Journal of Inorganic Materials ›› 2015, Vol. 30 ›› Issue (4): 351-356.DOI: 10.15541/jim20140352

• Orginal Article • Previous Articles Next Articles

HUANG Yan-Hua1, HAN Xiang2, CHEN Hui-Xin3, CHEN Song-Yan2, YANG Yong3

Received:2014-07-07

Revised:2014-09-03

Published:2015-04-29

Online:2015-03-26

About author:HUANG Yan-Hua. E-mail: yanhuahuang@126.com

CLC Number:

HUANG Yan-Hua, HAN Xiang, CHEN Hui-Xin, CHEN Song-Yan, YANG Yong. Investigation of Porous Silicon/Carbon Composite as Anodes for Lithium Ion Batteries[J]. Journal of Inorganic Materials, 2015, 30(4): 351-356.

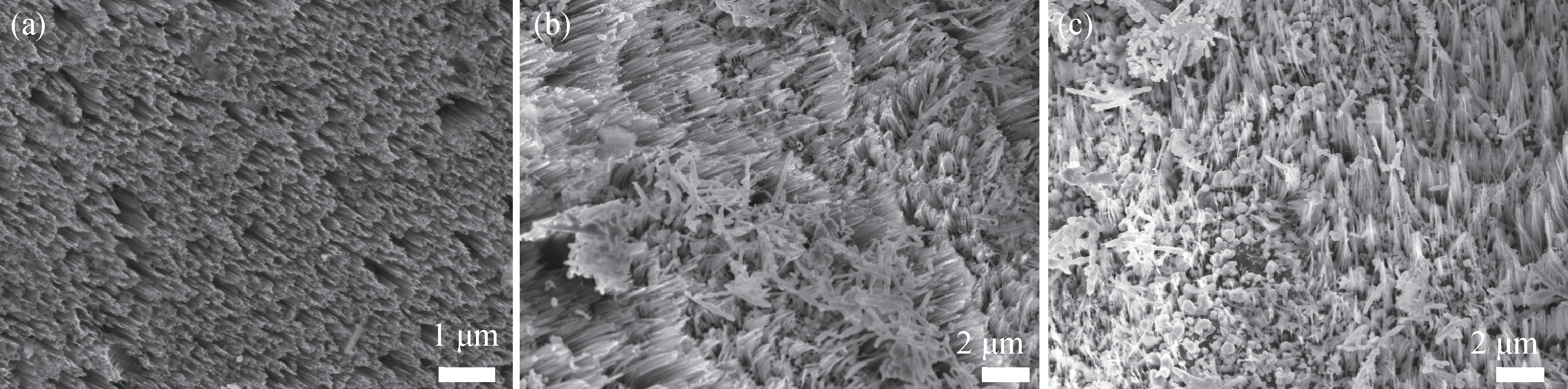

Fig. 1 SEM images of PS etching using different concentrations of AgNO3 solution (a) 0.02 mol/L AgNO3+2%HF; (b) 0.04 mol/L AgNO3+2%HF; (c) 0.06 mol/L AgNO3+2%HF

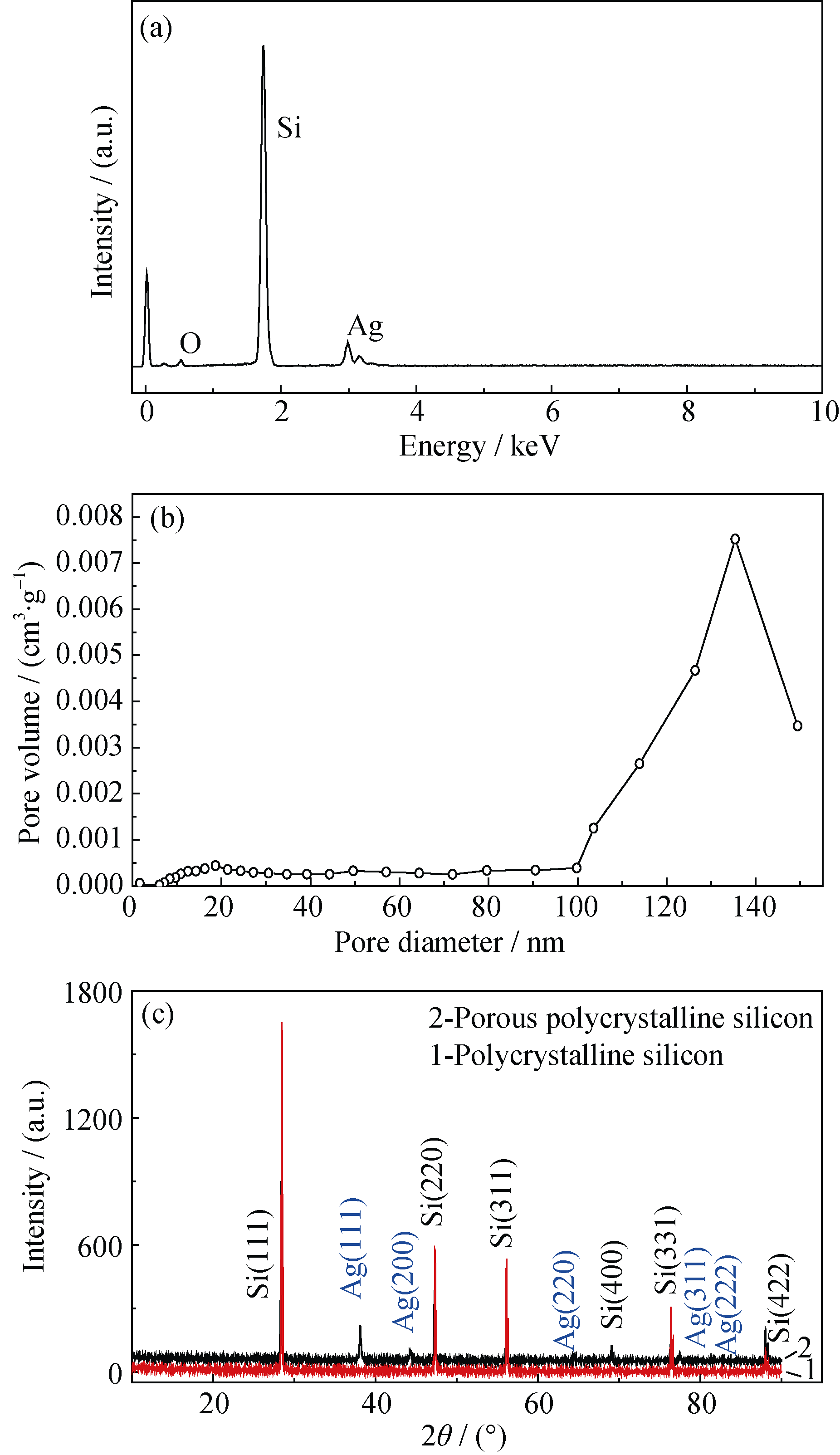

Fig. 3 Component and size analysis of PS particles prepared at optimum concentration (a) EDS pattern of Ag-deposited Si; (b) BJH shows the pore size distribution of PS particles; (c) XRD patterns of polycrystalline before and after metal-assisted chemical etching

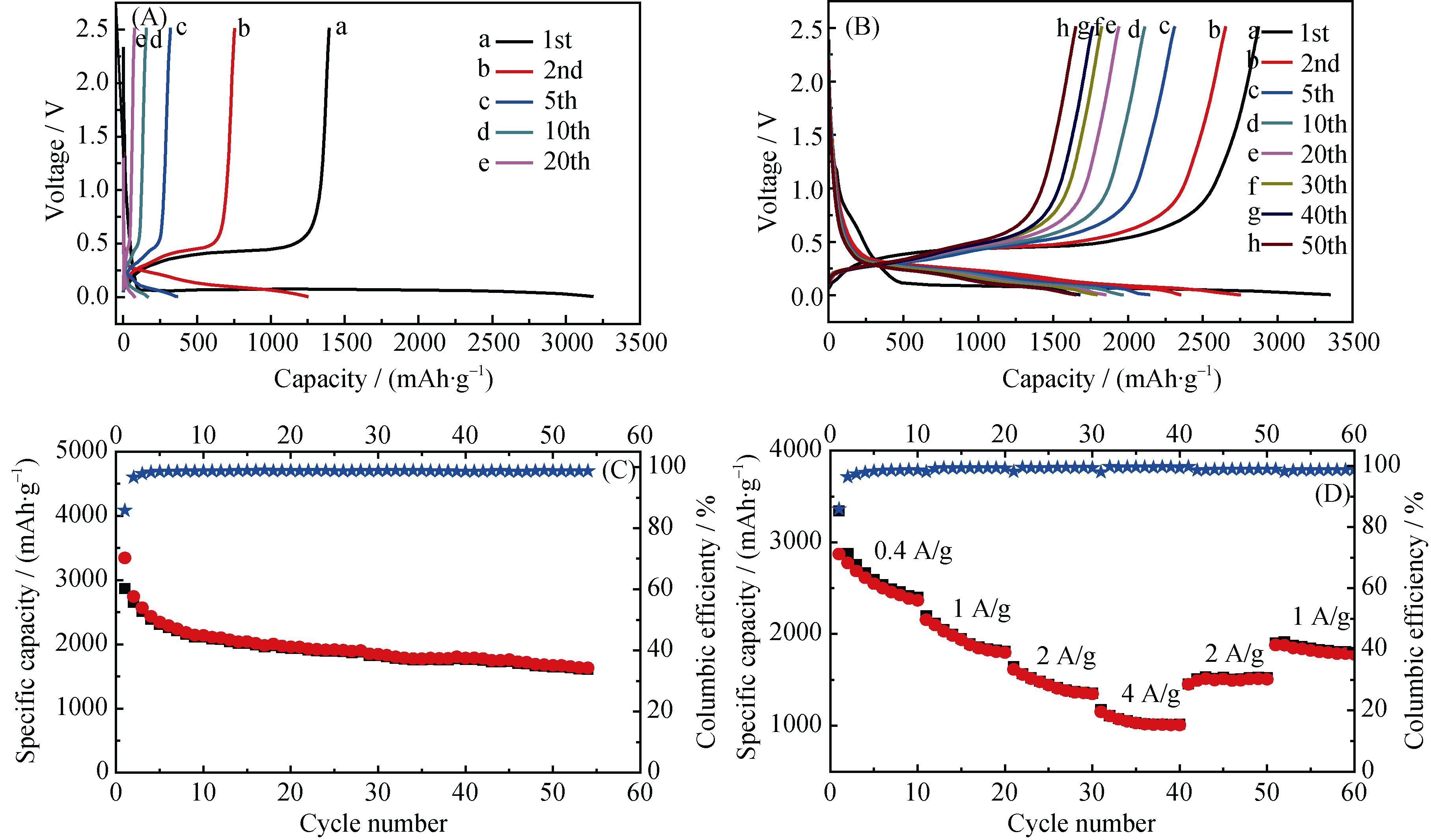

Fig. 6 Electrochemical performance of PS and PS/C electrode anode (A) Voltage profiles of PS anodes at 0.1 A/g; (B) Voltage profiles of PS/C anodes at 0.4 A/g; (C) Cycling performance of the PS/C electrode at 0.4 A/g; (D) Rate capability of PS/C electrode

| [1] | ARMAND M, TARASCON J M.Building better batteries.Nature, 2008, 451(7179): 652-657. |

| [2] | LI J L, DANIEL C, WOOD D.Materials processing for lithium- ion batteries.Journal of Power Sources, 2011, 196(5): 2452-2460. |

| [3] | HUGGINS R A. Lithium alloy negative electrodes. Journal of Power Sources, 1999, 81-82(1): 13-19. |

| [4] | HOLZAPFEL M, BUQA H, HARDWICK L J, et al.Nano silicon for lithium-ion batteries.Electrochimica Acta, 2006, 52(3): 973-978. |

| [5] | JIA H, GAO P, YANG J, et al.Novel three-dimensional mesoporous silicon for high power lithium-ion battery anode material.Advanced Energy Materials, 2011, 1(6): 1036-1039. |

| [6] | KOVALENKO I, ZDYRKO B, MAGASINSKI A, et al.A major constituent of brown algae for use in high-capacity Li-ion batteries.Science, 2011, 334(6052): 75-79. |

| [7] | MA H, CHENG F Y, CHEN J, et al.Nest-like silicon nanospheres for high-capacity lithium storage.Advanced Materials, 2007, 19(22): 4067-4070. |

| [8] | CHAN C K, PENG H L, LIU G, et al.High-performance lithium battery anodes using silicon nanowires.Nature Nanotechnology, 2007, 3(1): 31-35. |

| [9] | CHAN C K, PATEL R N, O’CONNELL M J, et al. Solution-grown silicon nanowires for lithium-ion battery anodes.ACS Nano, 2010, 4(3): 1443-1450. |

| [10] | PARK M H, KIM M G, JOO J, et al.Silicon nanotube battery anodes.Nano Letters, 2009, 9(11):3844-3847. |

| [11] | YOO J K, KIM J, JUNG Y S, et al.Scalable fabrication of silicon nanotubes and their application to energy storage.Advanced Materials, 2012, 24(40): 5452-5456. |

| [12] | YU C J, LI X, MA T, et al.Silicon thin films as anodes for high-performance lithium-ion batteries with effective stress relaxation.Advanced Energy Materials, 2012, 2(1): 68-73. |

| [13] | FENG X J, YANG J, GAO P F, et al. Facile approach to an advanced nanoporous silicon/carbon composite anode material for |

| lithium ion batteries.RSC Advances, 2012, 2(13): 5701-5706. | |

| [14] | WU H, ZHENG G Y, LIU N A, et al.Engineering empty space between Si nanoparticles for lithium-ion battery anodes.Nano Letters, 2012, 12(2): 904-909. |

| [15] | YU Y, GU L, ZHU C, et al.Reversible storage of lithium in silver- coated three-dimensional macroporous silicon.Advanced Materials, 2010, 22(20): 2247-2250. |

| [16] | DU JIN-YAN, CHEN JING-BO, SHANG YU-MING, et al.Study on Si/Ag composite materials for lithium battery anode.Chemistry Industry and Engineering Progress, 2012, (S1): 336-339. |

| [17] | LIU N, WU H, MCDOWELL M T, et al.A yolk-shell design for stabilized and scalable Li-ion battery alloy anodes.Nano Letters, 2012, 12(6): 3315-3321. |

| [18] | WU H, YU G, PAN L, et al.Stable Li-ion battery anodes by in-situ polymerization of conducting hydrogel to conformally coat silicon nanoparticles.Nature Communications, 2013,4: 6. |

| [19] | CHEN X L, LI X L, DING F, et al.Conductive rigid skeleton supported silicon as high-performance Li-ion battery anodes.Nano Letters, 2012,12(8): 4124-4130. |

| [20] | OSKAM G, LONG J G, NATARAJAN A, et al.Electrochemical deposition of metals onto silicon.Journal of Physics D: Applied Physics, 1998, 31(16): 1927. |

| [21] | PENG K Q, LU A J, ZHANG R Q, et al.Motility of metal nanoparticles in silicon and induced anisotropic silicon etching.Advanced Functional Materials, 2008, 18(19): 3026-3035. |

| [22] | QU Y, LIAO L, LI Y J, et al.Electrically conductive and optically active porous silicon nanowires.Nano Letters, 2009, 9(12): 4539-4543. |

| [23] | CHARTIER C, BASTIDE S, LEVY-CLEMENT C, Metal-assisted chemical etching of silicon in HF-H2O2.Electrochimica Acta, 2008, 53(17):5509-5516. |

| [24] | LI JIAN-WEN, ZHOU AI-JUN, LIU XING-QUAN, et al.Si nanowire anode prepared by chemical etching for high energy density lithium-ion battery.Journal of Inorganic Materials, 2013, 28(11): 1207-1212. |

| [25] | HUANG Z, GEYER N, WERNER P, et al.Metal-assisted chemical etching of silicon:a review.Advanced Materials, 2011, 23(2): 285-308. |

| [26] | BANG B M, KIM H, LEE J P, et al.Mass production of uniform-sized nanoporous silicon nanowire anodes via block copolymer lithography.Energy & Environmental Science, 2011, 4(9): 3395-3399. |

| [27] | LIU JING-JING, SUN QIN-QIN, HAN XIANG, et al.Preparation of porous silicon materials as anode for lithium ion batteries.Journal of Xiamen University (Natural Science), 2013, 52(4): 450-454. |

| [28] | HASSAN F M, CHABOT V, ELSAYED A R, et al.Engineered Si electrode nanoarchitecture: a scalable postfabrication treatment for the production of next-generation Li-ion batteries.Nano Letters, 2013, 14(1): 277-283. |

| [29] | HUANG X, PU H, CHANG J, et al.Improved cyclic performance of Si anodes for lithium-ion batteries by forming intermetallic interphases between Si nanoparticles and metal microparticles.ACS Applied Materials & Interfaces, 2013, 5(22): 11965-11970. |

| [1] | CHENG Jie, ZHOU Yue, LUO Xintao, GAO Meiting, LUO Sifei, CAI Danmin, WU Xueyin, ZHU Licai, YUAN Zhongzhi. Construction and Electrochemical Properties of Yolk-shell Structured FeF3·0.33H2O@N-doped Graphene Nanoboxes [J]. Journal of Inorganic Materials, 2024, 39(3): 299-305. |

| [2] | HU Mengfei, HUANG Liping, LI He, ZHANG Guojun, WU Houzheng. Research Progress on Hard Carbon Anode for Li/Na-ion Batteries [J]. Journal of Inorganic Materials, 2024, 39(1): 32-44. |

| [3] | WU Xiaowei, LI Jiayan. Texturing Technology on Multicrystalline Silicon Wafer by Metal-catalyzed Chemical Etching: a Review [J]. Journal of Inorganic Materials, 2021, 36(6): 570-578. |

| [4] | CHEN Lichi, WANG Yaogong, WANG Wenjiang, MA Xiaoqin, YANG Jingyuan, ZHANG Xiaoning. Preparation of Silicon Nanowires and Porous Silicon Composite Structure by Electrocatalytic Metal Assisted Chemical Etching [J]. Journal of Inorganic Materials, 2021, 36(6): 608-614. |

| [5] | ZHAN Jing,XU Changfan,LONG Yiyu,LI Qihou. Bi2Mn4O10: Preparation by Polyacrylamide Gel Method and Electrochemical Performance [J]. Journal of Inorganic Materials, 2020, 35(7): 827-833. |

| [6] | MA Ya-Nan, LIU Yu-Fei, YU Chen-Xu, ZHANG Chuan-Kun, LUO Shi-Jun, GAO Yi-Hua. Monolayer Ti3C2Tx Nanosheets with Different Lateral Dimension: Preparation and Electrochemical Property [J]. Journal of Inorganic Materials, 2020, 35(1): 93-98. |

| [7] | CAI Jian-Xin, LI Zhi-Peng, LI Wei, ZHAO Peng-Fei, YANG Zhen-Yu, YU Ji. Synthesis and Electrochemical Performance of Fe2O3 Nanofibers as Anode Materials for LIBs [J]. Journal of Inorganic Materials, 2018, 33(3): 301-306. |

| [8] | LI Ling, LI Yun-Jiao, XU Bin, LU Wei-Sheng, SU Qian-Ye, CHEN Yong-Xiang, LI Lin. LiNixCoyMn1-x-yO2 Cathode Material Synthesized through Construction of E-pH Diagram and Its Electrochemical Performance [J]. Journal of Inorganic Materials, 2018, 33(3): 320-324. |

| [9] | LI Jun, CAO Ya-Li, WANG Lu-Xiang, JIA Dian-Zeng. Performance of Coal-derived Spherical Porous Carbon as Anode Materials for Lithium Ion Batterie [J]. Journal of Inorganic Materials, 2017, 32(9): 909-915. |

| [10] | XU Li, SHENG Peng, CHEN Xin, HAN Yu, LIU Shuang-Yu, WANG Bo, ZHAO Guang-Yao, LIU Hai-Zhen. Preparation and Application of Three-dimensional Graphene Nanospheres in Lithium Ion Battery [J]. Journal of Inorganic Materials, 2016, 31(9): 976-980. |

| [11] | LIANG Pei, XING Song, SHU Hai-Bo, ZHANG Lin, HU Chen-Li. Analogous Three-dimensional MoS2/Graphene Composites for Reversible Li Storage [J]. Journal of Inorganic Materials, 2016, 31(6): 575-580. |

| [12] | BAO Xiao-Hui, MING Ping-Mei, BI Xiang-Yang. Preparation of Superhydrophobic Surface Based on SiC Particulate Reinforced Composite [J]. Journal of Inorganic Materials, 2016, 31(4): 383-387. |

| [13] | CUI Yu, WANG Yan-Zhi, CHEN Zhao-Fan. Preparation and Electrochemical Lithium Insertion of TiO2/Graphene Nanocomposites [J]. Journal of Inorganic Materials, 2015, 30(11): 1218-1222. |

| [14] | LIU Qin, YUAN Wen, GAO Xue-Ping. Surface Modification of Li-rich Layered Li(Li0.17Ni0.2Mn0.58Co0.05)O2 Oxide with TiO2(B) as the Cathode for Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2014, 29(12): 1257-1264. |

| [15] | SHI Chang-Chuan, YANG Xue-Lin, ZHANG Lu-Lu, ZHOU Yong-Tao, WEN Zhao-Yin. High-performance SiO/C/G Composite Anode for Lithium Ion Batteries [J]. Journal of Inorganic Materials, 2013, 28(9): 943-948. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||