无机材料学报 ›› 2025, Vol. 40 ›› Issue (12): 1395-1404.DOI: 10.15541/jim20250004 CSTR: 32189.14.jim20250004

收稿日期:2025-01-03

修回日期:2025-03-20

出版日期:2025-12-20

网络出版日期:2025-04-15

通讯作者:

李 平, 教授. E-mail: lipingunilab@ecust.edu.cn作者简介:李薛茹(2000‒), 女, 硕士研究生. E-mail: y82220019@mail.ecust.edu.cn

基金资助:

LI Xueru( ), MA Zhejie, GUO Yujie, LI Ping(

), MA Zhejie, GUO Yujie, LI Ping( )

)

Received:2025-01-03

Revised:2025-03-20

Published:2025-12-20

Online:2025-04-15

Contact:

LI Ping, professor. E-mail: lipingunilab@ecust.edu.cnAbout author:LI Xueru (2000‒), female, Master candidate. E-mail: y82220019@mail.ecust.edu.cn

Supported by:摘要:

碳载体是质子交换膜燃料电池膜电极常用Pt/C催化剂的重要组成部分, 离聚物是构成膜电极催化层的关键成分之一。本研究针对六种不同类型的商业化碳载体(VC、KB1、KB2、BP、SJR、AB), 采用多种表征手段系统分析了碳载体、添加离聚物前后Pt/C催化剂的微观结构与表面化学性质, 并且测试了各类Pt/C催化剂的氧还原反应(ORR)性能, 以探究代表性碳载体负载Pt催化剂的电催化构效关系。研究发现, 具有大比表面积和丰富孔结构的碳载体, 如KB1、KB2、BP, 可减小沉积的Pt粒径。强亲水性的实心碳载体(VC、SJR)上的含氧官能团也有助于分散Pt粒子。同时, 含有大量2~8 nm介孔的碳载体(KB1、KB2)有利于Pt分布在碳颗粒内孔中, 而在微孔(<2 nm)居多的大比表面积碳载体(BP)以及中等与小比表面积碳载体(VC、SJR、AB)上, 绝大部分Pt粒子分布在碳颗粒外表面。进一步结合离聚物加入前后Pt/C样品比表面积与孔结构的变化, 测算离聚物的覆盖度, 并提出了离聚物在催化剂颗粒上的分布模型。在实心碳负载催化剂上, 一定量的离聚物基本覆盖了碳颗粒外表面; 在微孔主导的BP负载催化剂上, 离聚物堵塞微孔, 造成比表面积与孔容大幅下降; 而在介孔碳负载的催化剂上, 相同量的离聚物不足以堵塞全部微孔(<2 nm)与介孔(2~8 nm), 使得覆盖度较低。Pt/C催化剂的ORR活性主要由Pt粒径大小决定, 并且, 分布在碳颗粒内孔的Pt粒子可免受离聚物的毒化作用, 因此, KB系列碳载体负载的Pt催化剂在液相ORR动力学过程中表现优异。

中图分类号:

李薛茹, 马哲杰, 郭宇杰, 李平. 载体特性对Pt/C催化剂上离聚物覆盖度及氧还原性能的影响[J]. 无机材料学报, 2025, 40(12): 1395-1404.

LI Xueru, MA Zhejie, GUO Yujie, LI Ping. Influence of Support Characteristics on Coverage of Ionomer and Oxygen Reduction Performance for Pt/C Catalysts[J]. Journal of Inorganic Materials, 2025, 40(12): 1395-1404.

| Sample | VC | KB1 | KB2 | BP | SJR | AB |

|---|---|---|---|---|---|---|

| Contact angle/(°) | 40 | 47 | 125 | 94 | 34 | 137 |

| Zeta potential/mV | 9.8 | 21.0 | 24.7 | 15.3 | -1.1 | - |

表1 不同碳载体的接触角和Zeta电位

Table 1 Contact angles and Zeta potentials of different carbon supports

| Sample | VC | KB1 | KB2 | BP | SJR | AB |

|---|---|---|---|---|---|---|

| Contact angle/(°) | 40 | 47 | 125 | 94 | 34 | 137 |

| Zeta potential/mV | 9.8 | 21.0 | 24.7 | 15.3 | -1.1 | - |

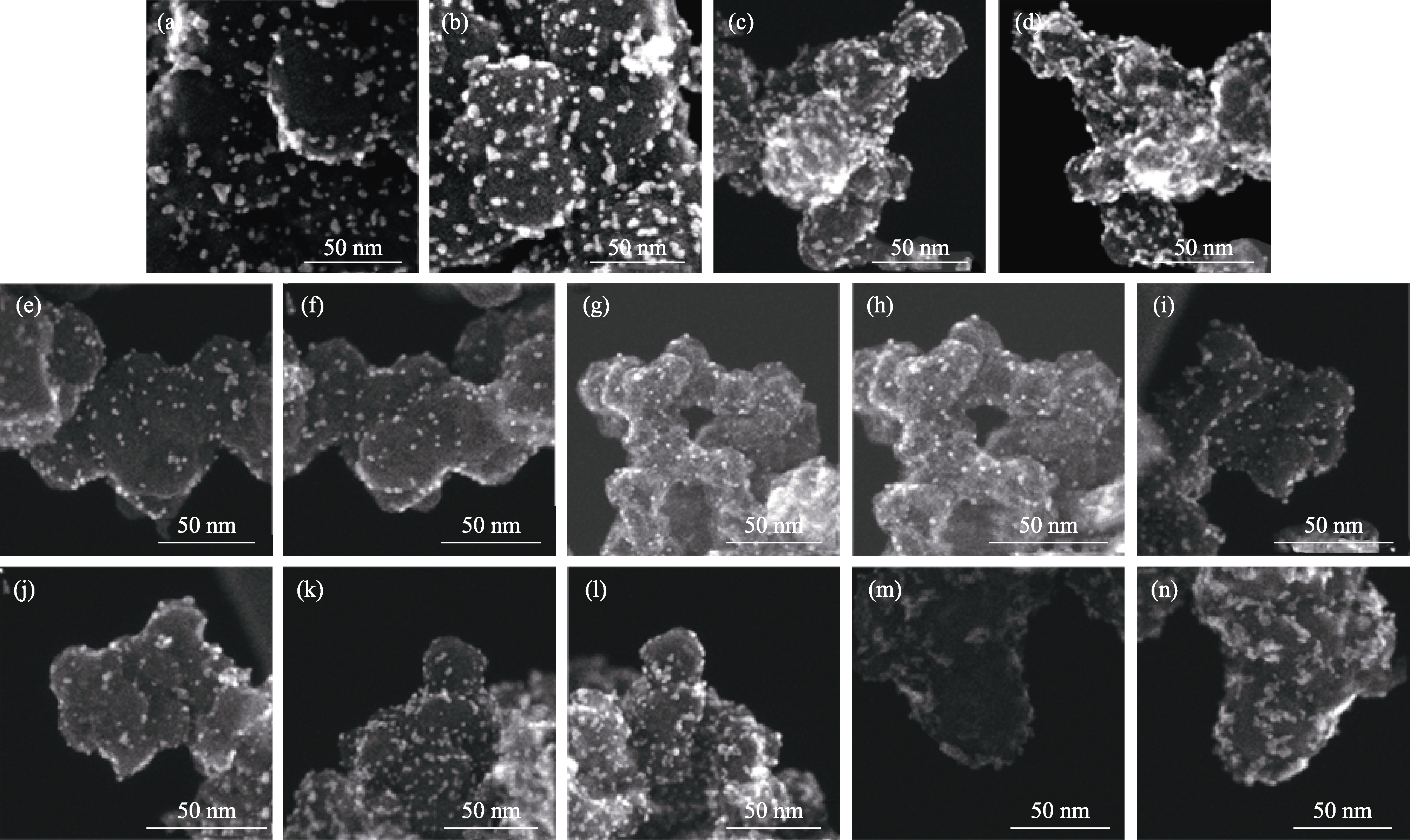

图3 不同碳载体负载Pt催化剂的STEM照片(二次电子模式)

Fig. 3 STEM images with secondary electron (SE) mode for Pt catalysts loaded on different carbon supports (a) 0° and (b) 180° of PK-Pt/VC; (c) 0° and (d) 180° of Pt/VC; (e) 0° and (f) 180° of PK-Pt/KB1; (g) 0° and (h) 180° of Pt/KB2; (i) 0° and (j) 180° of Pt/BP; (k) 0° and (l) 180° of Pt/SJR; (m) 0° and (n) 180° of Pt/AB

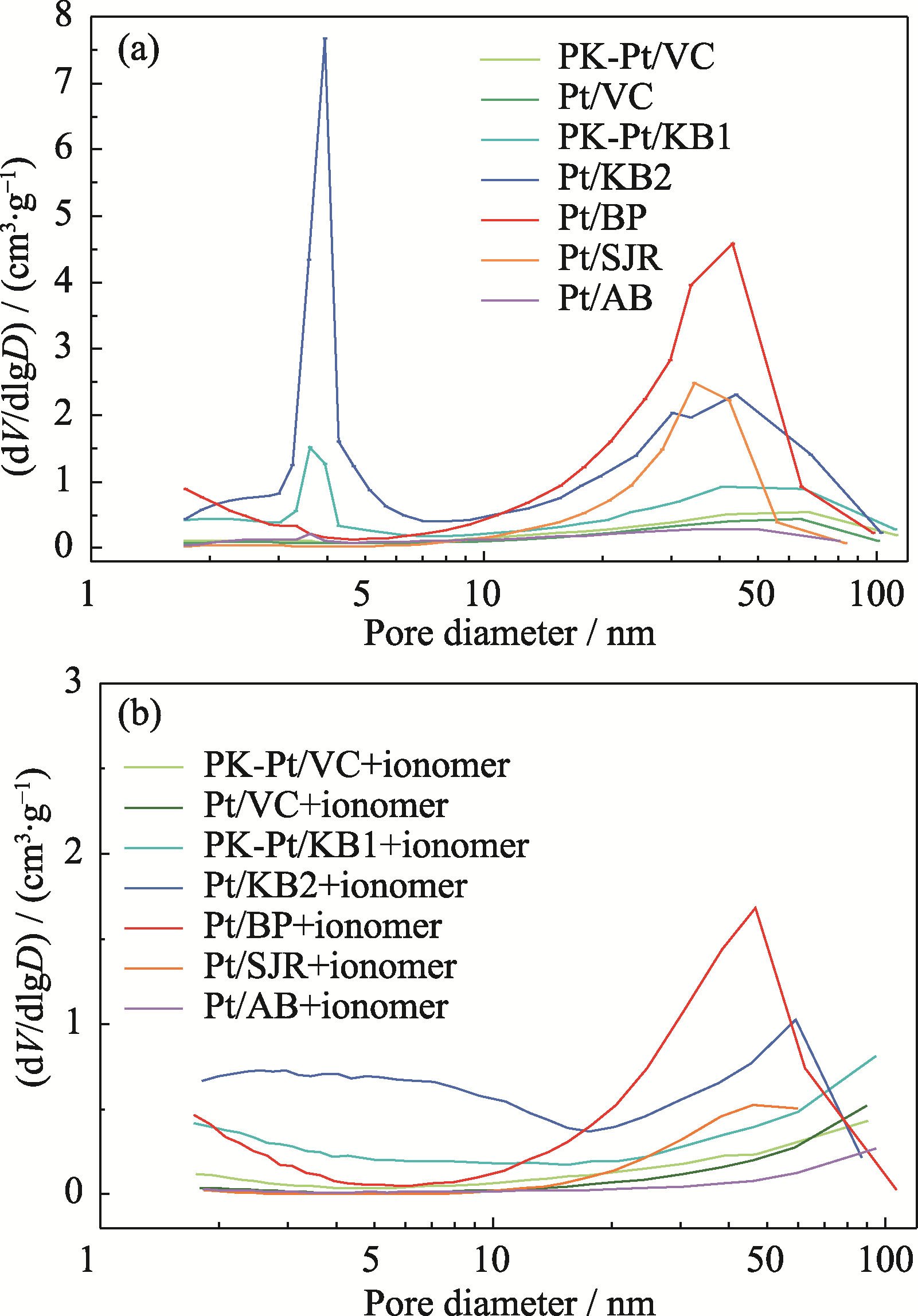

图5 离聚物加入(a)前(b)后不同Pt/C催化剂的孔径分布曲线

Fig. 5 Pore size distribution curves of different Pt/C catalysts (a) before and (b) after addition of ionomer Colorful figures are available on website

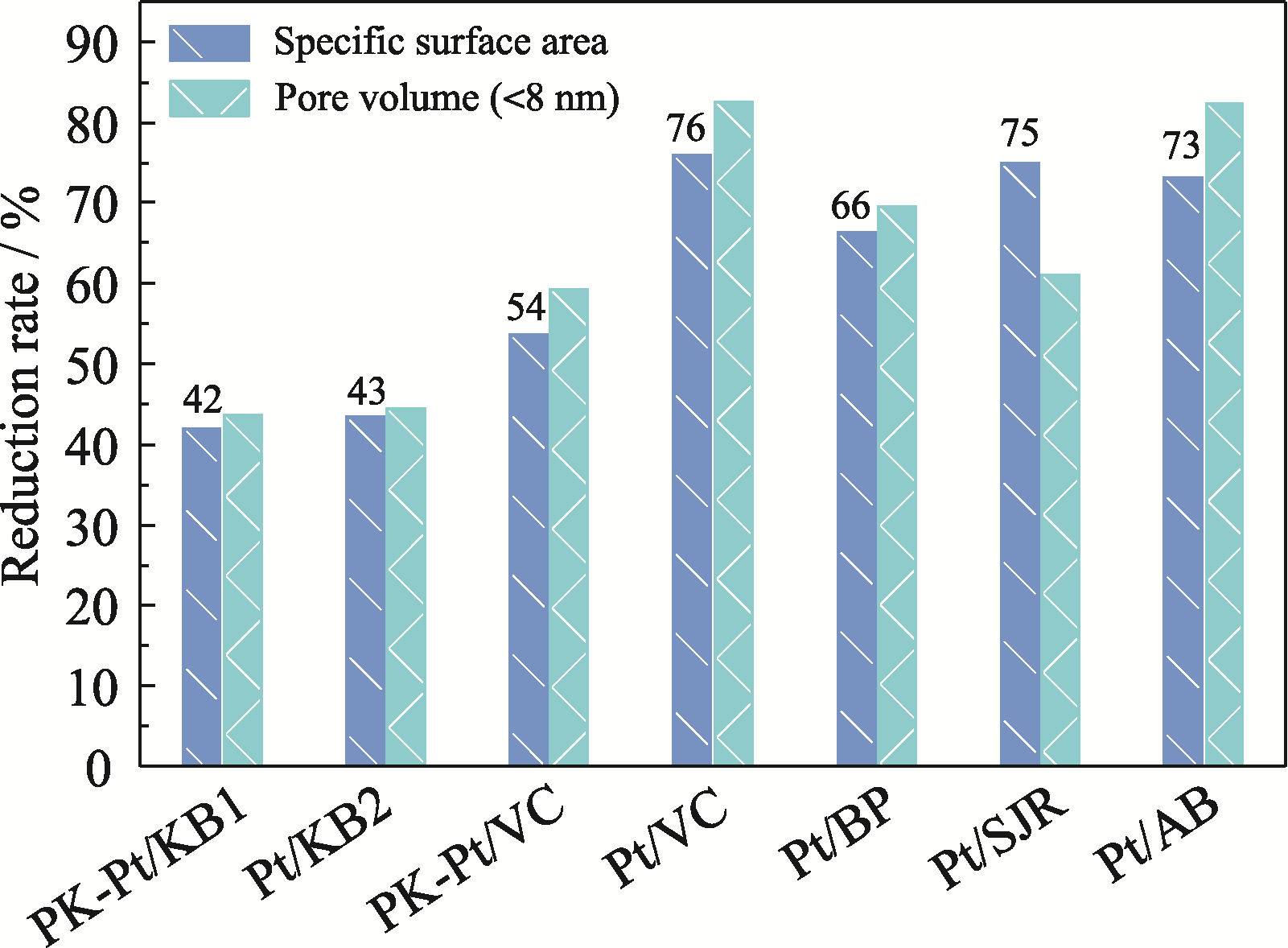

图6 加入离聚物后不同Pt/C催化剂比表面积和孔容的下降率

Fig. 6 Reduction rates of specific surface areas and pore volumes of different Pt/C catalysts after addition of ionomer Numbers in the figure represent coverages of ionomer

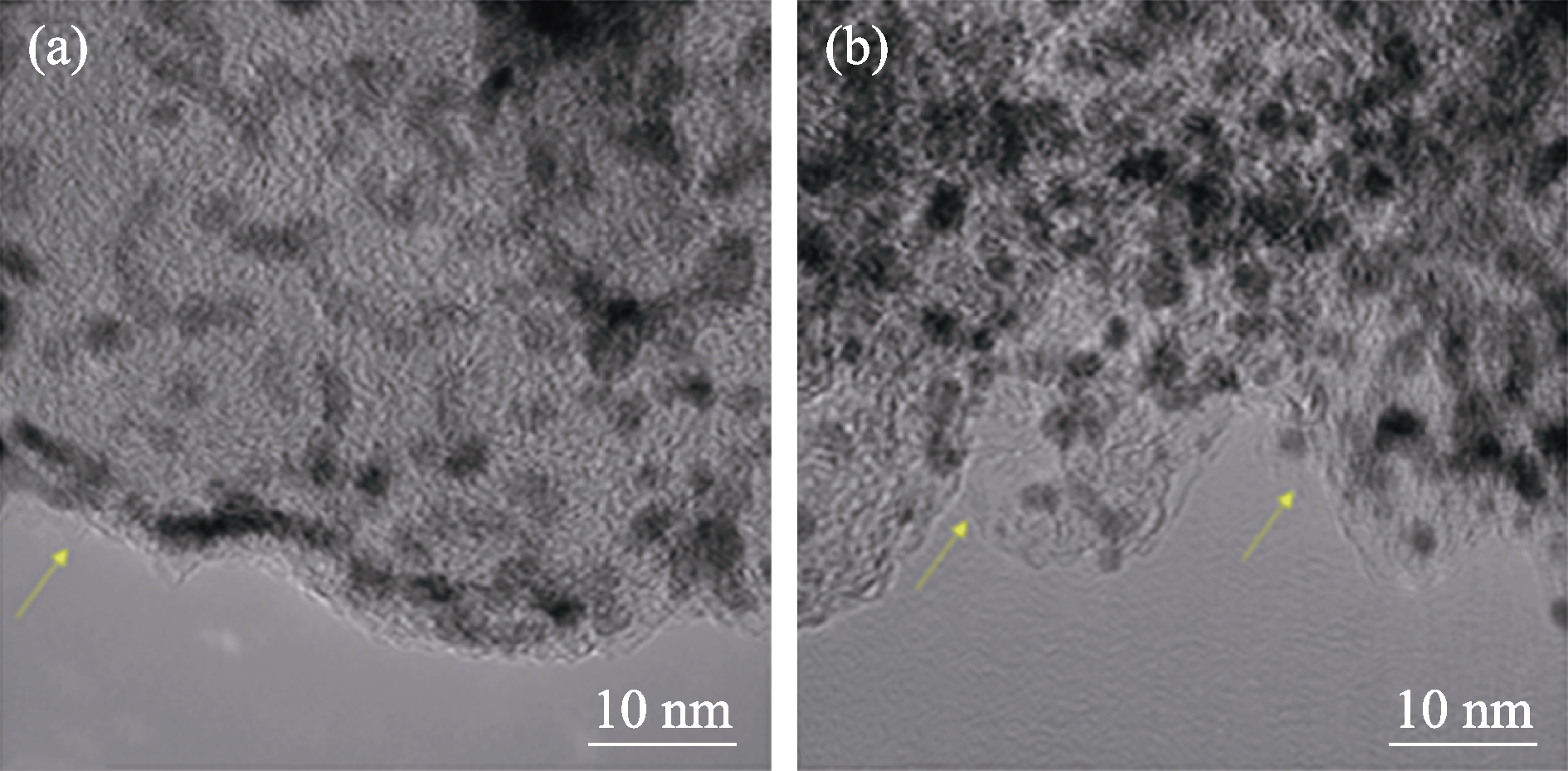

图7 含离聚物催化剂样品(a)Pt/VC和(b)Pt/KB2的TEM照片

Fig. 7 TEM images of catalysts containing ionomer for (a) Pt/VC and (b) Pt/KB2 Yellow arrows: ionomer film covering the outer surface of the catalyst particles

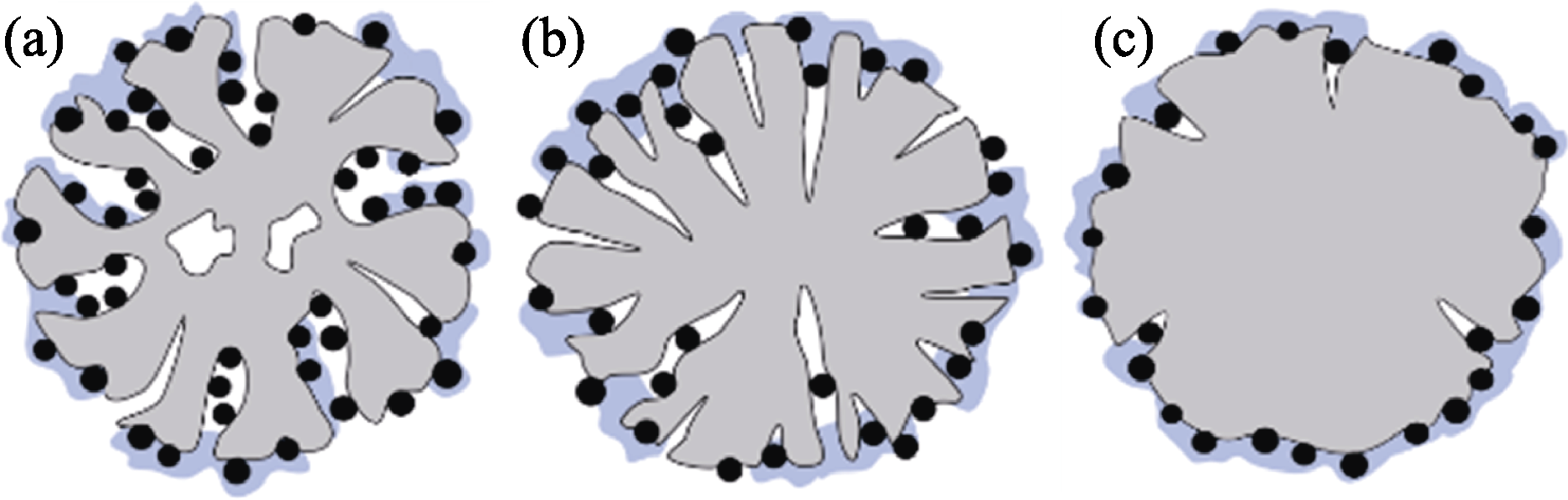

图8 离聚物在不同特征Pt/C颗粒上的分布示意图

Fig. 8 Schematic diagrams of the coverage states of ionomer on catalysts with different characteristics (a) PK-Pt/KB1, Pt/KB2; (b) Pt/BP; (c) Pt/VC, Pt/SJR and Pt/AB Black dot: Pt particle; Blue area: ionomer; Gray area: C

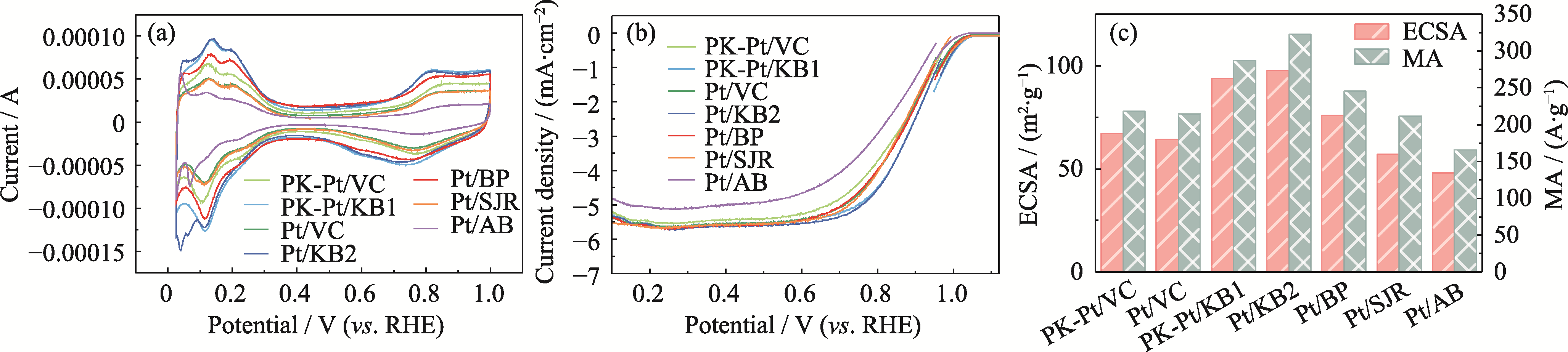

图9 不同Pt/C催化剂的(a) CV曲线、(b) LSV曲线以及(c) ECSA和MA比较

Fig. 9 (a) CV curves, (b) LSV curves, (c) calculated ECSA and MA of different Pt/C catalysts Colorful figures are available on website

| Sample | Specific surface area/(m2·g-1) | Pore area/(m2·g-1) | Pore volume/(cm3·g-1) | |||||

|---|---|---|---|---|---|---|---|---|

| <2 nm | 2-8 nm | >8 nm | <2 nm | 2-8 nm | >8 nm | Total | ||

| VC | 206.9 | 125.1 | 43.5 | 38.3 | 0.035 | 0.039 | 0.478 | 0.582 |

| KB1 | 811.1 | 372.8 | 353.1 | 85.2 | 0.194 | 0.308 | 0.730 | 1.232 |

| KB2 | 1361.0 | 291.3 | 834.3 | 235.4 | 0.167 | 0.807 | 1.613 | 2.587 |

| BP | 1313.1 | 903.6 | 249.0 | 160.5 | 0.444 | 0.204 | 1.909 | 2.577 |

| SJR | 121.2 | 15.1 | 33.4 | 72.7 | 0.009 | 0.032 | 0.757 | 0.798 |

| AB | 65.6 | 5.5 | 42.1 | 18.0 | 0.004 | 0.039 | 0.135 | 0.178 |

表S1 不同碳载体的总比表面积、孔容及其分布

Table S1 Specific surface areas, pore volumes and distributions of different carbon supports

| Sample | Specific surface area/(m2·g-1) | Pore area/(m2·g-1) | Pore volume/(cm3·g-1) | |||||

|---|---|---|---|---|---|---|---|---|

| <2 nm | 2-8 nm | >8 nm | <2 nm | 2-8 nm | >8 nm | Total | ||

| VC | 206.9 | 125.1 | 43.5 | 38.3 | 0.035 | 0.039 | 0.478 | 0.582 |

| KB1 | 811.1 | 372.8 | 353.1 | 85.2 | 0.194 | 0.308 | 0.730 | 1.232 |

| KB2 | 1361.0 | 291.3 | 834.3 | 235.4 | 0.167 | 0.807 | 1.613 | 2.587 |

| BP | 1313.1 | 903.6 | 249.0 | 160.5 | 0.444 | 0.204 | 1.909 | 2.577 |

| SJR | 121.2 | 15.1 | 33.4 | 72.7 | 0.009 | 0.032 | 0.757 | 0.798 |

| AB | 65.6 | 5.5 | 42.1 | 18.0 | 0.004 | 0.039 | 0.135 | 0.178 |

| Catalyst | PK-Pt/VC | Pt/VC | PK-Pt/KB1 | Pt/KB2 | Pt/BP | Pt/SJR | Pt/AB |

|---|---|---|---|---|---|---|---|

| Pt loading/% (in mass) | 38.6 | 32.0 | 38.3 | 35.8 | 35.8 | 37.0 | 31.9 |

| Average Pt particle size/nm | 3.9 | 3.0 | 2.5 | 2.4 | 2.5 | 2.6 | 2.8 |

表S2 不同碳载体上负载Pt粒子的平均粒径及负载量

Table S2 Average particle sizes and loading amounts of Pt particles on different carbon supports

| Catalyst | PK-Pt/VC | Pt/VC | PK-Pt/KB1 | Pt/KB2 | Pt/BP | Pt/SJR | Pt/AB |

|---|---|---|---|---|---|---|---|

| Pt loading/% (in mass) | 38.6 | 32.0 | 38.3 | 35.8 | 35.8 | 37.0 | 31.9 |

| Average Pt particle size/nm | 3.9 | 3.0 | 2.5 | 2.4 | 2.5 | 2.6 | 2.8 |

| Catalyst | PK-Pt/VC | Pt/VC | PK-Pt/KB1 | Pt/KB2 | Pt/BP | Pt/SJR | Pt/AB |

|---|---|---|---|---|---|---|---|

| Exterior frequency/% | 92 | 90 | 34 | 28 | 85 | 100 | 100 |

| Interior frequency/% | 8 | 10 | 66 | 72 | 15 | 0 | 0 |

表S3 Pt颗粒在不同碳载体的碳颗粒内外表面分布的百分比

Table S3 Percentages of Pt particles distributed inside and outside of the carbon particles for different carbon supports

| Catalyst | PK-Pt/VC | Pt/VC | PK-Pt/KB1 | Pt/KB2 | Pt/BP | Pt/SJR | Pt/AB |

|---|---|---|---|---|---|---|---|

| Exterior frequency/% | 92 | 90 | 34 | 28 | 85 | 100 | 100 |

| Interior frequency/% | 8 | 10 | 66 | 72 | 15 | 0 | 0 |

| Catalyst | jlim/(mA·cm-2) | jk/(mA·cm-2) | Eonset/V | E1/2/V |

|---|---|---|---|---|

| PK-Pt/VC | 5.9 | 4.3 | 1.037 | 0.88 |

| Pt/VC | 5.9 | 3.5 | 1.033 | 0.88 |

| PK-Pt/KB1 | 6.0 | 5.6 | 1.048 | 0.90 |

| Pt/KB2 | 6.1 | 5.9 | 1.042 | 0.90 |

| Pt/BP | 6.1 | 4.5 | 1.039 | 0.88 |

| Pt/SJR | 6.0 | 4.0 | 1.046 | 0.87 |

| Pt/AB | 5.5 | 2.7 | 1.014 | 0.84 |

表S4 不同Pt/C催化电极上ORR反应测试结果

Table S4 Testing results of ORR on various Pt/C catalytic electrodes

| Catalyst | jlim/(mA·cm-2) | jk/(mA·cm-2) | Eonset/V | E1/2/V |

|---|---|---|---|---|

| PK-Pt/VC | 5.9 | 4.3 | 1.037 | 0.88 |

| Pt/VC | 5.9 | 3.5 | 1.033 | 0.88 |

| PK-Pt/KB1 | 6.0 | 5.6 | 1.048 | 0.90 |

| Pt/KB2 | 6.1 | 5.9 | 1.042 | 0.90 |

| Pt/BP | 6.1 | 4.5 | 1.039 | 0.88 |

| Pt/SJR | 6.0 | 4.0 | 1.046 | 0.87 |

| Pt/AB | 5.5 | 2.7 | 1.014 | 0.84 |

图S1 不同碳载体负载Pt催化剂的HRTEM照片以及粒径分布图

Fig. S1 HRTEM images and histograms of particle size distributions of different Pt catalysts (a, a1) PK-Pt/VC; (b, b1) Pt/VC; (c, c1) PK-Pt/KB1; (d, d1) Pt/KB2; (e, e1) Pt/BP; (f, f1) Pt/SJR; (g, g1) Pt/AB

| [1] |

HAO C, LIU Z R, LIU W, et al. Research progress of carbon- supported metal single atom catalysts for oxygen reduction reaction. Journal of Inorganic Materials, 2021, 36(8): 820.

DOI |

| [2] | YAO Y S, GUO R H, AN S L, et al. In-situ loaded Pt-Co high index facets catalysts: preparation and elec-trocatalytic performance. Journal of Inorganic Materials, 2023, 38(1): 71. |

| [3] |

李薛茹, 马哲杰, 李平. 质子交换膜燃料电池阴极催化层微观结构表征研究进展. 储能科学与技术, 2025, 14(2): 812.

DOI |

| [4] |

NORMILE S J, ZENYUK I V. Imaging ionomer in fuel cell catalyst layers with synchrotron nano transmission X-ray microscopy. Solid State Ionics, 2019, 335: 38.

DOI URL |

| [5] |

MINAMI S, KAJIYA S, YAMADA H, et al. Measurement of ionomer coverage on carbon and Pt in catalyst layer of polymer electrolyte fuel cells by electrochemical impedance spectroscopy. Electrocatalysis, 2023, 14(4): 522.

DOI |

| [6] | KODAMA K, SHINOHARA A, HASEGAWA N, et al. Catalyst poisoning property of sulfonimide acid ionomer on Pt (111) surface. Journal of the Electrochemical Society, 2014, 161(5): F649. |

| [7] |

SHINOZAKI K, MORIMOTO Y, PIVOVAR B S, et al. Suppression of oxygen reduction reaction activity on Pt-based electrocatalysts from ionomer incorporation. Journal of Power Sources, 2016, 325: 745.

DOI URL |

| [8] |

OTT S, ORFANIDI A, SCHMIES H, et al. Ionomer distribution control in porous carbon-supported catalyst layers for high-power and low Pt-loaded proton exchange membrane fuel cells. Nature Materials, 2020, 19(1): 77.

DOI PMID |

| [9] |

SUN D D, WANG Z, JIN M, et al. Optimizing ionomer coverage in solid carbon-supported catalyst toward high performance for proton exchange membrane fuel cells. ACS Applied Energy Materials, 2024, 7(9): 4132.

DOI URL |

| [10] |

PARK Y C, TOKIWA H, KAKINUMA K, et al. Effects of carbon supports on Pt distribution, ionomer coverage and cathode performance for polymer electrolyte fuel cells. Journal of Power Sources, 2016, 315: 179.

DOI URL |

| [11] |

UCHIDA M, PARK Y C, KAKINUMA K, et al. Effect of the state of distribution of supported Pt nanoparticles on effective Pt utilization in polymer electrolyte fuel cells. Physical Chemistry Chemical Physics, 2013, 15(27): 11236.

DOI PMID |

| [12] |

YARLAGADDA V, CARPENTER M K, MOYLAN T E, et al. Boosting fuel cell performance with accessible carbon mesopores. ACS Energy Letters, 2018, 3(3): 618.

DOI URL |

| [13] |

RAMASWAMY N, GU W B, ZIEGELBAUER J M, et al. Carbon support microstructure impact on high current density transport resistances in PEMFC cathode. Journal of the Electrochemical Society, 2020, 167(6): 064515.

DOI |

| [14] |

WANG M N, ZHANG J G, FAVERO S, et al. Resolving optimal ionomer interaction in fuel cell electrodes via operando X-ray absorption spectroscopy. Nature Communications, 2024, 15: 9390.

DOI |

| [15] | 朱凤鹃, 吴爱明, 吴若飞. 催化剂中碳载体类型对燃料电池性能的影响研究. 现代工程科技, 2023, 2(2): 5. |

| [16] | XIANG Q, JIANG S K, LIU J, et al. Probing impact of support pore diameter on three-phase interfaces of Pt/C catalysts by molecular dynamic simulation. ACS Applied Materials & Interfaces, 2025, 17(5): 7619. |

| [17] |

BERLINGER S A, GARG S, WEBER A Z. Multicomponent, multiphase interactions in fuel-cell inks. Current Opinion in Electrochemistry, 2021, 29: 100744.

DOI URL |

| [18] |

SCHEIBA F, BENKER N, KUNZ U, et al. Electron microscopy techniques for the analysis of the polymer electrolyte distribution in proton exchange membrane fuel cells. Journal of Power Sources, 2008, 177(2): 273.

DOI URL |

| [19] |

GUÉTAZ L, LOPEZ-HARO M, ESCRIBANO S, et al. Catalyst- layer ionomer imaging of fuel cells. ECS Transactions, 2015, 69(17): 455.

DOI URL |

| [20] |

LOPEZ-HARO M, GUÉTAZ L, PRINTEMPS T, et al. Three- dimensional analysis of Nafion layers in fuel cell electrodes. Nature Communications, 2014, 5: 5229.

DOI |

| [21] | TAKESHITA T, KAMITAKA Y, SHINOZAKI K, et al. Evaluation of ionomer coverage on Pt catalysts in polymer electrolyte membrane fuel cells by CO stripping voltammetry and its effect on oxygen reduction reaction activity. Journal of Electroanalytical Chemistry, 2020, 871: 7. |

| [22] | 刘楠, 王宏伟. 单颗粒冷冻电镜技术的研究现状和未来展望. 中国基础科学, 2019, 21(5): 1. |

| [23] |

ZHAO X K, MA Z J, LI X R, et al. Optimization of atomic layer deposited Pt-shell thickness of PtCu3@Pt/C catalyst for oxygen reduction reaction. Materials Chemistry and Physics, 2025, 329: 130145.

DOI URL |

| [24] |

ITO T, MATSUWAKI U, OTSUKA Y, et al. Three-dimensional spatial distributions of Pt catalyst nanoparticles on carbon substrates in polymer electrolyte fuel cells. Electrochemistry, 2011, 79(5): 374.

DOI URL |

| [25] |

SING K S W. Reporting physisorption data for gas/solid systems with special reference to the determination of surface area and porosity. Pure and Applied Chemistry, 2013, 54(11): 2201.

DOI URL |

| [26] |

SHIN S, JANG J, YOON S H, et al. A study on the effect of heat treatment on functional groups of pitch based activated carbon fiber using FTIR. Carbon, 1997, 35(12): 1739.

DOI URL |

| [27] |

LI P, ZHAO T J, ZHOU J H, et al. Characterization of carbon nanofiber composites synthesized by shaping process. Carbon, 2005, 43(13): 2701.

DOI URL |

| [28] |

XIA G F, SHEN S Y, ZHU F J, et al. Effect of oxygen-containing functional groups of carbon materials on the performance of Li-O2 batteries. Electrochemistry Communications, 2015, 60: 26.

DOI URL |

| [29] |

VINAYAN B P, JAFRI R I, NAGAR R, et al. Catalytic activity of platinum-cobalt alloy nanoparticles decorated functionalized multiwalled carbon nanotubes for oxygen reduction reaction in PEMFC. International Journal of Hydrogen Energy, 2012, 37(1): 412.

DOI URL |

| [30] |

TERZYK A P. The influence of activated carbon surface chemical composition on the adsorption of acetaminophen (paracetamol) in vitro: part II. TG, FTIR, and XPS analysis of carbons and the temperature dependence of adsorption kinetics at the neutral pH. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2001, 177(1): 23.

DOI URL |

| [31] | MOHAMED E. Characterization of porous solids and powders: surface area, pore size and density. Journal of the American Chemical Society, 2005, 127(40): 14117. |

| [32] |

MA P C, SIDDIQUI N A, MÄDER E, et al. Correlation between electrokinetic potential, dispersibility, surface chemistry and energy of carbon nanotubes. Composites Science and Technology, 2011, 71(14): 1644.

DOI URL |

| [33] |

GIROD R, LAZARIDIS T, GASTEIGER H A, et al. Three- dimensional nanoimaging of fuel cell catalyst layers. Nature Catalysis, 2023, 6(5): 383.

DOI |

| [34] |

ZHONG G Y, XU S R, LIU L, et al. Effect of experimental operations on the limiting current density of oxygen reduction reaction evaluated by rotating-disk electrode. ChemElectroChem, 2020, 7(5): 1107.

DOI URL |

| [1] | 刘磊, 郭瑞华, 王丽, 王艳, 张国芳, 关丽丽. Pt3Co高指数晶面氧还原过程的密度泛函理论研究[J]. 无机材料学报, 2025, 40(1): 39-46. |

| [2] | 杨代辉, 孙甜, 田合鑫, 史晓斐, 马东伟. 铁氮共掺杂介孔碳材料的简易制备及其氧还原反应催化性能[J]. 无机材料学报, 2023, 38(11): 1309-1315. |

| [3] | 孙炼, 顾全超, 杨雅萍, 王洪磊, 余金山, 周新贵. 二维过渡金属硫属化合物氧还原反应催化剂的研究进展[J]. 无机材料学报, 2022, 37(7): 697-709. |

| [4] | 蒋丽丽, 徐帅帅, 夏宝凯, 陈胜, 朱俊武. 缺陷调控石墨烯复合催化剂在氧还原反应中的作用[J]. 无机材料学报, 2022, 37(2): 215-222. |

| [5] | 刘自若, 刘炜, 郝策, 胡金文, 史彦涛. 蜂窝状碳负载铁基单原子催化剂的制备及ORR催化性能研究[J]. 无机材料学报, 2021, 36(9): 943-949. |

| [6] | 郝策, 刘自若, 刘炜, 史彦涛. 用于氧还原反应的碳基负载金属单原子催化剂研究进展[J]. 无机材料学报, 2021, 36(8): 820-834. |

| [7] | 朱勇, 顾军, 于涛, 何海佟, 姚睿. 铂钴合金纳米电催化剂的制备及性能研究[J]. 无机材料学报, 2021, 36(3): 299-305. |

| [8] | 丁昇, 宁锴, 袁斌霞, 潘卫国, 尹诗斌, 刘建峰. 碱性溶液中不同微观结构的Fe-N/C催化剂氧还原性能的稳定性对比研究[J]. 无机材料学报, 2020, 35(8): 953-958. |

| [9] | 罗燚,冯军宗,冯坚,姜勇刚,李良军. 新型碳材料质子交换膜燃料电池Pt催化剂载体的研究进展[J]. 无机材料学报, 2020, 35(4): 407-415. |

| [10] | 何王涛, 马汝广, 朱钰方, 杨明杰, 王家成. 氢氧化钾活化制备可再生多孔碳及其电催化氧还原性能研究[J]. 无机材料学报, 2019, 34(10): 1115-1122. |

| [11] | 崔香枝, 张琳琳, 曾黎明, 张晓华, 陈航榕, 施剑林. 石墨化介孔碳包裹WC纳米粒子的构建及其氧还原性能研究[J]. 无机材料学报, 2018, 33(2): 213-220. |

| [12] | 李姝玲, 原鲜霞, 孔海川, 徐 进, 马紫峰. Fe-PPy-TsOH/C用作质子交换膜燃料电池氧电极催化剂的研究[J]. 无机材料学报, 2017, 32(4): 393-399. |

| [13] | 施 旗, 雷永鹏, 王应德, 王仲民. 氮掺杂石墨烯@碳纳米纤维的原位制备及其电催化氧还原性能[J]. 无机材料学报, 2016, 31(4): 351-357. |

| [14] | 李 琳, 原鲜霞, 夏小芸, 杜 娟, 马 忠, 马紫峰. Mo掺杂对Pt/C催化剂乙醇氧化催化性能的影响[J]. 无机材料学报, 2014, 29(10): 1044-1048. |

| [15] | 赵文文, 张 华, 李 梅. 恒压电沉积Pt-Fe合金催化剂及在PEMFC阴极的应用[J]. 无机材料学报, 2013, 28(11): 1217-1222. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||