无机材料学报 ›› 2020, Vol. 35 ›› Issue (6): 661-668.DOI: 10.15541/jim20190359 CSTR: 32189.14.10.15541/jim20190359

所属专题: 结构陶瓷论文精选(二)

张志刚1,2,卢晓通1,2,刘金莉1,2

收稿日期:2019-07-13

修回日期:2019-08-13

出版日期:2020-06-20

网络出版日期:2019-09-04

作者简介:张志刚(1983-), 男, 讲师. E-mail: zhangzg@smm.neu.edu.cn;基金资助:ZHANG Zhigang1,2,LU Xiaotong1,2,LIU Jinli1,2

Received:2019-07-13

Revised:2019-08-13

Published:2020-06-20

Online:2019-09-04

Supported by:摘要:

采用注浆成型和无压烧结技术制备铝电解测温热电偶NiFe2O4陶瓷U型保护套管, 对浆料稳定性、生坯烧结行为和组装热电偶的测温性能进行了研究。结果表明: 添加10wt% NiFe2O4纳米粉和5wt%纳米粘结剂能有效提高浆料体系的Zeta电位, pH在10.0~11.0之间时浆料体系的稳定性较好。升温至1100 ℃以上生坯开始大量收缩, 随烧结温度的升高线收缩和线收缩速率逐渐增大, 在1300 ℃时线收缩速率达到最大值; 烧结初期活化能为295.11 kJ·mol -1, 受体积扩散和晶界扩散共同控制。测温结果表明组装热电偶在升降温过程中温度响应及时, 具备良好的抗熔盐腐蚀性能和抗热震性能, 满足工业铝电解测温热电偶套管的要求, 具备工业应用前景。

中图分类号:

张志刚,卢晓通,刘金莉. NiFe2O4陶瓷U型套管的注浆成型和无压烧结[J]. 无机材料学报, 2020, 35(6): 661-668.

ZHANG Zhigang,LU Xiaotong,LIU Jinli. NiFe2O4 Ceramic U-shaped Sleeve Prepared by Slip Casting and Pressureless Sintering[J]. Journal of Inorganic Materials, 2020, 35(6): 661-668.

| Position | Particle size/μm | ||

|---|---|---|---|

| D10 | D50 | D90 | |

| Slurry | 0.45 | 2.51 | 5.35 |

| TopⅠ | 0.46 | 2.51 | 5.33 |

| TopⅡ | 0.45 | 2.52 | 5.34 |

| MiddleⅠ | 0.46 | 2.52 | 5.36 |

| MiddleⅡ | 0.46 | 2.53 | 5.34 |

| BottomⅠ | 0.46 | 2.52 | 5.36 |

| BottomⅡ | 0.46 | 2.52 | 5.34 |

表1 浆料和生坯不同部位的粒度分布

Table 1 Particle size distribution in different positions for the same green body

| Position | Particle size/μm | ||

|---|---|---|---|

| D10 | D50 | D90 | |

| Slurry | 0.45 | 2.51 | 5.35 |

| TopⅠ | 0.46 | 2.51 | 5.33 |

| TopⅡ | 0.45 | 2.52 | 5.34 |

| MiddleⅠ | 0.46 | 2.52 | 5.36 |

| MiddleⅡ | 0.46 | 2.53 | 5.34 |

| BottomⅠ | 0.46 | 2.52 | 5.36 |

| BottomⅡ | 0.46 | 2.52 | 5.34 |

| T/℃ | -1/(m+1) | CR |

|---|---|---|

| 1150 | -0.396 | 0.995 |

| 1175 | -0.401 | 0.998 |

| 1200 | -0.403 | 0.990 |

| 1225 | -0.397 | 0.991 |

| 1250 | -0.396 | 0.994 |

| Average | -0.399 | — |

表2 不同温度ln(ΔL/L0)T ~ lnC拟合直线斜率和线性回归系数

Table 2 Values of slope and linear regression coef?cient (CR) of relationship between ln(ΔL/L0)T and lnC under different temperatures

| T/℃ | -1/(m+1) | CR |

|---|---|---|

| 1150 | -0.396 | 0.995 |

| 1175 | -0.401 | 0.998 |

| 1200 | -0.403 | 0.990 |

| 1225 | -0.397 | 0.991 |

| 1250 | -0.396 | 0.994 |

| Average | -0.399 | — |

| Heating rate/(K·min-1) | a | CR |

|---|---|---|

| 5 | -14049 | 0.990 |

| 10 | -14165 | 0.987 |

| 20 | -14279 | 0.985 |

| Average | -14164 | — |

表3 不同升温速率ln[(ΔL/L0)/T] ~ 1/T曲线拟合直线斜率a和线性回归系数CR值

Table 3 The values of slope (a) and linear regression coef?cient (CR) of relationship between ln[(ΔL/L0)/T] and 1/T at different heating rates

| Heating rate/(K·min-1) | a | CR |

|---|---|---|

| 5 | -14049 | 0.990 |

| 10 | -14165 | 0.987 |

| 20 | -14279 | 0.985 |

| Average | -14164 | — |

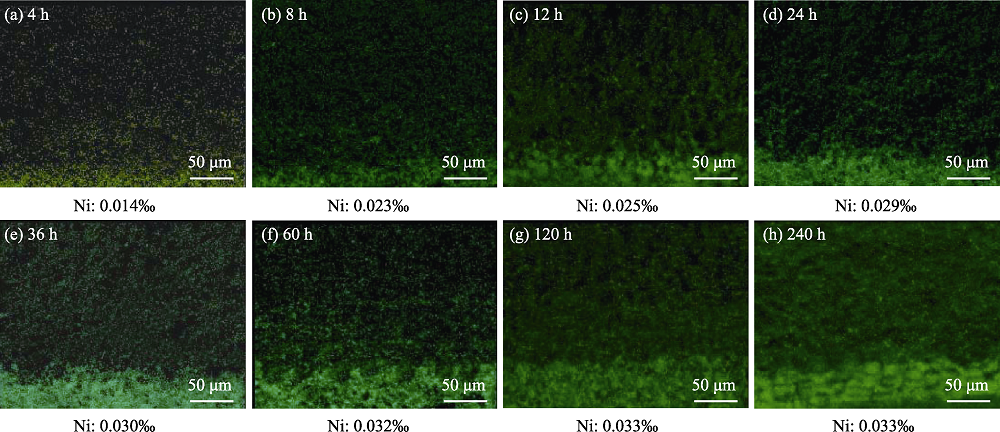

图8 测温腐蚀不同时间的NiFe2O4陶瓷表面F元素分布图和电解质中Ni含量

Fig. 8 Distribution diagrams of F element in the surfaces of NiFe2O4 ceramics and Ni contents in electrolysis after corroded different periods

| [1] | 冯乃祥. 铝电解. 北京: 化学工业出版社, 2006: 113-114. |

| [2] |

SOLLI P A, EGGEN T, SKYBAKMOEN E , et al. Current efficiency in the Hall-Heroult process for aluminum electrolysis: experimental and modeling studies. Journal of Applied Electrochemistry, 1997, 27(8):939-946.

DOI URL |

| [3] |

STERTEN Å . Current efficiency in aluminum reduction cells. Journal of Applied Electrochemistry, 1988,18(3):473-483.

DOI URL |

| [4] |

KOLÅS S, STØRE T . Bath temperature and AlF3 control of an aluminium electrolysis cell. Control Engineering Practice, 2009,17(9):1035-1043.

DOI URL |

| [5] |

CONSTANTIN V . Influence of the operating parameters over the current efficiency and corrosion rate in the Hall-Heroult aluminum cell with tin oxide anode substrate material. Chinese Journal of Chemical Engineering, 2015,23(4):722-726.

DOI URL |

| [6] |

TAYLOR M P, ZHANG W D, WILLS V , et al. A dynamic model for the energy balance of an electrolysis cell. Chemical Engineering Research and Design, 1996,74(8):913-933.

DOI URL |

| [7] |

SAFA Y, FLUECK M, RAPPAZ J . Numerical simulation of thermal problems coupled with magneto hydrodynamic effects in aluminium cell. Applied Mathematical Modelling, 2009,33(3):1479-1492.

DOI URL |

| [8] | 刘业翔, 李劼 . 现代铝电解. 北京: 冶金工业出版社, 2008: 172-174. |

| [9] | POSMYK A . Co-deposited composite coatings with a ceramic matrix destined for sliding pairs. Surface & Coatings Technology, 2013,206(15):3342-3349. |

| [10] |

OLSEN E, THONSTAD J . Nickel ferrite as inert anodes in aluminum electrolysis: Part I Material fabrication and preliminary testing. Journal of Applied Electrochemistry, 1999,29(3):293-299.

DOI URL |

| [11] |

MA J, BAO L, YAO G C , et al. Effect of MnO2 addition on properties of NiFe2O4-based cermets. Ceramics International, 2011,37(8):3381-3387.

DOI URL |

| [12] |

ZARRABIAN P, KALANTAR M, GHASEMI S S . Fabrication and characterization of nickel ferrite based inert anodes for aluminum electrolysis. Journal of Materials Engineering and Performance, 2014,23(5):1656-1664.

DOI URL |

| [13] |

TIAN Z L, LAI Y Q, LI Z Y , et al. Further development on NiFe2O4-based cermet inert anodes for aluminum electrolysis. JOM, 2014,66(11):2229-2234.

DOI URL |

| [14] |

ZHANG Z G, YAO G C, LUO H J , et al. Sintering behavior and properties of NiFe2O4 ceramic inert anode toughened by adding NiFe2O4 nanopowder. Journal of Inorganic Materials, 2016,31(7):761-768.

DOI URL |

| [15] |

MOUZON J, GLOWACKI E, ODÉN M. Comparison between slip-casting and uniaxial pressing for the fabrication of translucent yttria ceramics. Journal of Materials Science, 2008,43(8):2849-2856.

DOI URL |

| [16] |

COMBE E, GUILMEAU E, SAVARY E , et al. Microwave sintering of Ge-doped In2O3 thermoelectric ceramics prepared by slip casting process. Journal of the European Ceramic Society, 2015,35(1):145-151.

DOI URL |

| [17] |

ORTIZ A L, CANDELARIO V M, MORENO R , et al. Near-net shape manufacture of B4C-Co and ZrC-Co composites by slip casting and pressureless sintering. Journal of the European Ceramic Society, 2017,37(15):4577-4584.

DOI URL |

| [18] |

DENG J, YAO D X, XIA Y F , et al. Gradient porous silicon nitride by slip casting and vacuum foaming. Journal of Inorganic Materials, 2016,31(8):865-868.

DOI URL |

| [19] |

HASSANIN H, JIANG K . Fabrication and characterization of stabilised zirconia micro parts via slip casting and soft moulding. Scripta Materialia, 2013,69(6):433-436.

DOI URL |

| [20] |

ZHOU J, PAN Y B, ZHANG W X , et al. Fabrication of YAG transparent ceramics using slip casting with ethanol. Journal of Inorganic Materials, 2011,26(3):254-256.

DOI URL |

| [21] |

SHAFEIEY A, ENAYATI M H, ALHAJI A . The effect of slip casting and spark plasma sintering (SPS) temperature on the transparency of MgAl2O4 spinel. Ceramics International, 2018,44(4):3536-3540.

DOI URL |

| [22] | YANG Z G, YU J B, LI C J , et al. Preparation of textured porous Al2O3 ceramics by slip casting in a strong magnetic field and its mechanical properties. Crystal Research & Technology, 2015,50(8):645-653. |

| [23] |

BROUCZEK D, KONEGGER T . Open-porous silicon nitride-based ceramics in tubular geometry obtained by slip-casting and gelcasting. Advanced Engineering Materials, 2017,19(10):1700434.

DOI URL |

| [24] |

ZHANG Z G, LIU Y H, YAO G C , et al. Solid-state reaction synthesis of NiFe2O4 nanoparticles by optimizing the synthetic conditions. Physica E: Low-dimensional Systems and Nanostructures, 2012,45:122-129.

DOI URL |

| [25] | 马佳 . 制备大尺寸耐火材料型铝电解惰性阳极的研究. 沈阳: 东北大学博士学位论文, 2011. |

| [26] | ZHANG R, GAO L, CHENG G F , et al. Fabrication and properties of SiC porous ceramics by slip casting process. Journal of Inorganic Materials, 2002,17(4):725-730. |

| [27] | 张志刚 . 纳米增韧NiFe2O4基铝电解惰性阳极的研究. 沈阳: 东北大学博士学位论文, 2013. |

| [28] | 严彪, 吴菊清, 李祖德 , 等. 现代粉末冶金手册. 北京: 化学工业出版社, 2013: 110. |

| [29] |

LIU X Y, LIU M Y, ZHANG L . Co-adsorption and sequential adsorption of the co-existence four heavy metal ions and three fluoroquinolones on the functionalized ferromagnetic 3D NiFe2O4 porous hollow microsphere. Journal of Colloid and Interface Science, 2018,511:135-144.

DOI URL |

| [30] |

BHOSALE S V, BANKAR D N, BHORASKAR S V , et al. Analysis of electrokinetic properties of NiFe2O4 nanoparticles synthesized by DC thermal plasma route and its use in adsorption of humic substances. Journal of Environmental Chemical Engineering, 2016,4(2):1584-1593.

DOI URL |

| [31] |

BANNISTER M J . Shape sensitivity of initial sintering equations. Journal of the American Ceramic Society, 1968,51(10):548-553.

DOI URL |

| [32] |

KESKI J R, CUTLER I B . Initial sintering of MnXO-Al2O3. Journal of the American Ceramic Society, 1968,51(8):440-444.

DOI URL |

| [33] |

WOOLFREY J L, BANNISTER M J . Nonisothermal techniques for studying initial-stage sintering. Journal of the American Ceramic Society, 1972,55(8):390-394.

DOI URL |

| [34] |

ZHANG T S, PETER H, HUANG H T , et al. Early-stage sintering mechanisms of Fe-doped CeO2. Journal of Materials Science, 2002,37(5):997-1003.

DOI URL |

| [35] |

HANSGN J D, RUSIN R P, TENG M H , et al. Combined-stage sintering model. Journal of the American Ceramic Society, 1992,75(5):1129-1135.

DOI URL |

| [1] | 江宗玉, 黄红花, 清江, 王红宁, 姚超, 陈若愚. 铝离子掺杂MIL-101(Cr)的制备及其VOCs吸附性能研究[J]. 无机材料学报, 2025, 40(7): 747-753. |

| [2] | 王鲁杰, 张玉新, 李彤阳, 于源, 任鹏伟, 王建章, 汤华国, 姚秀敏, 黄毅华, 刘学建, 乔竹辉. 深海服役环境下碳化硅陶瓷材料的腐蚀及磨损行为[J]. 无机材料学报, 2025, 40(7): 799-807. |

| [3] | 魏志帆, 陈国清, 祖宇飞, 刘渊, 李明浩, 付雪松, 周文龙. ZrB2-HfSi2复相陶瓷显微组织及其核-周结构形成机制[J]. 无机材料学报, 2025, 40(7): 817-825. |

| [4] | 杨燕, 张发强, 马名生, 王墉哲, 欧阳琪, 刘志甫. 基于CuO-TiO2-Nb2O5复合氧化物烧结助剂的ZnAl2O4陶瓷低温烧结研究[J]. 无机材料学报, 2025, 40(6): 711-718. |

| [5] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [6] | 梁锐辉, 钟鑫, 洪督, 黄利平, 牛亚然, 郑学斌. Yb2O3改性硅黏结层的环境障涂层体系耐高温水氧腐蚀行为研究[J]. 无机材料学报, 2025, 40(4): 425-432. |

| [7] | 苟燕子, 康伟峰, 王堋人. 烧结条件对制备高结晶近化学计量比SiC纤维的影响[J]. 无机材料学报, 2025, 40(4): 405-414. |

| [8] | 张继国, 吴田, 赵旭, 杨钒, 夏天, 孙士恩. 钠离子电池正极材料循环稳定性提升策略及产业化进程[J]. 无机材料学报, 2025, 40(4): 348-362. |

| [9] | 殷杰, 耿佳毅, 王康龙, 陈忠明, 刘学建, 黄政仁. SiC陶瓷的3D打印成形与致密化新进展[J]. 无机材料学报, 2025, 40(3): 245-255. |

| [10] | 樊文楷, 杨潇, 李宏华, 李永, 李江涛. 无压烧结制备(Y0.2Gd0.2Er0.2Yb0.2Lu0.2)2Zr2O7高熵陶瓷及其高温抗CMAS腐蚀性能[J]. 无机材料学报, 2025, 40(2): 159-167. |

| [11] | 李伟, 许志明, 苟燕子, 尹森虎, 余艺平, 王松. SiC纤维烧结陶瓷的制备及其性能研究[J]. 无机材料学报, 2025, 40(2): 177-183. |

| [12] | 叶君豪, 周真真, 胡辰, 王雁斌, 荆延秋, 李廷松, 程梓秋, 吴俊林, IVANOV Maxim, HRENIAK Dariusz, 李江. 共沉淀纳米粉体制备Yb:Sc2O3透明陶瓷的微结构与光学性能[J]. 无机材料学报, 2025, 40(2): 215-224. |

| [13] | 王智祥, 陈莹, 逄清阳, 李鑫, 王根水. 碳酸锰掺杂氧化镁基陶瓷的烧结行为和介电性能[J]. 无机材料学报, 2025, 40(1): 97-103. |

| [14] | 张婧慧, 陆晓彤, 毛海雁, 田亚州, 张山林. 烧结助剂对BaZr0.1Ce0.7Y0.2O3-δ电解质烧结行为及电导率的影响[J]. 无机材料学报, 2025, 40(1): 84-90. |

| [15] | 瞿牡静, 张淑兰, 朱梦梦, 丁浩杰, 段嘉欣, 代恒龙, 周国红, 李会利. CsPbBr3@MIL-53纳米复合荧光粉的合成、性能及其白光LEDs应用[J]. 无机材料学报, 2024, 39(9): 1035-1043. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||