High-entropy ceramics: present status, challenges, and a look forward

1

2021

... 高熵陶瓷是一种具有一个或多个Wyckoff位点的无机化合物的固溶体, 其中多个主元素的原子比相等或接近相等[1].高熵氧化物陶瓷(MgCoNiCuZn)O (HEO)作为首个被发现的高熵陶瓷[2], 不仅为发现新材料提供了新思路, 而且其本身及其衍生物也具有很好的性能, 在能量储存[3⇓⇓-6]、热和环境保护[7⇓-9]、催化[10-11]等方面有很好的应用前景. ...

Entropy-stabilized oxides

2

2015

... 高熵陶瓷是一种具有一个或多个Wyckoff位点的无机化合物的固溶体, 其中多个主元素的原子比相等或接近相等[1].高熵氧化物陶瓷(MgCoNiCuZn)O (HEO)作为首个被发现的高熵陶瓷[2], 不仅为发现新材料提供了新思路, 而且其本身及其衍生物也具有很好的性能, 在能量储存[3⇓⇓-6]、热和环境保护[7⇓-9]、催化[10-11]等方面有很好的应用前景. ...

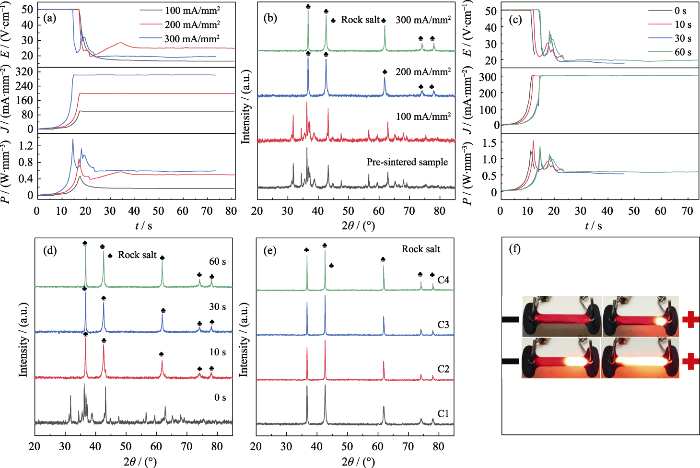

... 块状高熵陶瓷HEO的合成方法主要有传统烧结[2]、放电等离子烧结[12]和闪烧[13]等.其中, 闪烧以其显著加速固相反应和诱导相变而备受关注[14].本课题组[14]采用反应辅助闪烧成功地在室温下合成了HEO, 与传统烧结相比, 五元混合氧化物在几十秒内完全转变为单一的岩盐相.分析表明, 电场显著加快了相变速率, 验证了采用反应辅助闪烧技术合成熵稳定氧化物的可行性.随后, Yoon[15]和Kumar[16]等也得到了类似的结果.但是, 上述研究得到的高熵陶瓷相对密度较低, 难以研究其性能.为了探究闪烧合成HEO的性能, 本研究利用闪烧合成技术低温快速传质的特性, 合成了相对致密的高熵氧化物陶瓷(MgCoNiCuZn)O, 并与传统烧结试样的性能进行了对比. ...

High entropy oxides as anode material for Li-ion battery applications: a practical approach

1

2019

... 高熵陶瓷是一种具有一个或多个Wyckoff位点的无机化合物的固溶体, 其中多个主元素的原子比相等或接近相等[1].高熵氧化物陶瓷(MgCoNiCuZn)O (HEO)作为首个被发现的高熵陶瓷[2], 不仅为发现新材料提供了新思路, 而且其本身及其衍生物也具有很好的性能, 在能量储存[3⇓⇓-6]、热和环境保护[7⇓-9]、催化[10-11]等方面有很好的应用前景. ...

Colossal dielectric constant in high entropy oxides

2

2016

... 高熵陶瓷是一种具有一个或多个Wyckoff位点的无机化合物的固溶体, 其中多个主元素的原子比相等或接近相等[1].高熵氧化物陶瓷(MgCoNiCuZn)O (HEO)作为首个被发现的高熵陶瓷[2], 不仅为发现新材料提供了新思路, 而且其本身及其衍生物也具有很好的性能, 在能量储存[3⇓⇓-6]、热和环境保护[7⇓-9]、催化[10-11]等方面有很好的应用前景. ...

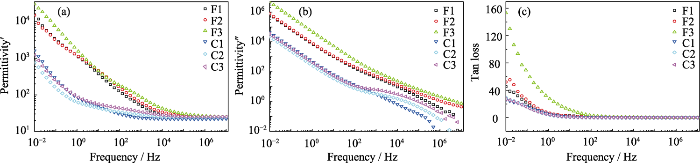

... 图5是闪烧试样与传统烧结试样的介电常数的实部、虚部以及介电损耗的数据.闪烧试样低于2 Hz, 介电常数在103以上; 而传统烧结只有当频率为10-2 Hz时, 最大介电常数才为103.值得注意的是, 巨大的介电常数并非是所含有的二价阳离子氧化物的共同特征, 而是形成高熵氧化物的特征[4].这可能是源于晶界或者晶粒表面的电荷累积所引起的Maxwell-Wagner极化效应[34].在高频(大于104 Hz)下, 传统烧结试样与闪烧试样的介电常数相近, 而在低频(2 Hz)下, 闪烧试样的介电常数比传统烧结试样高一个数量级.图5(c)是不同频率下的介电损耗, 可以看到当闪烧电流密度较大时(如F3), 与相应传统烧结试样的介电损耗相比较大; 但当闪烧电流密度较小时(如F1, F2), 闪烧试样具有更大介电常数的同时, 可以保持与传统烧结试样相近的介电损耗.在低频(<103 Hz)下, 主要的介电机制为空间电荷极化, 极化程度越高, 介电常数越大[35].空间电荷极化是指内部电荷在电场下移动的过程中被这些缺陷捕获, 造成电荷的局部聚集, 使电荷分布不均, 从而引起的极化.在外加电场作用下, 闪烧试样中可能引入大量的缺陷[20,26,36-37], 从而导致在低频下闪烧试样的极化程度比传统烧结的极化程度大, 这可能是低频下闪烧试样的介电常数比传统烧结试样高的原因. ...

Room temperature lithium superionic conductivity in high entropy oxides

1

2016

... 高熵陶瓷是一种具有一个或多个Wyckoff位点的无机化合物的固溶体, 其中多个主元素的原子比相等或接近相等[1].高熵氧化物陶瓷(MgCoNiCuZn)O (HEO)作为首个被发现的高熵陶瓷[2], 不仅为发现新材料提供了新思路, 而且其本身及其衍生物也具有很好的性能, 在能量储存[3⇓⇓-6]、热和环境保护[7⇓-9]、催化[10-11]等方面有很好的应用前景. ...

A high entropy oxide (Mg0.2Co0.2Ni0.2Cu0.2Zn0.2O) with superior lithium storage performance

1

2019

... 高熵陶瓷是一种具有一个或多个Wyckoff位点的无机化合物的固溶体, 其中多个主元素的原子比相等或接近相等[1].高熵氧化物陶瓷(MgCoNiCuZn)O (HEO)作为首个被发现的高熵陶瓷[2], 不仅为发现新材料提供了新思路, 而且其本身及其衍生物也具有很好的性能, 在能量储存[3⇓⇓-6]、热和环境保护[7⇓-9]、催化[10-11]等方面有很好的应用前景. ...

Stability and compressibility of cation-doped high-entropy oxide MgCoNiCuZnO5

1

2019

... 高熵陶瓷是一种具有一个或多个Wyckoff位点的无机化合物的固溶体, 其中多个主元素的原子比相等或接近相等[1].高熵氧化物陶瓷(MgCoNiCuZn)O (HEO)作为首个被发现的高熵陶瓷[2], 不仅为发现新材料提供了新思路, 而且其本身及其衍生物也具有很好的性能, 在能量储存[3⇓⇓-6]、热和环境保护[7⇓-9]、催化[10-11]等方面有很好的应用前景. ...

Charge-induced disorder controls the thermal conductivity of entropy-stabilized oxides

1

2018

... 高熵陶瓷是一种具有一个或多个Wyckoff位点的无机化合物的固溶体, 其中多个主元素的原子比相等或接近相等[1].高熵氧化物陶瓷(MgCoNiCuZn)O (HEO)作为首个被发现的高熵陶瓷[2], 不仅为发现新材料提供了新思路, 而且其本身及其衍生物也具有很好的性能, 在能量储存[3⇓⇓-6]、热和环境保护[7⇓-9]、催化[10-11]等方面有很好的应用前景. ...

Microstructural evolution and mechanical properties of (Mg,Co,Ni,Cu,Zn)O high-entropy ceramics

1

2019

... 高熵陶瓷是一种具有一个或多个Wyckoff位点的无机化合物的固溶体, 其中多个主元素的原子比相等或接近相等[1].高熵氧化物陶瓷(MgCoNiCuZn)O (HEO)作为首个被发现的高熵陶瓷[2], 不仅为发现新材料提供了新思路, 而且其本身及其衍生物也具有很好的性能, 在能量储存[3⇓⇓-6]、热和环境保护[7⇓-9]、催化[10-11]等方面有很好的应用前景. ...

Mechanochemical synthesis of high entropy oxide materials under ambient conditions: dispersion of catalysts via entropy maximization

1

2019

... 高熵陶瓷是一种具有一个或多个Wyckoff位点的无机化合物的固溶体, 其中多个主元素的原子比相等或接近相等[1].高熵氧化物陶瓷(MgCoNiCuZn)O (HEO)作为首个被发现的高熵陶瓷[2], 不仅为发现新材料提供了新思路, 而且其本身及其衍生物也具有很好的性能, 在能量储存[3⇓⇓-6]、热和环境保护[7⇓-9]、催化[10-11]等方面有很好的应用前景. ...

Entropy-stabilized metal oxide solid solutions as CO oxidation catalysts with high-temperature stability

1

2018

... 高熵陶瓷是一种具有一个或多个Wyckoff位点的无机化合物的固溶体, 其中多个主元素的原子比相等或接近相等[1].高熵氧化物陶瓷(MgCoNiCuZn)O (HEO)作为首个被发现的高熵陶瓷[2], 不仅为发现新材料提供了新思路, 而且其本身及其衍生物也具有很好的性能, 在能量储存[3⇓⇓-6]、热和环境保护[7⇓-9]、催化[10-11]等方面有很好的应用前景. ...

Entropic phase transformation in nanocrystalline high entropy oxides

1

2018

... 块状高熵陶瓷HEO的合成方法主要有传统烧结[2]、放电等离子烧结[12]和闪烧[13]等.其中, 闪烧以其显著加速固相反应和诱导相变而备受关注[14].本课题组[14]采用反应辅助闪烧成功地在室温下合成了HEO, 与传统烧结相比, 五元混合氧化物在几十秒内完全转变为单一的岩盐相.分析表明, 电场显著加快了相变速率, 验证了采用反应辅助闪烧技术合成熵稳定氧化物的可行性.随后, Yoon[15]和Kumar[16]等也得到了类似的结果.但是, 上述研究得到的高熵陶瓷相对密度较低, 难以研究其性能.为了探究闪烧合成HEO的性能, 本研究利用闪烧合成技术低温快速传质的特性, 合成了相对致密的高熵氧化物陶瓷(MgCoNiCuZn)O, 并与传统烧结试样的性能进行了对比. ...

Design and synthesis of chemically complex ceramics from the perspective of entropy

1

2020

... 块状高熵陶瓷HEO的合成方法主要有传统烧结[2]、放电等离子烧结[12]和闪烧[13]等.其中, 闪烧以其显著加速固相反应和诱导相变而备受关注[14].本课题组[14]采用反应辅助闪烧成功地在室温下合成了HEO, 与传统烧结相比, 五元混合氧化物在几十秒内完全转变为单一的岩盐相.分析表明, 电场显著加快了相变速率, 验证了采用反应辅助闪烧技术合成熵稳定氧化物的可行性.随后, Yoon[15]和Kumar[16]等也得到了类似的结果.但是, 上述研究得到的高熵陶瓷相对密度较低, 难以研究其性能.为了探究闪烧合成HEO的性能, 本研究利用闪烧合成技术低温快速传质的特性, 合成了相对致密的高熵氧化物陶瓷(MgCoNiCuZn)O, 并与传统烧结试样的性能进行了对比. ...

Ultrafast synthesis of entropy- stabilized oxide at room temperature

2

2020

... 块状高熵陶瓷HEO的合成方法主要有传统烧结[2]、放电等离子烧结[12]和闪烧[13]等.其中, 闪烧以其显著加速固相反应和诱导相变而备受关注[14].本课题组[14]采用反应辅助闪烧成功地在室温下合成了HEO, 与传统烧结相比, 五元混合氧化物在几十秒内完全转变为单一的岩盐相.分析表明, 电场显著加快了相变速率, 验证了采用反应辅助闪烧技术合成熵稳定氧化物的可行性.随后, Yoon[15]和Kumar[16]等也得到了类似的结果.但是, 上述研究得到的高熵陶瓷相对密度较低, 难以研究其性能.为了探究闪烧合成HEO的性能, 本研究利用闪烧合成技术低温快速传质的特性, 合成了相对致密的高熵氧化物陶瓷(MgCoNiCuZn)O, 并与传统烧结试样的性能进行了对比. ...

... [14]采用反应辅助闪烧成功地在室温下合成了HEO, 与传统烧结相比, 五元混合氧化物在几十秒内完全转变为单一的岩盐相.分析表明, 电场显著加快了相变速率, 验证了采用反应辅助闪烧技术合成熵稳定氧化物的可行性.随后, Yoon[15]和Kumar[16]等也得到了类似的结果.但是, 上述研究得到的高熵陶瓷相对密度较低, 难以研究其性能.为了探究闪烧合成HEO的性能, 本研究利用闪烧合成技术低温快速传质的特性, 合成了相对致密的高熵氧化物陶瓷(MgCoNiCuZn)O, 并与传统烧结试样的性能进行了对比. ...

Reactive flash sintering of the entropy-stabilized oxide Mg0.2Ni0.2Co0.2Cu0.2Zn0.2O

1

2020

... 块状高熵陶瓷HEO的合成方法主要有传统烧结[2]、放电等离子烧结[12]和闪烧[13]等.其中, 闪烧以其显著加速固相反应和诱导相变而备受关注[14].本课题组[14]采用反应辅助闪烧成功地在室温下合成了HEO, 与传统烧结相比, 五元混合氧化物在几十秒内完全转变为单一的岩盐相.分析表明, 电场显著加快了相变速率, 验证了采用反应辅助闪烧技术合成熵稳定氧化物的可行性.随后, Yoon[15]和Kumar[16]等也得到了类似的结果.但是, 上述研究得到的高熵陶瓷相对密度较低, 难以研究其性能.为了探究闪烧合成HEO的性能, 本研究利用闪烧合成技术低温快速传质的特性, 合成了相对致密的高熵氧化物陶瓷(MgCoNiCuZn)O, 并与传统烧结试样的性能进行了对比. ...

Flash assisted synthesis and densification of five component high entropy oxide (Mg, Co, Cu, Ni, Zn)O at 350 ℃ in 3 min.

1

2020

... 块状高熵陶瓷HEO的合成方法主要有传统烧结[2]、放电等离子烧结[12]和闪烧[13]等.其中, 闪烧以其显著加速固相反应和诱导相变而备受关注[14].本课题组[14]采用反应辅助闪烧成功地在室温下合成了HEO, 与传统烧结相比, 五元混合氧化物在几十秒内完全转变为单一的岩盐相.分析表明, 电场显著加快了相变速率, 验证了采用反应辅助闪烧技术合成熵稳定氧化物的可行性.随后, Yoon[15]和Kumar[16]等也得到了类似的结果.但是, 上述研究得到的高熵陶瓷相对密度较低, 难以研究其性能.为了探究闪烧合成HEO的性能, 本研究利用闪烧合成技术低温快速传质的特性, 合成了相对致密的高熵氧化物陶瓷(MgCoNiCuZn)O, 并与传统烧结试样的性能进行了对比. ...

Nanocrystalline multicomponent entropy stabilised transition metal oxides

1

2017

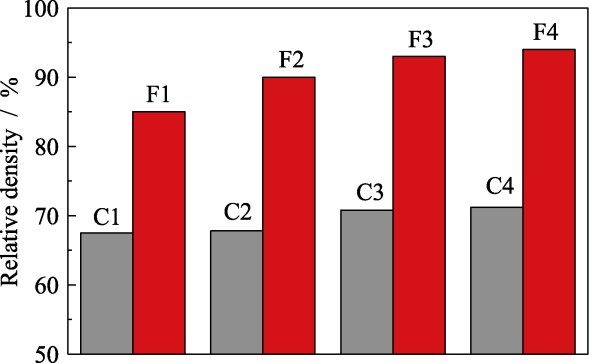

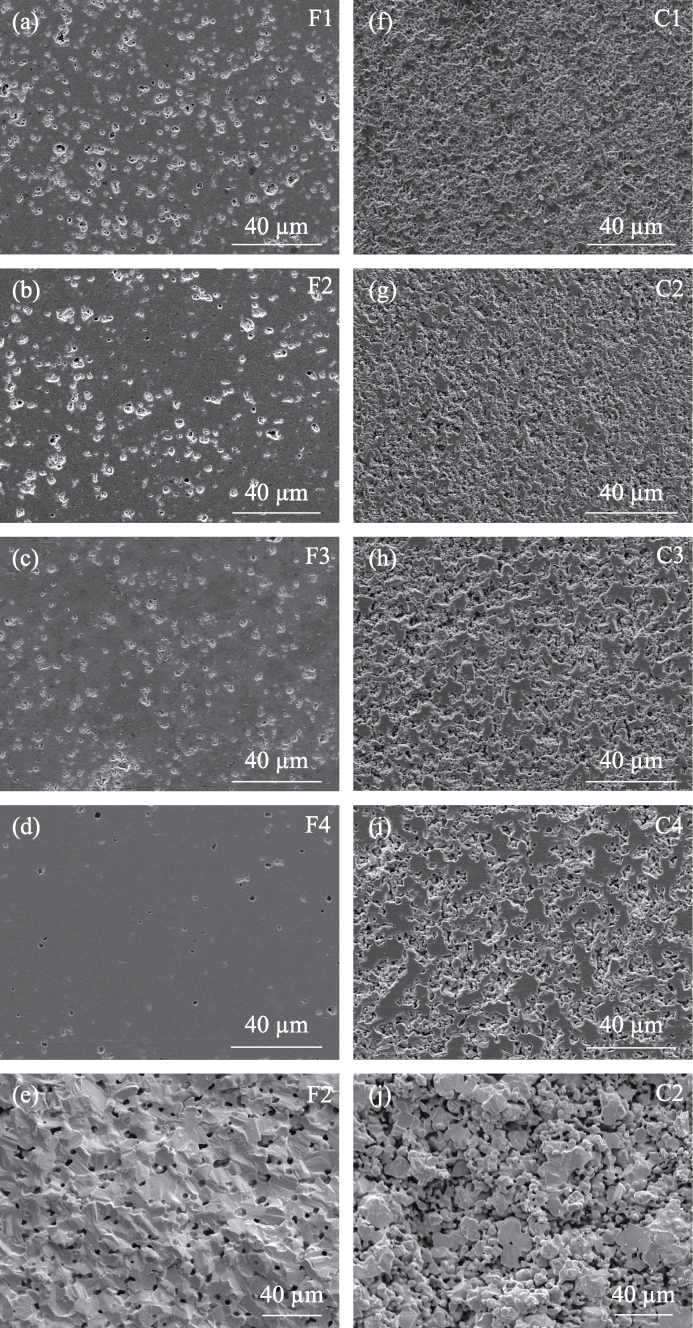

... 图2显示了闪烧和传统烧结试样的相对密度(绝对密度按6.137 g/cm3计算[17]).随着电流密度增大, 闪烧试样的密度呈现增大的趋势.闪烧试样的致密度一般与温度场效应以及电场引起的非热效应有关[18⇓⇓-21].试样的温度受电流密度显著影响, 电流密度越大, 试样温度越高[22].为了研究温度场对试样致密度的影响, 采用黑体辐射模型估算闪烧试样的温度, 并在相应温度下制备了传统烧结试样(见表1).从图2可以看出, 传统烧结试样的致密度随着温度升高而升高, 这说明温度场对试样致密度的影响明显[18].有研究者认为闪烧瞬间会使晶界处出现局部高温, 形成液相, 从而提高致密化速率[23].除此之外, Zhang[24]和Ji[25]等几乎同时提出闪烧瞬间极高的加热速率是造成快速致密化的根本原因, 并通过快速升温烧结实验进行了对比验证.然而, 闪烧试样的密度远高于传统烧结试样的密度, 例如电流密度为300 mA/mm2的闪烧试样, 相对密度为94%, 比传统烧结的相对密度高22.8%, 这难以从单一的温度场效应来解释, 因此电场引起的非热效应可能对试样致密度也会产生重要影响.Ren等[26]认为临界电场下氧空位的产生和运动会在粉体颗粒间产生库仑力, 这有利于烧结前期的致密化过程, 同时致密化过程中伴随着金属阳离子的快速运动.Cologna等[27]提出Frenkel缺陷在电场作用下发生雪崩是造成快速致密化的原因.总之, 闪烧试样具有更高致密度是温度场和电场耦合的结果. ...

In situ thermometry measuring temperature flashes exceeding 1,700 ℃ in 8mol% Y2O3-stablized zirconia under constant-voltage heating

2

2013

... 图2显示了闪烧和传统烧结试样的相对密度(绝对密度按6.137 g/cm3计算[17]).随着电流密度增大, 闪烧试样的密度呈现增大的趋势.闪烧试样的致密度一般与温度场效应以及电场引起的非热效应有关[18⇓⇓-21].试样的温度受电流密度显著影响, 电流密度越大, 试样温度越高[22].为了研究温度场对试样致密度的影响, 采用黑体辐射模型估算闪烧试样的温度, 并在相应温度下制备了传统烧结试样(见表1).从图2可以看出, 传统烧结试样的致密度随着温度升高而升高, 这说明温度场对试样致密度的影响明显[18].有研究者认为闪烧瞬间会使晶界处出现局部高温, 形成液相, 从而提高致密化速率[23].除此之外, Zhang[24]和Ji[25]等几乎同时提出闪烧瞬间极高的加热速率是造成快速致密化的根本原因, 并通过快速升温烧结实验进行了对比验证.然而, 闪烧试样的密度远高于传统烧结试样的密度, 例如电流密度为300 mA/mm2的闪烧试样, 相对密度为94%, 比传统烧结的相对密度高22.8%, 这难以从单一的温度场效应来解释, 因此电场引起的非热效应可能对试样致密度也会产生重要影响.Ren等[26]认为临界电场下氧空位的产生和运动会在粉体颗粒间产生库仑力, 这有利于烧结前期的致密化过程, 同时致密化过程中伴随着金属阳离子的快速运动.Cologna等[27]提出Frenkel缺陷在电场作用下发生雪崩是造成快速致密化的原因.总之, 闪烧试样具有更高致密度是温度场和电场耦合的结果. ...

... [18].有研究者认为闪烧瞬间会使晶界处出现局部高温, 形成液相, 从而提高致密化速率[23].除此之外, Zhang[24]和Ji[25]等几乎同时提出闪烧瞬间极高的加热速率是造成快速致密化的根本原因, 并通过快速升温烧结实验进行了对比验证.然而, 闪烧试样的密度远高于传统烧结试样的密度, 例如电流密度为300 mA/mm2的闪烧试样, 相对密度为94%, 比传统烧结的相对密度高22.8%, 这难以从单一的温度场效应来解释, 因此电场引起的非热效应可能对试样致密度也会产生重要影响.Ren等[26]认为临界电场下氧空位的产生和运动会在粉体颗粒间产生库仑力, 这有利于烧结前期的致密化过程, 同时致密化过程中伴随着金属阳离子的快速运动.Cologna等[27]提出Frenkel缺陷在电场作用下发生雪崩是造成快速致密化的原因.总之, 闪烧试样具有更高致密度是温度场和电场耦合的结果. ...

On the kinetics of liquid-assisted densification during flash sintering of ceramic nanoparticles

1

2019

... 图2显示了闪烧和传统烧结试样的相对密度(绝对密度按6.137 g/cm3计算[17]).随着电流密度增大, 闪烧试样的密度呈现增大的趋势.闪烧试样的致密度一般与温度场效应以及电场引起的非热效应有关[18⇓⇓-21].试样的温度受电流密度显著影响, 电流密度越大, 试样温度越高[22].为了研究温度场对试样致密度的影响, 采用黑体辐射模型估算闪烧试样的温度, 并在相应温度下制备了传统烧结试样(见表1).从图2可以看出, 传统烧结试样的致密度随着温度升高而升高, 这说明温度场对试样致密度的影响明显[18].有研究者认为闪烧瞬间会使晶界处出现局部高温, 形成液相, 从而提高致密化速率[23].除此之外, Zhang[24]和Ji[25]等几乎同时提出闪烧瞬间极高的加热速率是造成快速致密化的根本原因, 并通过快速升温烧结实验进行了对比验证.然而, 闪烧试样的密度远高于传统烧结试样的密度, 例如电流密度为300 mA/mm2的闪烧试样, 相对密度为94%, 比传统烧结的相对密度高22.8%, 这难以从单一的温度场效应来解释, 因此电场引起的非热效应可能对试样致密度也会产生重要影响.Ren等[26]认为临界电场下氧空位的产生和运动会在粉体颗粒间产生库仑力, 这有利于烧结前期的致密化过程, 同时致密化过程中伴随着金属阳离子的快速运动.Cologna等[27]提出Frenkel缺陷在电场作用下发生雪崩是造成快速致密化的原因.总之, 闪烧试样具有更高致密度是温度场和电场耦合的结果. ...

The densification behavior of flash sintered BaTiO3

2

2020

... 图2显示了闪烧和传统烧结试样的相对密度(绝对密度按6.137 g/cm3计算[17]).随着电流密度增大, 闪烧试样的密度呈现增大的趋势.闪烧试样的致密度一般与温度场效应以及电场引起的非热效应有关[18⇓⇓-21].试样的温度受电流密度显著影响, 电流密度越大, 试样温度越高[22].为了研究温度场对试样致密度的影响, 采用黑体辐射模型估算闪烧试样的温度, 并在相应温度下制备了传统烧结试样(见表1).从图2可以看出, 传统烧结试样的致密度随着温度升高而升高, 这说明温度场对试样致密度的影响明显[18].有研究者认为闪烧瞬间会使晶界处出现局部高温, 形成液相, 从而提高致密化速率[23].除此之外, Zhang[24]和Ji[25]等几乎同时提出闪烧瞬间极高的加热速率是造成快速致密化的根本原因, 并通过快速升温烧结实验进行了对比验证.然而, 闪烧试样的密度远高于传统烧结试样的密度, 例如电流密度为300 mA/mm2的闪烧试样, 相对密度为94%, 比传统烧结的相对密度高22.8%, 这难以从单一的温度场效应来解释, 因此电场引起的非热效应可能对试样致密度也会产生重要影响.Ren等[26]认为临界电场下氧空位的产生和运动会在粉体颗粒间产生库仑力, 这有利于烧结前期的致密化过程, 同时致密化过程中伴随着金属阳离子的快速运动.Cologna等[27]提出Frenkel缺陷在电场作用下发生雪崩是造成快速致密化的原因.总之, 闪烧试样具有更高致密度是温度场和电场耦合的结果. ...

... 图5是闪烧试样与传统烧结试样的介电常数的实部、虚部以及介电损耗的数据.闪烧试样低于2 Hz, 介电常数在103以上; 而传统烧结只有当频率为10-2 Hz时, 最大介电常数才为103.值得注意的是, 巨大的介电常数并非是所含有的二价阳离子氧化物的共同特征, 而是形成高熵氧化物的特征[4].这可能是源于晶界或者晶粒表面的电荷累积所引起的Maxwell-Wagner极化效应[34].在高频(大于104 Hz)下, 传统烧结试样与闪烧试样的介电常数相近, 而在低频(2 Hz)下, 闪烧试样的介电常数比传统烧结试样高一个数量级.图5(c)是不同频率下的介电损耗, 可以看到当闪烧电流密度较大时(如F3), 与相应传统烧结试样的介电损耗相比较大; 但当闪烧电流密度较小时(如F1, F2), 闪烧试样具有更大介电常数的同时, 可以保持与传统烧结试样相近的介电损耗.在低频(<103 Hz)下, 主要的介电机制为空间电荷极化, 极化程度越高, 介电常数越大[35].空间电荷极化是指内部电荷在电场下移动的过程中被这些缺陷捕获, 造成电荷的局部聚集, 使电荷分布不均, 从而引起的极化.在外加电场作用下, 闪烧试样中可能引入大量的缺陷[20,26,36-37], 从而导致在低频下闪烧试样的极化程度比传统烧结的极化程度大, 这可能是低频下闪烧试样的介电常数比传统烧结试样高的原因. ...

In-situ observation of oxygen mobility and abnormal lattice expansion in ceria during flash sintering

1

2018

... 图2显示了闪烧和传统烧结试样的相对密度(绝对密度按6.137 g/cm3计算[17]).随着电流密度增大, 闪烧试样的密度呈现增大的趋势.闪烧试样的致密度一般与温度场效应以及电场引起的非热效应有关[18⇓⇓-21].试样的温度受电流密度显著影响, 电流密度越大, 试样温度越高[22].为了研究温度场对试样致密度的影响, 采用黑体辐射模型估算闪烧试样的温度, 并在相应温度下制备了传统烧结试样(见表1).从图2可以看出, 传统烧结试样的致密度随着温度升高而升高, 这说明温度场对试样致密度的影响明显[18].有研究者认为闪烧瞬间会使晶界处出现局部高温, 形成液相, 从而提高致密化速率[23].除此之外, Zhang[24]和Ji[25]等几乎同时提出闪烧瞬间极高的加热速率是造成快速致密化的根本原因, 并通过快速升温烧结实验进行了对比验证.然而, 闪烧试样的密度远高于传统烧结试样的密度, 例如电流密度为300 mA/mm2的闪烧试样, 相对密度为94%, 比传统烧结的相对密度高22.8%, 这难以从单一的温度场效应来解释, 因此电场引起的非热效应可能对试样致密度也会产生重要影响.Ren等[26]认为临界电场下氧空位的产生和运动会在粉体颗粒间产生库仑力, 这有利于烧结前期的致密化过程, 同时致密化过程中伴随着金属阳离子的快速运动.Cologna等[27]提出Frenkel缺陷在电场作用下发生雪崩是造成快速致密化的原因.总之, 闪烧试样具有更高致密度是温度场和电场耦合的结果. ...

Joule heating during flash-sintering

1

2012

... 图2显示了闪烧和传统烧结试样的相对密度(绝对密度按6.137 g/cm3计算[17]).随着电流密度增大, 闪烧试样的密度呈现增大的趋势.闪烧试样的致密度一般与温度场效应以及电场引起的非热效应有关[18⇓⇓-21].试样的温度受电流密度显著影响, 电流密度越大, 试样温度越高[22].为了研究温度场对试样致密度的影响, 采用黑体辐射模型估算闪烧试样的温度, 并在相应温度下制备了传统烧结试样(见表1).从图2可以看出, 传统烧结试样的致密度随着温度升高而升高, 这说明温度场对试样致密度的影响明显[18].有研究者认为闪烧瞬间会使晶界处出现局部高温, 形成液相, 从而提高致密化速率[23].除此之外, Zhang[24]和Ji[25]等几乎同时提出闪烧瞬间极高的加热速率是造成快速致密化的根本原因, 并通过快速升温烧结实验进行了对比验证.然而, 闪烧试样的密度远高于传统烧结试样的密度, 例如电流密度为300 mA/mm2的闪烧试样, 相对密度为94%, 比传统烧结的相对密度高22.8%, 这难以从单一的温度场效应来解释, 因此电场引起的非热效应可能对试样致密度也会产生重要影响.Ren等[26]认为临界电场下氧空位的产生和运动会在粉体颗粒间产生库仑力, 这有利于烧结前期的致密化过程, 同时致密化过程中伴随着金属阳离子的快速运动.Cologna等[27]提出Frenkel缺陷在电场作用下发生雪崩是造成快速致密化的原因.总之, 闪烧试样具有更高致密度是温度场和电场耦合的结果. ...

A new mechanism for field-assisted processing and flash sintering of materials

1

2013

... 图2显示了闪烧和传统烧结试样的相对密度(绝对密度按6.137 g/cm3计算[17]).随着电流密度增大, 闪烧试样的密度呈现增大的趋势.闪烧试样的致密度一般与温度场效应以及电场引起的非热效应有关[18⇓⇓-21].试样的温度受电流密度显著影响, 电流密度越大, 试样温度越高[22].为了研究温度场对试样致密度的影响, 采用黑体辐射模型估算闪烧试样的温度, 并在相应温度下制备了传统烧结试样(见表1).从图2可以看出, 传统烧结试样的致密度随着温度升高而升高, 这说明温度场对试样致密度的影响明显[18].有研究者认为闪烧瞬间会使晶界处出现局部高温, 形成液相, 从而提高致密化速率[23].除此之外, Zhang[24]和Ji[25]等几乎同时提出闪烧瞬间极高的加热速率是造成快速致密化的根本原因, 并通过快速升温烧结实验进行了对比验证.然而, 闪烧试样的密度远高于传统烧结试样的密度, 例如电流密度为300 mA/mm2的闪烧试样, 相对密度为94%, 比传统烧结的相对密度高22.8%, 这难以从单一的温度场效应来解释, 因此电场引起的非热效应可能对试样致密度也会产生重要影响.Ren等[26]认为临界电场下氧空位的产生和运动会在粉体颗粒间产生库仑力, 这有利于烧结前期的致密化过程, 同时致密化过程中伴随着金属阳离子的快速运动.Cologna等[27]提出Frenkel缺陷在电场作用下发生雪崩是造成快速致密化的原因.总之, 闪烧试样具有更高致密度是温度场和电场耦合的结果. ...

Probing the densification mechanisms during flash sintering of ZnO.

1

2017

... 图2显示了闪烧和传统烧结试样的相对密度(绝对密度按6.137 g/cm3计算[17]).随着电流密度增大, 闪烧试样的密度呈现增大的趋势.闪烧试样的致密度一般与温度场效应以及电场引起的非热效应有关[18⇓⇓-21].试样的温度受电流密度显著影响, 电流密度越大, 试样温度越高[22].为了研究温度场对试样致密度的影响, 采用黑体辐射模型估算闪烧试样的温度, 并在相应温度下制备了传统烧结试样(见表1).从图2可以看出, 传统烧结试样的致密度随着温度升高而升高, 这说明温度场对试样致密度的影响明显[18].有研究者认为闪烧瞬间会使晶界处出现局部高温, 形成液相, 从而提高致密化速率[23].除此之外, Zhang[24]和Ji[25]等几乎同时提出闪烧瞬间极高的加热速率是造成快速致密化的根本原因, 并通过快速升温烧结实验进行了对比验证.然而, 闪烧试样的密度远高于传统烧结试样的密度, 例如电流密度为300 mA/mm2的闪烧试样, 相对密度为94%, 比传统烧结的相对密度高22.8%, 这难以从单一的温度场效应来解释, 因此电场引起的非热效应可能对试样致密度也会产生重要影响.Ren等[26]认为临界电场下氧空位的产生和运动会在粉体颗粒间产生库仑力, 这有利于烧结前期的致密化过程, 同时致密化过程中伴随着金属阳离子的快速运动.Cologna等[27]提出Frenkel缺陷在电场作用下发生雪崩是造成快速致密化的原因.总之, 闪烧试样具有更高致密度是温度场和电场耦合的结果. ...

Ultra-fast firing: effect of heating rate on sintering of 3YSZ, with and without an electric field

1

2017

... 图2显示了闪烧和传统烧结试样的相对密度(绝对密度按6.137 g/cm3计算[17]).随着电流密度增大, 闪烧试样的密度呈现增大的趋势.闪烧试样的致密度一般与温度场效应以及电场引起的非热效应有关[18⇓⇓-21].试样的温度受电流密度显著影响, 电流密度越大, 试样温度越高[22].为了研究温度场对试样致密度的影响, 采用黑体辐射模型估算闪烧试样的温度, 并在相应温度下制备了传统烧结试样(见表1).从图2可以看出, 传统烧结试样的致密度随着温度升高而升高, 这说明温度场对试样致密度的影响明显[18].有研究者认为闪烧瞬间会使晶界处出现局部高温, 形成液相, 从而提高致密化速率[23].除此之外, Zhang[24]和Ji[25]等几乎同时提出闪烧瞬间极高的加热速率是造成快速致密化的根本原因, 并通过快速升温烧结实验进行了对比验证.然而, 闪烧试样的密度远高于传统烧结试样的密度, 例如电流密度为300 mA/mm2的闪烧试样, 相对密度为94%, 比传统烧结的相对密度高22.8%, 这难以从单一的温度场效应来解释, 因此电场引起的非热效应可能对试样致密度也会产生重要影响.Ren等[26]认为临界电场下氧空位的产生和运动会在粉体颗粒间产生库仑力, 这有利于烧结前期的致密化过程, 同时致密化过程中伴随着金属阳离子的快速运动.Cologna等[27]提出Frenkel缺陷在电场作用下发生雪崩是造成快速致密化的原因.总之, 闪烧试样具有更高致密度是温度场和电场耦合的结果. ...

Densification kinetics of flash sintered 3mol% Y2O3 stabilized zirconia

2

2018

... 图2显示了闪烧和传统烧结试样的相对密度(绝对密度按6.137 g/cm3计算[17]).随着电流密度增大, 闪烧试样的密度呈现增大的趋势.闪烧试样的致密度一般与温度场效应以及电场引起的非热效应有关[18⇓⇓-21].试样的温度受电流密度显著影响, 电流密度越大, 试样温度越高[22].为了研究温度场对试样致密度的影响, 采用黑体辐射模型估算闪烧试样的温度, 并在相应温度下制备了传统烧结试样(见表1).从图2可以看出, 传统烧结试样的致密度随着温度升高而升高, 这说明温度场对试样致密度的影响明显[18].有研究者认为闪烧瞬间会使晶界处出现局部高温, 形成液相, 从而提高致密化速率[23].除此之外, Zhang[24]和Ji[25]等几乎同时提出闪烧瞬间极高的加热速率是造成快速致密化的根本原因, 并通过快速升温烧结实验进行了对比验证.然而, 闪烧试样的密度远高于传统烧结试样的密度, 例如电流密度为300 mA/mm2的闪烧试样, 相对密度为94%, 比传统烧结的相对密度高22.8%, 这难以从单一的温度场效应来解释, 因此电场引起的非热效应可能对试样致密度也会产生重要影响.Ren等[26]认为临界电场下氧空位的产生和运动会在粉体颗粒间产生库仑力, 这有利于烧结前期的致密化过程, 同时致密化过程中伴随着金属阳离子的快速运动.Cologna等[27]提出Frenkel缺陷在电场作用下发生雪崩是造成快速致密化的原因.总之, 闪烧试样具有更高致密度是温度场和电场耦合的结果. ...

... 图5是闪烧试样与传统烧结试样的介电常数的实部、虚部以及介电损耗的数据.闪烧试样低于2 Hz, 介电常数在103以上; 而传统烧结只有当频率为10-2 Hz时, 最大介电常数才为103.值得注意的是, 巨大的介电常数并非是所含有的二价阳离子氧化物的共同特征, 而是形成高熵氧化物的特征[4].这可能是源于晶界或者晶粒表面的电荷累积所引起的Maxwell-Wagner极化效应[34].在高频(大于104 Hz)下, 传统烧结试样与闪烧试样的介电常数相近, 而在低频(2 Hz)下, 闪烧试样的介电常数比传统烧结试样高一个数量级.图5(c)是不同频率下的介电损耗, 可以看到当闪烧电流密度较大时(如F3), 与相应传统烧结试样的介电损耗相比较大; 但当闪烧电流密度较小时(如F1, F2), 闪烧试样具有更大介电常数的同时, 可以保持与传统烧结试样相近的介电损耗.在低频(<103 Hz)下, 主要的介电机制为空间电荷极化, 极化程度越高, 介电常数越大[35].空间电荷极化是指内部电荷在电场下移动的过程中被这些缺陷捕获, 造成电荷的局部聚集, 使电荷分布不均, 从而引起的极化.在外加电场作用下, 闪烧试样中可能引入大量的缺陷[20,26,36-37], 从而导致在低频下闪烧试样的极化程度比传统烧结的极化程度大, 这可能是低频下闪烧试样的介电常数比传统烧结试样高的原因. ...

Flash-sintering of cubic yttria-stabilized zirconia at 750 ℃ for possible use in SOFC manufacturing

1

2011

... 图2显示了闪烧和传统烧结试样的相对密度(绝对密度按6.137 g/cm3计算[17]).随着电流密度增大, 闪烧试样的密度呈现增大的趋势.闪烧试样的致密度一般与温度场效应以及电场引起的非热效应有关[18⇓⇓-21].试样的温度受电流密度显著影响, 电流密度越大, 试样温度越高[22].为了研究温度场对试样致密度的影响, 采用黑体辐射模型估算闪烧试样的温度, 并在相应温度下制备了传统烧结试样(见表1).从图2可以看出, 传统烧结试样的致密度随着温度升高而升高, 这说明温度场对试样致密度的影响明显[18].有研究者认为闪烧瞬间会使晶界处出现局部高温, 形成液相, 从而提高致密化速率[23].除此之外, Zhang[24]和Ji[25]等几乎同时提出闪烧瞬间极高的加热速率是造成快速致密化的根本原因, 并通过快速升温烧结实验进行了对比验证.然而, 闪烧试样的密度远高于传统烧结试样的密度, 例如电流密度为300 mA/mm2的闪烧试样, 相对密度为94%, 比传统烧结的相对密度高22.8%, 这难以从单一的温度场效应来解释, 因此电场引起的非热效应可能对试样致密度也会产生重要影响.Ren等[26]认为临界电场下氧空位的产生和运动会在粉体颗粒间产生库仑力, 这有利于烧结前期的致密化过程, 同时致密化过程中伴随着金属阳离子的快速运动.Cologna等[27]提出Frenkel缺陷在电场作用下发生雪崩是造成快速致密化的原因.总之, 闪烧试样具有更高致密度是温度场和电场耦合的结果. ...

Grain-size- independent plastic flow at ultrahigh pressures and strain rates

1

2015

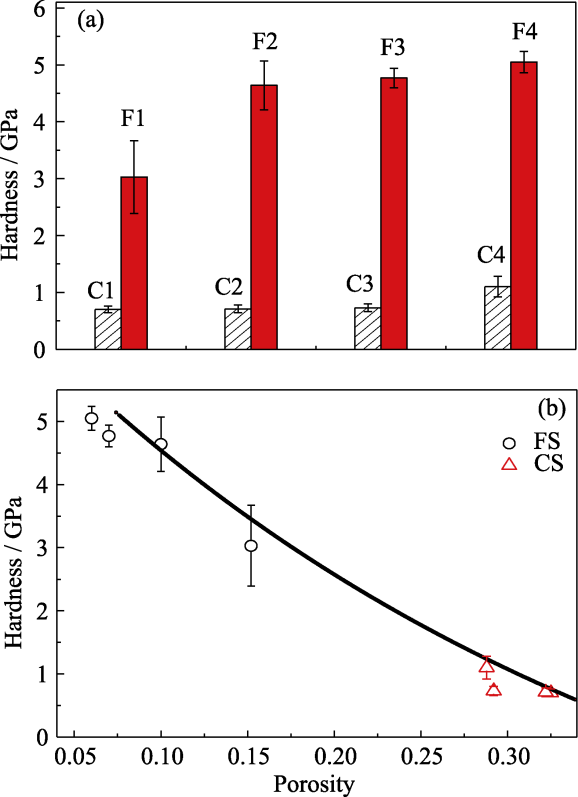

... 图4是闪烧试样与相应传统烧结试样的硬度.从图4(a)中看出, 闪烧试样的硬度随着电流密度增加而增大.当电流密度为300 mA/mm2时, 闪烧试样的硬度约为(5.05±0.19) GPa, 而传统烧结试样的硬度仅为(1.10±0.18) GPa, 试样的硬度提高了400%.陶瓷材料的硬度主要与晶粒尺寸和密度有关.当晶粒尺寸>0.2 μm时, 晶粒尺寸对硬度的影响可忽略不计[28].进一步, 给出试样的硬度随气孔率的变化曲线, 见图4(b).无论是闪烧试样还是传统烧结试样, 硬度都随气孔率的减小而增大, 且都在一条曲线上, 这说明试样硬度的提高主要归因于致密度的提高[29-30].此外, 闪烧试样的硬度值偏差明显大于传统烧结试样, 这可能与直流闪烧试样的微观结构不均匀有关, 这种微观结构的不均匀性在其它闪烧体系中也有报道[31⇓-33]. ...

Effect of oscillatory pressure on the sintering behavior of ZrO2 ceramic

1

2020

... 图4是闪烧试样与相应传统烧结试样的硬度.从图4(a)中看出, 闪烧试样的硬度随着电流密度增加而增大.当电流密度为300 mA/mm2时, 闪烧试样的硬度约为(5.05±0.19) GPa, 而传统烧结试样的硬度仅为(1.10±0.18) GPa, 试样的硬度提高了400%.陶瓷材料的硬度主要与晶粒尺寸和密度有关.当晶粒尺寸>0.2 μm时, 晶粒尺寸对硬度的影响可忽略不计[28].进一步, 给出试样的硬度随气孔率的变化曲线, 见图4(b).无论是闪烧试样还是传统烧结试样, 硬度都随气孔率的减小而增大, 且都在一条曲线上, 这说明试样硬度的提高主要归因于致密度的提高[29-30].此外, 闪烧试样的硬度值偏差明显大于传统烧结试样, 这可能与直流闪烧试样的微观结构不均匀有关, 这种微观结构的不均匀性在其它闪烧体系中也有报道[31⇓-33]. ...

Sintering behavior and mechanical properties of alumina ceramics exposed to oscillatory pressure at different sintering stages

1

2021

... 图4是闪烧试样与相应传统烧结试样的硬度.从图4(a)中看出, 闪烧试样的硬度随着电流密度增加而增大.当电流密度为300 mA/mm2时, 闪烧试样的硬度约为(5.05±0.19) GPa, 而传统烧结试样的硬度仅为(1.10±0.18) GPa, 试样的硬度提高了400%.陶瓷材料的硬度主要与晶粒尺寸和密度有关.当晶粒尺寸>0.2 μm时, 晶粒尺寸对硬度的影响可忽略不计[28].进一步, 给出试样的硬度随气孔率的变化曲线, 见图4(b).无论是闪烧试样还是传统烧结试样, 硬度都随气孔率的减小而增大, 且都在一条曲线上, 这说明试样硬度的提高主要归因于致密度的提高[29-30].此外, 闪烧试样的硬度值偏差明显大于传统烧结试样, 这可能与直流闪烧试样的微观结构不均匀有关, 这种微观结构的不均匀性在其它闪烧体系中也有报道[31⇓-33]. ...

Grain growth kinetics of 3mol% yttria- stabilized zirconia during flash sintering

1

2019

... 图4是闪烧试样与相应传统烧结试样的硬度.从图4(a)中看出, 闪烧试样的硬度随着电流密度增加而增大.当电流密度为300 mA/mm2时, 闪烧试样的硬度约为(5.05±0.19) GPa, 而传统烧结试样的硬度仅为(1.10±0.18) GPa, 试样的硬度提高了400%.陶瓷材料的硬度主要与晶粒尺寸和密度有关.当晶粒尺寸>0.2 μm时, 晶粒尺寸对硬度的影响可忽略不计[28].进一步, 给出试样的硬度随气孔率的变化曲线, 见图4(b).无论是闪烧试样还是传统烧结试样, 硬度都随气孔率的减小而增大, 且都在一条曲线上, 这说明试样硬度的提高主要归因于致密度的提高[29-30].此外, 闪烧试样的硬度值偏差明显大于传统烧结试样, 这可能与直流闪烧试样的微观结构不均匀有关, 这种微观结构的不均匀性在其它闪烧体系中也有报道[31⇓-33]. ...

Position-sensitive electric property of flash-sintered 3Y-TZP ceramics based on DC bias assisted impedance analysis

1

2022

... 图4是闪烧试样与相应传统烧结试样的硬度.从图4(a)中看出, 闪烧试样的硬度随着电流密度增加而增大.当电流密度为300 mA/mm2时, 闪烧试样的硬度约为(5.05±0.19) GPa, 而传统烧结试样的硬度仅为(1.10±0.18) GPa, 试样的硬度提高了400%.陶瓷材料的硬度主要与晶粒尺寸和密度有关.当晶粒尺寸>0.2 μm时, 晶粒尺寸对硬度的影响可忽略不计[28].进一步, 给出试样的硬度随气孔率的变化曲线, 见图4(b).无论是闪烧试样还是传统烧结试样, 硬度都随气孔率的减小而增大, 且都在一条曲线上, 这说明试样硬度的提高主要归因于致密度的提高[29-30].此外, 闪烧试样的硬度值偏差明显大于传统烧结试样, 这可能与直流闪烧试样的微观结构不均匀有关, 这种微观结构的不均匀性在其它闪烧体系中也有报道[31⇓-33]. ...

Ultrafast preparation of Al2O3-ZrO2 multiphase ceramics with eutectic morphology via flash sintering

1

2021

... 图4是闪烧试样与相应传统烧结试样的硬度.从图4(a)中看出, 闪烧试样的硬度随着电流密度增加而增大.当电流密度为300 mA/mm2时, 闪烧试样的硬度约为(5.05±0.19) GPa, 而传统烧结试样的硬度仅为(1.10±0.18) GPa, 试样的硬度提高了400%.陶瓷材料的硬度主要与晶粒尺寸和密度有关.当晶粒尺寸>0.2 μm时, 晶粒尺寸对硬度的影响可忽略不计[28].进一步, 给出试样的硬度随气孔率的变化曲线, 见图4(b).无论是闪烧试样还是传统烧结试样, 硬度都随气孔率的减小而增大, 且都在一条曲线上, 这说明试样硬度的提高主要归因于致密度的提高[29-30].此外, 闪烧试样的硬度值偏差明显大于传统烧结试样, 这可能与直流闪烧试样的微观结构不均匀有关, 这种微观结构的不均匀性在其它闪烧体系中也有报道[31⇓-33]. ...

Optical response of high-dielectric-constant perovskite-related oxide

1

2001

... 图5是闪烧试样与传统烧结试样的介电常数的实部、虚部以及介电损耗的数据.闪烧试样低于2 Hz, 介电常数在103以上; 而传统烧结只有当频率为10-2 Hz时, 最大介电常数才为103.值得注意的是, 巨大的介电常数并非是所含有的二价阳离子氧化物的共同特征, 而是形成高熵氧化物的特征[4].这可能是源于晶界或者晶粒表面的电荷累积所引起的Maxwell-Wagner极化效应[34].在高频(大于104 Hz)下, 传统烧结试样与闪烧试样的介电常数相近, 而在低频(2 Hz)下, 闪烧试样的介电常数比传统烧结试样高一个数量级.图5(c)是不同频率下的介电损耗, 可以看到当闪烧电流密度较大时(如F3), 与相应传统烧结试样的介电损耗相比较大; 但当闪烧电流密度较小时(如F1, F2), 闪烧试样具有更大介电常数的同时, 可以保持与传统烧结试样相近的介电损耗.在低频(<103 Hz)下, 主要的介电机制为空间电荷极化, 极化程度越高, 介电常数越大[35].空间电荷极化是指内部电荷在电场下移动的过程中被这些缺陷捕获, 造成电荷的局部聚集, 使电荷分布不均, 从而引起的极化.在外加电场作用下, 闪烧试样中可能引入大量的缺陷[20,26,36-37], 从而导致在低频下闪烧试样的极化程度比传统烧结的极化程度大, 这可能是低频下闪烧试样的介电常数比传统烧结试样高的原因. ...

1

2018

... 图5是闪烧试样与传统烧结试样的介电常数的实部、虚部以及介电损耗的数据.闪烧试样低于2 Hz, 介电常数在103以上; 而传统烧结只有当频率为10-2 Hz时, 最大介电常数才为103.值得注意的是, 巨大的介电常数并非是所含有的二价阳离子氧化物的共同特征, 而是形成高熵氧化物的特征[4].这可能是源于晶界或者晶粒表面的电荷累积所引起的Maxwell-Wagner极化效应[34].在高频(大于104 Hz)下, 传统烧结试样与闪烧试样的介电常数相近, 而在低频(2 Hz)下, 闪烧试样的介电常数比传统烧结试样高一个数量级.图5(c)是不同频率下的介电损耗, 可以看到当闪烧电流密度较大时(如F3), 与相应传统烧结试样的介电损耗相比较大; 但当闪烧电流密度较小时(如F1, F2), 闪烧试样具有更大介电常数的同时, 可以保持与传统烧结试样相近的介电损耗.在低频(<103 Hz)下, 主要的介电机制为空间电荷极化, 极化程度越高, 介电常数越大[35].空间电荷极化是指内部电荷在电场下移动的过程中被这些缺陷捕获, 造成电荷的局部聚集, 使电荷分布不均, 从而引起的极化.在外加电场作用下, 闪烧试样中可能引入大量的缺陷[20,26,36-37], 从而导致在低频下闪烧试样的极化程度比传统烧结的极化程度大, 这可能是低频下闪烧试样的介电常数比传统烧结试样高的原因. ...

Creep behavior of zirconia ceramics under a strong DC field

1

2022

... 图5是闪烧试样与传统烧结试样的介电常数的实部、虚部以及介电损耗的数据.闪烧试样低于2 Hz, 介电常数在103以上; 而传统烧结只有当频率为10-2 Hz时, 最大介电常数才为103.值得注意的是, 巨大的介电常数并非是所含有的二价阳离子氧化物的共同特征, 而是形成高熵氧化物的特征[4].这可能是源于晶界或者晶粒表面的电荷累积所引起的Maxwell-Wagner极化效应[34].在高频(大于104 Hz)下, 传统烧结试样与闪烧试样的介电常数相近, 而在低频(2 Hz)下, 闪烧试样的介电常数比传统烧结试样高一个数量级.图5(c)是不同频率下的介电损耗, 可以看到当闪烧电流密度较大时(如F3), 与相应传统烧结试样的介电损耗相比较大; 但当闪烧电流密度较小时(如F1, F2), 闪烧试样具有更大介电常数的同时, 可以保持与传统烧结试样相近的介电损耗.在低频(<103 Hz)下, 主要的介电机制为空间电荷极化, 极化程度越高, 介电常数越大[35].空间电荷极化是指内部电荷在电场下移动的过程中被这些缺陷捕获, 造成电荷的局部聚集, 使电荷分布不均, 从而引起的极化.在外加电场作用下, 闪烧试样中可能引入大量的缺陷[20,26,36-37], 从而导致在低频下闪烧试样的极化程度比传统烧结的极化程度大, 这可能是低频下闪烧试样的介电常数比传统烧结试样高的原因. ...

Microstructure and dielectric property of flash sintered SiO2-coated BaTiO3 ceramics

1

2019

... 图5是闪烧试样与传统烧结试样的介电常数的实部、虚部以及介电损耗的数据.闪烧试样低于2 Hz, 介电常数在103以上; 而传统烧结只有当频率为10-2 Hz时, 最大介电常数才为103.值得注意的是, 巨大的介电常数并非是所含有的二价阳离子氧化物的共同特征, 而是形成高熵氧化物的特征[4].这可能是源于晶界或者晶粒表面的电荷累积所引起的Maxwell-Wagner极化效应[34].在高频(大于104 Hz)下, 传统烧结试样与闪烧试样的介电常数相近, 而在低频(2 Hz)下, 闪烧试样的介电常数比传统烧结试样高一个数量级.图5(c)是不同频率下的介电损耗, 可以看到当闪烧电流密度较大时(如F3), 与相应传统烧结试样的介电损耗相比较大; 但当闪烧电流密度较小时(如F1, F2), 闪烧试样具有更大介电常数的同时, 可以保持与传统烧结试样相近的介电损耗.在低频(<103 Hz)下, 主要的介电机制为空间电荷极化, 极化程度越高, 介电常数越大[35].空间电荷极化是指内部电荷在电场下移动的过程中被这些缺陷捕获, 造成电荷的局部聚集, 使电荷分布不均, 从而引起的极化.在外加电场作用下, 闪烧试样中可能引入大量的缺陷[20,26,36-37], 从而导致在低频下闪烧试样的极化程度比传统烧结的极化程度大, 这可能是低频下闪烧试样的介电常数比传统烧结试样高的原因. ...