无机材料学报 ›› 2022, Vol. 37 ›› Issue (12): 1275-1280.DOI: 10.15541/jim20220294 CSTR: 32189.14.10.15541/jim20220294

吴西士1,2( ), 朱云洲2(

), 朱云洲2( ), 黄庆1, 黄政仁1,2(

), 黄庆1, 黄政仁1,2( )

)

收稿日期:2022-05-25

修回日期:2022-06-30

出版日期:2022-12-20

网络出版日期:2022-08-04

通讯作者:

朱云洲, 副研究员. E-mail: yunzhouzhu@mail.sic.ac.cn;作者简介:吴西士(1991-), 男, 博士. E-mail: wuxishi@nimte.ac.cn

基金资助:

WU Xishi1,2( ), ZHU Yunzhou2(

), ZHU Yunzhou2( ), HUANG Qing1, HUANG Zhengren1,2(

), HUANG Qing1, HUANG Zhengren1,2( )

)

Received:2022-05-25

Revised:2022-06-30

Published:2022-12-20

Online:2022-08-04

Contact:

ZHU Yunzhou, associate professor. E-mail: yunzhouzhu@mail.sic.ac.cn;About author:WU Xishi (1991-), male, PhD. E-mail: wuxishi@nimte.ac.cn

Supported by:摘要:

连接技术是实现大尺寸以及复杂构型Cf/SiC复合材料制备及工程化应用的关键技术。本工作使用酚醛树脂作为碳源, 通过反应连接法实现了Cf/SiC复合材料的稳定连接, 研究了多孔碳坯的体积密度和孔径对接头连接性能和微观结构的影响, 讨论了惰性填料含量对接头连接性能和显微组织的影响。研究表明: 树脂基多孔碳素坯的体积密度和孔径分别选定在0.71~0.90 g·cm-3和200~600 nm比较合适, 随着多孔碳素坯孔径增加, 游离硅尺寸逐渐增大; 当孔径为190 nm时, 连接件强度最大为(125±12) MPa。添加SiC惰性填料可以明显减小多孔碳素坯的体积收缩, 当SiC惰性填料质量分数为50%时, 连接件强度最高达到(216±44) MPa, 基本与基体材料强度相当。总体而言, 本研究为实现Cf/SiC复合材料稳定连接提供了理论指导, 对实现复杂形状或大型Cf/SiC复合材料的制备和工程应用具有重要意义。

中图分类号:

吴西士, 朱云洲, 黄庆, 黄政仁. 树脂基多孔碳孔结构对Cf/SiC复合材料连接性能的影响[J]. 无机材料学报, 2022, 37(12): 1275-1280.

WU Xishi, ZHU Yunzhou, HUANG Qing, HUANG Zhengren. Effect of Pore Structure of Organic Resin-based Porous Carbon on Joining Properties of Cf/SiC Composites[J]. Journal of Inorganic Materials, 2022, 37(12): 1275-1280.

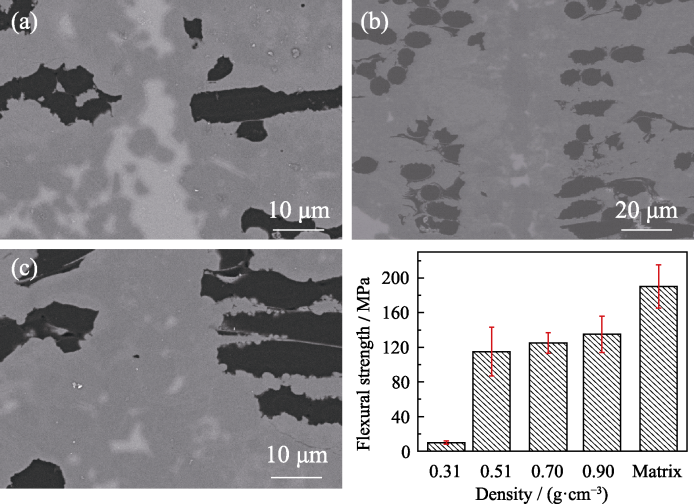

图1 不同体积密度碳素坯((a)0.51, (b)0.70, (c)0.90)接头微观结构, (d)连接样品力学性能

Fig. 1 Microstructures of joints with different volumn densities ((a) 0.51, (b) 0.70, (b) 0.90) and (d) flexural strengths of the joined specimens

| Sample | PF/% | EG/% | Pore former* | Residual carbon**/% | Average pore size/nm | Bulk density/(g·cm-3) |

|---|---|---|---|---|---|---|

| 1 | 50 | 50 | FeCl2 (1%) | 23+1.1 | 190±15 | 0.73±0.01 |

| 2 | 50 | 50 | H3BO3 (1.5%) | 24.3±0.9 | 642±15 | 0.74±0.01 |

| 3 | 50 | 50 | FeCl2 (1%) + H3BO3 (1.5%) | 24.1±1.7 | 1226±48 | 0.74±0.03 |

| 4 | 50 | 50 | H3BO3 (2.5%) | 25.8±2.1 | 1552±38 | 0.79±0.03 |

| 5 | 50 | 50 | H3BO3 (3.5%) | 26.7±1.5 | 2363±54 | 0.79±0.03 |

表1 树脂溶液组成及裂解后多孔碳素坯性能参数

Table 1 Composition of resin solution and properties of porous carbons after pyrolysis

| Sample | PF/% | EG/% | Pore former* | Residual carbon**/% | Average pore size/nm | Bulk density/(g·cm-3) |

|---|---|---|---|---|---|---|

| 1 | 50 | 50 | FeCl2 (1%) | 23+1.1 | 190±15 | 0.73±0.01 |

| 2 | 50 | 50 | H3BO3 (1.5%) | 24.3±0.9 | 642±15 | 0.74±0.01 |

| 3 | 50 | 50 | FeCl2 (1%) + H3BO3 (1.5%) | 24.1±1.7 | 1226±48 | 0.74±0.03 |

| 4 | 50 | 50 | H3BO3 (2.5%) | 25.8±2.1 | 1552±38 | 0.79±0.03 |

| 5 | 50 | 50 | H3BO3 (3.5%) | 26.7±1.5 | 2363±54 | 0.79±0.03 |

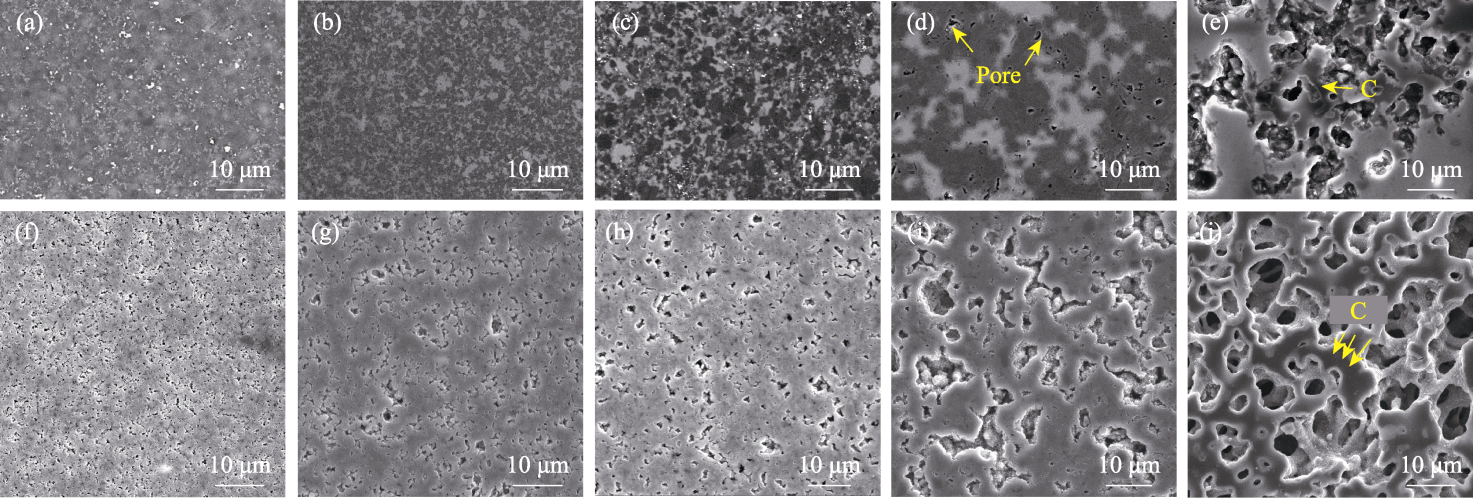

图2 HF-HNO3腐蚀前后不同孔径碳素坯制备反应烧结碳化硅陶瓷表面微观形貌

Fig. 2 Morphologies of the polished surfaces before and after HF-HNO3 corrosion of RBSC fabricated from preforms with different pore sizes (a, f) 190 nm; (b, g) 642 nm; (c, h) 1226 nm; (d, i) 1552 nm; (e, j) 2363 nm

| Pore size/nm | Open porosity/% | Density/ (g·cm-3) | Flexural strength/MPa | Residual Si/(%, in volume) |

|---|---|---|---|---|

| 190 | 0.97 | 2.93 | 296±28 | 16 |

| 642 | 1.26 | 2.91 | 268±46 | 14 |

| 1226 | 1.87 | 2.88 | 248±22 | 16 |

| 1552 | 3.51 | 2.81 | 238±44 | 12 |

| 2363 | 18.76 | 2.10 | 115±32 | 13 |

表2 不同孔径的多孔碳素坯反应烧结样品性能

Table 2 Properties of the RBSC fabricated from preforms with different pore sizes

| Pore size/nm | Open porosity/% | Density/ (g·cm-3) | Flexural strength/MPa | Residual Si/(%, in volume) |

|---|---|---|---|---|

| 190 | 0.97 | 2.93 | 296±28 | 16 |

| 642 | 1.26 | 2.91 | 268±46 | 14 |

| 1226 | 1.87 | 2.88 | 248±22 | 16 |

| 1552 | 3.51 | 2.81 | 238±44 | 12 |

| 2363 | 18.76 | 2.10 | 115±32 | 13 |

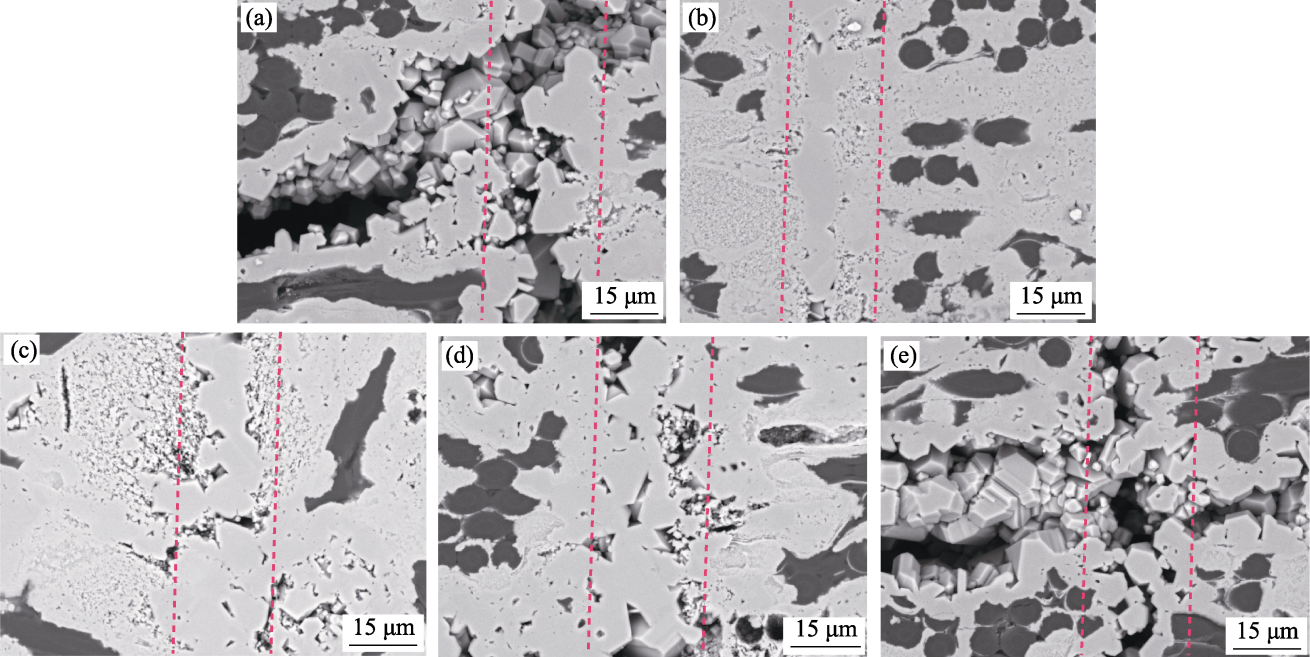

图4 HF-HNO3腐蚀后不同孔径多孔碳素坯连接样品表面形貌

Fig. 4 Surface microstructures after HF-HNO3 corrosion of joining samples with different pore sizes (a) 14 nm; (b) 190 nm; (c) 316 nm; (d) 642 nm; (e) 1226 nm

| Pore size/nm | Flexural strength/MPa | Strength retention/% |

|---|---|---|

| 14 | 90±28 | 61 |

| 190 | 125±12 | 85 |

| 316 | 77±10 | 52 |

| 642 | 107±15 | 73 |

| 1226 | 65±22 | 44 |

表3 不同孔径连接样品力学性能

Table 3 Properties of joining samples with different pore sizes

| Pore size/nm | Flexural strength/MPa | Strength retention/% |

|---|---|---|

| 14 | 90±28 | 61 |

| 190 | 125±12 | 85 |

| 316 | 77±10 | 52 |

| 642 | 107±15 | 73 |

| 1226 | 65±22 | 44 |

| Sample | PF/ % | EG/ % | Dispersant*/% | Pore former** (FeCl2)/% | α-SiC powder/% |

|---|---|---|---|---|---|

| 1 | 40 | 40 | 4 | 1 | 20 |

| 2 | 35 | 35 | 4 | 1 | 30 |

| 3 | 30 | 30 | 4 | 1 | 40 |

| 4 | 25 | 25 | 4 | 1 | 50 |

| 5 | 22.5 | 22.5 | 4 | 1 | 55 |

表4 树脂基浆料组成

Table 4 Composition of resin-based slurry

| Sample | PF/ % | EG/ % | Dispersant*/% | Pore former** (FeCl2)/% | α-SiC powder/% |

|---|---|---|---|---|---|

| 1 | 40 | 40 | 4 | 1 | 20 |

| 2 | 35 | 35 | 4 | 1 | 30 |

| 3 | 30 | 30 | 4 | 1 | 40 |

| 4 | 25 | 25 | 4 | 1 | 50 |

| 5 | 22.5 | 22.5 | 4 | 1 | 55 |

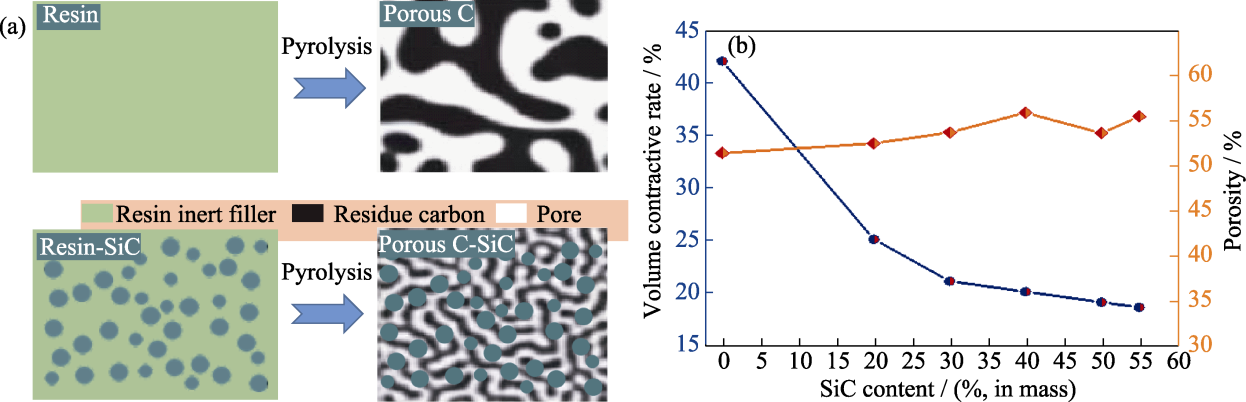

图5 (a)惰性填料添加后作用示意图和(b)多孔碳素坯的体积收缩和孔隙率变化曲线

Fig. 5 (a) Schematic of the action of inert filler and (b) volume shrinkage and porosity change curves of porous carbon blanks

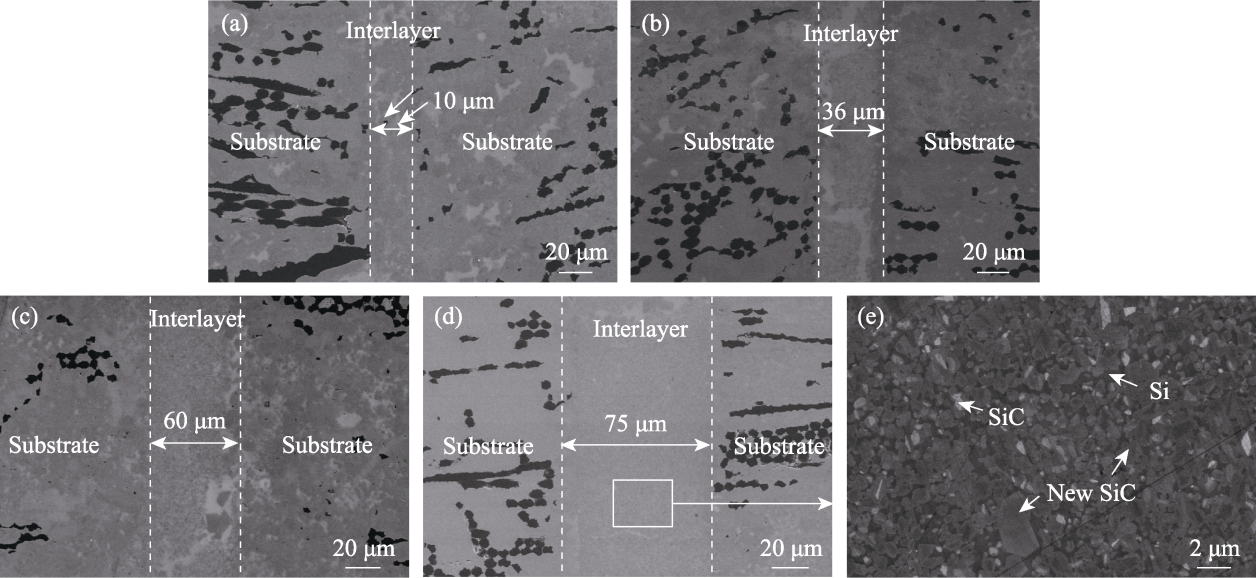

图6 不同含量((a) 30%; (b) 40%; (c) 50%; (d) 55%, 质量分数)惰性填料连接件表面微观结构及(e)图(d)的局部放大图

Fig. 6 Microstructures of the joint with different contents of inert filler ((a) 30%; (b) 40%; (c) 50%; (d) 55%, in mass) and (e) partial enlargement of (d)

| [1] |

CHENG T B, WANG X R, ZHANG R B, et al. Tensile properties of two-dimensional carbon fiber reinforced silicon carbide composites at temperatures up to 2300 ℃. Journal of the European Ceramic Society, 2020, 40(3): 630-635.

DOI URL |

| [2] |

CHEN S, CHEN P, DUAN J, et al. Thermal cycling behavior of bi-layer Yb2Si2O7/SiC EBC coated Cf/SiC composites in burner rig tests. Advanced Composites and Hybrid Materials, 2022, 5: 2184-2192.

DOI URL |

| [3] |

BERBON M Z, DIETRICH D R, MARSHALL D B, et al. Transverse thermal conductivity of thin C/SiC composites fabricated by slurry infiltration and pyrolysis. Journal of the American Ceramic Society, 2001, 84(10): 2229-2234.

DOI URL |

| [4] |

CAO X Y, YIN X W, FAN X M, et al. High temperature flexural properties of SiBC modified C/SiC composites. Ceramics International, 2014, 40(4): 6185-6190.

DOI URL |

| [5] |

LIU Y, ZHU Y Z, YANG Y, et al. Microstructure of reaction layer and its effect on the joining strength of SiC/SiC joints brazed using Ag-Cu-In-Ti alloy. Journal of Advanced Ceramics, 2014, 3(1): 71-75.

DOI URL |

| [6] |

SAIED M A, LLOYD I K, HALLER W K, et al. Joining dental ceramic layers with glass. Dental Materials, 2011, 27(10): 1011-1016.

DOI PMID |

| [7] |

YANG H, ZHOU X B, SHI W, et al. Thickness-dependent phase evolution and bonding strength of SiC ceramics joints with active Ti interlayer. Journal of the European Ceramic Society, 2017, 37(4): 1233-1241.

DOI URL |

| [8] |

JEONG D H, SEPTIADI A, FITRIANI P, et al. Joining of SiCf/SiC using polycarbosilane and polysilazane preceramic mixtures. Ceramics International, 2018, 44(9): 10443-10450.

DOI URL |

| [9] |

SINGH M, LARA-CURZIO E. Design, fabrication, and testing of ceramic joints for high temperature SiC/SiC composites. Journal of Engineering for Gas Turbines and Power-Transactions of the ASME, 2001, 123(2): 288-292.

DOI URL |

| [10] |

SINGH M. Microstructure and mechanical properties of reaction- formed joints in reaction-bonded silicon carbide ceramics. Journal of Materials Science, 1998, 33(24): 5781-5787.

DOI URL |

| [11] |

LI S B, MA M L, GAO J Q, et al. Reaction forming of joints in silicon carbide ceramic materials. Materials Science and Engineering A-Structural Materials Properties Microstructure and Processing, 2008, 483-484: 747-750.

DOI URL |

| [12] |

LUO Z H, JIANG D L, ZHANG J X, et al. Development of SiC-SiC joint by reaction bonding method using SiC/C tapes as the interlayer. Journal of the European Ceramic Society, 2012, 32(14): 3819-3824.

DOI URL |

| [13] |

ZHANG Y M, YUAN Z Y, ZHOU Y F. Gelcasting of silicon carbide ceramics using phenolic resin and furfuryl alcohol as the gel former. Ceramics International, 2014, 40(23): 7873-7878.

DOI URL |

| [14] |

WU X S, ZHU Y Z, PEI B B, et al. Effect of FeCl2 on the pore structure of porous carbon obtained from phenol formaldehyde resin and ethylene glycol. Materials Letters, 2018, 215: 50-52.

DOI URL |

| [15] |

WU X S, SU R H, ZHU Y Z, et al. Pore structure control of porous carbon obtained from phenol formaldehyde resin and ethylene glycol: the effect of H3BO3 on the pore structure. RSC Advances, 2019, 9(8): 4203-4209.

DOI URL |

| [16] |

WU X S, SU R H, PEI B B, et al. Pore structure control of porous carbon via the synergistic effect of boric acid and divalent metal iron salt. Materials Letters, 2019, 255: 126539.

DOI URL |

| [17] | BEHRENDT D, SINGH M. Effect of carbon preform pore volume and infiltrants on the composition of reaction-formed silicon carbide materials. J. Mater. Synth. Process., 1994, 2(2): 117-123. |

| [18] |

WANG Y, TAN S, JIANG D. The effect of porous carbon preform and the infiltration process on the properties of reaction-formed SiC. Carbon, 2004, 42(8/9): 1833-1839.

DOI URL |

| [19] | HILLIG W B. Melt infiltration approach to ceramic matrix composites. Journal of the American Ceramic Society, 1988, 71(2): 96-99. |

| [20] |

XU S J, QIAO G J, WANG H J, et al. Microstructure evolution and reaction mechanism of microporous carbon derived SiC ceramic. Journal of Inorganic Materials, 2009, 24(2): 291-296.

DOI URL |

| [21] |

SUYAMA S, KAMEDA T, ITOH Y. Development of high-strength reaction-sintered silicon carbide. Diamond and Related Materials, 2003, 12(3-7): 1201-1204.

DOI URL |

| [1] | 陈义, 邱海鹏, 陈明伟, 徐昊, 崔恒. SiC/SiC复合材料基体硼改性方法及其力学性能研究[J]. 无机材料学报, 2025, 40(5): 504-510. |

| [2] | 崔宁, 张玉新, 王鲁杰, 李彤阳, 于源, 汤华国, 乔竹辉. (TiVNbMoW)Cx高熵陶瓷的单相形成过程与碳空位调控[J]. 无机材料学报, 2025, 40(5): 511-520. |

| [3] | 郭子玉, 朱云洲, 王力, 陈健, 李红, 黄政仁. Zn2+催化剂对酚醛树脂/乙二醇制备多孔碳微观孔结构的影响[J]. 无机材料学报, 2025, 40(5): 466-472. |

| [4] | 李紫薇, 弓伟露, 崔海峰, 叶丽, 韩伟健, 赵彤. 前驱体法制备(Zr, Hf, Nb, Ta, W)C-SiC复相陶瓷及性能研究[J]. 无机材料学报, 2025, 40(3): 271-280. |

| [5] | 高晨光, 孙晓亮, 陈君, 李达鑫, 陈庆庆, 贾德昌, 周玉. 基于湿法纺丝技术的SiBCN-rGO陶瓷纤维的组织结构、力学和吸波性能[J]. 无机材料学报, 2025, 40(3): 290-296. |

| [6] | 穆浩洁, 张源江, 喻彬, 付秀梅, 周世斌, 李晓东. ZrO2掺杂Y2O3-MgO纳米复相陶瓷的制备及性能研究[J]. 无机材料学报, 2025, 40(3): 281-289. |

| [7] | 李伟, 许志明, 苟燕子, 尹森虎, 余艺平, 王松. SiC纤维烧结陶瓷的制备及其性能研究[J]. 无机材料学报, 2025, 40(2): 177-183. |

| [8] | 范武刚, 曹雄, 周响, 李玲, 赵冠楠, 张兆泉. 8YSZ陶瓷在模拟压水堆水环境中的耐腐蚀性能[J]. 无机材料学报, 2024, 39(7): 803-809. |

| [9] | 姜灵毅, 庞生洋, 杨超, 张悦, 胡成龙, 汤素芳. C/SiC-BN复合材料的制备及氧化行为[J]. 无机材料学报, 2024, 39(7): 779-786. |

| [10] | 王伟明, 王为得, 粟毅, 马青松, 姚冬旭, 曾宇平. 以非氧化物为烧结助剂制备高导热氮化硅陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 634-646. |

| [11] | 孙海洋, 季伟, 王为民, 傅正义. TiB-Ti周期序构复合材料设计、制备及性能研究[J]. 无机材料学报, 2024, 39(6): 662-670. |

| [12] | 蔡飞燕, 倪德伟, 董绍明. 高熵碳化物超高温陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 591-608. |

| [13] | 刘国昂, 王海龙, 方成, 黄飞龙, 杨欢. B4C含量对(Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C陶瓷力学性能及抗氧化性能的影响[J]. 无机材料学报, 2024, 39(6): 697-706. |

| [14] | 吴晓晨, 郑瑞晓, 李露, 马浩林, 赵培航, 马朝利. SiCf/SiC陶瓷基复合材料高温环境损伤原位监测研究进展[J]. 无机材料学报, 2024, 39(6): 609-622. |

| [15] | 粟毅, 史扬帆, 贾成兰, 迟蓬涛, 高扬, 马青松, 陈思安. 浆料浸渍辅助PIP工艺制备C/HfC-SiC复合材料的微观结构及性能研究[J]. 无机材料学报, 2024, 39(6): 726-732. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||