无机材料学报 ›› 2016, Vol. 31 ›› Issue (7): 761-768.DOI: 10.15541/jim20150602 CSTR: 32189.14.10.15541/jim20150602

张志刚, 姚广春, 罗洪杰, 张 啸, 马俊飞, 徐建荣

收稿日期:2015-12-02

修回日期:2016-01-19

出版日期:2016-07-20

网络出版日期:2016-06-22

基金资助:ZHANG Zhi-Gang, YAO Guang-Chun, LUO Hong-Jie, ZHANG Xiao, MA Jun-Fei, XU Jian-Rong

Received:2015-12-02

Revised:2016-01-19

Published:2016-07-20

Online:2016-06-22

Supported by:摘要:

采用粉末冶金法制备NiFe2O4纳米粉增韧NiFe2O4陶瓷铝电解惰性阳极, 研究了NiFe2O4纳米粉添加量对NiFe2O4陶瓷惰性阳极烧结行为和材料性能的影响。通过线收缩和SEM对NiFe2O4陶瓷的烧结性能和显微结果进行分析。研究结果表明: 随着NiFe2O4纳米粉添加量的增加, 烧结收缩程度逐渐增大, 烧结致密化开始温度和烧结初期活化能逐渐降低, 添加量为40%时试样从900℃开始大幅度收缩, 烧结初期表观活化能下降到291.43 kJ/mol。NiFe2O4陶瓷惰性阳极的体积密度、抗弯强度和断裂韧性随NiFe2O4纳米粉添加量的增加均呈现先上升后下降的变化趋势, 气孔率和静态腐蚀率呈先下降后上升的趋势, 均在30%达到极值, 断裂韧性达到最大值3.12 MPa•m1/2, 是未添加纳米粉试样的2.14倍。NiFe2O4纳米粉的添加能够明显增强晶界结合强度, 降低陶瓷材料气孔率, 从而提高断裂表面能实现增韧作用。

中图分类号:

张志刚, 姚广春, 罗洪杰, 张 啸, 马俊飞, 徐建荣. 纳米增韧NiFe2O4陶瓷惰性阳极烧结行为与性能的研究[J]. 无机材料学报, 2016, 31(7): 761-768.

ZHANG Zhi-Gang, YAO Guang-Chun, LUO Hong-Jie, ZHANG Xiao, MA Jun-Fei, XU Jian-Rong. Sintering Behavior and Properties of NiFe2O4 Ceramic Inert Anode Toughened by Adding NiFe2O4 Nanopowder[J]. Journal of Inorganic Materials, 2016, 31(7): 761-768.

| Main granule (500-355 μm) | Filler granule (105-74 μm) | Fine granule (<74 μm) | Nanopowder (30-65 nm) |

|---|---|---|---|

| 42wt% | 18wt% | 40wt% | 0 |

| 30wt% | 10wt% | ||

| 20wt% | 20wt% | ||

| 10wt% | 30wt% | ||

| 0 | 40wt% |

表1 粒度级配设计表

Table 1 Design of particle gradation

| Main granule (500-355 μm) | Filler granule (105-74 μm) | Fine granule (<74 μm) | Nanopowder (30-65 nm) |

|---|---|---|---|

| 42wt% | 18wt% | 40wt% | 0 |

| 30wt% | 10wt% | ||

| 20wt% | 20wt% | ||

| 10wt% | 30wt% | ||

| 0 | 40wt% |

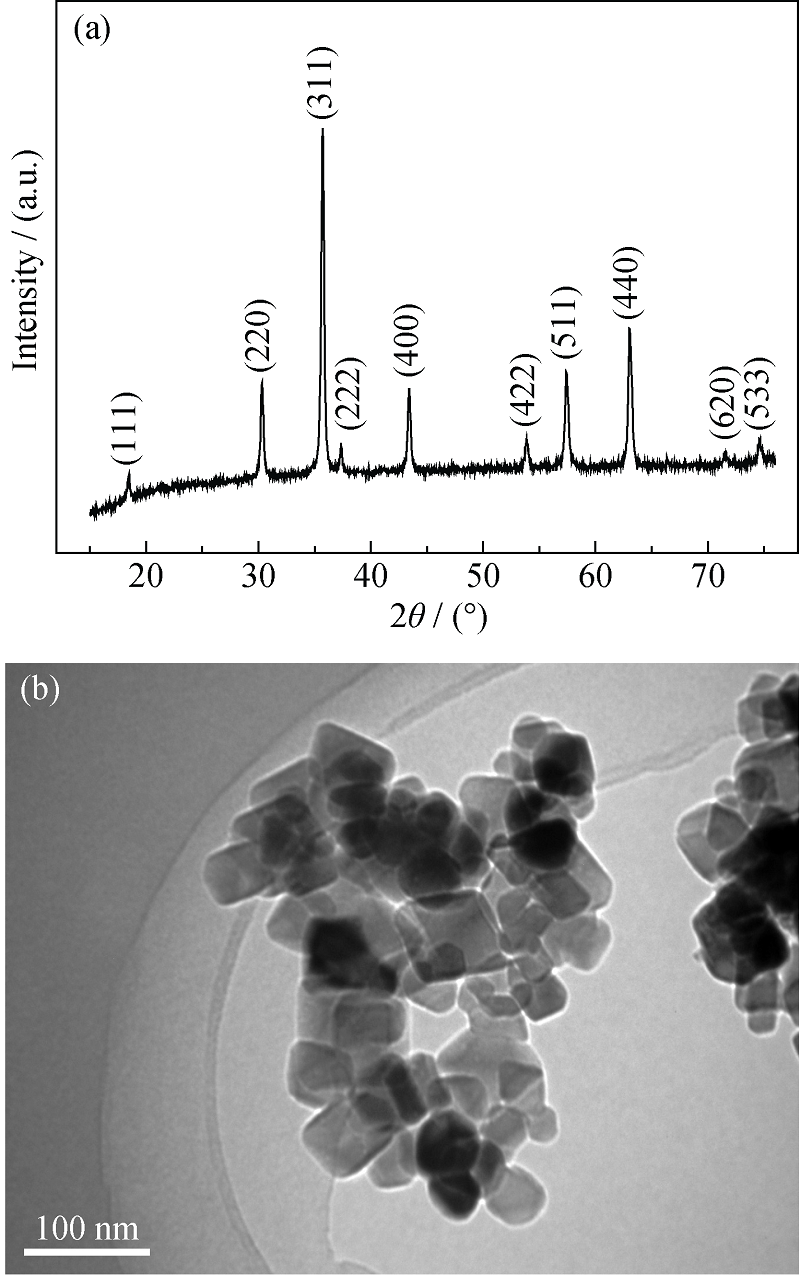

图1 低温固相反应制备得到NiFe2O4纳米粉的XRD图谱(a)和TEM照片(b)

Fig. 1 XRD pattern (a) and TEM image (b) of NiFe2O4 nanopowders prepared by low temperature solid-state reaction

| Nanopowder content/wt % | 0 | 10 | 20 | 30 | 40 |

|---|---|---|---|---|---|

| Linear shrinkage/ % | -5.23 | -6.09 | -6.93 | -9.41 | -10.41 |

表2 不同纳米粉添加量试样1300℃时的线收缩

Table 2 Linear shrinkage of samples prepared by adding different amount of nanopowders at 1300℃

| Nanopowder content/wt % | 0 | 10 | 20 | 30 | 40 |

|---|---|---|---|---|---|

| Linear shrinkage/ % | -5.23 | -6.09 | -6.93 | -9.41 | -10.41 |

| T/℃ | 1150 | 1175 | 1200 | 1225 | 1250 | Average |

|---|---|---|---|---|---|---|

| -1/(m+1) | -0.352 | -0.338 | -0.362 | -0.373 | -0.365 | -0.358 |

| R | 0.991 | 0.994 | 0.985 | 0.987 | 0.992 | - |

表3 不添加NiFe2O4纳米粉试样在不同温度下的ln(△L/L0)T ~lnC拟合直线斜率和线性回归系数

Table 3 Values of slope and linear regression coefficient (R) of relationship between ln(△L/L0)T and lnC for samples without nanopowders under different temperatures

| T/℃ | 1150 | 1175 | 1200 | 1225 | 1250 | Average |

|---|---|---|---|---|---|---|

| -1/(m+1) | -0.352 | -0.338 | -0.362 | -0.373 | -0.365 | -0.358 |

| R | 0.991 | 0.994 | 0.985 | 0.987 | 0.992 | - |

| Heating rate/(K·min-1) | 5 | 10 | 20 | Average |

|---|---|---|---|---|

| a | -16731 | -17165 | -15889 | -16595 |

| R | 0.978 | 0.985 | 0.981 | - |

表4 不添加NiFe2O4纳米粉试样不同升温速率ln[(△L/L0)/T] ~ 1/T曲线拟合直线斜率a和线性回归系数R值

Table 4 Values of slope (a) and linear regression coefficient (R) of relationship between ln[(△L/L0)/T] and 1/T for samples without nanopowders under different heating rates

| Heating rate/(K·min-1) | 5 | 10 | 20 | Average |

|---|---|---|---|---|

| a | -16731 | -17165 | -15889 | -16595 |

| R | 0.978 | 0.985 | 0.981 | - |

| Nanopowder content /wt% | 0 | 10 | 20 | 30 | 40 |

|---|---|---|---|---|---|

| Exponent m | 1.793 | 1.648 | 1.564 | 1.486 | 1.453 |

| Apparent activation energy, Q/(kJ·mol-1) | 385.35 | 349.52 | 324.27 | 302.69 | 291.43 |

表5 不同NiFe2O4纳米粉试样烧结初期的指数m和表观活化能Q值

Table 5 Values of exponent and apparent activation energy for samples with various contents of NiFe2O4 nanopowders at the early-stage sintering

| Nanopowder content /wt% | 0 | 10 | 20 | 30 | 40 |

|---|---|---|---|---|---|

| Exponent m | 1.793 | 1.648 | 1.564 | 1.486 | 1.453 |

| Apparent activation energy, Q/(kJ·mol-1) | 385.35 | 349.52 | 324.27 | 302.69 | 291.43 |

| [1] | KVANDE H, HAUPIN W.Inert anodes for al smelters: energy balances and environmental impact.JOM, 2001, 53(5): 29-33. |

| [2] | EDWARDS L, RICHARDS N, KVANDE H.Inert anodes and other new al technologies-benefits, challenges, and impact on present technology.JOM, 2001, 53(5): 48-50. |

| [3] | OLSEN E, THONSTAD J.Nickel ferrite as inert anodes in aluminum electrolysis: Part I Material fabrication and preliminary testing.Journal of Applied Electrochemistry, 1999, 29(3): 293-299. |

| [4] | HE H B, WANG Y, LONG J J, et al.Corrosion of NiFe2O4- 10NiO-based cermet inert anodes for aluminium electrolysis.Transactions of Nonferrous Metals Society of China, 2013, 23(12): 3816-3821. |

| [5] | LI J, WANG Z G, LAI Y Q, et al.Effect of structural parameters on the thermal stress of a NiFe2O4-based cermet inert anode in aluminum electrolysis.Acta Metallurgica Sinica (English Letters), 2007, 20(2): 139-147. |

| [6] | LAI Y Q, HUANG L F, TIAN Z L, et al.Effect of CaO doping on corrosion resistance of Cu/(NiFe2O4-10NiO) cermet inert anode for aluminum electrolysis.Journal of Central South University of Technology, 2008, 15(6): 743-747. |

| [7] | DU J J, YAO G C, LIU Y H, et al.Influence of V2O5 as an effective dopant on the sintering behavior and magnetic properties of NiFe2O4 ferrite ceramics.Ceramics International, 2012, 38(2): 1707-1711. |

| [8] | MA J, BAO L, YAO G C, et al.Effect of MnO2 addition on properties of NiFe2O4-based cermets.Creamics International, 2011, 37(8): 3381-3387. |

| [9] | HE H B, ZHOU K C, LI Z Y, et al.Effect of BaO addition on electric conductivity of xCu/10NiO-NiFe2O4 cermets.Transactions of Nonferrous Metals Society of China, 2008, 18(5): 1134-1138. |

| [10] | GAN X P, LI Z Y, TAN Z Q, et al.Influence of Yb2O3 addition on microstructure and corrosion resistance of 10Cu/(10NiO-NiFe2O4) cermets.Transactions of Nonferrous Metals Society of China, 2009, 19(6): 1514-1519. |

| [11] | ZHANG Z G, LIU Y H, YAO G C, et al.Effect of Nanopowder Content on Properties of NiFe2O4 Matrix Inert Anode for Aluminum Electrolysis. TMS (The Minerals, Metals & Materials Society), Orlando, 2012: 1381-1384. |

| [12] | ZHANG Z G, LIU Y H, YAO G C, et al.Solid-state reaction synthesis of NiFe2O4 nanoparticles by optimizing the synthetic conditions.Physica E: Low-dimensional Systems and Nanostructures, 2012, 45: 122-129. |

| [13] | 席锦会. 两步烧结制备铝电解惰性阳极材料的研究. 沈阳: 东北大学博士学位论文, 2006. |

| [14] | PAMU D, LAKSHMI NARAYANA RAO G, JAMES RAJU K C. Enhanced microwave dielectric properties of (Zr0.8Sn0.2)TiO4 ceramics with the addition of its own nanoparticles.Journal of the American Ceramic Society, 2012, 95(1): 126-132. |

| [15] | BANNISTER M J.Shape sensitivity of initial sintering equations.Journal of the American Ceramic Society, 1968, 51(10): 548-553. |

| [16] | KESKI J R, CUTLER I B.Initial sintering of MnXO-Al2O3.Journal of the American Ceramic Society, 1968, 51(8): 440-444. |

| [17] | WOOLFREY J L, BANNISTER M J.Nonisothermal techniques for studying initial-stage sintering.Journal of the American Ceramic Society, 1972, 55(8): 390-394. |

| [18] | ZHANG T S, PETER H, HUANG H T, et al.Early-stage sintering mechanisms of Fe-doped CeO2.Journal of Materials Science, 2002, 37(5): 997-1003. |

| [19] | TAN H L, YANG W.Toughening mechanisms of nano-composite ceramics.Mechanics of Materials, 1998, 30(2): 111-123. |

| [20] | 龚江宏. 陶瓷材料断裂力学. 北京: 清华大学出版社, 2011: 132-228. |

| [21] | LI Q G, WU C, WANG Z.Mechanical properties and microstructures of Nano-Al2O3 particles reinforced Al2O3/AlN composite.Journal of Alloys and Compounds, 2015, 636: 20-23. |

| [22] | LIU B G, ZHANG L, ZHOU K C, et al.Electrical conductivity and molten salt corrosion behavior of spinel nickel ferrite.Solid State Sciences, 2011, 13(8): 1483-1487. |

| [23] | TIAN Z L, ZHANG T, WEI C J, et al.Effect of current density on corrosion of NiFe2O4 based cermet inert anode for aluminum electrolysis.The Chinese Journal of Nonferrous Metals, 2014, 24(9): 2360-2365. |

| [24] | NIGHTINGALE S A, LONGBOTTOM R J, MONAGHAN B J.Corrosion of nickel ferrite refractory by Na3AlF6-AlF3-CaF2-Al2O3 bath.Journal of the European Ceramic Society, 2013, 33(13/14): 2761-2765. |

| [1] | 孙川, 何鹏飞, 胡振峰, 王荣, 邢悦, 张志彬, 李竞龙, 万春磊, 梁秀兵. 含有石墨烯阵列的SiC基陶瓷材料的制备与力学性能[J]. 无机材料学报, 2024, 39(3): 267-273. |

| [2] | 曹丹,周明扬,刘志军,颜晓敏,刘江. 阳极支撑质子导体电解质固体氧化物燃料电池的制备及其性能研究[J]. 无机材料学报, 2020, 35(9): 1047-1052. |

| [3] | 代钊,王铭,王双,李静,陈翔,汪大林,祝迎春. 氧化锆基微量元素共掺杂羟基磷灰石增韧涂层研究[J]. 无机材料学报, 2020, 35(2): 179-186. |

| [4] | 党潇琳, 范晓孟, 殷小玮, 马昱昭, 马晓康. 多功能一体化MAX相改性连续纤维增韧陶瓷基复合材料的研究进展[J]. 无机材料学报, 2020, 35(1): 29-34. |

| [5] | 高 鑫, 刘祥萱, 朱左明, 谢 拯, 佘兆斌. NiFe2O4/TiO2纳米棒阵列薄膜光电化学性能和光催化性能研究[J]. 无机材料学报, 2016, 31(9): 935-942. |

| [6] | 李要辉, 王晋珍, 黄幼榕. 硅碱钙石微晶玻璃的析晶特性及其增韧机理研究[J]. 无机材料学报, 2015, 30(9): 977-983. |

| [7] | 林青青, 董绍明, 何 平, 周海军, 胡建宝. TiB2颗粒增强反应结合B4C陶瓷的显微结构与性能[J]. 无机材料学报, 2015, 30(6): 667-672. |

| [8] | 杨治刚, 余建波, 李传军, 玄伟东, 张振强, 邓 康, 任忠鸣. 热固性硅树脂压注法制备多孔硅基陶瓷型芯研究[J]. 无机材料学报, 2015, 30(2): 147-152. |

| [9] | 薛伟江, 谢志鹏. 低温环境下结构陶瓷的相变、断裂机理与性能的研究进展[J]. 无机材料学报, 2014, 29(4): 337-344. |

| [10] | 王 坤, 于庆波, 秦 勤, 李玖重, 王志美. 化学链制氧技术中铜-锆氧载体的动力学分析[J]. 无机材料学报, 2014, 29(3): 301-308. |

| [11] | 王宝全, 余建波, 任忠鸣, 曾宇平. 多孔铝基陶瓷型芯的制备及其性能[J]. 无机材料学报, 2012, 27(3): 239-244. |

| [12] | 赵 琰, 孙康宁, 刘 鹏. 铌酸锂增韧碳纳米管/羟基磷灰石生物复合材料的低温烧结和力学性能研究[J]. 无机材料学报, 2011, 26(8): 863-868. |

| [13] | 司 伟, 王 晶, 王修慧, 高 宏, 翟玉春. 纳米荧光粉Eu0.12Y1.78Ca0.10O3-δ的合成动力学[J]. 无机材料学报, 2011, 26(7): 726-730. |

| [14] | 王严东1,2, 吕 喆2, 魏 波2. La0.6Sr0.4Co0.2Fe0.8O3–δ-Ce0.9Gd0.1O1.95高温电导弛豫的研究[J]. 无机材料学报, 2010, 25(6): 635-640. |

| [15] | 顾 巍, 杨 建, 丘 泰, 祝社民. 原位合成(TiB2+TiC)/Ti3SiC2复相材料及其性能研究[J]. 无机材料学报, 2010, 25(10): 1081-1086. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||