Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (4): 461-468.DOI: 10.15541/jim20220469

• RESEARCH LETTER • Previous Articles Next Articles

LIU Wenlong1,2( ), ZHAO Jin1,2(

), ZHAO Jin1,2( ), LIU Juan1,2, MAO Xiaojian1,2, ZHANG Jian1,2, WANG Shiwei1,2(

), LIU Juan1,2, MAO Xiaojian1,2, ZHANG Jian1,2, WANG Shiwei1,2( )

)

Received:2022-08-09

Revised:2022-11-25

Published:2023-04-20

Online:2022-12-09

Contact:

ZHAO Jin, lecturer. E-mail: zhaojin@mail.sic.ac.cn;About author:LIU Wenlong (1997-), male, Master candidate. E-mail: liuwenlong20@mails.ucas.ac.cn

Supported by:CLC Number:

LIU Wenlong, ZHAO Jin, LIU Juan, MAO Xiaojian, ZHANG Jian, WANG Shiwei. Microwave Drying of Spontaneous-Coagulation-Cast Wet Alumina Green Body[J]. Journal of Inorganic Materials, 2023, 38(4): 461-468.

| Drying method | Microwave power/W | CRP/ h | Residual water after CRP/% (in vol.) | Residual water after drying/% (in vol.) |

|---|---|---|---|---|

| Conventional | — | 10 | (20.4±1.5) | 0.8 |

| Microwave | 250 | 1.8 | (11.2±1.4) | 0.6 |

| 400 | 1.3 | (9.4±1.4) | 0.5 | |

| 550 | 1.0 | (7.7±0.7) | 0.4 |

Table 1 CRP and residual water (after CRP and drying) of samples

| Drying method | Microwave power/W | CRP/ h | Residual water after CRP/% (in vol.) | Residual water after drying/% (in vol.) |

|---|---|---|---|---|

| Conventional | — | 10 | (20.4±1.5) | 0.8 |

| Microwave | 250 | 1.8 | (11.2±1.4) | 0.6 |

| 400 | 1.3 | (9.4±1.4) | 0.5 | |

| 550 | 1.0 | (7.7±0.7) | 0.4 |

| Drying method | Microwave power/W | Shrinkage stop time/h | Shrinkage/% |

|---|---|---|---|

| Conventional | — | 6.0 | (4.9±0.1) |

| Microwave | 250 | 1.0 | (5.2±0.1) |

| 400 | 0.7 | (5.1±0.1) | |

| 550 | 0.5 | (4.8±0.1) |

Table 2 Shrinkage stop time and shrinkage of samples

| Drying method | Microwave power/W | Shrinkage stop time/h | Shrinkage/% |

|---|---|---|---|

| Conventional | — | 6.0 | (4.9±0.1) |

| Microwave | 250 | 1.0 | (5.2±0.1) |

| 400 | 0.7 | (5.1±0.1) | |

| 550 | 0.5 | (4.8±0.1) |

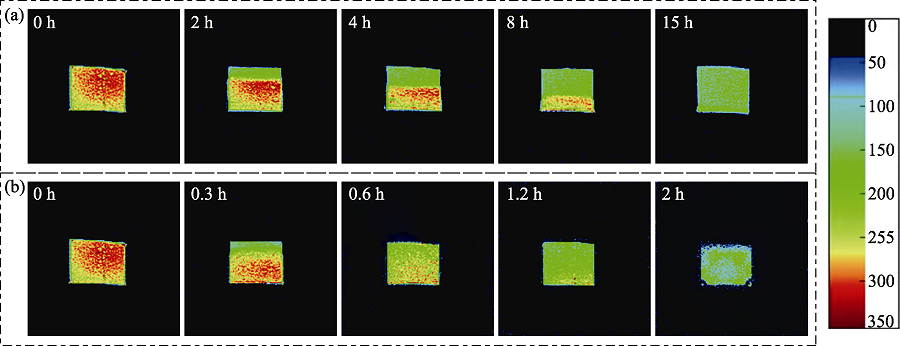

Fig. 7 Moisture distributions of wet alumina green bodies in the drying process (a) Conventional drying for 0, 2, 4, 8, and 15 h; (b) 250-W microwave drying for 0, 0.3, 0.6, 1.2, and 2 h

| [1] |

YANG Y, SHIMAI S, WANG S. Room-temperature gelcasting of alumina with a water-soluble copolymer. Journal of Materials Research, 2013, 28(11):1512.

DOI URL |

| [2] |

CHEN H, SHIMAI S, ZHAO J, et al. Hydrophobic coagulation of alumina slurries. Journal of the American Ceramic Society, 2021, 104(1):284.

DOI URL |

| [3] |

SUN Y, SHIMAI S, PENG X, et al. A method for gelcasting high-strength alumina ceramics with low shrinkage. Journal of Materials Research, 2014, 29(2):247.

DOI URL |

| [4] | WU C, YU Z, SOKOLOV A S, et al. Tailoring magnetic properties of self-biased hexaferrites using an alternative copolymer of isobutylene and maleic anhydride. AIP Advances, 2018, 8(5):221. |

| [5] | WANG F, YIN J, YAO D, et al. Fabrication of porous SiC ceramics through a modified gelcasting and solid state sintering. Materials Science and Engineering A--Structural Materials Properties Microstructure and Processing, 2016, 654: 292. |

| [6] |

WANG L, AN L, ZHAO J, et al. High-strength porous alumina ceramics prepared from stable wet foams. Journal of Advanced Ceramics, 2021, 10(4):852.

DOI |

| [7] |

SUN Y, SHIMAI S, PENG X, et al. Fabrication of transparent Y2O3 ceramics via aqueous gelcasting. Ceramics International, 2014, 40(6):8841.

DOI URL |

| [8] | ZHANG P, LIU P, SUN Y, et al. Aqueous gelcasting of the transparent MgAl2O4 spinel ceramics. Journal of Alloys and Compounds, 2015, 646: 833. |

| [9] |

WANG J, ZHANG F, CHEN F, et al. Fabrication of aluminum oxynitride (c-AlON) transparent ceramics with modified gelcasting. Journal of the American Ceramic Society, 2014, 97(5):1353.

DOI URL |

| [10] |

CHEN H, ZHAO J, SHIMAI S, et al. High transmittance and grain-orientated alumina ceramics fabricated by adding fine template particles. Journal of Advanced Ceramics, 2022, 11(4):582.

DOI |

| [11] |

YOUNG A C, OMATETE O O, JANNEY M A, et al. Gelcasting of alumina. Journal of the American Ceramic Society, 1991, 74(3):612.

DOI URL |

| [12] | BAADER F H, GRAULE T J, GAUCKLER L J. Direct coagulation casting-a new green shape technique. 2. Application to alumina. Industrial Ceramics, 1996, 16(1):36. |

| [13] | GRAULE T J, GAUCKLER L J, BAADER F H. Direct coagulation casting-a new green shaping technique. 1. Processing principles. Industrial Ceramics, 1996, 16(1):31. |

| [14] |

SCHERER G W. Theory of drying. Journal of the American Ceramic Society, 1990, 73(1):3.

DOI URL |

| [15] | OMATETE O O, STREHLOW R A, WALLS C A. Drying of gelcast ceramics. United States, 1991, 26(2):101. |

| [16] |

MA L G, HUANG Y, YANG J L, et al. Control of the inner stresses in ceramic green bodies formed by gelcasting. Ceramics International, 2006, 32(2):93.

DOI URL |

| [17] |

BARATI A, KOKABI M, FAMILI M H N. Drying of gelcast ceramic parts via the liquid desiccant method. Journal of the European Ceramic Society, 2003, 23(13):2265.

DOI URL |

| [18] |

BILBAO-SAINZ C, ANDRES A, FITO P. Hydration kinetics of dried apple as affected by drying conditions. Journal of Food Engineering, 2005, 68(3):369.

DOI URL |

| [19] |

SHIRAI T, YASUOKA M, HOTTA Y, et al. Rapid microwave drying for slip cast bodies. Journal of the Ceramic Society of Japan, 2006, 114(1326):217.

DOI URL |

| [20] |

OZKAN I A, AKBUDAK B, AKBUDAK N. Microwave drying characteristics of spinach. Journal of Food Engineering, 2007, 78(2):577.

DOI URL |

| [21] |

VONGPRADUBCHAI S, RATTANADECHO P. Microwave and hot air drying of wood using a rectangular waveguide. Drying Technology, 2011, 29(4):451.

DOI URL |

| [22] |

CHONG C H, FIGIEL A, LAW C L, et al. Combined drying of apple cubes by using of heat pump, vacuum-microwave, and intermittent techniques. Food and Bioprocess Technology, 2014, 7(4):975.

DOI URL |

| [23] |

ITAYA Y, OKOUCHI K, MORI S. Effect of heating modes on internal strain-stress formation during drying of molded ceramics. Drying Technology, 2001, 19(7):1491.

DOI URL |

| [24] | ESIN A, MAHMUTYAZICIOGLU N, ALTINTAS S. Drying and sintering of ceramic based parts using microwave heating. Key Engineering Materials, 2004, 268(3):731. |

| [25] |

SHIRAI T, ISOBE T, YASUOKA M, et al. Rapid microwave drying for wet green body using nanosized particles. Journal of the Ceramic Society of Japan, 2007, 115(1343):440.

DOI URL |

| [26] |

HEMANTHAKUMARI P N, SATAPATHY L N. A comparison of the effects of microwave versus conventional drying on the mechanical properties distribution of dried green porcelains. International Journal of Applied Ceramic Technology, 2008, 5(1):94.

DOI URL |

| [27] |

ZHANG L, MCCARTHY M J. NMR study of hydration of navy bean during cooking. Lwt-Food Science and Technology, 2013, 53(2):402.

DOI URL |

| [28] |

BORISJUK L, ROLLETSCHEK H, NEUBERGER T. Surveying the plant's world by magnetic resonance imaging. Plant Journal, 2012, 70(1):129.

DOI URL |

| [29] |

ISHIDA N, KOIZUMI M, KANO H. The NMR microscope: a unique and promising tool for plant science. Annals of Botany, 2000, 86(2):259.

DOI URL |

| [30] |

DADALI G, APAR D K, OZBEK B. Microwave drying kinetics of okra. Drying Technology, 2007, 25(4/5/6):917.

DOI URL |

| [1] | WU Xiangquan, TENG Jiachen, JI Xiangxu, HAO Yubo, ZHANG Zhongming, XU Chunjie. Textured Porous Al2O3-SiO2 Composite Ceramic Platelet-sphere Slurry: Characteristics and Simulation of Light Intensity Distribution [J]. Journal of Inorganic Materials, 2024, 39(7): 769-778. |

| [2] | JIA Yuna, CAO Xu, JIAO Xiuling, CHEN Dairong. Preparation of Alumina Ceramic Continuous Fibers with Inorganic Acidic Aluminum Sol as Precursor [J]. Journal of Inorganic Materials, 2023, 38(11): 1257-1264. |

| [3] | MU Licheng, YANG Jinping, WANG Junping, ZHAO Jin, LIU Mengwei, WANG Dewen, ZHANG Jian. Preparation of YAG Transparent Ceramics by Epoxy Resin Modified Spontaneous Coagulation Casting [J]. Journal of Inorganic Materials, 2022, 37(9): 941-946. |

| [4] | WANG Shiwei. Progress of Spontaneous Coagulation Casting of Ceramic Slurries Based on Hydrophobic Interaction [J]. Journal of Inorganic Materials, 2022, 37(8): 809-820. |

| [5] | WANG Xingang, YANG Qingqing, LIN Genlian, GAO Wei, QIN Fulin, LI Rongzhen, KANG Zhuang, WANG Xiaofei, JIANG Danyu, YAN Jina. High Temperature Tensile Property of Domestic 550-grade Continuous Alumina Ceramic Fiber [J]. Journal of Inorganic Materials, 2022, 37(6): 629-635. |

| [6] | ZHOU Ganghuai, LIU Yao, SHI Yuan, LIU Shaojun. Slurry Preparation and Stereolithography for Activated Alumina Catalyst Carrier [J]. Journal of Inorganic Materials, 2022, 37(3): 297-302. |

| [7] | ZENG Yong, ZHANG Zijia, SUN Lijun, YAO Haihua, CHEN Jiming. Atmosphere Debinding Heat Treatment of 3D Printed Alumina Ceramics [J]. Journal of Inorganic Materials, 2022, 37(3): 333-337. |

| [8] | WEI Hailang, CAO Xueqiang, DENG Longhui, JIANG Jianing. Thermodynamic Properties and Thermal Cycling Lifetimes of LaMeAl11O19/YSZ Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2022, 37(12): 1259-1266. |

| [9] | HAO Hongjian, LI Haiyan, WAN Detian, BAO Yiwang, LI Yueming. Enhanced Flexural Strength and Thermal Shock Resistance of Alumina Ceramics by Mullite/Alumina Pre-stressed Coating [J]. Journal of Inorganic Materials, 2022, 37(12): 1295-1301. |

| [10] | PENG Fei, JIANG Yonggang, FENG Jian, CAI Huafei, FENG Junzong, LI Liangjun. Research Progress on Alumina Aerogel Composites for High-temperature Thermal Insulation [J]. Journal of Inorganic Materials, 2021, 36(7): 673-684. |

| [11] | FENG Mingxing, WANG Bin, XU Pengyu, TU Bingtian, WANG Hao. Predicting Thermomechanical Properties of MgAl2O4 Transparent Ceramic Based on Bond Valence Models [J]. Journal of Inorganic Materials, 2021, 36(10): 1067-1073. |

| [12] | HAN Hai-Bo, WANG You-He, LI Kang, LEI Jie, LIU Dan-He, YAN Zi-Feng. Acetic Acid Leaching on the Structure, Acidity and Performance of HMOR Catalyst [J]. Journal of Inorganic Materials, 2019, 34(2): 179-185. |

| [13] | CHEN Wen-Bo, CHEN Lun-Jiang, LIU Chuan-Dong, CHENG Chang-Ming, TONG Hong-Hui, ZHU Hai-Long. Preparation of Spherical Alumina Powder by RF Thermal Plasma: Numerical Simulation and Experimentation [J]. Journal of Inorganic Materials, 2018, 33(5): 550-556. |

| [14] | YANG Jing-Feng, WANG Qi-Hua, WANG Ting-Mei. Synthesis and Property of Alumina Aerogel [J]. Journal of Inorganic Materials, 2018, 33(3): 259-265. |

| [15] | WANG You-He, WANG Xiao-Dong, XU Jing-Wei, SUN Hong-Man, WU Cheng-Cheng, YAN Zi-Feng, JI Sheng-Fu. Hierarchical ZSM-5 Zeolite: Preparation by Sequential Desilication-dealumination and Catalytic Performance in Methanol to Gasoline Reaction [J]. Journal of Inorganic Materials, 2018, 33(11): 1193-1200. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||