microwave power/W | Shrinkage stop time/h | Shrinkage/% |

|---|---|---|---|

| Conventional | — | 6.0 | (4.9±0.1) |

| Microwave | 250 | 1.0 | (5.2±0.1) |

| 400 | 0.7 | (5.1±0.1) | |

| 550 | 0.5 | (4.8±0.1) |

Table 2 Shrinkage stop time and shrinkage of samples

| Drying method | Microwave power/W | Shrinkage stop time/h | Shrinkage/% |

|---|---|---|---|

| Conventional | — | 6.0 | (4.9±0.1) |

| Microwave | 250 | 1.0 | (5.2±0.1) |

| 400 | 0.7 | (5.1±0.1) | |

| 550 | 0.5 | (4.8±0.1) |

Fig. 7 Moisture distributions of wet alumina green bodies in the drying process (a) Conventional drying for 0, 2, 4, 8, and 15 h; (b) 250-W microwave drying for 0, 0.3, 0.6, 1.2, and 2 h

| [1] |

YANG Y, SHIMAI S, WANG S. Room-temperature gelcasting of alumina with a water-soluble copolymer. Journal of Materials Research, 2013, 28(11):1512.

DOI URL |

| [2] |

CHEN H, SHIMAI S, ZHAO J, et al. Hydrophobic coagulation of alumina slurries. Journal of the American Ceramic Society, 2021, 104(1):284.

DOI URL |

| [3] |

SUN Y, SHIMAI S, PENG X, et al. A method for gelcasting high-strength alumina ceramics with low shrinkage. Journal of Materials Research, 2014, 29(2):247.

DOI URL |

| [4] | WU C, YU Z, SOKOLOV A S, et al. Tailoring magnetic properties of self-biased hexaferrites using an alternative copolymer of isobutylene and maleic anhydride. AIP Advances, 2018, 8(5):221. |

| [5] | WANG F, YIN J, YAO D, et al. Fabrication of porous SiC ceramics through a modified gelcasting and solid state sintering. Materials Science and Engineering A--Structural Materials Properties Microstructure and Processing, 2016, 654: 292. |

| [6] |

WANG L, AN L, ZHAO J, et al. High-strength porous alumina ceramics prepared from stable wet foams. Journal of Advanced Ceramics, 2021, 10(4):852.

DOI |

| [7] |

SUN Y, SHIMAI S, PENG X, et al. Fabrication of transparent Y2O3 ceramics via aqueous gelcasting. Ceramics International, 2014, 40(6):8841.

DOI URL |

| [8] | ZHANG P, LIU P, SUN Y, et al. Aqueous gelcasting of the transparent MgAl2O4 spinel ceramics. Journal of Alloys and Compounds, 2015, 646: 833. |

| [9] |

WANG J, ZHANG F, CHEN F, et al. Fabrication of aluminum oxynitride (c-AlON) transparent ceramics with modified gelcasting. Journal of the American Ceramic Society, 2014, 97(5):1353.

DOI URL |

| [10] |

CHEN H, ZHAO J, SHIMAI S, et al. High transmittance and grain-orientated alumina ceramics fabricated by adding fine template particles. Journal of Advanced Ceramics, 2022, 11(4):582.

DOI |

| [11] |

YOUNG A C, OMATETE O O, JANNEY M A, et al. Gelcasting of alumina. Journal of the American Ceramic Society, 1991, 74(3):612.

DOI URL |

| [12] | BAADER F H, GRAULE T J, GAUCKLER L J. Direct coagulation casting-a new green shape technique. 2. Application to alumina. Industrial Ceramics, 1996, 16(1):36. |

| [13] | GRAULE T J, GAUCKLER L J, BAADER F H. Direct coagulation casting-a new green shaping technique. 1. Processing principles. Industrial Ceramics, 1996, 16(1):31. |

| [14] |

SCHERER G W. Theory of drying. Journal of the American Ceramic Society, 1990, 73(1):3.

DOI URL |

| [15] | OMATETE O O, STREHLOW R A, WALLS C A. Drying of gelcast ceramics. United States, 1991, 26(2):101. |

| [16] |

MA L G, HUANG Y, YANG J L, et al. Control of the inner stresses in ceramic green bodies formed by gelcasting. Ceramics International, 2006, 32(2):93.

DOI URL |

| [17] |

BARATI A, KOKABI M, FAMILI M H N. Drying of gelcast ceramic parts via the liquid desiccant method. Journal of the European Ceramic Society, 2003, 23(13):2265.

DOI URL |

| [18] |

BILBAO-SAINZ C, ANDRES A, FITO P. Hydration kinetics of dried apple as affected by drying conditions. Journal of Food Engineering, 2005, 68(3):369.

DOI URL |

| [19] |

SHIRAI T, YASUOKA M, HOTTA Y, et al. Rapid microwave drying for slip cast bodies. Journal of the Ceramic Society of Japan, 2006, 114(1326):217.

DOI URL |

| [20] |

OZKAN I A, AKBUDAK B, AKBUDAK N. Microwave drying characteristics of spinach. Journal of Food Engineering, 2007, 78(2):577.

DOI URL |

| [21] |

VONGPRADUBCHAI S, RATTANADECHO P. Microwave and hot air drying of wood using a rectangular waveguide. Drying Technology, 2011, 29(4):451.

DOI URL |

| [22] |

CHONG C H, FIGIEL A, LAW C L, et al. Combined drying of apple cubes by using of heat pump, vacuum-microwave, and intermittent techniques. Food and Bioprocess Technology, 2014, 7(4):975.

DOI URL |

| [23] |

ITAYA Y, OKOUCHI K, MORI S. Effect of heating modes on internal strain-stress formation during drying of molded ceramics. Drying Technology, 2001, 19(7):1491.

DOI URL |

| [24] | ESIN A, MAHMUTYAZICIOGLU N, ALTINTAS S. Drying and sintering of ceramic based parts using microwave heating. Key Engineering Materials, 2004, 268(3):731. |

| [25] |

SHIRAI T, ISOBE T, YASUOKA M, et al. Rapid microwave drying for wet green body using nanosized particles. Journal of the Ceramic Society of Japan, 2007, 115(1343):440.

DOI URL |

| [26] |

HEMANTHAKUMARI P N, SATAPATHY L N. A comparison of the effects of microwave versus conventional drying on the mechanical properties distribution of dried green porcelains. International Journal of Applied Ceramic Technology, 2008, 5(1):94.

DOI URL |

| [27] |

ZHANG L, MCCARTHY M J. NMR study of hydration of navy bean during cooking. Lwt-Food Science and Technology, 2013, 53(2):402.

DOI URL |

| [28] |

BORISJUK L, ROLLETSCHEK H, NEUBERGER T. Surveying the plant's world by magnetic resonance imaging. Plant Journal, 2012, 70(1):129.

DOI URL |

| [29] |

ISHIDA N, KOIZUMI M, KANO H. The NMR microscope: a unique and promising tool for plant science. Annals of Botany, 2000, 86(2):259.

DOI URL |

| [30] |

DADALI G, APAR D K, OZBEK B. Microwave drying kinetics of okra. Drying Technology, 2007, 25(4/5/6):917.

DOI URL |

| [1] | 袁利萍, 吴袁泊, 俞佳静, 张世琰, 孙铱, 胡云楚, 范友华. 磷钼酸插层水滑石复合CNFs气凝胶的制备及其隔热保温性能[J]. 无机材料学报, 2025, 40(4): 415-424. |

| [2] | 武向权, 滕家琛, 季祥旭, 郝禹博, 张忠明, 徐春杰. 织构化多孔Al2O3-SiO2复合陶瓷片-球混合浆料特性及光强分布仿真[J]. 无机材料学报, 2024, 39(7): 769-778. |

| [3] | 叶梓滨, 邹高昌, 吴琪雯, 颜晓敏, 周明扬, 刘江. 阳极支撑型锥管串接式直接碳固体氧化物燃料电池组的制备及性能[J]. 无机材料学报, 2024, 39(7): 819-827. |

| [4] | 程博, 安晓航, 李定华, 杨荣杰. ATH/ADP配比对EVA阻燃性能及机理转变的影响[J]. 无机材料学报, 2024, 39(5): 509-516. |

| [5] | 沈斌, 张旭, 熊怀, 李海元, 谢兴龙. 溶胶-凝胶SiO2减反膜的制备与光学性能研究[J]. 无机材料学报, 2024, 39(5): 525-530. |

| [6] | 孔剑锋, 黄杰成, 刘兆林, 林存生, 王治宇. 基于DPEPA聚合物凝胶电解质的准固态钠离子电池[J]. 无机材料学报, 2024, 39(12): 1331-1338. |

| [7] | 戴乐, 刘洋, 高轩, 王书豪, 宋雅婷, 唐明猛, 刘丽莎, 汪尧进. 浓度梯度掺杂实现BiFeO3薄膜自极化[J]. 无机材料学报, 2024, 39(1): 99-106. |

| [8] | 郭宇翔, 黄立强, 王刚, 王宏志. 双锂盐凝胶复合电解质的制备及其在锂金属电池中的应用[J]. 无机材料学报, 2023, 38(7): 785-792. |

| [9] | 张祥松, 刘业通, 王永瑛, 武子瑞, 刘振中, 李毅, 杨娟. 自组装制备PtIr合金气凝胶及其高效电催化氨氧化性能[J]. 无机材料学报, 2023, 38(5): 511-520. |

| [10] | 靳喜海, 董满江, 阚艳梅, 梁波, 董绍明. 透明AlON陶瓷凝胶浇注成型及其无压烧结制备[J]. 无机材料学报, 2023, 38(2): 193-198. |

| [11] | 贾玉娜, 曹旭, 焦秀玲, 陈代荣. 无机酸铝体系氧化铝连续纤维的制备技术研究[J]. 无机材料学报, 2023, 38(11): 1257-1264. |

| [12] | 李文俊, 王皓, 涂兵田, 谌强国, 郑凯平, 王为民, 傅正义. 宽光谱透过Mg0.9Al2.08O3.97N0.03透明陶瓷的制备与性能研究[J]. 无机材料学报, 2022, 37(9): 969-975. |

| [13] | 王士维. 基于疏水作用的陶瓷浆料自发凝固成型研究进展[J]. 无机材料学报, 2022, 37(8): 809-820. |

| [14] | 王晓俊, 许文, 刘润路, 潘辉, 朱申敏. 水凝胶负载的纳米银/氮化碳光催化剂的制备及性能研究[J]. 无机材料学报, 2022, 37(7): 731-740. |

| [15] | 王新刚, 杨青青, 林根连, 高巍, 秦福林, 李荣臻, 康庄, 王小飞, 蒋丹宇, 闫继娜. 国产550级连续氧化铝陶瓷纤维的高温拉伸性能研究[J]. 无机材料学报, 2022, 37(6): 629-635. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||