Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (8): 947-953.DOI: 10.15541/jim20230009

Special Issue: 【能源环境】储能电池(202506); 【能源环境】锂离子电池(202412)

• RESEARCH ARTICLE • Previous Articles Next Articles

SU Nan1( ), QIU Jieshan1,3(

), QIU Jieshan1,3( ), WANG Zhiyu1,2(

), WANG Zhiyu1,2( )

)

Received:2023-01-05

Revised:2023-02-20

Published:2023-08-20

Online:2023-03-06

Contact:

WANG Zhiyu, professor. E-mail: zywang@dlut.edu.cn;About author:SU Nan (1998-), female, Master candidate. E-mail: 18895369203@163.com

Supported by:CLC Number:

SU Nan, QIU Jieshan, WANG Zhiyu. F-doped Carbon Coated Nano-Si Anode with High Capacity: Preparation by Gaseous Fluorination and Performance for Lithium Storage[J]. Journal of Inorganic Materials, 2023, 38(8): 947-953.

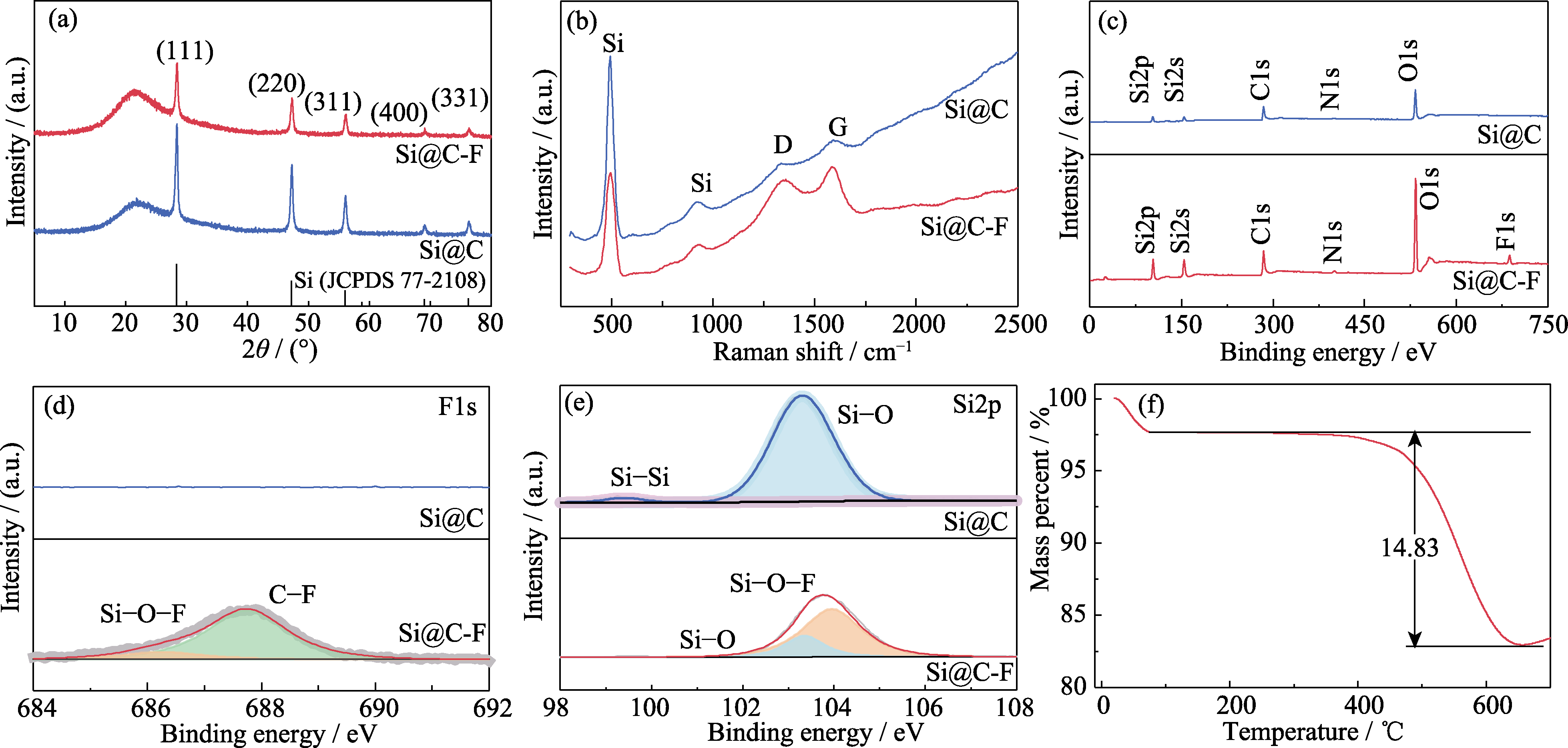

Fig. 2 (a) XRD patterns, (b) Raman spectra, (c) XPS survey scan, (d) high-resolution F1s and (e) Si2p XPS spectra of Si@C and Si@C-F, (f) TGA curve of Si@C-F

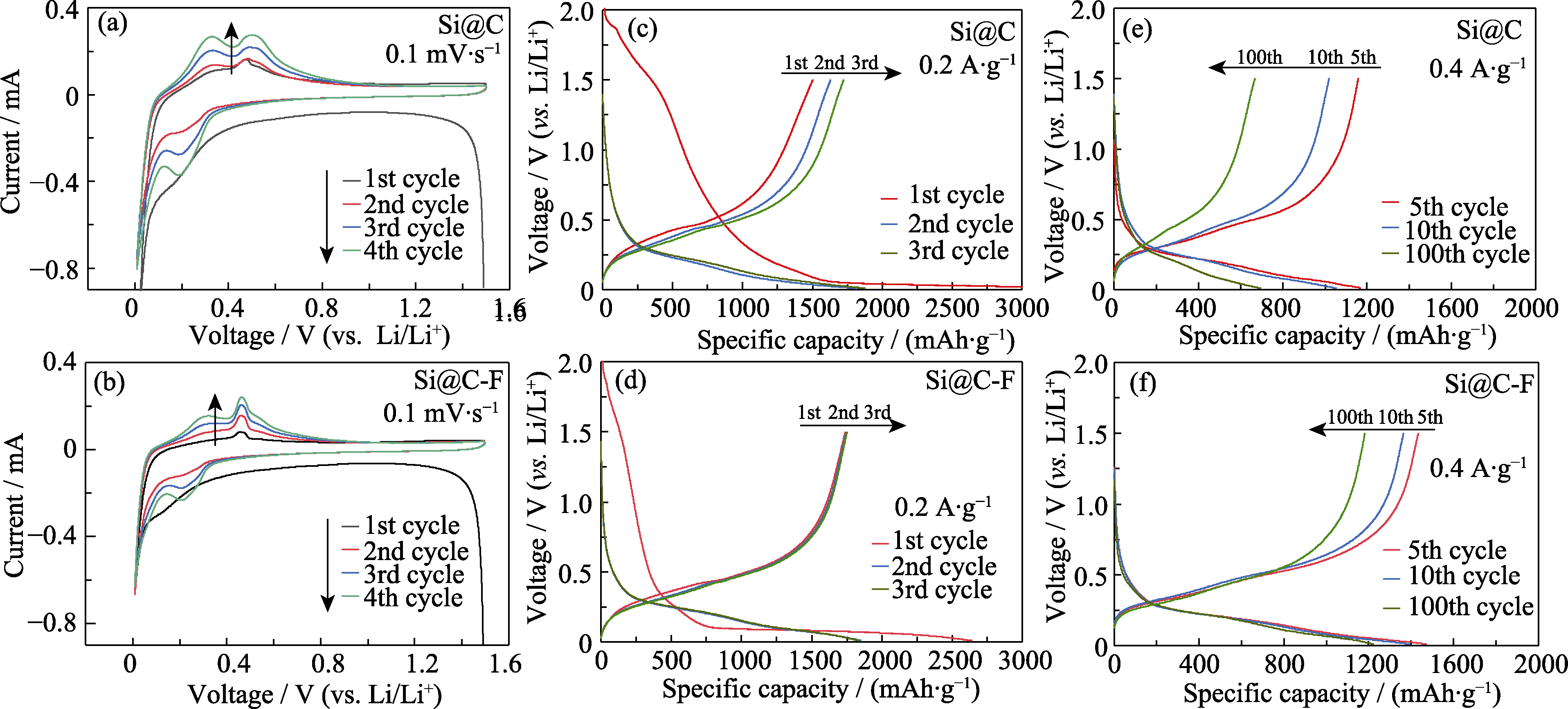

Fig. 4 (a, b) CV curves at a scan rate of 0.1 mV·s-1 and charge-discharge voltage curves at (c, d) 0.2 and (e, f) 0.4 A·g-1 for (a, c, e) Si@C and (b, d, f) Si@C-F anodes

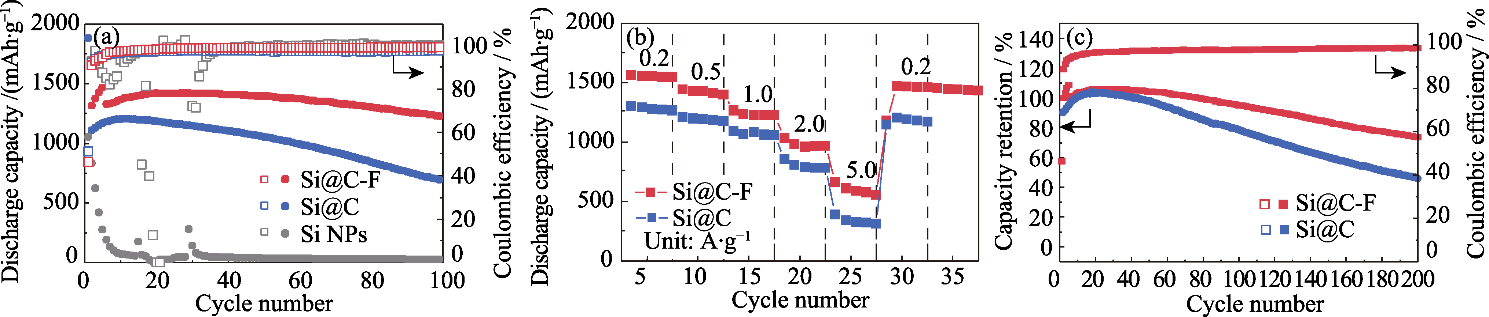

Fig. 5 (a) Cycling stability at a current density of 0.4 A·g-1 with anodes activated by 4 cycles at 0.2 A·g-1 before cycling, and (b) rate capability at various current densities ranging from 0.2 to 5.0 A·g−1 and (c) capacity retention at a current density of 0.2 A·g-1 for lithium storage in Si@C and Si@C-F anode Colorful figures are available on website

| Materials | Initial CE | Initial capacity/(mAh·g-1) | Capacity retention | Ref. |

|---|---|---|---|---|

| Si@C-F | 65.9% | 2640 | 85% (100 cycles) 75 % (cycles) | This work |

| nano-Si/TiN@ carbon | 71% | 2716 | 59.4% (110 cycles) | [ |

| Si@C@RGO | 74.5% | 1474 | 48.9% (40 cycles) | [ |

| Si@FA | 65% | 1334 | 68.7% (100 cycles) | [ |

| p-Si@C | 58% | 3460 | 57.5% (100 cycles) | [ |

| Si@void@C | - | 900 | 70% (100 cycles) | [ |

| Si/C@C | - | 1120 | 80% (100 cycles) | [ |

Table 1 Comparison of Si@C-F anode with reported Si-based anode in electrochemical performance

| Materials | Initial CE | Initial capacity/(mAh·g-1) | Capacity retention | Ref. |

|---|---|---|---|---|

| Si@C-F | 65.9% | 2640 | 85% (100 cycles) 75 % (cycles) | This work |

| nano-Si/TiN@ carbon | 71% | 2716 | 59.4% (110 cycles) | [ |

| Si@C@RGO | 74.5% | 1474 | 48.9% (40 cycles) | [ |

| Si@FA | 65% | 1334 | 68.7% (100 cycles) | [ |

| p-Si@C | 58% | 3460 | 57.5% (100 cycles) | [ |

| Si@void@C | - | 900 | 70% (100 cycles) | [ |

| Si/C@C | - | 1120 | 80% (100 cycles) | [ |

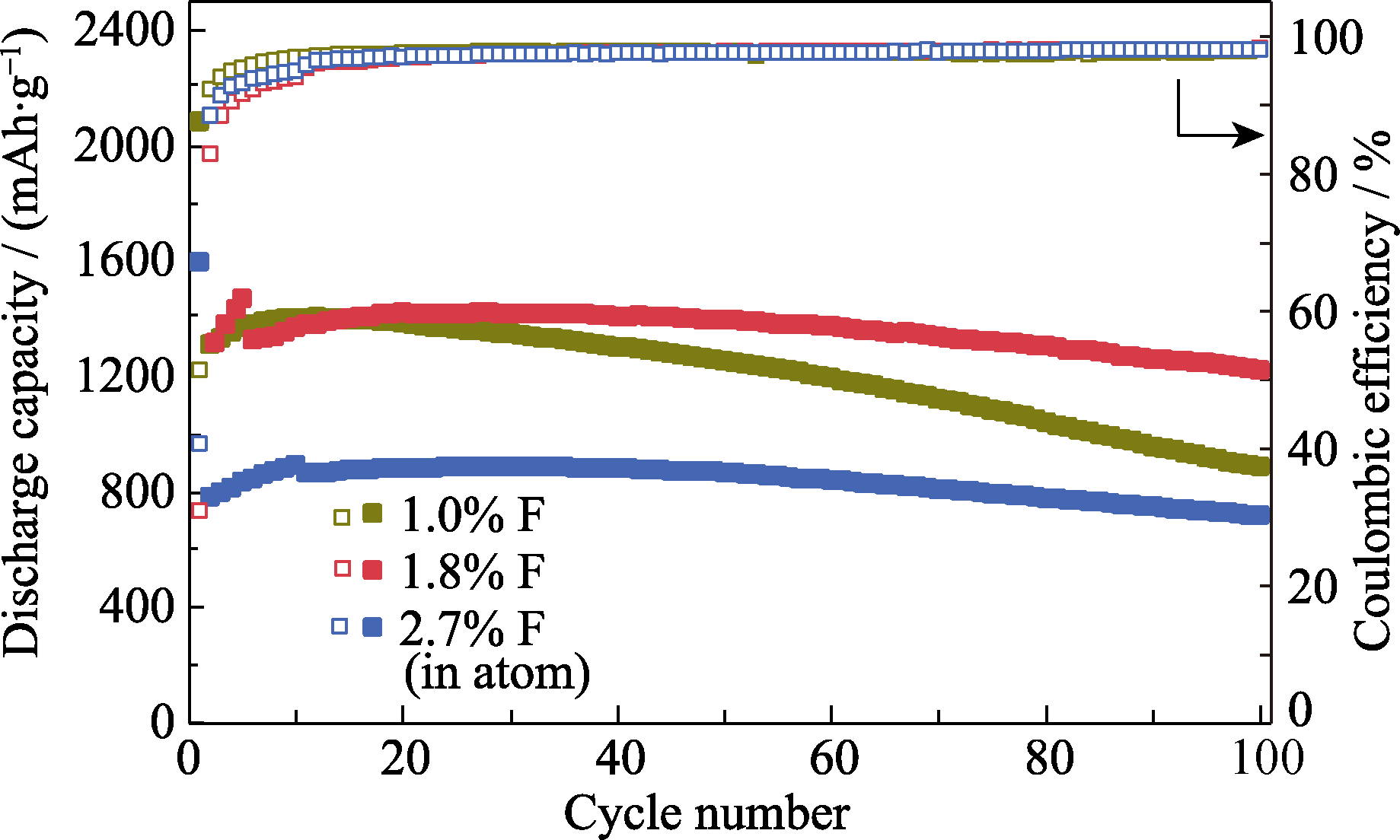

Fig. 6 Cycling stability of Si@C-F anodes with different F ratios at a current density of 0.4 A·g-1 with anodes activated by 4-10 cycles at 0.2 A·g-1 before cycling Colorful figures are available on website

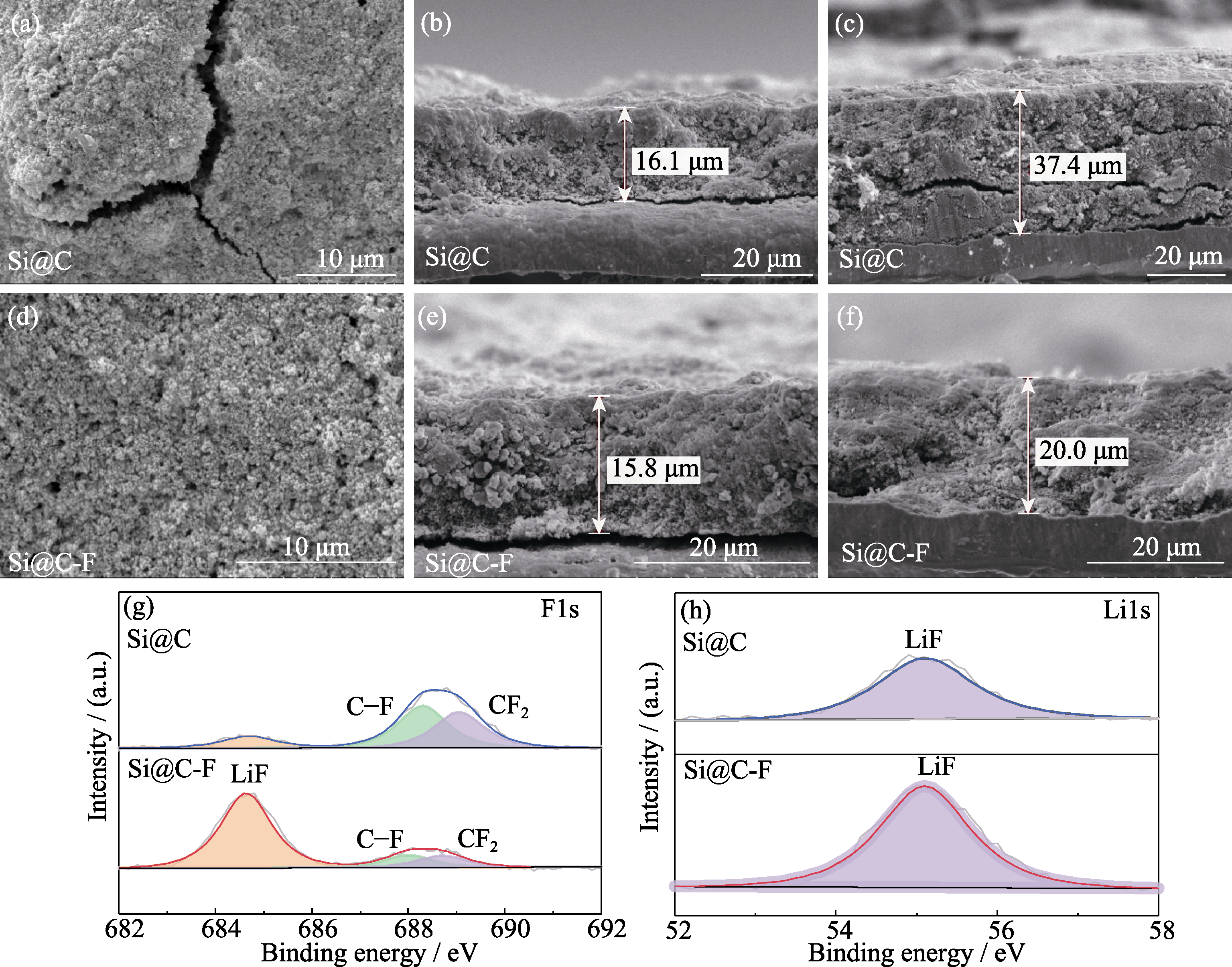

Fig. 8 Top SEM images of (a) Si@C and (d) Si@C-F anodes after cycling; Cross-section SEM images of (b, c) Si@C and (e, f) Si@C-F anodes (b, e) before and (c, f) after cycling; High-resolution (g) F1s and (h) Li1s XPS spectra of SEI on Si@C and Si@C-F anodes after cycling

| [1] |

NIU S S, WANG Z Y, YU M L, et al. MXene-based electrode with enhanced pseudocapacitance and volumetric capacity for power- type and ultra-long life lithium storage. ACS Nano, 2018, 12(4): 3928.

DOI URL |

| [2] | SU X, WU Q L, LI J C, et al. Silicon-based nanomaterials for lithium-ion batteries: a review. Advanced Energy Materials, 2014, 4(1): 1300882. |

| [3] | GE M Z, CAO C Y, GILL M B, et al. Recent advances in silicon- based electrodes: from fundamental research toward practical applications. Advanced Materials, 2021, 33(16): 2004577. |

| [4] |

LI P, ZHAO G Q, ZHENG X B, et al. Recent progress on silicon- based anode materials for practical lithium-ion battery applications. Energy Storage Materials, 2018, 15: 422.

DOI URL |

| [5] |

LIU X H, ZHONG L, HUANG S, et al. Size-dependent fracture of silicon nanoparticles during lithiation. ACS Nano, 2012, 6(2): 1522.

DOI URL |

| [6] |

LUO W, WANG Y X, CHOU S L, et al. Critical thickness of phenolic resin-based carbon interfacial layer for improving long cycling stability of silicon nanoparticle anodes. Nano Energy, 2016, 27: 255.

DOI URL |

| [7] |

DOU F, SHI L Y, CHEN G R, Silicon/carbon composite anode materials for lithium-ion batteries. Electrochemical Energy Reviews, 2019, 2(1): 149.

DOI |

| [8] | JIA H P, ZOU L F, GAO P Y, et al. High-performance silicon anodes enabled by nonflammable localized high-concentration electrolytes. Advanced Energy Materials, 2019, 9(31): 1900784. |

| [9] |

CHOI S H, KWON T W, COSKUN A, et al. Highly elastic binders integrating polyrotaxanes for silicon microparticle anodes in lithium ion batteries. Science, 2017, 357: 279.

DOI URL |

| [10] | LI Z H, ZHANG Y P, LIU T F, et al. Silicon anode with high initial Coulombic efficiency by modulated trifunctional binder for high‐areal-capacity lithium-ion batteries. Advanced Energy Materials, 2020, 10(20): 1903110. |

| [11] |

XU Z L, CAO K, ABOUALI S, et al. Study of lithiation mechanisms of high performance carbon-coated Si anodes by in-situ microscopy. Energy Storage Materials, 2016, 3: 45.

DOI URL |

| [12] |

TEKI R, MONI K D, RAHUL K, et al. Nanostructured silicon anodes for lithium ion rechargeable batteries. Small, 2009, 5(20): 2236.

DOI URL |

| [13] | XIA S X, ZHANG X, LUO L L, et al. Highly stable and ultrahigh- rate Li metal anode enabled by fluorinated carbon fibers. Small, 2021, 17: 2006002. |

| [14] |

ZHANG S L, WANG X, HO K S, et al. Raman spectra in a broad frequency region of p-type porous silicon. Journal of Applied Physics, 1994, 76(5): 3016.

DOI URL |

| [15] |

HUANG W, WANG Y, LUO G H, et al. 99.9% Purity multi-walled carbon nanotubes by vacuum high-temperature annealing. Carbon, 2003, 41(13): 2585.

DOI URL |

| [16] |

MCDOWELL M T, LEE S W, NIX W D, et al. 25th Anniversary article: understanding the lithiation of silicon and other alloying anodes for lithium-ion batteries. Advanced Materials, 2013, 25(36): 4966.

DOI URL |

| [17] |

KEY B, MORCRETTE M, TARASCON J M. Pair distribution function analysis and solid state NMR studies of silicon electrodes for lithium ion batteries: understanding the (de)lithiation mechanisms. Journal of American Chemical Society, 2011, 133(3): 503.

DOI URL |

| [18] |

GAO H, XIAO L S, PLUMEL I, et al. Parasitic reactions in nanosized silicon anodes for lithium-ion batteries. Nano Letters, 2017, 17(3): 1512.

DOI URL |

| [19] |

CHEN J, FAN X L, LI Q, et al. Electrolyte design for LiF-rich solid-electrolyte interfaces to enable high-performance microsized alloy anodes for batteries. Nature Energy, 2020, 5(5): 386.

DOI |

| [20] | ZHANG P, GAO Y Q, RU Q, et al. Scalable preparation of porous nano-silicon/TiN@carbon anode for lithiumion batteries. Applied Surface Science, 2019, 498: 143829. |

| [21] |

SU M R, WAN H F, LIU Y J, et al. Multi-layered carbon coated Si-based composite as anode for lithium-ion batteries. Powder Technology, 2018, 323: 294.

DOI URL |

| [22] | PU J B, QIN J, WANG Y Z, et al. Synthesis of micro-nano sphere structure silicon-carbon composite as anode material for lithium- ion batteries. Chemical Physics Letters, 2022, 806: 140006. |

| [23] | GAO R S, TANG J, YU X L, et al. A sandwich-like silicon-carbon composite prepared by surface-polymerization for rapid lithium-ion storage. Nano Energy, 2020, 70: 104444. |

| [24] |

GONG X H, ZHENG Y B, ZHENG J, et al. Yolk-shell silicon/ carbon composites prepared from aluminum-silicon alloy as anode materials for lithium-ion batteries. Ionics, 2021, 27: 1939.

DOI |

| [25] |

LIA Y R, WANG R Y, ZHANG J W, et al. Sandwich structure of carbon-coated silicon/carbon nanofiber anodes for lithium-ion batteries. Ceramics International, 2019, 45: 16195.

DOI URL |

| [26] | YANG X M AND ROGACH A L. Electrochemical techniques in battery research: a tutorial for nonelectrochemists. Advanced Energy Materials, 2019, 9(25): 1900747. |

| [1] | XIAO Meixia, LI Miaomiao, SONG Erhong, SONG Haiyang, LI Zhao, BI Jiaying. Halogenated Ti3C2 MXene as High Capacity Electrode Material for Li-ion Batteries [J]. Journal of Inorganic Materials, 2022, 37(6): 660-668. |

| [2] | WANG Jing, CHENG Zhi-Ning, GUO Yu-Zhong, HUANG Rui-An, WANG Jian-Hua. Preparation and Electrochemical Performance of Ordered Mesoporous Si/C Composite for Anode Material [J]. Journal of Inorganic Materials, 2018, 33(3): 313-319. |

| [3] | LI Jian, YAO Shu-Heng, ZHOU Hong-Ming, GENG Wen-Jun. Preparation of LiMn0.4Fe0.6PO4/C Composite by A New Route Combining Solid-state Reaction with Hydrothermal Synthesis [J]. Journal of Inorganic Materials, 2014, 29(4): 443-448. |

| [4] | QIU Cai-Xia, YUAN Zhong-Zhi, LIU Ling, CHENG Si-Jie, LIU Jin-Cheng. Preparation and Characterization of Ge4+-doping Li4Ti5O12 Anode Material for Li-ion Battery and Its Electrochemical Properties [J]. Journal of Inorganic Materials, 2013, 28(7): 727-732. |

| [5] | ZHANG Qian, LIU Wei-Wei, FANG Guo-Qing, XIA Bing-Bo, SUN Hong-Dan, KANEKO Shingo, YANG Yu-Sheng, ZHENG Jun-Wei, LI De-Cheng. Structural and Electrochemical Performances of Li1+2xMn0.3+xNi0.3-3xCr0.4O2 Synthesized by Spray-dry Method [J]. Journal of Inorganic Materials, 2013, 28(06): 616-622. |

| [6] | SHAO Jin, REN Yu-Rong, LI Guo-Qiang, HUANG Xiao-Bing, ZHOU Gu-Min, QU Mei-zhen. Carbon Coated Helical Carbon Nanotubes used as Anode Materials of Li-ion Battery [J]. Journal of Inorganic Materials, 2011, 26(6): 631-637. |

| [7] | ZHANG Xi-Gui,ZHANG Jian,YANG Chuan-Zheng,LI Jia. Simulation and Experimental Study on Mixed Arrange of Li/Ni Atoms in LiMeO2 Materials [J]. Journal of Inorganic Materials, 2010, 25(1): 8-12. |

| [8] | ZHU Yong-Jun,LI Xin-Hai,WANG Zhi-Xing,YANG Zhi,HU Qi-Yang. Synthesis and Electrochemical Performance of Spherical LiNi0.5-xCo2xMn0.5-x O2 [J]. Journal of Inorganic Materials, 2007, 22(5): 873-878. |

| [9] | YAO Yao-Chun,DAI Yong-Nian,YANG Bin,CUI Meng-Jia,LI Wei-Hong. Synthesis and Performance of LiCrxMn2-xO4 Cathode Materials for Li-ion Battery [J]. Journal of Inorganic Materials, 2005, 20(5): 1127-1131. |

| [10] | CHEN Fang,LIANG Hai-Chao,LI Ren-Gui,LIU Li,DENG Zheng-Hua. Progress in Research on Li4Ti5O12 as Anode for Electrochemical Devices [J]. Journal of Inorganic Materials, 2005, 20(3): 537-544. |

| [11] | XIA Jun-Lei,ZHAO Shi-Xi,LIU Han-Xing,OUYANG Shi-Xi,. Synthesis and Performance of S-Co Co-doped LiMn2O4 [J]. Journal of Inorganic Materials, 2003, 18(4): 942-946. |

| [12] | KANG Kai,DAI Shou-Hui,WAN Yu-Hua. Progress in Synthetic Methods of Cathode Material LiMxMn2-xO4 for Lithium Ion Batteries [J]. Journal of Inorganic Materials, 2001, 16(4): 586-594. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||