Journal of Inorganic Materials ›› 2019, Vol. 34 ›› Issue (6): 667-672.DOI: 10.15541/jim20180381

Previous Articles Next Articles

Chao LEI1,2,Fei WEI2

Received:2018-08-31

Revised:2018-10-03

Published:2019-06-20

Online:2019-05-23

Supported by:CLC Number:

Chao LEI, Fei WEI. Mass Production of α-silicon Nitride Single-crystalline Nanowires[J]. Journal of Inorganic Materials, 2019, 34(6): 667-672.

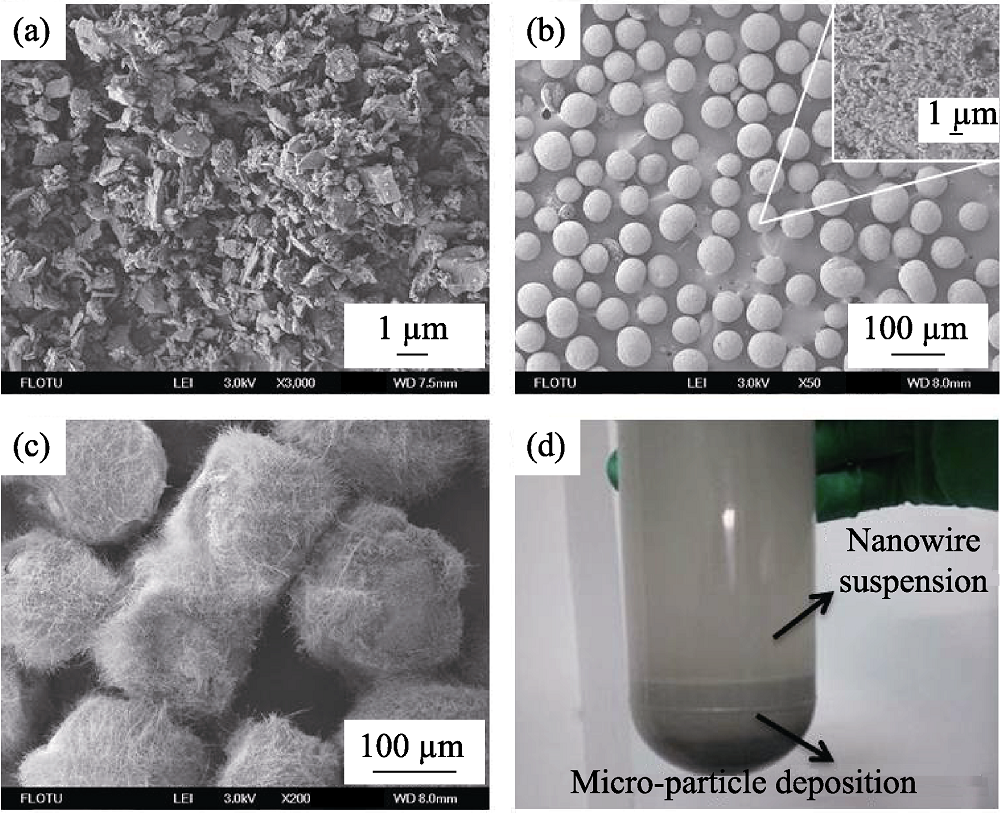

Fig. 1 SEM images and photograph of different samples (a) SEM image of Si raw materials; (b) SEM images of Granulation Si powders; (c) SEM image of granulation Si powders after 3 h nitridation; (d) Photograph of Si3N4/ alcohol mixture after stratification

| Element/wt% | Fe | Ca | Al | O | C |

|---|---|---|---|---|---|

| Si raw materials | 0.008 | 0.013 | 0.012 | 0.14 | - |

| Si3N4 nanowires | 0.011 | 0.007 | 0.031 | 1.56 | - |

| Si3N4 particles | 0.006 | 0.014 | 0.049 | 1.07 | - |

Table 1 Impurity elements analysis results

| Element/wt% | Fe | Ca | Al | O | C |

|---|---|---|---|---|---|

| Si raw materials | 0.008 | 0.013 | 0.012 | 0.14 | - |

| Si3N4 nanowires | 0.011 | 0.007 | 0.031 | 1.56 | - |

| Si3N4 particles | 0.006 | 0.014 | 0.049 | 1.07 | - |

| Spectrum | Element/at% | |||

|---|---|---|---|---|

| Si | N | O | Fe | |

| 1 | 41.42 | 55.43 | 3.16 | 0 |

| 2 | 49.17 | 46.22 | 4.17 | 0.45 |

Table 2 Elemental analysis results of Si3N4 nanowires

| Spectrum | Element/at% | |||

|---|---|---|---|---|

| Si | N | O | Fe | |

| 1 | 41.42 | 55.43 | 3.16 | 0 |

| 2 | 49.17 | 46.22 | 4.17 | 0.45 |

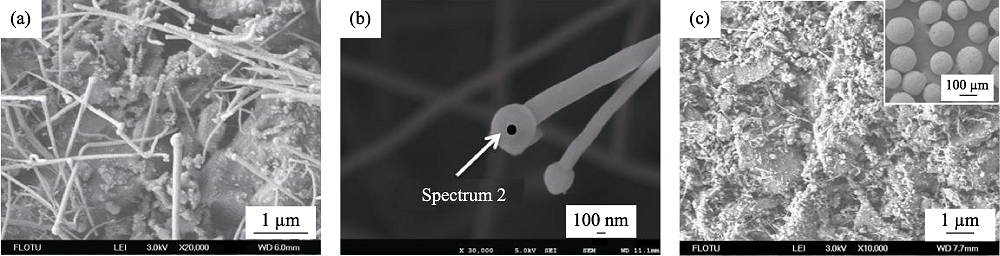

Fig. 5 Morphologies of nanowires on the granulation Si powder surface (a-b) 15 min nitridation in the 90vol% N2-10vol% H2 mixture gas; (c) 3 h nitridation in N2

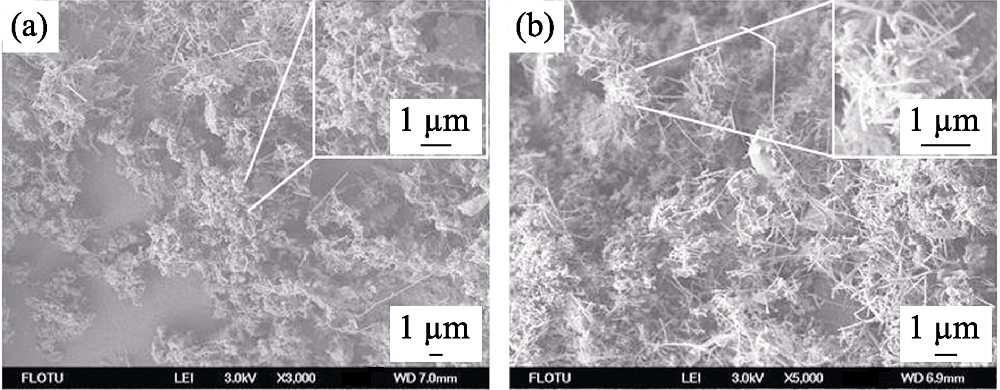

Fig. 6 SEM images of different Si powders after 3 h nitridation in the 90vol% N2+10vol% H2 mixture gas (a) Raw Si powders; (b) Inside of the granulation Si powders

| [1] | CHEN L, FENG J . Research status and application of silicon nitride ceramic materials. Journal of Cemented Carbide, 2002,19(4):26-229. |

| [2] | XIE T, WU Y C, ZHANG L D . Synthesis and photoluminescence of single-crystalline α-Si3N4 nanowires. Journal of Functional Materials, 2004,35(z1):3027-3029. |

| [3] |

JING G Y, JI H, YANG W Y , et al. Study of the bending modulus of individual silicon nitride nano-belts via atomic force microscopy. Applied Physics A, 2006,82(3):475-478.

DOI URL |

| [4] |

MAIRE G, VIVIEN L, SATTLE G , et al. High efficiency silicon nitride surface grating couplers. Optics Express, 2008,16(1):328-333.

DOI URL |

| [5] | HUANG J, HUANG Z, YI S , et al. Fe-catalyzed growth of one-dimensional α-Si3N4 nanostructures and >their cathodoluminescence properties. Scientific Reports, 2013, 3: 3504-1-9. |

| [6] |

GU Y, LU L, ZHANG H , et al. Nitridation of silicon powders catalyzed by cobalt nanoparticles. Journal of the American Ceramic Society, 2015,98(6):1762-1768.

DOI URL |

| [7] |

WANG F, HAO Y J, QIN G Q , et al. Effects of the reaction conditions in preparation of Si3N4 nanowires. Acta Physico-Chimica Sinica, 2007,23(10):1503-1507.

DOI URL |

| [8] |

LI K, ZHAO K, WANG Y . In-situ synthesis and growth mechanism of silicon nitride nanowires on carbon fiber fabrics. Ceramics International, 2014,40(10):15381-15389.

DOI URL |

| [9] | GUO G F, LI X W, FENG W , et al. Pyrolytic synthesis of single- crystal Si3N4 nanowires by polymeric precursor. Rare Metal Materials and Engineering, 2009,38(s2):967-969. |

| [10] |

RAN G Z, YOU L P, DAI L , et al. Catalystless synthesis of crystalline Si3N4/amorphous SiO2 nanocables from silicon substrates and N2. Chemical Physics Letters, 2004,384(1):94-97.

DOI URL |

| [11] |

WANG F, JIN G Q, GUO X Y . Formation mechanism of Si3N4 nanowires via carbothermal reduction of carbonaceous silica xerogels. Journal of Physical Chemistry B, 2006,110(30):14546-14549.

DOI URL |

| [12] |

DU H L, ZHANG W, LI Y . Effects of growth parameters on the yield and morphology of Si3N4 microcoil prepared by chemical vapor deposition. Materials Research Bulletin, 2014,50(2):57-62.

DOI URL |

| [13] |

HUANG J, ZHANG S, HUANG Z , et al. Catalyst-assisted synthesis and growth mechanism of ultra-long single crystal α-Si3N4 nanobelts with strong violet-blue luminescent properties. CrystEngComm, 2012,14(21):7301-7305.

DOI URL |

| [14] |

RODRIGUEZ M A, MAKHONIN N S, ESCRINA J A , et al. Single crystal β-Si3N4 fibers obtained by self-propagating high temperature synthesis. Advanced Materials, 1995,7(8):745-747.

DOI URL |

| [15] |

CAO Y G, GE C C, ZHOU Z J , et al. Combustion synthesis of α-Si3N4 whiskers. Journal of Materials Research, 1999,14(3):876-880.

DOI URL |

| [16] | 杨春 . 硅粉声场流态化及直接氮化研究. 杭州: 浙江大学硕士学位论文, 2015. |

| [17] | YUAN C M, LI C, LI G . Kinetic parameters of maize starch in nitrogen atmosphere. Journal of Northeastern University Natural Science, 2012,33(4):584-587. |

| [18] |

CYPRES R, GHODSI M, LEMPEREUR J P . Direct hydrogenation of carbons by isothermal microthermogravimetry at atmospheric pressure. Fuel Process Technol., 1979,2:171-178.

DOI URL |

| [19] |

LI Z, GAO W, MENG A , et al. Large-scale synthesis and Raman and photoluminescence properties of single crystalline β-SiC nanowires periodically wrapped by amorphous SiO2 nanospheres. Journal of Physical Chemistry C, 2009,113(1):91-96.

DOI URL |

| [20] | LIU H, HUANG Z, HUANG J , et al. Novel, low-cost solid-liquid- solid process for the synthesis of α-Si3N4 nanowires at lower temperatures and their luminescence properties. Scientific Reports, 2015, 5: 17250-1-9. |

| [21] | 唐元洪 . 硅纳米线及硅纳米管(精). 北京: 化学工业出版社, 2007: 53-78. |

| [22] |

WANG F, JIN G Q, GUO X Y . Sol-Gel synthesis of Si3N4 nanowires and nanotubes. Materials Letters, 2006,60(3):330-333.

DOI URL |

| [23] | 董文麟 . 氮化硅陶瓷. 北京: 中国建筑工业出版社, 1987: 73-75. |

| [1] | WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping. Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives [J]. Journal of Inorganic Materials, 2024, 39(6): 634-646. |

| [2] | QIU Zihao, TIAN Zhilin, ZHENG Liya, LI Bin. Corrosion Behavior of Si3N4 Ceramic in High-temperature Molten Salt-water Vapor Environment [J]. Journal of Inorganic Materials, 2024, 39(3): 274-282. |

| [3] | ZHANG Ye, YAO Dongxu, ZUO Kaihui, XIA Yongfeng, YIN Jinwei, ZENG Yuping. Combustion Synthesis of Si3N4-BN-SiC Composites by in-situ Introduction of BN and SiC [J]. Journal of Inorganic Materials, 2022, 37(5): 574-578. |

| [4] | WU Qiuqin, YAO Fenfa, JIN Chuanhong, ZHENG Yifan. One-dimensional Sub-stoichiometric W3O8 Nanowires Filled Carbon Nanotubes [J]. Journal of Inorganic Materials, 2022, 37(4): 413-419. |

| [5] | LI Meng, HUANG Hailu, WU Jiamin, LIU Chunlei, WU Yaru, ZHANG Jingxian, SHI Yusheng. Effect of Solid Loading of Slurry on Properties of Si3N4 Ceramics Formed by Digital Light Processing [J]. Journal of Inorganic Materials, 2022, 37(3): 310-316. |

| [6] | LIANG Hanqin, YIN Jinwei, ZUO Kaihui, XIA Yongfeng, YAO Dongxu, ZENG Yuping. Mechanical and Dielectric Properties of Hot-pressed Si3N4 Ceramics with BaTiO3 Addition [J]. Journal of Inorganic Materials, 2021, 36(5): 535-540. |

| [7] | XIAO Yumin, Li Bin, QIN Lizhao, LIN Hua, LI Qing, LIAO Bin. Efficient Preparation of CuGeO3 with Controllable Morphology Using CuCl2 as Copper Source [J]. Journal of Inorganic Materials, 2021, 36(1): 69-74. |

| [8] | ZHANG Tong,LI Zi-Juan,GUO Ze-Kun,TIAN Yan,LIN Hao-Jian,XU Ning-Sheng,CHEN Jun,DENG Shao-Zhi,LIU Fei. Single Crystalline SmB6 Nanostructure Arrays: Controllable Synthesis and Field Emission Property [J]. Journal of Inorganic Materials, 2020, 35(2): 199-204. |

| [9] | YE Chang-Hui, GU Yu-Jia, WANG Gui-Xin, BI Li-Li. Degradation Mechanism of Silver Nanowire Transparent Conductive Films: a Review [J]. Journal of Inorganic Materials, 2019, 34(12): 1257-1264. |

| [10] | WANG Xiao, WANG Ran-Ran, SHI Liang-Jing, SUN Jing. Synthesis, Optimization of Cu Nanowires and Application of Its Transparent Electrodes [J]. Journal of Inorganic Materials, 2019, 34(1): 49-59. |

| [11] | LU Chang-Jian, ZHU Fa-Quan, Yin Ji-Guang, ZHANG Jian-Bo, YU Ya-Wei, HU Xiu-Lan. Synthesis of α-MnO2 Nanowires via Facile Hydrothermal Method and Their Application in Li-O2 Battery [J]. Journal of Inorganic Materials, 2018, 33(9): 1029-1034. |

| [12] | ZHOU Xin, MA Lei, LIU Tao, GUO Yong-Bin, WANG Dao, DONG Pei-Lin. Crystal Structure and Magnetic Property of Si3N4/FePd/Si3N4 Thin Films [J]. Journal of Inorganic Materials, 2018, 33(8): 909-913. |

| [13] | WANG Jun-Xia, ZHAO Jian-Wei, QIN Li-Rong, ZHAO Bing-Ling, JIANG Zheng-Yan. Synthesis and Supercapacitor Property of Ni-doped Co3O4 Nanowire Array [J]. Journal of Inorganic Materials, 2018, 33(5): 501-506. |

| [14] | CHEN Ang-Ran, ZHAO Wei, CUI Hou-Lei, ZHI Jian, HUANG Fu-Qiang. TiO2 Nanowires Infiltrated with Graphene-decorated Mesoporous TiO2 for Enhanced Dye-sensitized Solar Cell [J]. Journal of Inorganic Materials, 2015, 30(8): 891-896. |

| [15] | HU Hai-Long, YAO Dong-Xu, XIA Yong-Feng, ZUO Kai-Hui, ZENG Yu-Ping. Mechanical Properties of Reaction-bonded Si3N4/SiC Composite Ceramics [J]. Journal of Inorganic Materials, 2014, 29(6): 594-598. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||