无机材料学报 ›› 2025, Vol. 40 ›› Issue (4): 415-424.DOI: 10.15541/jim20240378 CSTR: 32189.14.10.15541/jim20240378

袁利萍1( ), 吴袁泊1, 俞佳静1, 张世琰1, 孙铱1, 胡云楚1, 范友华2(

), 吴袁泊1, 俞佳静1, 张世琰1, 孙铱1, 胡云楚1, 范友华2( )

)

收稿日期:2024-08-15

修回日期:2024-12-16

出版日期:2025-04-20

网络出版日期:2024-12-27

通讯作者:

范友华, 研究员. E-mail: yh_fan@163.com作者简介:袁利萍(1975-), 女, 副教授. E-mail: tiansiyuan@126.com

基金资助:

YUAN Liping1( ), WU Yuanbo1, YU Jiajing1, ZHANG Shiyan1, SUN Yi1, HU Yunchu1, FAN Youhua2(

), WU Yuanbo1, YU Jiajing1, ZHANG Shiyan1, SUN Yi1, HU Yunchu1, FAN Youhua2( )

)

Received:2024-08-15

Revised:2024-12-16

Published:2025-04-20

Online:2024-12-27

Contact:

FAN Youhua, professor. E-mail: yh_fan@163.comAbout author:YUAN Liping (1975-), female, associate professor. E-mail: tiansiyuan@126.com

Supported by:摘要:

轻质、隔热和耐高温材料是航天人员和精密设备的必要保障。纳米纤维素(CNFs)因高比表面积、低热膨胀系数和高强度等特性, 在轻质航天航空材料领域具有潜在的应用前景, 但是质脆易燃限制了其在高温领域的广泛应用。为了提升CNFs的耐高温性能, 本工作采用共沉淀法和离子交换法成功制备了[PMo12O40]3-插层改性的ZnAl-PMo12O40-LDHs(PMo-LDHs, LDHs: 类水滑石插层材料), 将其与硼酸(BA)复合CNFs制备了PMo-LDHs+BA/CNFs气凝胶。当PMo-LDHs和BA的质量分数分别为CNFs的62.5%和2.0%时, 所制得的62.5PMo-LDHs+BA/CNFs气凝胶的密度为16.28 kg·m-3, 导热系数为0.044 W/(m·K)。隔热背温实验表明, 该气凝胶的t250(隔热背温达到250 ℃所需时间)长达2022.8 s, 比纯CNFs延长867.8 s; 其R250(隔热背温达到250 ℃时的升温速率)只有0.124 ℃·s-1, 仅为纯CNFs R250的57.4%, 表现出优异的隔热保温性能。灼烧实验显示, 纯CNFs气凝胶在15 s内完全燃烧, 而62.5PMo-LDHs+BA/CNFs气凝胶在81 s内未被点燃, 且未出现明显收缩或变形。燃烧残余物的形貌结果表明, PMo-LDHs受热分解, 在CNFs基材表面催化形成致密均匀的连续炭层, 从而提高了CNFs气凝胶的耐火性能。

中图分类号:

袁利萍, 吴袁泊, 俞佳静, 张世琰, 孙铱, 胡云楚, 范友华. 磷钼酸插层水滑石复合CNFs气凝胶的制备及其隔热保温性能[J]. 无机材料学报, 2025, 40(4): 415-424.

YUAN Liping, WU Yuanbo, YU Jiajing, ZHANG Shiyan, SUN Yi, HU Yunchu, FAN Youhua. CNFs Aerogel Composite with Phosphomolybdic Acid Intercalated Hydrotalcite: Preparation and Thermal Insulation Performance[J]. Journal of Inorganic Materials, 2025, 40(4): 415-424.

| No. | Sample | CNFs/mL | NO3-LDHs/g | PMo-LDHs/g | BA/g | ρ/(kg·m-3) |

|---|---|---|---|---|---|---|

| 1 | CNFs | 10.0 | — | — | — | 10.01 |

| 2 | NO3-LDHs/CNFs | 10.0 | 0.0375 | — | — | 14.12 |

| 3 | PMo-LDHs/CNFs | 10.0 | — | 0.0375 | — | 14.23 |

| 4 | NO3-LDHs+BA/CNFs | 10.0 | 0.0375 | — | 0.0020 | 14.67 |

| 5 | PMo-LDHs+BA/CNFs | 10.0 | — | 0.0375 | 0.0020 | 14.95 |

| 6 | 50.0PMo-LDHs+BA/CNFs | 10.0 | — | 0.0500 | 0.0020 | 15.72 |

| 7 | 62.5PMo-LDHs+BA/CNFs | 10.0 | — | 0.0625 | 0.0020 | 16.28 |

表1 LDHs/CNFs气凝胶的组成配方和密度

Table 1 Composition formula and density of LDHs/CNFs aerogel

| No. | Sample | CNFs/mL | NO3-LDHs/g | PMo-LDHs/g | BA/g | ρ/(kg·m-3) |

|---|---|---|---|---|---|---|

| 1 | CNFs | 10.0 | — | — | — | 10.01 |

| 2 | NO3-LDHs/CNFs | 10.0 | 0.0375 | — | — | 14.12 |

| 3 | PMo-LDHs/CNFs | 10.0 | — | 0.0375 | — | 14.23 |

| 4 | NO3-LDHs+BA/CNFs | 10.0 | 0.0375 | — | 0.0020 | 14.67 |

| 5 | PMo-LDHs+BA/CNFs | 10.0 | — | 0.0375 | 0.0020 | 14.95 |

| 6 | 50.0PMo-LDHs+BA/CNFs | 10.0 | — | 0.0500 | 0.0020 | 15.72 |

| 7 | 62.5PMo-LDHs+BA/CNFs | 10.0 | — | 0.0625 | 0.0020 | 16.28 |

| Sample | d(003)/nm | d(006)/nm | d(009)/nm | d(110)/nm | 2θ(003)/(o) | a/nm | c/nm |

|---|---|---|---|---|---|---|---|

| NO3-LDHs | 0.888 | 0.445 | 0.265 | 0.153 | 9.94 | 0.307 | 2.67 |

| PMo-LDHs | 0.975 | 0.488 | 0.267 | 0.153 | 9.06 | 0.306 | 2.92 |

表2 NO3-LDHs与PMo-LDHs的晶面间距和晶格参数

Table 2 Interplanar spacing and lattice parameters of NO3-LDHs and PMo-LDHs

| Sample | d(003)/nm | d(006)/nm | d(009)/nm | d(110)/nm | 2θ(003)/(o) | a/nm | c/nm |

|---|---|---|---|---|---|---|---|

| NO3-LDHs | 0.888 | 0.445 | 0.265 | 0.153 | 9.94 | 0.307 | 2.67 |

| PMo-LDHs | 0.975 | 0.488 | 0.267 | 0.153 | 9.06 | 0.306 | 2.92 |

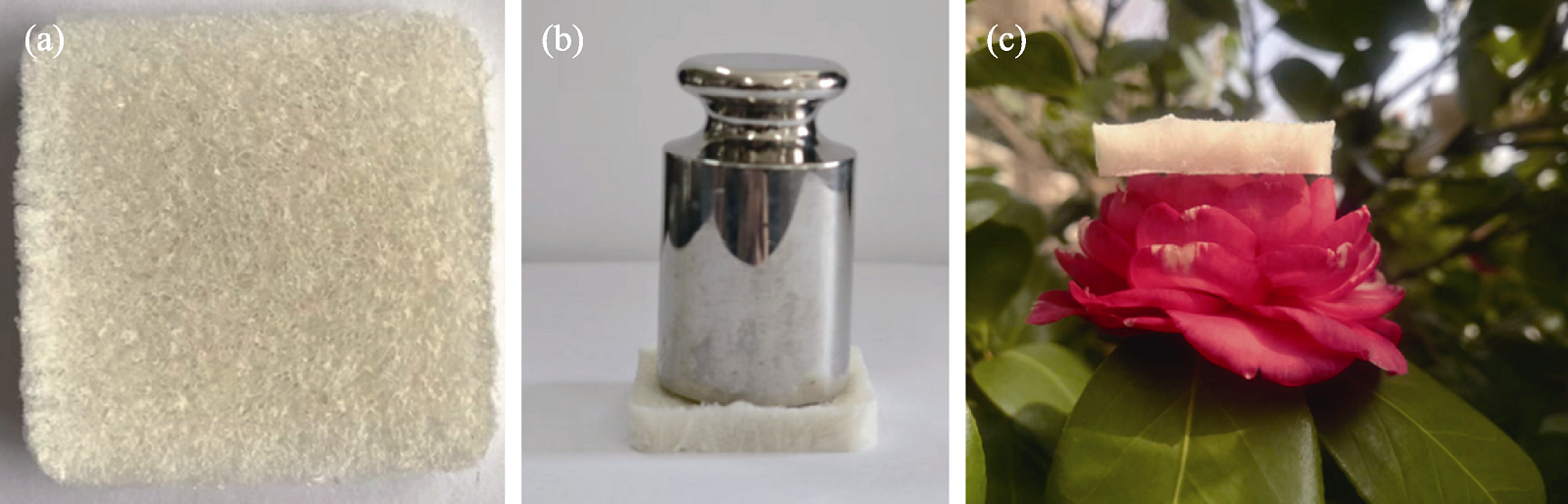

图4 62.5PMo-LDHs+BA/CNFs气凝胶的(a)外观形貌及其置于(b)砝码下和(c)花瓣上的照片

Fig. 4 Morphology of 62.5PMo-LDHs+BA/CNFs aerogel (a) and digital photos when it placed (b) under weight and (c) on petals

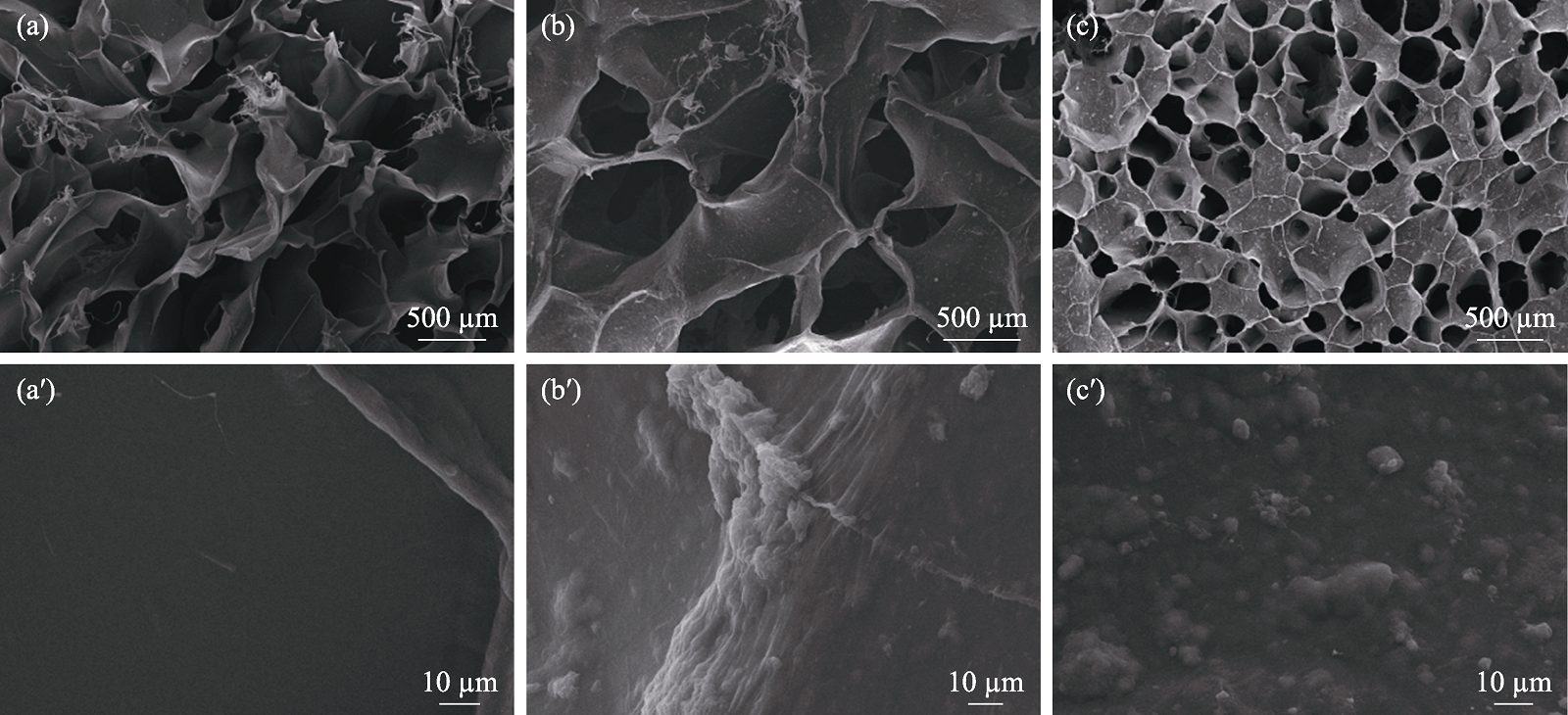

图5 (a, a')纯CNFs、(b, b')NO3-LDHs+BA/CNFs和(c, c') 62.5PMo-LDHs+BA/CNFs气凝胶的SEM照片

Fig. 5 SEM images of (a, a') pure CNFs, (b, b') NO3-LDHs+BA/CNFs, and (c, c') 62.5PMo-LDHs+BA/CNFs aerogels

| Sample | T1/℃ | R1/(%·℃-1) | T2/℃ | R2/(%·℃-1) | T50/℃ | M800/% |

|---|---|---|---|---|---|---|

| CNFs | 56.7 | 0.186 | 257.3 | 0.569 | 297.1 | 20.8 |

| NO3-LDHs/CNFs | 58.1 | 0.160 | 304.5 | 0.595 | 322.7 | 23.6 |

| PMo-LDHs/CNFs | 55.7 | 0.172 | 286.8 | 0.418 | 360.1 | 27.3 |

| NO3-LDHs+BA/CNFs | 48.2 | 0.157 | 305.6 | 0.587 | 348.7 | 27.2 |

| PMo-LDHs+BA/CNFs | 53.5 | 0.169 | 295.8 | 0.401 | 381.2 | 27.6 |

| 50.0PMo-LDHs+BA/CNFs | 51.8 | 0.154 | 294.1 | 0.352 | 423.4 | 31.9 |

| 62.5PMo-LDHs+BA/CNFs | 50.7 | 0.127 | 282.2 | 0.306 | 620.2 | 38.9 |

表3 LDHs/CNFs气凝胶的TG/DTG参数

Table 3 TG/DTG parameters of LDHs/CNFs aerogels

| Sample | T1/℃ | R1/(%·℃-1) | T2/℃ | R2/(%·℃-1) | T50/℃ | M800/% |

|---|---|---|---|---|---|---|

| CNFs | 56.7 | 0.186 | 257.3 | 0.569 | 297.1 | 20.8 |

| NO3-LDHs/CNFs | 58.1 | 0.160 | 304.5 | 0.595 | 322.7 | 23.6 |

| PMo-LDHs/CNFs | 55.7 | 0.172 | 286.8 | 0.418 | 360.1 | 27.3 |

| NO3-LDHs+BA/CNFs | 48.2 | 0.157 | 305.6 | 0.587 | 348.7 | 27.2 |

| PMo-LDHs+BA/CNFs | 53.5 | 0.169 | 295.8 | 0.401 | 381.2 | 27.6 |

| 50.0PMo-LDHs+BA/CNFs | 51.8 | 0.154 | 294.1 | 0.352 | 423.4 | 31.9 |

| 62.5PMo-LDHs+BA/CNFs | 50.7 | 0.127 | 282.2 | 0.306 | 620.2 | 38.9 |

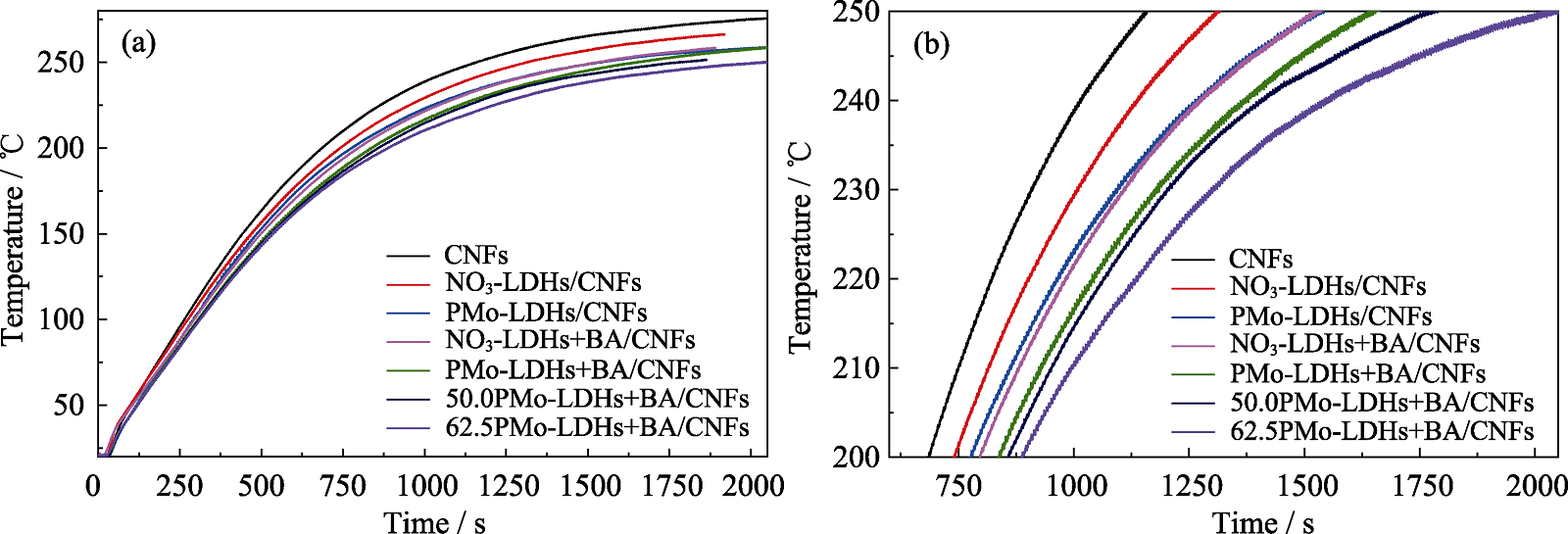

图8 LDHs/CNFs气凝胶的(a)隔热背温曲线和(b) 750 s后隔热背温曲线放大图

Fig. 8 Thermal insulation back-fire temperature curves (a) and magnified curves of thermal insulation back-fire temperature curves after 750 s (b) of LDHs/CNFs aerogels Colorful figures are available on website

| Sample | t200/s | t250/s | R200/(℃·s-1) | R250/(℃·s-1) | λ/(W·m-1·K-1) |

|---|---|---|---|---|---|

| CNFs | 685.4 | 1155.0 | 0.292 | 0.216 | 0.045 |

| NO3-LDHs/CNFs | 739.4 | 1306.6 | 0.270 | 0.191 | — |

| PMo-LDHs/CNFs | 776.7 | 1527.5 | 0.258 | 0.164 | — |

| NO3-LDHs+BA/CNFs | 793.5 | 1524.4 | 0.252 | 0.164 | 0.047 |

| PMo-LDHs+BA/CNFs | 837.6 | 1642.6 | 0.239 | 0.152 | — |

| 50.0PMo-LDHs+BA/CNFs | 857.6 | 1771.2 | 0.233 | 0.141 | — |

| 62.5PMo-LDHs+BA/CNFs | 886.5 | 2022.8 | 0.226 | 0.124 | 0.044 |

表4 LDHs/CNFs气凝胶的隔热背温参数和导热系数

Table 4 Thermal insulation back-fire temperature test parameters and thermal conductivity of LDHs/CNFs aerogels

| Sample | t200/s | t250/s | R200/(℃·s-1) | R250/(℃·s-1) | λ/(W·m-1·K-1) |

|---|---|---|---|---|---|

| CNFs | 685.4 | 1155.0 | 0.292 | 0.216 | 0.045 |

| NO3-LDHs/CNFs | 739.4 | 1306.6 | 0.270 | 0.191 | — |

| PMo-LDHs/CNFs | 776.7 | 1527.5 | 0.258 | 0.164 | — |

| NO3-LDHs+BA/CNFs | 793.5 | 1524.4 | 0.252 | 0.164 | 0.047 |

| PMo-LDHs+BA/CNFs | 837.6 | 1642.6 | 0.239 | 0.152 | — |

| 50.0PMo-LDHs+BA/CNFs | 857.6 | 1771.2 | 0.233 | 0.141 | — |

| 62.5PMo-LDHs+BA/CNFs | 886.5 | 2022.8 | 0.226 | 0.124 | 0.044 |

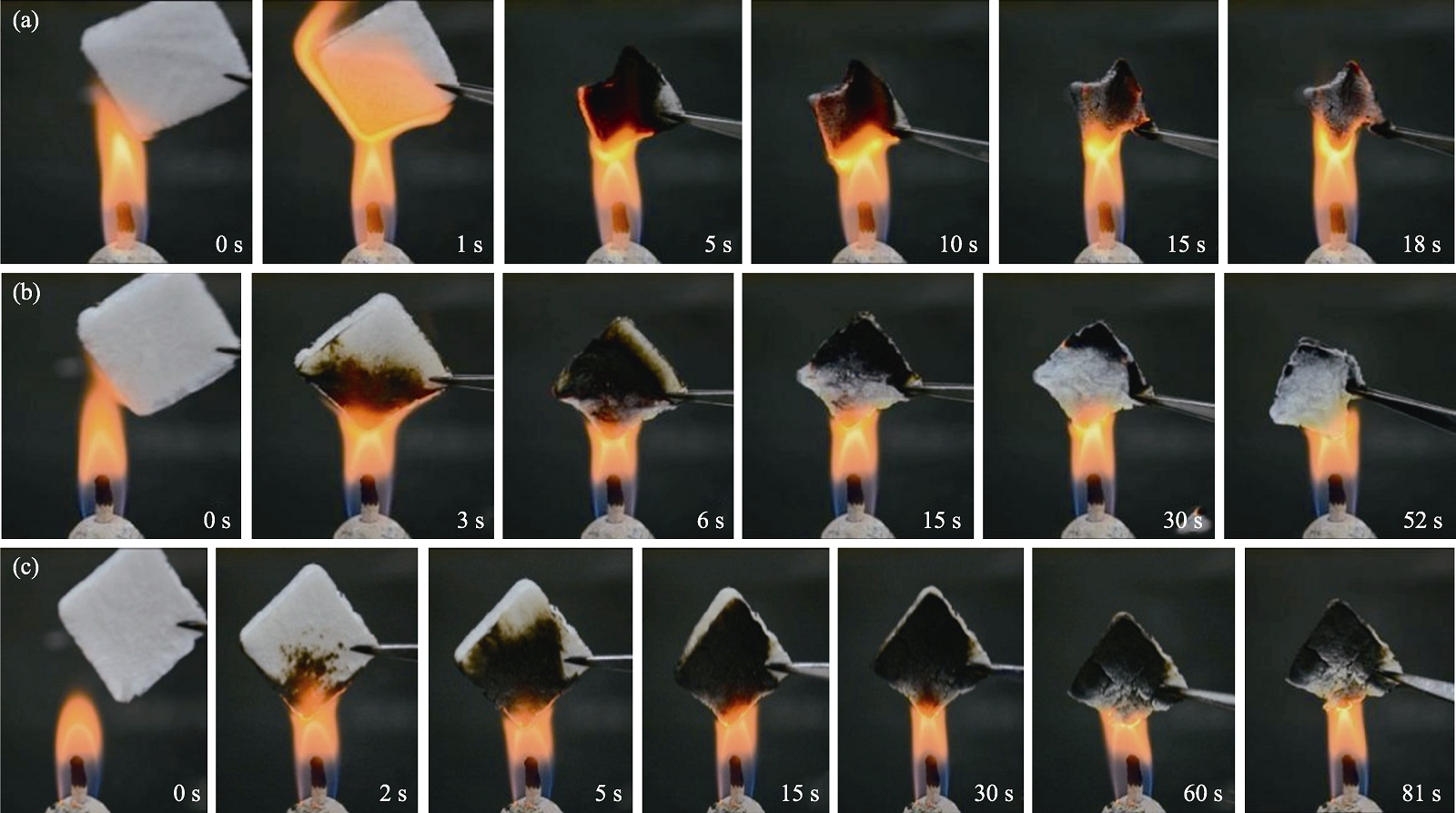

图9 (a)纯CNFs、(b) NO3-LDHs+BA/CNFs和(c) 62.5PMo-LDHs+BA/CNFs气凝胶的灼烧试验

Fig. 9 Combustion tests of (a) pure CNFs, (b) NO3-LDHs+BA/CNFs, and (c) 62.5PMo-LDHs+BA/CNFs aerogels

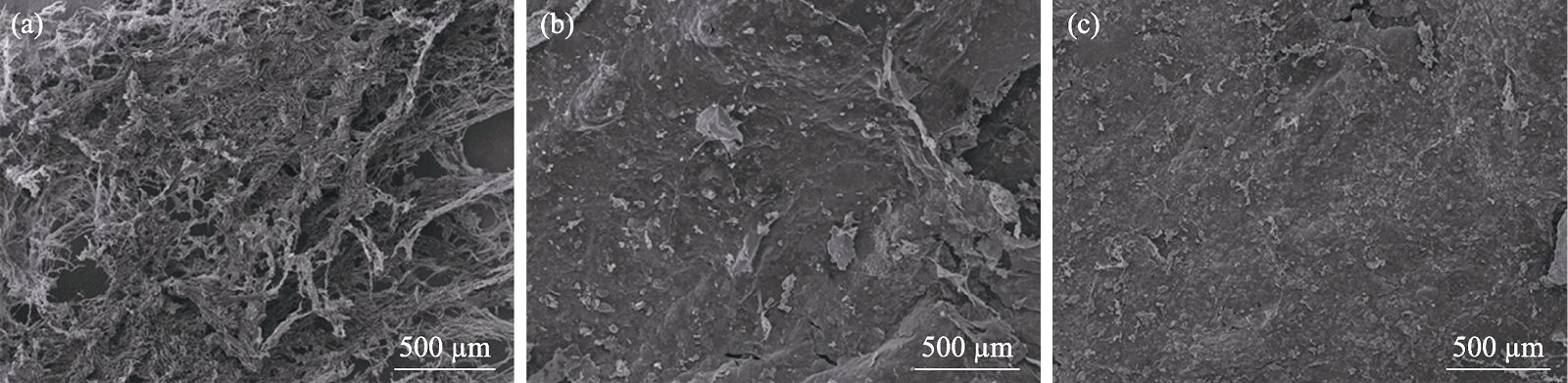

图10 (a)纯CNFs、(b) NO3-LDHs+BA/CNFs和(c) 62.5PMo-LDHs+BA/CNFs气凝胶灼烧残余物的SEM照片

Fig. 10 SEM images of combustion residues of (a) pure CNFs, (b) NO3-LDHs+BA/CNFs, and (c) 62.5PMo-LDHs+BA/CNFs aerogels

| [1] | LI Y G, LIU X F, DONG L H, et al. Preparation and high- temperature service performance of hierarchically pore-structured BN fiber aerogels. Ceramics International, 2022, 48(24):36287. |

| [2] | JIN R Z, ZHOU Z H, LIU J, et al. Aerogels for thermal protection and their application in aerospace. Gels, 2023, 9(8):606. |

| [3] | GUO P F, SU L, PENG K, et al. Additive manufacturing of resilient SiC nanowire aerogels. ACS Nano, 2022, 16(4):6625. |

| [4] | LIAO Y R, ZHANG S Z, YANG Z Y, et al. Ambient drying to fabricate polybenzoxazine aerogels for thermal insulation in aerospace. Materials Today Nano, 2024, 28: 100517. |

| [5] |

杨冬晖, 李猛, 尚坤. 航天服隔热材料技术研究进展. 航空材料学报, 2016, 36(2):87.

DOI |

| [6] |

CHHOWALLA M, JARIWALA D. Hyperbolic 3D architectures with 2D ceramics. Science, 2019, 363(6428):694.

DOI PMID |

| [7] | LI M M, XU Q Y, JIANG W, et al. Preparation and investigation of Fe3O4@rGO/CNF foams for electromagnetic interference shielding. Fibers and Polymers, 2023, 24: 771. |

| [8] | ZHOU X J, LI B, XU Y, et al. Tannin-furanic resin foam reinforced with cellulose nanofibers (CNF). Industrial Crops & Products, 2019, 134: 107. |

| [9] | SONG Y P, XUE C H, GUO W C, et al. Foamed geopolymer insulation materials: research progress on insulation performance and durability. Journal of Cleaner Production, 2024, 444: 140991. |

| [10] | ZHAO J J, LI S, TANG Y M. Preparation of building insulation foam materials by recycling industrial and agroforestry wastes. Journal of Building Engineering, 2023, 68: 105988. |

| [11] | BURATTI C, BELLONI E, LASCARO E, et al. Rice husk panels for building applications: thermal, acoustic and environmental characterization and comparison with other innovative recycled waste materials. Construction and Building Materials, 2018, 171: 338. |

| [12] | MUTHURAJ R, LACOSTE C, LACROIX P, et al. Sustainable thermal insulation biocomposites from rice husk, wheat husk, wood fibers and textile waste fibers: elaboration and performances evaluation. Industrial Crops and Products, 2019, 135: 238. |

| [13] | ALI M, ALABDULKAREM A, NUHAIT A, et al. Thermal and acoustic characteristics of novel thermal insulating materials made of eucalyptus globulus leaves and wheat straw fibers. Journal of Building Engineering, 2020, 32: 101. |

| [14] | LIU L, LI H Q, LAZZARETTO A, et al. The development history and prospects of biomass-based insulation materials for buildings. Renewable and Sustainable Energy Reviews, 2017, 69: 912. |

| [15] | KUMAR D, ALAM M, ZOU P X W, et al. Comparative analysis of building insulation material properties and performance. Renewable and Sustainable Energy Reviews, 2020, 131: 110. |

| [16] | WANG D, FENG X M, ZHANG L P, et al. Cyclotriphosphazene- bridged periodic mesoporous organosilica-integrated cellulose nanofiber aniso-tropic foam with highly flame-retardant and thermally insulating properties. Chemical Engineering Journal, 2019, 375: 121933. |

| [17] | CHRISTINE T G, VANESSA P, CLAUDE F, et al. Tailoring hybrid layered double hydroxides for the development of innovative applications. Advanced Functional Materials, 2017, 28(27):1702868. |

| [18] |

GUO Y X, WANG J, LI D Q, et al. Micrometer-sized dihydrogenphosphate-intercalated layered double hydroxides: synthesis, selective infrared absorption properties, and applications as agricultural films. Dalton Trans, 2018, 47(9):3144.

DOI PMID |

| [19] | HUANG F L, TIAN S Q, QI Y, et al. Synthesis of FePcS-PMA-LDH cointercalation composite with enhanced visible light photo-fenton catalytic activity for BPA degradation at circumneutral pH. Materials, 2020, 13(8): 1951. |

| [20] | PENG Y, WANG W, CAO J Z, et al. Synthesis of 5-sulfosalicylic acid-intercalated layered double hydroxide and its effects on wood flour/polypropylene composites during accelerated UV weathering. Journal of Applied Polymer Science, 2017, 134(11):44597. |

| [21] | LI L, MA R Z, EBINA Y, et al. Positively charged nanosheets derived via total delamination of layyered doubled hydroxides. Chemistry of Materials, 2005, 17: 4386. |

| [22] | ZHANG L L, CHEN K L, HE L. Super-reinforced photothermal stability of cellulose nanofibrils films by armour-type ordered doping Mg-Al layered double hydroxides. Carbohydrate Polymers, 2019, 212: 229. |

| [23] | ZHANG Z, SONG F F, ZHANG M, et al. Cellulose nanopaper with controllable optical haze and high efficiency ultraviolet blocking for flexible optoelectronics. Cellulose, 2019, 26(4): 2201. |

| [24] | DENG Y, GUAN Q Q, HE L, et al. The photothermal stability of CNFs/ ZnAl-LDHs composited films: influence of the crystal morphology of ZnAl-LDHs. Carbohydrate Polymers, 2021, 263: 117981. |

| [25] | KAUL P K, SAMSON J A, SELVAN T G, et al. Synergistic effect of LDH in the presence of organophosphate on thermal and flammable properties of an epoxy nanocomposite. Applied Clay Science, 2017, 135: 234. |

| [26] | CHEN C, TAO L, DU S Q, et al. Advanced exfoliation strategies for layered double hydroxides and applications in energy conversion and storage. Advanced Functional Materials, 2020, 30(14):1909832. |

| [27] | CHEN X, WAG B Y, HAO Z F, et al. Synergistic effect of multifunctional layered double hydroxide based hybrids and modified phosphagen with an active amino group for enhancing the smoke suppression and flame retardancy of epoxy. ACS Omega, 2022, 7(25):21714. |

| [28] | ZHANG S, YAN Y X, WANG W J, et al. Intercalation of phosphotungstic acid into layered double hydroxides by reconstruction method and its application in intumescent flame retardant poly (lactic acid) composites. Polymer Degradation and Stability, 2018, 147: 142. |

| [29] | XU Y, HUANG W J, CHEN X Y, et al. Self-assembled ZnAl-LDH/PMo12 nano-hybrids as effective catalysts on the degradation of methyl orange under room temperature and ambient pressure. Applied Catalysis A: General, 2018, 550: 206. |

| [30] | MENG R R, HE X M, CHEN J J, et al. Silver and sodium fluorescein co-doped phosphomolybdate microspindle: synthesis and spectroscopic properties. Journal of Cluster Science, 2019, 30: 141. |

| [31] | LI C, WU S P, CHEN Z W, et al. Synthesis of Fe3O4-decorated Mg-Al layered double hydroxides magnetic nanosheets to improve anti-ultraviolet aging and microwave absorption properties used in asphalt materials. Construction and Building Materials, 2019, 30(220):320. |

| [32] | LI W, ZHU J N, SHEN N N, et al. Assembling [M(P4Mo6)2] (M = Na, Mn, Na/Cu) dimeric clusters via transition metal/sodium ions into 0D to 3D phosphomolybdates. CrystEngComm, 2019, 21: 971. |

| [33] | HONG N N, SONG L, WANG B B, et al. Co-precipitation synthesis of reduced graphene oxide/NiAl-layered double hydroxide hybrid and its application in flame retarding poly (methyl methacrylate). Materials Research Bulletin, 2014, 49: 657. |

| [1] | 李福平, 褚家宝, 仇海波, 党薇, 李晨曦, 赵康, 汤玉斐. SiO2纤维气凝胶的压缩回弹机理[J]. 无机材料学报, 2025, 40(9): 981-988. |

| [2] | 张祥松, 刘业通, 王永瑛, 武子瑞, 刘振中, 李毅, 杨娟. 自组装制备PtIr合金气凝胶及其高效电催化氨氧化性能[J]. 无机材料学报, 2023, 38(5): 511-520. |

| [3] | 罗艺, 夏书海, 牛波, 张亚运, 龙东辉. 柔性有机硅气凝胶的制备及其高温无机化转变研究[J]. 无机材料学报, 2022, 37(12): 1281-1288. |

| [4] | 彭飞, 姜勇刚, 冯坚, 蔡华飞, 冯军宗, 李良军. 耐高温氧化铝气凝胶隔热复合材料研究进展[J]. 无机材料学报, 2021, 36(7): 673-684. |

| [5] | 张晓山, 王兵, 吴楠, 韩成, 吴纯治, 王应德. 高温隔热用微纳陶瓷纤维研究进展[J]. 无机材料学报, 2021, 36(3): 245-256. |

| [6] | 李一敏,王成乐,李娟. 磷钼酸盐中金属离子对聚丙烯阻燃效率的提升[J]. 无机材料学报, 2020, 35(9): 1029-1033. |

| [7] | 张泽,王晓栋,沈军. 气凝胶骨架结构的有机-无机交联度对其力学、热学性能的影响[J]. 无机材料学报, 2020, 35(4): 454-460. |

| [8] | 罗燚,冯军宗,冯坚,姜勇刚,李良军. 新型碳材料质子交换膜燃料电池Pt催化剂载体的研究进展[J]. 无机材料学报, 2020, 35(4): 407-415. |

| [9] | 柳凤琦, 冯坚, 姜勇刚, 李良军. 氮化硼气凝胶的制备及其应用进展[J]. 无机材料学报, 2020, 35(11): 1193-1202. |

| [10] | 丁卓峰, 杨永强, 李在均. 组氨酸功能化碳点/石墨烯气凝胶的制备及超级电容器性能[J]. 无机材料学报, 2020, 35(10): 1130-1136. |

| [11] | 吕子夜, 唐谊平, 曹华珍, 郑国渠, 侯广亚. V掺杂对Ni-Co-S/细菌纤维素基碳气凝胶电催化性能的影响[J]. 无机材料学报, 2020, 35(10): 1142-1148. |

| [12] | 朱召贤, 王飞, 姚鸿俊, 董金鑫, 龙东辉. 遮光剂掺杂Al2O3-SiO2气凝胶/莫来石纤维毡复合材料的高温隔热性能研究[J]. 无机材料学报, 2018, 33(9): 969-975. |

| [13] | 王勇, 于云, 冯爱虎, 江峰, 胡学兵, 宋力昕. Nafion改性多级孔径石墨烯气凝胶制备与性能研究[J]. 无机材料学报, 2018, 33(4): 469-474. |

| [14] | 杨景锋, 王齐华, 王廷梅. 氧化铝气凝胶的合成与性能[J]. 无机材料学报, 2018, 33(3): 259-265. |

| [15] | 何 飞, 李 亚, 骆 金, 方旻翰, 赫晓东. 具有气凝胶结构特征的C/SiO2和C/SiC复合材料研究进展[J]. 无机材料学报, 2017, 32(5): 449-458. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||