Journal of Inorganic Materials ›› 2016, Vol. 31 ›› Issue (3): 324-328.DOI: 10.15541/jim20150524

• RESEARCH LETTER • Previous Articles Next Articles

YU Yin-Hu( ), WANG Tao(

), WANG Tao( ), LIAO Qiu-Ping, MIAO Run-Jie, PAN Jian-Feng, ZHANG Du-Bao

), LIAO Qiu-Ping, MIAO Run-Jie, PAN Jian-Feng, ZHANG Du-Bao

Received:2015-10-27

Revised:2015-11-06

Published:2016-03-20

Online:2016-02-24

About author:YU Yin-Hu (1984-), male, candidate of PhD. E-mail: yinhuyu@nuaa.edu.cn

Supported by:CLC Number:

YU Yin-Hu, WANG Tao, LIAO Qiu-Ping, MIAO Run-Jie, PAN Jian-Feng, ZHANG Du-Bao. Low-temperature Solid-state Synthesis of Nanometer TiB2-TiC Composite Powder[J]. Journal of Inorganic Materials, 2016, 31(3): 324-328.

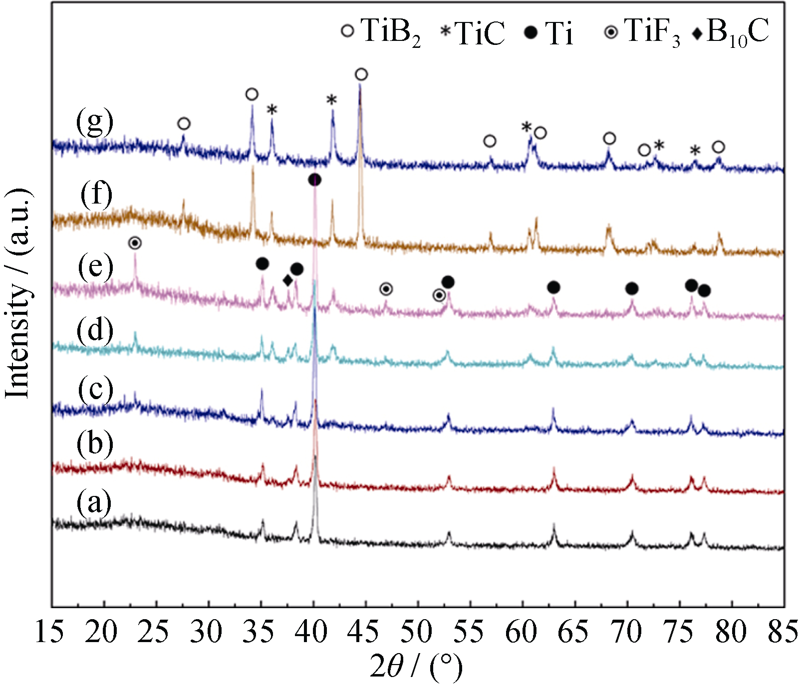

Fig. 2 XRD patterns of the Ti-B mixtures with (a) 0wt%, (b) 1wt%, (c) 3wt%, (d) 5wt%, (e) 8wt%, (f) 10wt%, and (g) 12wt% PTFE after reactions in argon atmosphere at 550℃

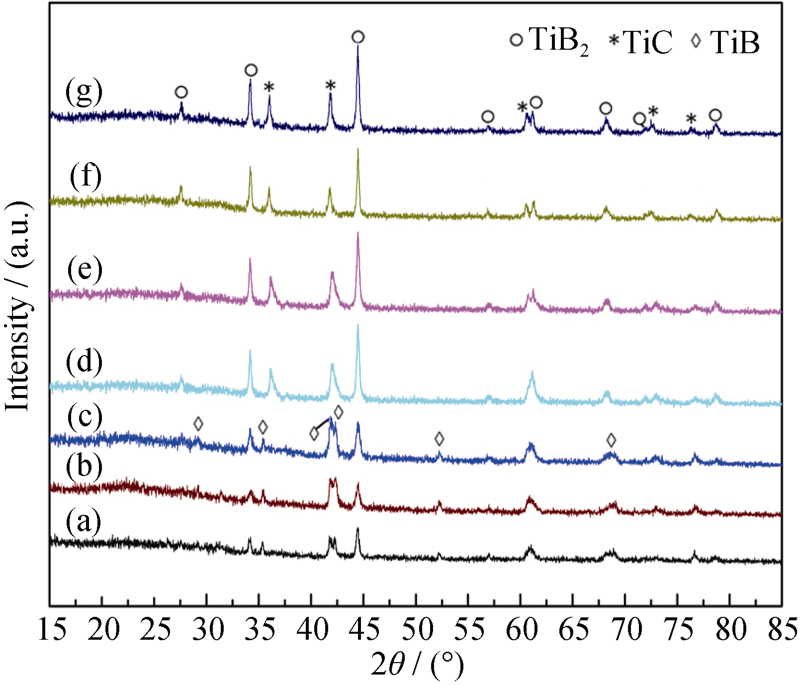

Fig. 3 XRD patterns of the Ti-B mixtures with (a) 0wt%, (b) 1wt%, (c) 3wt%, (d) 5wt%, (e) 8wt%, (f) 10wt%, and (g) 12wt% PTFE after reactions in argon atmosphere at 1300℃

| [1] | JENSEN M S, EINARSRUD M A, GRANDE T.The effect of surface oxides during hot pressing of TiB2.J. Am. Ceram. Soc., 2009, 92(3): 623-630. |

| [2] | BILGI E, CAMURLU H E, AKGUN B, et al. Formation of TiB2 by volume combustion and mechanochemical process. Mater. Res. Bull., 2008, 43(4): 873-881. |

| [3] | KHANRA A K, GODKHINDI M M, PATHAK L C. Sintering behaviour of ultra-fine titanium diboride powder prepared by self-propagating high-temperature synthesis (SHS) technique. Mater. Sci. Eng. A, 2007, 454-455: 281-287. |

| [4] | CHENG Y, SHIGETA M, CHOI S, et al. Formation mechanism of titanium boride nanoparticles by RF induction thermal plasma. Chem. Eng. J., 2012, 183: 483-491. |

| [5] | NEKAHI A, FIROOZI S.Effect of KCl, NaCl and CaCl2 mixture on volume combustion synthesis of TiB2 nanoparticles.Mater. Res. Bull., 2011, 46(9): 1377-1383. |

| [6] | KANG S H, KIM D J.Synthesis of nano-titanium diboride powders by carbothermal reduction.J. Eur. Ceram. Soc., 2007, 27(2/3): 715-718. |

| [7] | CONTRERAS L, TURRILLAS X, VAUGHAN G B M, et al. Time-resolved XRD study of TiC-TiB2 composites obtained by SHS. Acta Mater., 2004, 52(16): 4783-4790. |

| [8] | CALKA A, OLESZAK D.Synthesis of TiB2 by electric discharge assisted mechanical milling.J. Alloys Compd., 2007, 440(1/2): 346-348. |

| [9] | AVILES M A, CHICARDI E, CORDOBA J M, et al. In situ-synthesis of ceramic composite materials in the Ti-B-C-N system by a mechanically induced self-sustaining reaction. J. Am. Ceram. Soc., 2012, 95(7): 2133-2139. |

| [10] | YU YIN-HU, WANG TAO, ZHANG HONG-MIN, et al. Low temperature combustion synthesis of TiC powder induced by PTFE. J. Inorg. Mater., 2015, 30(3): 272-276. |

| [11] | LICHERI R, ORRU R, CAO G.Chemically-activated combustion synthesis of TiC-Ti composites.Mater. Sci. Eng. A, 2004, 367(1/2): 185-197. |

| [12] | HAMBARTSUMYAN A A, KHACHATRYAN H L, KHARATYAN S L.Mechanically and chemically activated SHS in the Mo-Si-C system: Synthesis of MoSi2-SiC composites.Int. J. SHS, 2007, 16(2): 87-91. |

| [13] | ZURNACHYAN A R, KHARATYAN S L, KHACHATRYAN H L, et al. Self-propagating high temperature synthesis of SiC-Cu and SiC-Al cermets: Role of chemical activation, Int. J. Refract. Met. Hard Mater., 2011, 29(2): 250-255. |

| [14] | NIKZAD L, LICHERI R, VAEZI M R, et al. Chemically and mechanically activated combustion synthesis of B4C-TiB2 composites. Int. J. Refract. Met. Hard. Mater., 2012, 35: 41-48. |

| [15] | NERSISYAN H H, NIKOGOSOV V N, KHARATYAN S L, et al. The chemical mechanism of transformations and combustion in the Si-C-teflon system. Fiz. Goreniya Vzryva, 1991, 27(6): 77-81. |

| [16] | ABOVYAN L S, NERSISYAN H H, KHARATYAN S L, et al. Synthesis of alumina-silicon carbide composites by chemically activated self-propagating reactions. Ceram. Int., 2001, 27(2): 163-169. |

| [17] | LEE I, REED R R, BRADY V L, et al. Energy release in the reaction of metal powders with fluorine containing polymers. J. Therm. Anal. Calorim., 1997, 49(3): 1699-1705. |

| [18] | KUWAHARA T, MATSUO S, SHINOZAKI N.Combustion and sensitivity characteristics of Mg/TF pyrolants.Propell. Explos. Pyrotech., 1997, 22: 198-202. |

| [19] | BINNEWIES M, MILKE E.Thermochemical Data of Elements and Compounds, 2nd ed. Weinheim: Wiley-VCH, 2002. |

| [20] | NIELSON D B, TRUITT R M, ASHCROFT B N. Reactive Material Enhanced Projectiles and Related Methods. US, Patent, 20120167793A1. 2012. |

| [21] | SHERIDAN E W, HUGUS I V G D, BELLOMO F, et al. Thermal Enhanced Blast Warhead. US, Patent, 8250986B1. 2012. |

| [22] | NERONOV V A, KORCHAGIN M A, ALEKSANDROV V V, et al. Investigation of the interaction between boron and titanium. J. Less-common Met., 1981, 82: 125-129. |

| [23] | BHAUMIK S K, DIVAKAR C, SINGH A K, et al. Synthesis and sintering of TiB2 and TiB2-TiC composite under high pressure. Mater. Sci. Eng. A, 2000, 279: 275-281. |

| [24] | TARASOV A V, ALIKHANIAN A S, KIRAKOSYAN G A, et al. Chemical interaction of metallic titanium with a tetrafluoroethylene- vinylidene fluoride copolymer. Inorg. Mater., 2010, 46(12): 1308-1312. |

| [25] | WANG H, WU W, SUN S, et al. Characterization of the structure of TiB2/TiC nanocomposite powders fabricated by high-energy ball milling. Ceram. Int., 2011, 37(7): 2689-2693. |

| [26] | CARLO S R, PERRY C C, TORRES J, et al. Surface reactions of vapor phase titanium atoms with halogen and nitrogen containing polymers studied using in situ X-ray photoelectron spectroscopy and atomic force microscopy. Appl. Surf. Sci., 2002, 195(1-4): 93-106. |

| [27] | DUNMEAD S D, READEY D W, SEMLER C E, et al. Kinetics of combustion synthesis in the Ti-C and Ti-C-Ni systems. J. Am. Ceram. Soc., 1989, 72(12): 2318-2324. |

| [28] | HOLT J B, KINGMAN D D, BIANCHINI G M.Kinetics of the combustion synthesis of TiB2.Mater. Sci. Eng., 1985, 71: 321-327. |

| [1] | ZHANG Ruiyang, WANG Yi, OU Bowen, ZHOU Ying. α-Ni(OH)2 Surface Hydroxyls Synergize Ni3+ Sites for Catalytic Formaldehyde Oxidation [J]. Journal of Inorganic Materials, 2023, 38(10): 1216-1222. |

| [2] | GAO Wa, XIONG Yujie, WU Congping, ZHOU Yong, ZOU Zhigang. Recent Progress on Photocatalytic CO2 Reduction with Ultrathin Nanostructures [J]. Journal of Inorganic Materials, 2022, 37(1): 3-14. |

| [3] | ZHENG Yanning, JI Junrong, LIANG Xueling, LAI Zhengjie, CHENG Qifan, LIAO Dankui. Performance of Nitrogen-doped Hollow Carbon Spheres as Oxidase Mimic [J]. Journal of Inorganic Materials, 2021, 36(5): 527-534. |

| [4] | XU Yun-Qing,WANG Hai-Zeng. Sodium Magnesium Fluoride Particles of Different Morphologies: Prepared by EDTA-assisted Hydrothermal Method [J]. Journal of Inorganic Materials, 2019, 34(9): 933-937. |

| [5] | YU Yin-Hu, WANG Tao, ZHANG Hong-Min, ZHANG Du-Bao, PAN Jian-Feng. Low Temperature Combustion Synthesis of TiC Powder Induced by PTFE [J]. Journal of Inorganic Materials, 2015, 30(3): 272-276. |

| [6] | DOU Zhi-He, ZHANG Ting-An, WEN Ming, SHI Guan-Yong, HE Ji-Cheng. Preparation of Ultra-fine NdB6 Powders by Combustion Synthesis and Its Reaction Mechanism [J]. Journal of Inorganic Materials, 2014, 29(7): 711-716. |

| [7] | GUO Xiang-Xin, HUANG Shi-Ting, ZHAO Ning, CUI Zhong-Hui, FAN Wu-Gang, LI Chi-Lin, LI Hong. Rapid Development and Critical Issues of Secondary Lithium-air Batteries [J]. Journal of Inorganic Materials, 2014, 29(2): 113-123. |

| [8] | SUN Dan-Dan, PAN Shang-Ke, REN Guo-Hao, WU Yun-Tao, SHANG Shan-Shan, ZHANG Guo-Qing. Luminescence Properties of High Y3+-doped Ce:Li6Lu(BO3)3 Scintillators [J]. Journal of Inorganic Materials, 2013, 28(9): 987-991. |

| [9] | SUN Pei-Qiu, ZHU De-Gui, JIANG Xiao-Song, SUN Hong-Liang, XIA Zhao-Hui. Research on Microstructures and Properties of in-situ Synthesis of TiB2-TiC0.8-SiC Multiphase Ceramics [J]. Journal of Inorganic Materials, 2013, 28(4): 363-368. |

| [10] | SHI Xiao-Rui, WANG Qun, LV Ling-Yuan, LI Yang, YU Xiao, CHEN Gang. Controllable Synthesis and Electrical Conductivities of Cu7Te4 Nanostructures [J]. Journal of Inorganic Materials, 2012, 27(4): 433-438. |

| [11] | MU Yun-Chao, LIANG Bao-Yan, GUO Ji-Feng. Reaction Mechanism of Ti3SiC2 Formed on the Diamond [J]. Journal of Inorganic Materials, 2012, 27(10): 1099-1104. |

| [12] | XU Xiu-Hua,XIAO Han-Ning,GUO Wen-Ming,GAO Peng-Zhao,PENG Su-Hua. Preparation and Reaction Mechanism of LaB6 Powder by Solid-state Reaction at Atmospheric Pressure [J]. Journal of Inorganic Materials, 2011, 26(4): 417-421. |

| [13] | WU Hao1,2, CHEN Cheng1, JIANG DanYu2, LI Qiang1. Fast Mechanochemical Synthesis of Nanostructured PMN at Low Temperature [J]. Journal of Inorganic Materials, 2010, 25(5): 541-545. |

| [14] | XU Shun-Jian,QIAO Guan-Jun,WANG Hong-Jie,LI Di-Chen,LU Tian-Jian. Microstructure Evolution and Reaction Mechanism of Microporous Carbon Derived SiC Ceramic [J]. Journal of Inorganic Materials, 2009, 24(2): 291-296. |

| [15] | ZUO Ming-Wen,LI Wei,SHI Jian-Lin. Synthesis of BaSm 2 Ti 4 O 12 via Polymeric Precursor method [J]. Journal of Inorganic Materials, 2006, 21(6): 1443-1448. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||