无机材料学报 ›› 2022, Vol. 37 ›› Issue (12): 1267-1274.DOI: 10.15541/jim20220265 CSTR: 32189.14.10.15541/jim20220265

刘平平1,2( ), 钟鑫1(

), 钟鑫1( ), 张乐3, 李红2(

), 张乐3, 李红2( ), 牛亚然1, 张翔宇1, 李其连3, 郑学斌1

), 牛亚然1, 张翔宇1, 李其连3, 郑学斌1

收稿日期:2022-05-06

修回日期:2022-05-29

出版日期:2022-12-20

网络出版日期:2022-06-16

通讯作者:

钟 鑫, 助理研究员. E-mail: zhongxin@mail.sic.ac.cn;作者简介:刘平平(1995-), 女, 硕士研究生. E-mail: ppliu1234@163.com

基金资助:

LIU Pingping1,2( ), ZHONG Xin1(

), ZHONG Xin1( ), ZHANG Le3, LI Hong2(

), ZHANG Le3, LI Hong2( ), NIU Yaran1, ZHANG Xiangyu1, LI Qilian3, ZHENG Xuebin1

), NIU Yaran1, ZHANG Xiangyu1, LI Qilian3, ZHENG Xuebin1

Received:2022-05-06

Revised:2022-05-29

Published:2022-12-20

Online:2022-06-16

Contact:

ZHONG Xin, assistant professor. E-mail: zhongxin@mail.sic.ac.cn;About author:LIU Pingping (1995-), female, Master candidate. E-mail: ppliu1234@163.com

Supported by:摘要:

稀土硅酸盐环境障涂层(EBC)是应用于新一代高推重比航空发动机热端部件的重要材料, 但其在高温熔盐环境的腐蚀行为与机制尚不明晰。本工作采用真空等离子喷涂技术(VPS)制备了Yb2SiO5/Yb2Si2O7/Si环境障涂层, 并研究了该涂层体系在900 ℃、Na2SO4+25% NaCl(质量分数)熔盐环境中的腐蚀行为与机制。研究发现, 所制备的Yb2SiO5/Yb2Si2O7/Si涂层体系结构致密, 各层之间结合良好; 涂层体系腐蚀240 h, 熔盐组分渗透Yb2SiO5涂层, 在Yb2Si2O7中间层发生富集。涂层中Yb2SiO5相具有良好的稳定性, Yb2O3第二相与熔盐发生反应, 且随腐蚀时间延长, Yb2O3含量减少。中间层Yb2Si2O7相与熔盐反应生成磷灰石相NaYb9Si6O26和钠硅酸盐, 并产生Cl2和SO2等挥发性物质, 从而影响服役寿命。硅黏结层中未发现熔盐渗透现象, 保持完整。该涂层体系具有良好的抗熔盐腐蚀性能。

中图分类号:

刘平平, 钟鑫, 张乐, 李红, 牛亚然, 张翔宇, 李其连, 郑学斌. 硅酸镱环境障涂层抗熔盐腐蚀行为与机制研究[J]. 无机材料学报, 2022, 37(12): 1267-1274.

LIU Pingping, ZHONG Xin, ZHANG Le, LI Hong, NIU Yaran, ZHANG Xiangyu, LI Qilian, ZHENG Xuebin. Molten Salt Corrosion Behaviors and Mechanisms of Ytterbium Silicate Environmental Barrier Coating[J]. Journal of Inorganic Materials, 2022, 37(12): 1267-1274.

| Yb2SiO5 | Yb2Si2O7 | Si | |

|---|---|---|---|

| Primary Ar/(L·min-1) | 46 | 53 | 52 |

| Secondary H2/(L·min-1) | 14 | 10 | 13 |

| Carrier Ar/(L·min-1) | 2.3 | 2.3 | 2.0 |

| Spray distance/mm | 220 | 220 | 290 |

表1 真空等离子喷涂参数

Table 1 Operating parameters used for vacuum plasma spraying

| Yb2SiO5 | Yb2Si2O7 | Si | |

|---|---|---|---|

| Primary Ar/(L·min-1) | 46 | 53 | 52 |

| Secondary H2/(L·min-1) | 14 | 10 | 13 |

| Carrier Ar/(L·min-1) | 2.3 | 2.3 | 2.0 |

| Spray distance/mm | 220 | 220 | 290 |

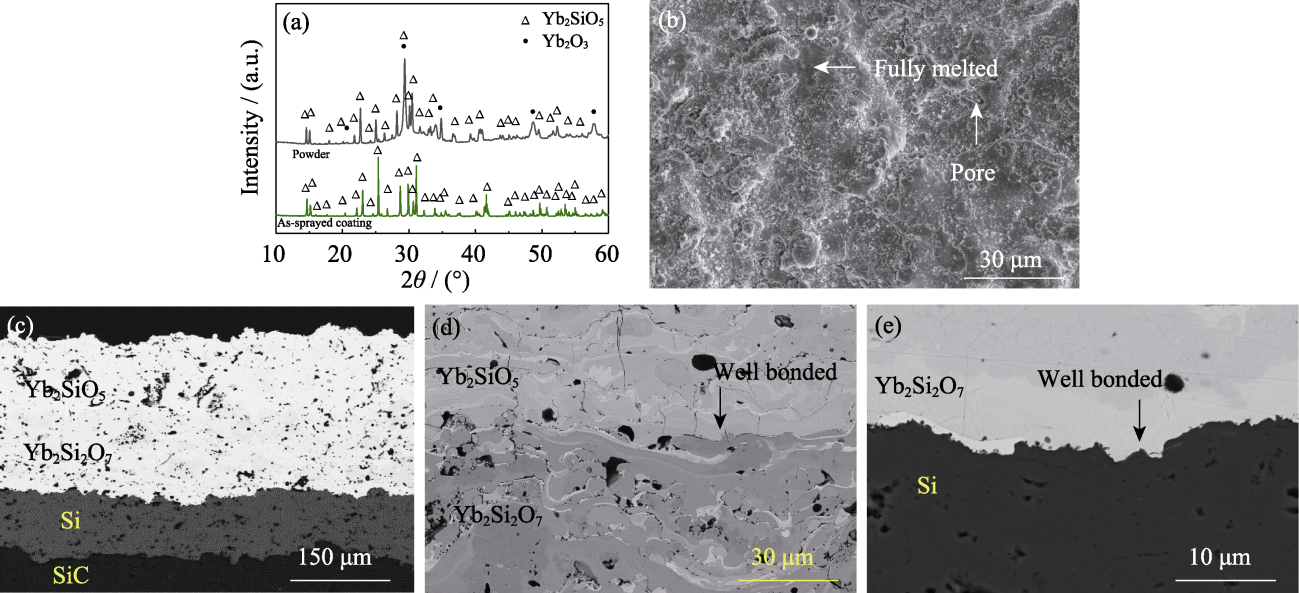

图1 喷涂态Yb2SiO5/Yb2Si2O7/Si涂层的XRD图谱和显微结构

Fig. 1 XRD patterns and SEM morphologies of as-sprayed Yb2SiO5/Yb2Si2O7/Si coating (a) XRD patterns; (b) Surface morphology; (c-e) Cross-sectional morphologies

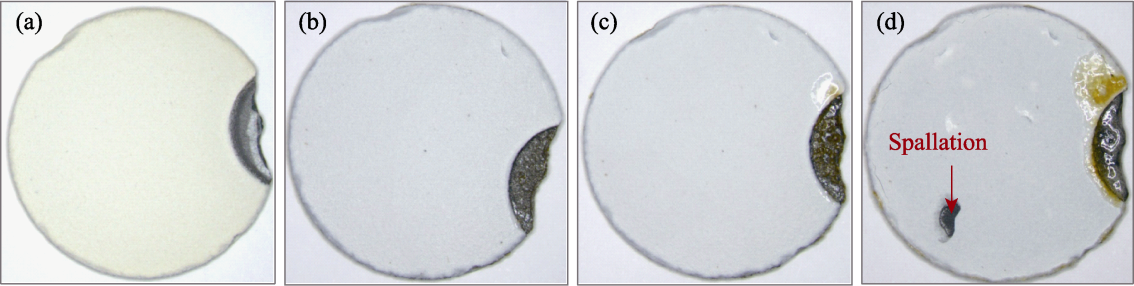

图2 Yb2SiO5/Yb2Si2O7/Si涂层熔盐腐蚀不同时间的宏观形貌

Fig. 2 Macro-photographs of Yb2SiO5/Yb2Si2O7/Si coating after molten salt corrosion for different time (a) As-sprayed; (b) 60 h; (c)100 h; (d) 240 h

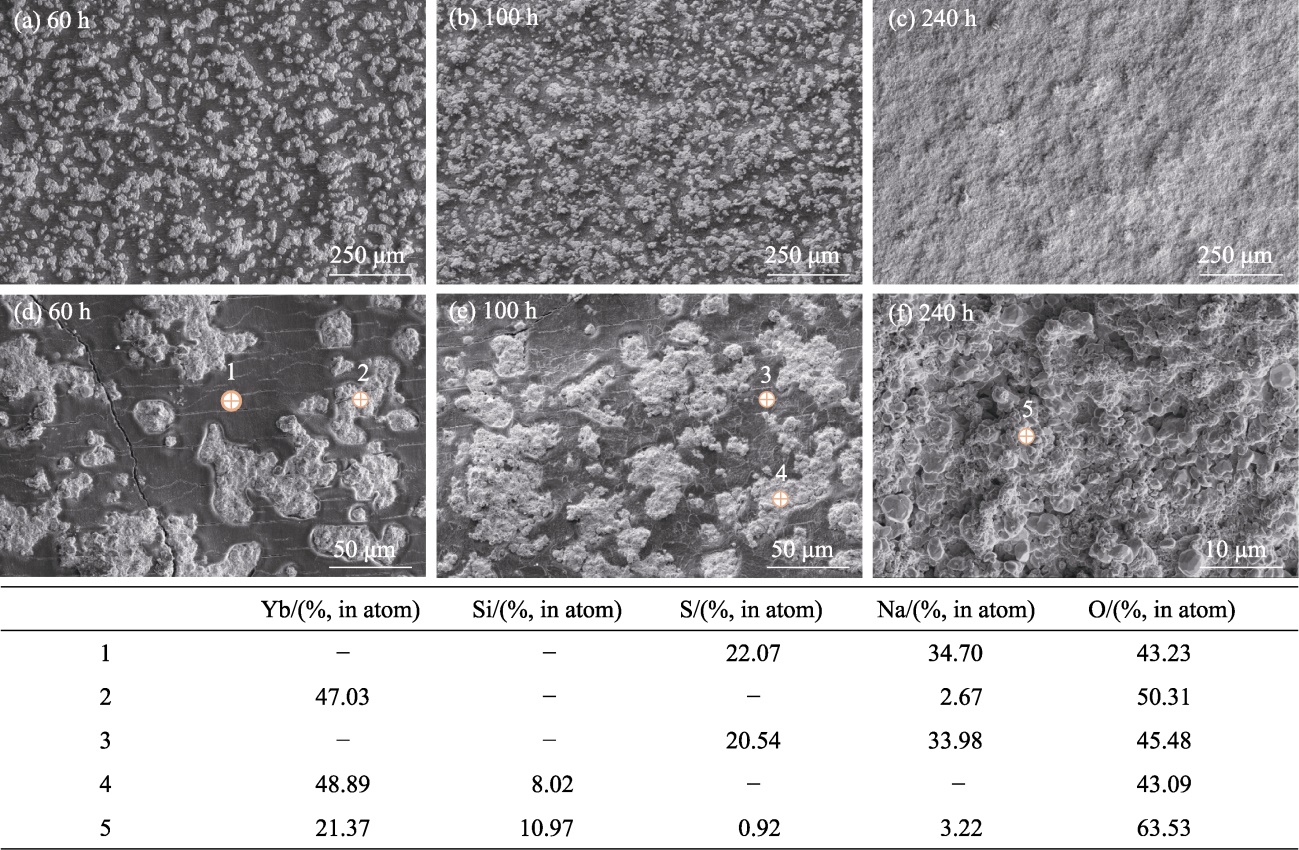

图4 Yb2SiO5/Yb2Si2O7/Si涂层经熔盐腐蚀不同时间的低倍和高倍形貌及其不同位置元素分析

Fig. 4 Surface morphologies of Yb2SiO5/Yb2Si2O7/Si coating after molten salt corrosion for different time and correponding EDS analyses of different areas (a-c) Low magnification; (d-f) High magnification

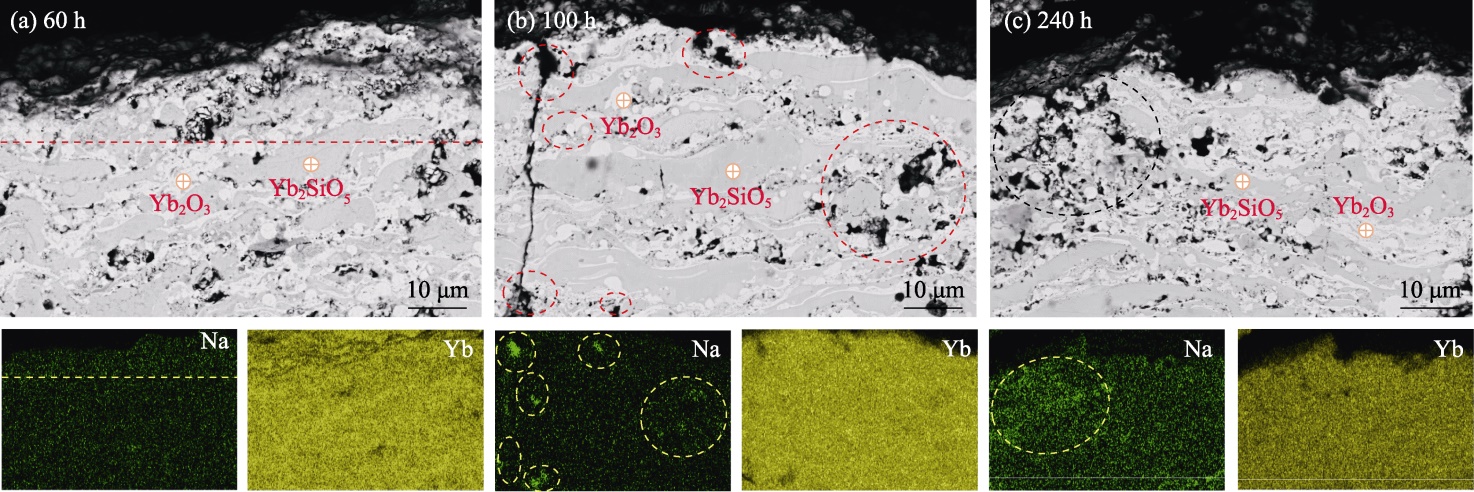

图5 Yb2SiO5 面层经熔盐腐蚀不同时间的截面形貌及其元素面分析

Fig. 5 Cross-sectional morphologies and corresponding element analyses of Yb2SiO5 top layer after molten salt corrosion for different time

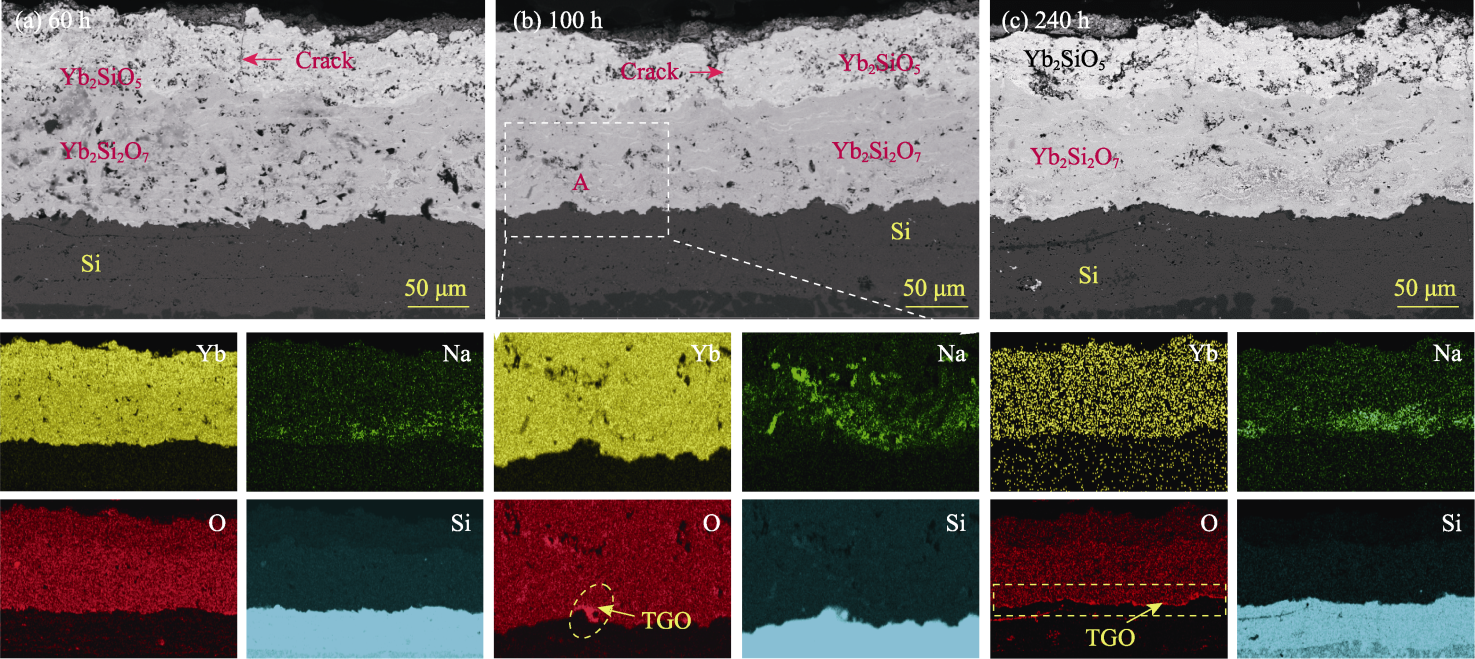

图6 Yb2SiO5/Yb2Si2O7/Si涂层经熔盐腐蚀不同时间的截面形貌及其EDS元素面分析

Fig. 6 Cross-sectional morphologies and corresponding EDS element mappings of Yb2SiO5/Yb2Si2O7/Si EBCs after molten salt corrosion for different time Colorful figures are available on website

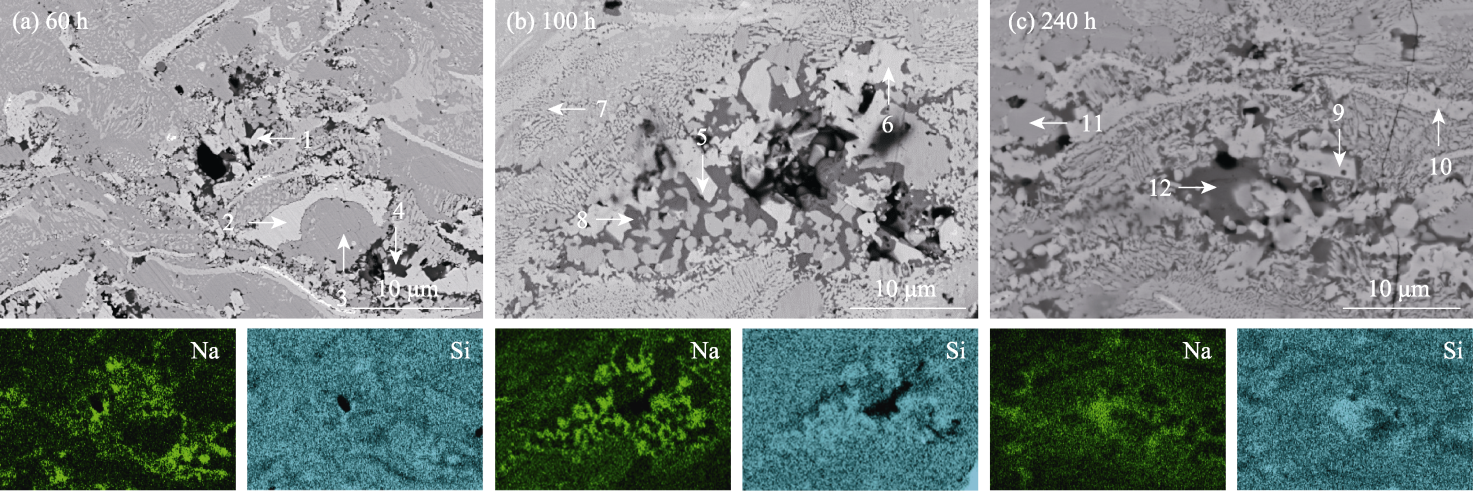

图7 经Na2SO4+25% NaCl熔盐腐蚀不同时间的涂层体系Yb2Si2O7中间层渗透区高倍截面形貌及EDS元素面分析

Fig. 7 High-magnification cross-sectional morphologies and corresponding EDS mappings of infiltration zone in Yb2Si2O7 interlayer after molten salt corrosion for different time Colorful figures are available on website

| Position | Yb | Si | Na | O |

|---|---|---|---|---|

| 1 | 21.69 | 14.27 | 1.98 | 62.06 |

| 2 | 24.91 | 12.57 | - | 62.52 |

| 3 | 18.29 | 18.09 | - | 63.62 |

| 4 | 10.15 | 18.67 | 2.41 | 58.77 |

| 5 | 22.50 | 13.75 | 1.67 | 62.08 |

| 6 | 24.92 | 12.57 | - | 62.51 |

| 7 | 18.03 | 18.31 | - | 63.66 |

| 8 | 8.95 | 19.25 | 13.25 | 58.55 |

| 9 | 22.93 | 13.20 | 2.04 | 61.82 |

| 10 | 24.45 | 12.96 | - | 62.59 |

| 11 | 17.82 | 18.04 | - | 63.25 |

| 12 | 8.91 | 19.21 | 13.39 | 58.49 |

表2 图7中标记区域的EDS元素组成/%(原子分数)

Table 2 EDS elemental compositions of the marked regions in Fig. 7/%(in atom)

| Position | Yb | Si | Na | O |

|---|---|---|---|---|

| 1 | 21.69 | 14.27 | 1.98 | 62.06 |

| 2 | 24.91 | 12.57 | - | 62.52 |

| 3 | 18.29 | 18.09 | - | 63.62 |

| 4 | 10.15 | 18.67 | 2.41 | 58.77 |

| 5 | 22.50 | 13.75 | 1.67 | 62.08 |

| 6 | 24.92 | 12.57 | - | 62.51 |

| 7 | 18.03 | 18.31 | - | 63.66 |

| 8 | 8.95 | 19.25 | 13.25 | 58.55 |

| 9 | 22.93 | 13.20 | 2.04 | 61.82 |

| 10 | 24.45 | 12.96 | - | 62.59 |

| 11 | 17.82 | 18.04 | - | 63.25 |

| 12 | 8.91 | 19.21 | 13.39 | 58.49 |

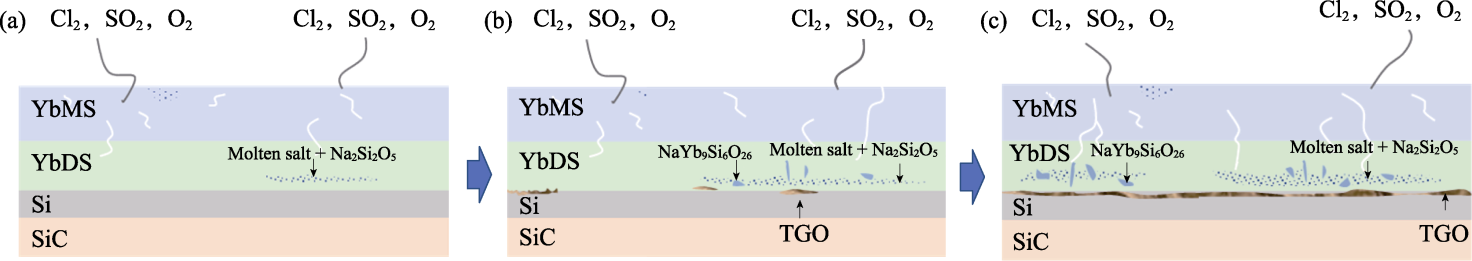

图8 Yb2SiO5/Yb2Si2O7/Si涂层经900 ℃、Na2SO4+25% NaCl熔盐腐蚀示意图

Fig. 8 Schematic diagrams of Yb2SiO5/Yb2Si2O7/Si coating under Na2SO4+25% NaCl molten salt corrosion at 900 ℃

| [1] |

PADTURE N P. Advanced structural ceramics in aerospace propulsion. Nature Materials, 2016, 15(8): 804-809.

DOI PMID |

| [2] | LEE K N, FOX D S, ELDRIDGE J I, et al. Advanced environmental barrier coatings developed for SiC/SiC composite vanes (2022-06-01). https://ntrs.nasa.gov/search.jsp?R=20050214693. |

| [3] |

EATON H E, LINSEY G D. Accelerated oxidation of SiC CMC's by water vapor and protection via environmental barrier coating approach. Journal of the European Ceramic Society, 2002, 22(14/15): 2741-2747.

DOI URL |

| [4] |

RICHARDS B T, WADLEY H N G. Plasma spray deposition of tri-layer environmental barrier coatings. Journal of the European Ceramic Society, 2014, 34(12): 3069-3083.

DOI URL |

| [5] |

TIAN Z L, ZHENG L Y, WANG J M, et al. Theoretical and experimental determination of the major thermo-mechanical properties of RE2SiO5 (RE=Tb, Dy, Ho, Er, Tm, Yb, Lu, and Y) for environmental and thermal barrier coating applications. Journal of the European Ceramic Society, 2016, 36(1): 189-202.

DOI URL |

| [6] |

LIU J, ZHANG L T, LIU Q M, et al. Calcium-magnesium- aluminosilicate corrosion behaviors of rare-earth disilicates at 1400 ℃. Journal of the European Ceramic Society, 2013, 33(15/16): 3419-3428.

DOI URL |

| [7] |

JIANG F R, CHENG L F, WANG Y G. Hot corrosion of RE2SiO5 with different cation substitution under calcium-magnesium- aluminosilicate attack. Ceramics International, 2017, 43(12): 9019-9023.

DOI URL |

| [8] |

DONG Y, REN K, LU Y H, et al. High-entropy environmental barrier coating for the ceramic matrix composites. Journal of the European Ceramic Society, 2019, 39(7): 2574-2579.

DOI URL |

| [9] |

SUN L C, REN X M, DU T F, et al. High entropy engineering: new strategy for the critical property optimizations of rare earth silicates. Journal of Inorganic Materials, 2021, 36(4): 339-346.

DOI |

| [10] |

ZHONG X, NIU Y R, LI H, et al. Thermal shock resistance of tri-layer Yb2SiO5/Yb2Si2O7/Si coating for SiC and SiC-matrix composites. Journal of the American Ceramic Society, 2018, 101(10): 4743-4752.

DOI URL |

| [11] |

ZHU T, NIU Y R, ZHONG X, et al. Influence of phase composition on microstructure and thermal properties of ytterbium silicate coatings deposited by atmospheric plasma spray. Journal of the European Ceramic Society, 2018, 38(11): 3974-3985.

DOI URL |

| [12] |

ZHONG X, NIU Y R, LI HONG, et al. Microstructure evolution and thermomechanical properties of plasma-sprayed Yb2SiO5 coating during thermal aging. Journal of the American Ceramic Society, 2017, 100(5): 1896-1906.

DOI URL |

| [13] |

ZHONG X, WANG Y W, NIU Y R, et al. Corrosion behaviors and mechanisms of ytterbium silicate environmental barrier coatings by molten calcium-magnesium-alumino-silicate melts. Corrosion Science, 2021, 191: 109718.

DOI URL |

| [14] |

WANG Y W, NIU Y R, ZHONG X, et al. Water vapor corrosion behaviors of plasma sprayed RE2SiO5 (RE=Gd, Y, Er) coatings. Corrosion Science, 2020, 167: 108529.

DOI URL |

| [15] | ZHONG X, ZHU T, NIU Y R, et al. Effect of microstructure evolution and crystal structure on thermal properties for plasma- sprayed RE2SiO5 (RE=Gd, Y, Er) environmental barrier coatings. Journal of Materials Science & Technology, 2021, 85: 141-151. |

| [16] |

LI G, QIN L, CAO X Q, et al. Water vapor corrosion resistance and failure mechanism of SiCf/SiC composites completely coated with plasma sprayed tri-layer EBCs. Ceramics International, 2022, 48(5): 7082-7092.

DOI URL |

| [17] |

LEE K N, FOX D S, BANSAL N P. Rare earth silicate environmental barrier coatings for SiC/SiC composites and Si3N4 ceramics. Journal of the European Ceramic Society, 2005, 25(10): 1705-1715.

DOI URL |

| [18] |

ZHANG X F, ZHOU K S, LIU M, et al. Preparation of Si/mullite/ Yb2SiO5 environment barrier coating (EBC) by plasma spray- physical vapor deposition (PS-PVD). Journal of Inorganic Materials, 2018, 33(3): 325-330.

DOI URL |

| [19] | WANG C, ZHANG X F, ZHOU K S, et al. Nano-composite structured environmental barrier coat-ings prepared by plasma spray- physical vapor deposition and their thermal cycle performance. Rare Metal Materials and Engineering, 2019, 48(11): 3455-3462 |

| [20] |

ZHANG X F, SONG J B, DENG Z Q, et al. Interface evolution of Si/Mullite/Yb2SiO5 PS-PVD environmental barrier coatings under high temperature. Journal of the European Ceramic Society, 2020, 40(4): 1478-1487.

DOI URL |

| [21] |

ZHANG X F, ZHOU K S, LIU M, et al. Oxidation and thermal shock resistant properties of Al-modified environmental barrier coating on SiCf/SiC composites. Ceramics International, 2017, 43(16): 13075-13082.

DOI URL |

| [22] |

HU X X, XU F F, LI K W, et al. Water vapor corrosion behavior and failure mechanism of plasma sprayed mullite/Lu2Si2O7-Lu2SiO5 coatings. Ceramics International, 2018, 44(12): 14177-14185.

DOI URL |

| [23] | LIU P P, ZHONG X, NIU Y R, et al. Reaction behaviors and mechanisms of tri-layer Yb2SiO5/Yb2Si2O7/Si environmental barrier coatings with molten calcium-magnesium-alumino-silicate. Corrosion Science, 2022: 110069. |

| [24] |

WU S J, CHENG L F, ZHANG L T, et al. Corrosion of SiC/SiC composite in Na2SO4 vapor environments from 1000 ℃ to 1500 ℃. Composites Part A: Applied Science and Manufacturing, 2006, 37(9): 1396-1401.

DOI URL |

| [25] |

KOSIENIAK E, BIESIADA K, KACZOROWSKI J, et al. Corrosion failures in gas turbine hot components. Journal of Failure Analysis and Prevention, 2012, 12(3): 330-337.

DOI URL |

| [26] |

JACOBSON N S. Kinetics and mechanism of corrosion of SiC by molten salts. Journal of the American Ceramic Society, 1986, 69(1): 74-82.

DOI URL |

| [27] |

HERWEYER L A, OPILA E J. High-temperature Na2SO4 interaction with air plasma sprayed Yb2Si2O7+Si EBC system: Topcoat behavior. Journal of the American Ceramic Society, 2021, 104(12): 6496-6507.

DOI URL |

| [28] |

LI L, LU J, LIU X Z, et al. AlxCoCrFeNi high entropy alloys with superior hot corrosion resistance to Na2SO4+25% NaCl at 900 ℃. Corrosion Science, 2021, 187: 109479.

DOI URL |

| [29] |

HAGAN J M, OPILA E J. High-temperature Na2SO4 deposit- assisted corrosion of silicon carbide-I: temperature and time dependence. Journal of the American Ceramic Society, 2015, 98(4): 1275-1284.

DOI URL |

| [30] |

SUN Z Q, LI M S, ZHOU Y C. Kinetics and mechanism of hot corrosion of γ-Y2Si2O7 in thin-film Na2SO4 molten salt. Journal of the American Ceramic Society, 2008, 91(7): 2236-2242.

DOI URL |

| [31] |

FAN X Y, SUN R J, DONG J, et al. Effects of sintering additives on hot corrosion behavior of γ-Y2Si2O7 ceramics in Na2SO4+V2O5 molten salt. Journal of the European Ceramic Society, 2021, 41(1): 517-525.

DOI URL |

| [32] |

LATSHAW A M, YEON J, SMITH M D, et al. Synthesis, structure, and polymorphism of A3LnSi2O7 (A=Na, K; Ln=Sm, Ho, Yb). Journal of Solid State Chemistry, 2016, 235: 100-106.

DOI URL |

| [33] |

LATSHAW A M, WILKINS B O, CHANCE W M, et al. Influence of rare earth cation size on the crystal structure in rare earth silicates, Na2RESiO4 (OH) (RE=Sc, Yb) and NaRESiO4 (RE=La, Yb). Solid State Sciences, 2016, 51: 59-65.

DOI URL |

| [34] |

JONNALAGADDA K P, MAHADE S, KRAMER S, et al. Failure of multilayer suspension plasma sprayed thermal barrier coatings in the presence of Na2SO4 and NaCl at 900 ℃. Journal of Thermal Spray Technology, 2019, 28(1): 212-222.

DOI URL |

| [35] | 蒋凤瑞. B1-xSxAS及稀土硅酸盐环境障碍涂层热腐蚀性能研究. 西安: 西北工业大学博士学位论文, 2017. |

| [1] | 梁锐辉, 钟鑫, 洪督, 黄利平, 牛亚然, 郑学斌. Yb2O3改性硅黏结层的环境障涂层体系耐高温水氧腐蚀行为研究[J]. 无机材料学报, 2025, 40(4): 425-432. |

| [2] | 李捷, 罗志新, 崔阳, 张广珩, 孙鲁超, 王京阳. 大气等离子喷涂Y3Al5O12/Al2O3陶瓷涂层的CMAS腐蚀抗力[J]. 无机材料学报, 2024, 39(6): 671-680. |

| [3] | 范栋, 钟鑫, 王亚文, 张振忠, 牛亚然, 李其连, 张乐, 郑学斌. 富铝CMAS对稀土硅酸盐环境障涂层的腐蚀行为与机制研究[J]. 无机材料学报, 2023, 38(5): 544-552. |

| [4] | 孙鲁超, 任孝旻, 杜铁锋, 罗颐秀, 张洁, 王京阳. 高熵化设计: 稀土硅酸盐材料关键性能优化新策略[J]. 无机材料学报, 2021, 36(4): 339-346. |

| [5] | 张小锋, 周克崧, 刘敏, 邓春明, 牛少鹏, 许世鸣. 等离子喷涂-物理气相沉积Si/莫来石/Yb2SiO5环境障涂层[J]. 无机材料学报, 2018, 33(3): 325-330. |

| [6] | 张小锋, 周克崧, 宋进兵, 邓春明, 牛少鹏, 邓子谦. 等离子喷涂-物理气相沉积7YSZ热障涂层沉积机理及 其CMAS腐蚀失效机制[J]. 无机材料学报, 2015, 30(3): 287-293. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||