Journal of Inorganic Materials ›› 2021, Vol. 36 ›› Issue (10): 1111-1117.DOI: 10.15541/jim20210045

• RESEARCH LETTER • Previous Articles Next Articles

LI Longbin1,2( ), XUE Yudong1,2, HU Jianbao1,2, YANG Jinshan1,2, ZHANG Xiangyu1,2, DONG Shaoming1,2(

), XUE Yudong1,2, HU Jianbao1,2, YANG Jinshan1,2, ZHANG Xiangyu1,2, DONG Shaoming1,2( )

)

Received:2021-01-27

Revised:2021-04-15

Published:2021-10-20

Online:2021-05-10

Contact:

DONG Shaoming, professor. E-mail: smdong@mail.sic.ac.cn

About author:LI Longbin(1997–), male, Master candidate. Email: medolia97@student.sic.ac.cn

Supported by:CLC Number:

LI Longbin, XUE Yudong, HU Jianbao, YANG Jinshan, ZHANG Xiangyu, DONG Shaoming. Influence of SiC Nanowires on the Damage Evolution of SiCf/SiC Composites[J]. Journal of Inorganic Materials, 2021, 36(10): 1111-1117.

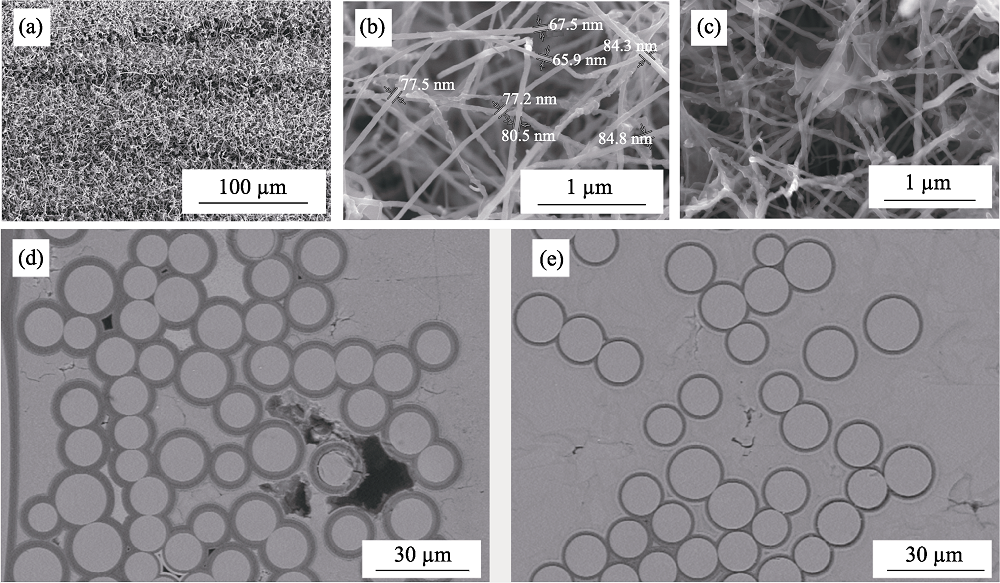

Fig. 2 Typical SEM images of (a, b) as-grown SiCnw, (c) BN-coated SiCnw, and typical SEM images demonstrating the pore size of (d) SiCf/SiC and (e) SiCf/SiC-SiCnw composites

| Composite | SiCf/SiC | SiCf/SiC- SiCnw/BN | SiCf/ SiC-SiCnw |

|---|---|---|---|

| Bulk density/(g·cm-3) | (1.98±0.03) | (2.02±0.04) | (2.08±0.03) |

| Open porosity/% | (17.64±1.08) | (14.39±0.60) | (11.58±1.35) |

| Composite | SiCf/SiC | SiCf/SiC- SiCnw/BN | SiCf/ SiC-SiCnw |

|---|---|---|---|

| Bulk density/(g·cm-3) | (1.98±0.03) | (2.02±0.04) | (2.08±0.03) |

| Open porosity/% | (17.64±1.08) | (14.39±0.60) | (11.58±1.35) |

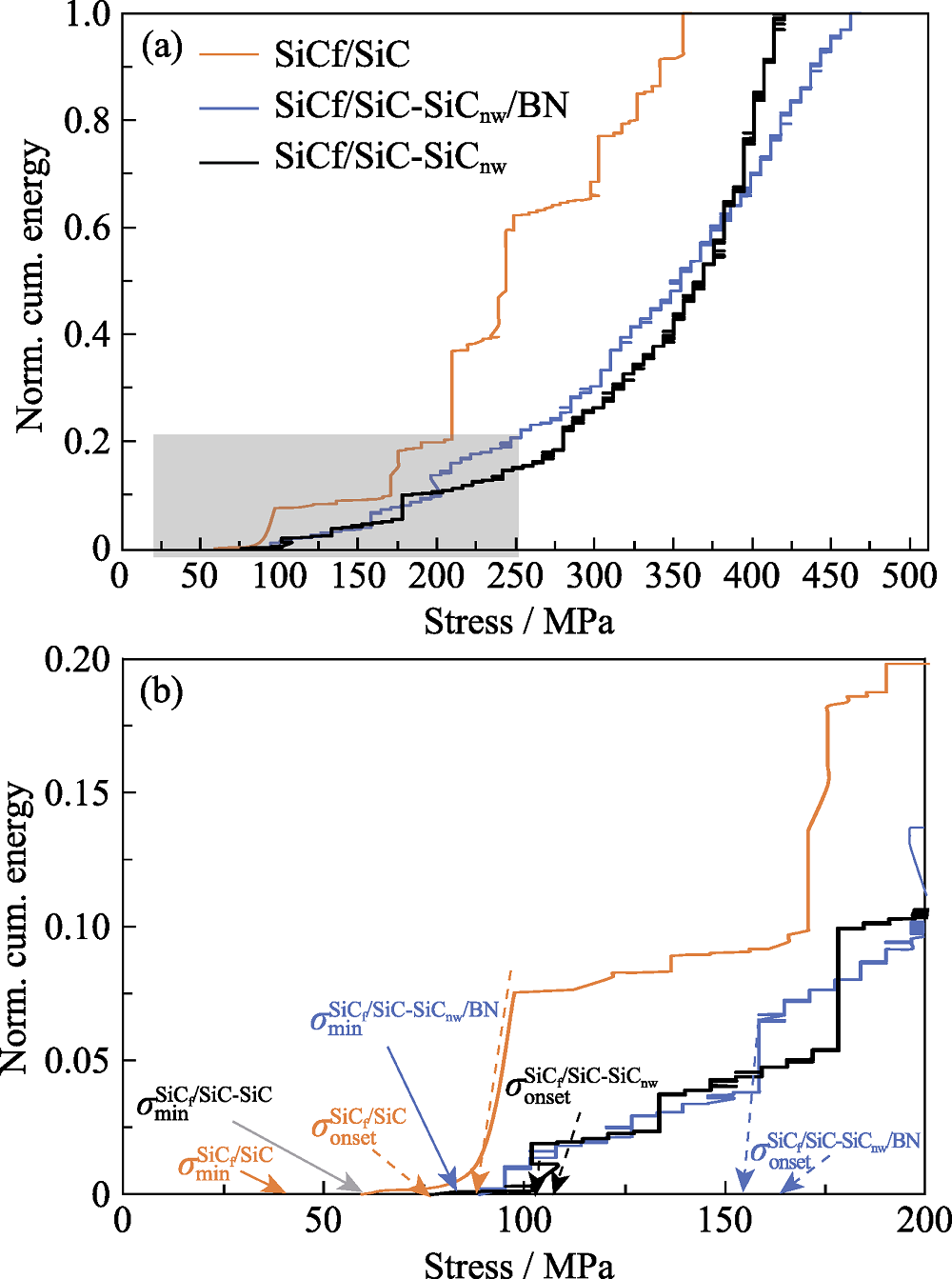

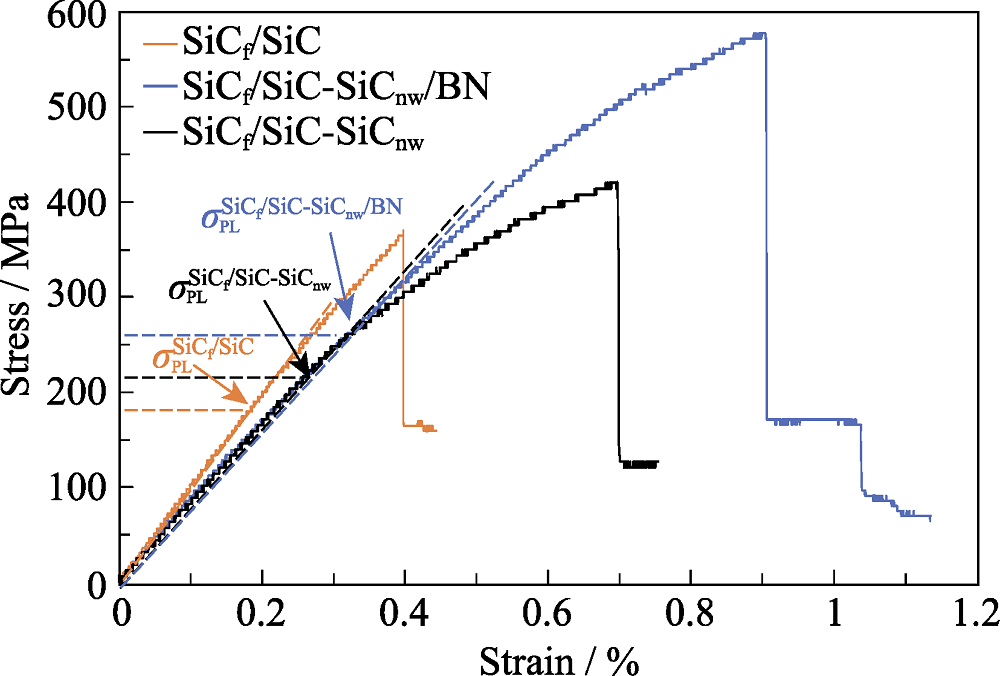

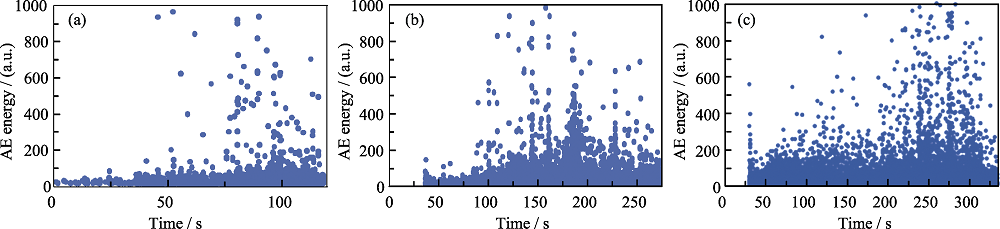

| Composite | SiCnw content / wt% | Flexural strength, σu/MPa | Proportional limit stress, σPL/MPa | Strain at flexural strength, εu/% | First AE stress, σmin/MPa | AE onset stress, σonset/MPa |

|---|---|---|---|---|---|---|

| SiCf/SiC | 0 | (356.7±16.2) | (153.9±6.4) | (0.39±0.05) | (58.8±7.5) | (116.1±8.9) |

| SiCf/SiC-SiCnw | 2.0 | (412.6±22.4) | (185.1±7.7) | (0.63±0.06) | (66.1±6.2) | (155.8±7.7) |

| SiCf/SiC-SiCnw/BN | 2.0 | (506.4±28.3) | (247.7±8.6) | (0.88±0.12) | (78.5±5.2) | (171.6±15.9) |

| Composite | SiCnw content / wt% | Flexural strength, σu/MPa | Proportional limit stress, σPL/MPa | Strain at flexural strength, εu/% | First AE stress, σmin/MPa | AE onset stress, σonset/MPa |

|---|---|---|---|---|---|---|

| SiCf/SiC | 0 | (356.7±16.2) | (153.9±6.4) | (0.39±0.05) | (58.8±7.5) | (116.1±8.9) |

| SiCf/SiC-SiCnw | 2.0 | (412.6±22.4) | (185.1±7.7) | (0.63±0.06) | (66.1±6.2) | (155.8±7.7) |

| SiCf/SiC-SiCnw/BN | 2.0 | (506.4±28.3) | (247.7±8.6) | (0.88±0.12) | (78.5±5.2) | (171.6±15.9) |

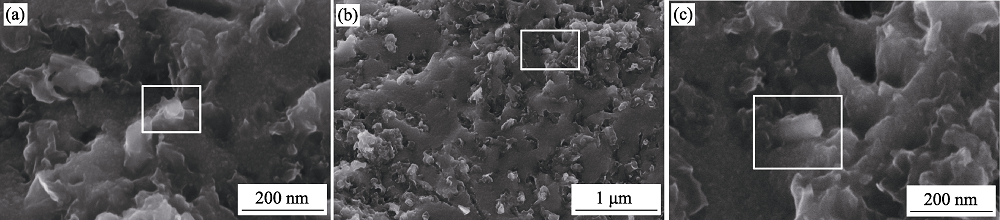

Fig. 3 SEM fractural morphologies of (a) as-grown SiCnw, (b, c) BN-coated SiCnw in composites Local parts marked by white rectangular borders demonstrating that SiCnw tends to break (a) or pull out (b, c)

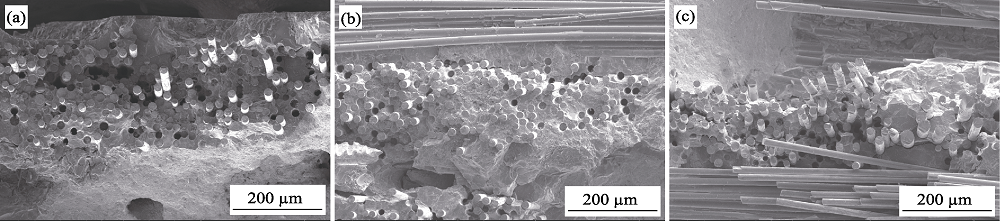

Fig. 4 Fracture morphologies of composite (a) SiCf/SiC, (b) SiCf/SiC-SiCnw and (c) SiCf/SiC-SiCnw/BN The images demonstrating the pull-out length of fibers

Fig. 5 Representative normalized cumulative AE energy curves as a function of stress (a) for composite SiCf/SiC (orange), SiCf/SiC-SiCnw (black) and SiCf/SiC-SiCnw/BN (blue) To clarify the difference of damage threshold among these three groups, initial key part (grey area) in (a) is magnified in (b). Colorful figures are available on website

Fig. 6 Typical stress-strain curves of SiCf/SiC(orange), SiCf/SiC-SiCnw (black) and SiCf/SiC-SiCnw/BN (blue) The proportional limit is pointed out in the picture. Colorful figures are available on website

Fig. 7 Scatter diagrams of the energy of individual AE events as a function of time in composites (a) SiCf/SiC, (b) SiCf/SiC-SiCnw, and (c) SiCf/SiC-SiCnw/BN Considering the massive amount of data, diagrams are depicted after compression

| [1] |

NASLAIN R. Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: an overview. Composites Science and Technology, 2004, 64(2):155-170.

DOI URL |

| [2] | DICARLO J A, van ROODE M. Ceramic Composite Development for Gas Turbine Engine Hot Section Components. Proceedings of the ASME Turbo Expo 2006: Power for Land, Sea, and Air, F, 2006. Volume 2: Aircraft Engine; Ceramics; Coal, Biomass and Alternative Fuels; Controls, Diagnostics and Instrumentation; Environmental and Regulatory Affairs. Barcelona, Spain. May 8-11, 2006: 221-231. |

| [3] |

NASLAIN R R. Processing of non-oxide ceramic matrix composites: an overview. Advances in Science and Technology, 2006, 50:64-74.

DOI URL |

| [4] |

YIN X, CHENG L, ZHANG L, et al. Fibre-reinforced multifunctional SiC matrix composite materials. International Materials Reviews, 2017, 62(3):117-172.

DOI URL |

| [5] |

YANG W, ARAKI H, TANG C, et al. Single-crystal SiC nanowires with a thin carbon coating for stronger and tougher ceramic composites. Advanced Materials, 2005, 17(12):1519-1523.

DOI URL |

| [6] |

HU J, DONG S, FENG Q, et al. Tailoring carbon nanotube/matrix interface to optimize mechanical properties of multiscale composites. Carbon, 2014, 69:621-625.

DOI URL |

| [7] |

ZHU G, XUE Y, HU J, et al. Influence of boron nitride nanotubes on the damage evolution of SiCf/SiC composites. Journal of the European Ceramic Society, 2018, 38(14):4614-4622.

DOI URL |

| [8] |

HE F, LIU Y, TIAN Z, et al. Carbon fiber/SiC composites modified SiC nanowires with improved strength and toughness. Materials Science and Engineering: A, 2018, 734:374-384.

DOI URL |

| [9] |

CHU Y, LI H, FU Q, et al. Oxidation protection and behavior of C/C composites with an in situ SiC nanowire-SiC-Si/SiC-Si coating. Corrosion Science, 2013, 70:285-289.

DOI URL |

| [10] |

ZHAO K, LI K, WANG Y. Rapid densification of C/SiC composite by incorporating SiC nanowires. Composites Part B: Engineering, 2013, 45(1):1583-1586.

DOI URL |

| [11] | DONG R, YANG W, WU P, et al. Effect of reinforcement shape on the stress-strain behavior of aluminum reinforced with SiC nanowire. Materials & Design, 2015, 88:1015-1020. |

| [12] |

THOULESS M D, EVANS A G. Effects of pull-out on the mechanical properties of ceramic-matrix composites. Acta Metallurgica, 1988, 36(3):517-522.

DOI URL |

| [13] |

DE GREEF N, GORBATIKH L, GODARA A, et al. The effect of carbon nanotubes on the damage development in carbon fiber/epoxy composites. Carbon, 2011, 49(14):4650-4664.

DOI URL |

| [14] |

KANG S M, KIM W J, YOON S G, et al. Effects of the PyC interface coating on SiC nanowires of SiCf/SiC composite. Journal of Nuclear Materials, 2011, 417(1/2/3):367-370.

DOI URL |

| [15] |

MORSCHER G N, SINGH M, KISER J D, et al. Modeling stress-dependent matrix cracking and stress-strain behavior in 2D woven SiC fiber reinforced CVI SiC composites. Composites Science and Technology, 2007, 67(6):1009-1017.

DOI URL |

| [16] |

WHITLOW T, JONES E, PRZYBYLA C. In-sit damage monitoring of a SiC/SiC ceramic matrix composite using acoustic emission and digital image correlation. Composite Structures, 2016, 158:245-251.

DOI URL |

| [17] |

MORSCHER G N. Stress-dependent matrix cracking in 2D woven SiC-fiber reinforced melt-infiltrated SiC matrix composites. Composites Science and Technology, 2004, 64(9):1311-1319.

DOI URL |

| [18] | ARGON A S. Fracture of composites. Treatise on Materials Science and Technology, 1972, 1:79-114. |

| [1] | WU Xiaochen, ZHENG Ruixiao, LI Lu, MA Haolin, ZHAO Peihang, MA Chaoli. Research Progress on In-situ Monitoring of Damage Behavior of SiCf/SiC Ceramic Matrix Composites at High Temperature Environments [J]. Journal of Inorganic Materials, 2024, 39(6): 609-622. |

| [2] | SHEN Xuanyi, MA Qin, XUE Yudong, LIAO Chunjin, ZHU Min, ZHANG Xiangyu, YANG Jinshan, DONG Shaoming. Effects of Multilayered Interfaces on Mechanical Damage of SiCf/SiC Composites [J]. Journal of Inorganic Materials, 2023, 38(8): 917-922. |

| [3] | XIA Qian, SUN Shihao, ZHAO Yiliang, ZHANG Cuiping, RU Hongqiang, WANG Wei, YUE Xinyan. Effect of Boron Carbide Particle Size Distribution on the Microstructure and Properties of Reaction Bonded Boron Carbide Ceramic Composites by Silicon Infiltration [J]. Journal of Inorganic Materials, 2022, 37(6): 636-642. |

| [4] | RUAN Jing, YANG Jinshan, YAN Jingyi, YOU Xiao, WANG Mengmeng, HU Jianbao, ZHANG Xiangyu, DING Yusheng, DONG Shaoming. Electromagnetic Interference Shielding Properties of SiC Ceramic Matrix Composite Reinforced by Three-dimensional Silicon Carbide Nanowire Network [J]. Journal of Inorganic Materials, 2022, 37(5): 579-584. |

| [5] | ZHANG Yachen, MENG Jia, CAI Kun, SHENG Xiaochen, LE Jun, SONG Lixin. Bending Failure Mechanism Study of Si-Cr-Ti High Temperature Oxidation Resistance Coating via Acoustic Emission Technique [J]. Journal of Inorganic Materials, 2021, 36(11): 1185-1192. |

| [6] | ZHANG Yongzhen, TONG Xiaoyan, YAO Leijiang, LI Bin, BAI Guodong. Acoustic Emission Pattern Recognition on Tensile Damage Process of C/SiC Composites Using an Improved Genetic Algorithm [J]. Journal of Inorganic Materials, 2020, 35(5): 593-600. |

| [7] | ZHANG Xiao-Yang, PENG Hai-Bo, LIU Feng-Fei, ZHAO Yan, SUN Meng-Li, GUAN Ming, ZHANG Bing-Tao, DU Xin, YUAN Wei, WANG Tie-Shan. Mechanical Properties of Borosilicate Glass with Different Irradiation of Heavy Ions [J]. Journal of Inorganic Materials, 2019, 34(7): 741-747. |

| [8] | Jin-Jie WU, Yan LI, Ren-Chu WEI, Jian-Xin WANG, Shu-Xin QU, Jie WENG, Wei ZHI. Bioactivity and Mechanical Stability of Hydroxyapatite Ceramicsunder Micro-vibration Environment [J]. Journal of Inorganic Materials, 2019, 34(4): 417-424. |

| [9] | PANG Sheng-Yang, WANG Pei-Yao, HU Cheng-Long, ZHAO Ri-Da, TANG Su-Fang. Carbon Fiber Preform's Structure on Mechanical Property of C/C Composites and Bolts [J]. Journal of Inorganic Materials, 2019, 34(12): 1272-1278. |

| [10] | ZHANG Zhou, WANG Hao, TU Bing-Tian, XU Peng-Yu, WANG Wei-Min, FU Zheng-Yi. Characterization and Evaluation on Mechanical Property of Mg0.27Al2.58O3.73N0.27 Transparent Ceramic [J]. Journal of Inorganic Materials, 2018, 33(9): 1006-1010. |

| [11] | HUANG Xi-Peng, WANG Bo, YANG Cheng-Peng, PAN Wen-Ge, LIU Xiao-Ying. Evaluating Damage Evolution of Three-dimension Needled C/SiC Composite Based on Acoustic Emission Signal Analysis [J]. Journal of Inorganic Materials, 2018, 33(6): 609-616. |

| [12] | NIE Heng-Chang, WANG Yong-Ling, HE Hong-Liang, WANG Gen-Shui, DONG Xian-Lin. Recent Progress of Porous PZT95/5 Ferroelectric Ceramics [J]. Journal of Inorganic Materials, 2018, 33(2): 153-161. |

| [13] | GAO Jiao-Jiao, JIANG Long-Kai, SONG Jin-Peng, LIANG Guo-Xing, AN Jing, XIE Jun-Cai, CAO Lei, LV Ming. Effects of TiC Content on Microstructure and Mechanical Property of WC-TiC-TaC Cemented Carbides [J]. Journal of Inorganic Materials, 2017, 32(8): 891-896. |

| [14] | ZHANG Cui-Ping, GAO Xiang-Wei, RU Hong-Qiang, SUN Wei-Kang, ZHU Jing-Hui, ZONG Hui. Effect of Forming Pressure on Microstructure and Mechanical Properties of SiC/TiB2 Composites [J]. Journal of Inorganic Materials, 2017, 32(5): 502-508. |

| [15] | ZHANG Chang-Song, LIU Qiang, CHEN Wei. Effect of hBN Content on Property and Microstructure of Si3N4-hBN Composite Ceramics [J]. Journal of Inorganic Materials, 2017, 32(5): 509-516. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||