无机材料学报 ›› 2020, Vol. 35 ›› Issue (6): 717-723.DOI: 10.15541/jim20190285 CSTR: 32189.14.10.15541/jim20190285

所属专题: 2020年能源材料论文精选(二):超级电容器

收稿日期:2019-06-12

修回日期:2019-09-02

出版日期:2020-06-20

网络出版日期:2019-09-20

作者简介:蒋 浩(1998-), 男, 本科生. E-mail: 基金资助:

JIANG Hao,WU Hao,HOU Chengyi,LI Yaogang,XIAO Ru,ZHANG Qinghong( ),WANG Hongzhi(

),WANG Hongzhi( )

)

Received:2019-06-12

Revised:2019-09-02

Published:2020-06-20

Online:2019-09-20

Supported by:摘要:

生物源材料由于来源丰富、可循环使用、无污染, 并且能够实现多功能化而引起了广泛关注。本研究利用大自然中广泛分布的桦木树干为原料, 通过不同取向切割、去木质素和碳化等过程得到具有相应取向的微孔道结构的生物质炭, 并用作锂硫电池的隔层。生物质炭的比表面积为267.7 m 2/g, 有大量的微孔及介孔。测试结果表明: 沿与电极平面呈45°方向切割所得的生物质炭的电化学性能最好。在0.2C(1C=1650 mA/g)下该生物质炭隔层制备的锂硫电池初始比容量为979.4 mAh/g, 200次循环后保留有625.4 mAh/g, 每圈容量损失率仅为0.18%。该生物质炭隔层可以有效地吸附和阻挡多硫化锂, 减小充放电过程中产生的穿梭效应, 并且桦木的微通道结构和类蒸腾特性可以有效地提高电池的比容量、循环稳定性, 有利于锂硫电池的商业化应用。

中图分类号:

蒋浩,吴淏,侯成义,李耀刚,肖茹,张青红,王宏志. 切割方向对桦木衍生的取向微通道生物质炭锂硫电池隔膜性能的影响[J]. 无机材料学报, 2020, 35(6): 717-723.

JIANG Hao,WU Hao,HOU Chengyi,LI Yaogang,XIAO Ru,ZHANG Qinghong,WANG Hongzhi. Sawing Angles on Property of Lithium-sulfur Battery Interlayer Prepared with Birch Derived Orientedly Microchannel Biochar[J]. Journal of Inorganic Materials, 2020, 35(6): 717-723.

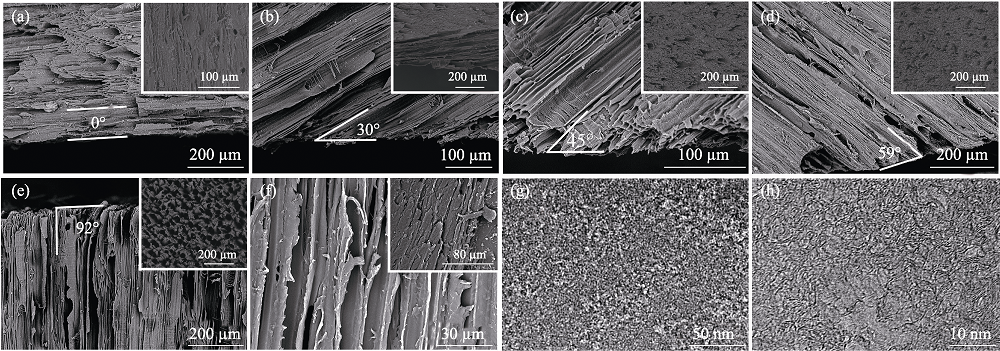

图2 取向分别为0°(a), 30° (b), 45° (c), 60° (d)和90° (e)的生物质炭截面和相应取向(插图)的SEM照片; 去除木质素前((f)中插图)后(f)的桦木SEM照片; 45°取向的生物质炭的TEM(g)和HR-TEM(h)照片

Fig. 2 Cross-sectional and longitudinal (inserts) SEM images of the of biochar saw along varying angles: 0°(a), 30° (b), 45° (c), 60° (d), and 90° (e); SEM images of wood before (insert in (f)) and after (f) delignification; TEM (g) and HRTEM(h) images of biochar oriented at 45°

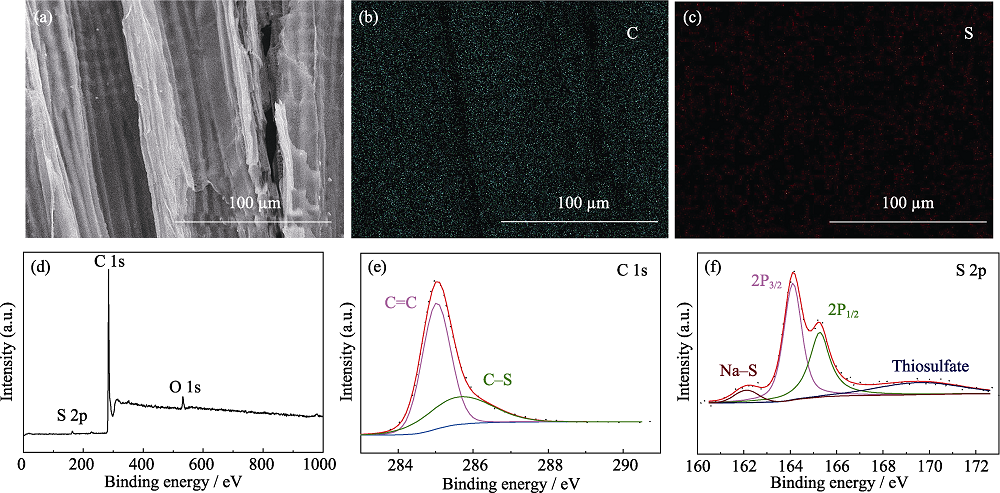

图3 45°取向的生物质炭的SEM照片(a)以及相应的碳(b)、硫(c)的元素面分布图; (d~f) 45°取向的生物质炭材料的XPS元素分析全谱(d)、C1s (e)和S2p (f)分谱图

Fig. 3 SEM image (a), corresponding C (b) and S (c) elements distribution mappings of biochar oriented at 45°, XPS spectra of biochar oriented at 45°, survey spectrum (d), C1s (e), and S2p (f)

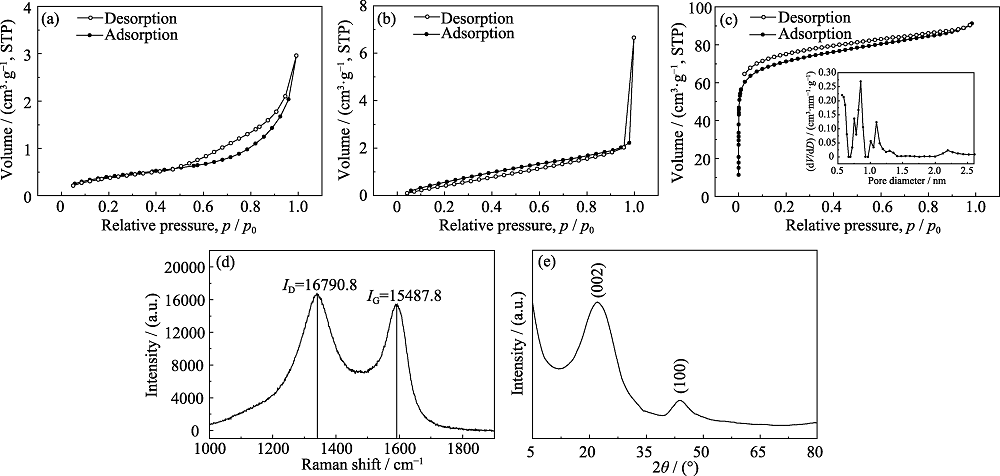

图4 (a~c) 沿45°切割所得未处理的桦木片(a)、去木质素后的桦木片(b)和45°取向的生物质炭(c)的N2等温吸-脱附曲线; 45°取向生物质炭的孔径分布曲线((c)中插图); (d) 45°取向的生物质炭的拉曼光谱图; (e) 45°取向的生物质炭XRD图谱

Fig. 4 (a-c) N2 adsorption-desorption isotherms of the untreated birch (a), lignin-free birch (b), biochar sawing along 45°(c) and pore size distribution curve (insert in (c)) of biochar sawing along 45°; Raman spectrum (d) and XRD pattern (e) of biochar oriented at 45°

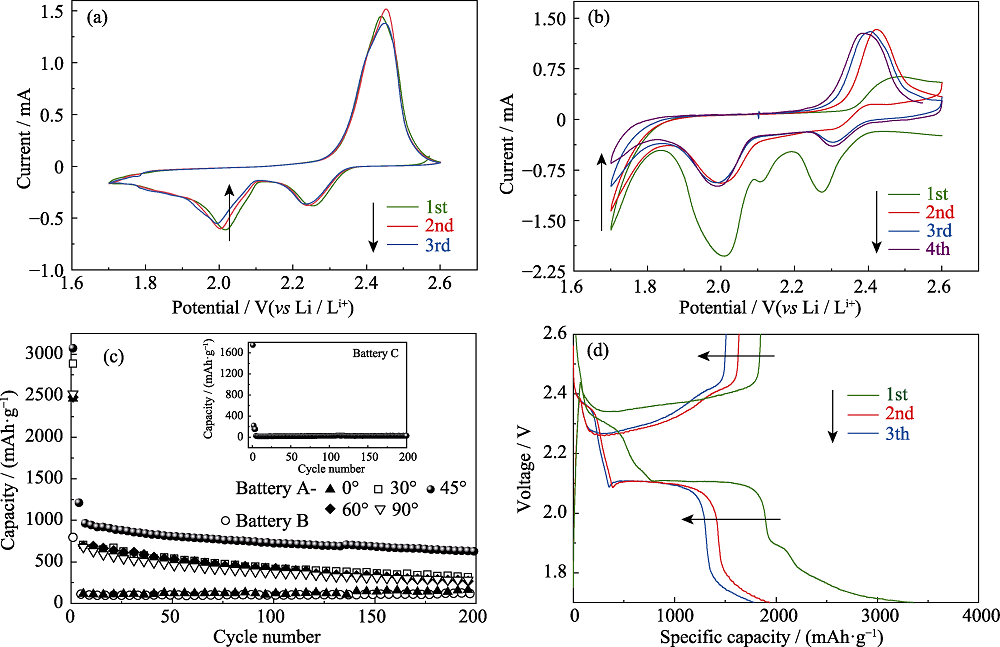

图5 电池B(a)与电池A-45°(b)在电压窗口为1.7~2.6 V、0.1 mV/s时的循环伏安曲线; (c)不同取向的电池A和电池B循环性能对比图, 插图为电池C循环性能图; (d) 0.05C时电池A-45°的前三次充放电曲线

Fig. 5 Cyclic voltammograms of battery B (a) and battery A-45° (b) between 1.7-2.6 V at 0.1 mV/s; (c) Cycling performances of batteries A with different cutting orientation biochar interlayers and battery B with insert showing the cycling performance of battery C; (d) Charging-discharging profiles of battery A-45° at 0.05C

| [1] |

ARMAND M, TARASCON J M . Building better batteries. Nature, 2008,451(7179):652-657.

DOI URL |

| [2] |

BRUCE P G, FREUNBERGER S A, HARDWICK L J , et al. LiO2 and Li-S batteries with high energy storage. Nature Materials, 2012,11(1):19-29.

DOI URL |

| [3] |

SEH Z W, SUN Y M, ZHANG Q F , et al. Designing high-energy lithium-sulfur batteries. Chemical Society Reviews, 2016,45(20):5605-5634.

DOI URL |

| [4] | FANG R P, ZHAO S Y, SUN Z H, et al. More reliable lithium- sulfur batteries: status, solutions and prospects. Advanced Materials, 2017, 29(48): 1606823-1-25. |

| [5] |

JI X L, LEE K T, NAZAR LINDA F . A highly ordered nanostructured carbon-sulphur cathode for lithium-sulphur batteries. Nature Materials, 2009,8(6):500-506.

DOI URL |

| [6] |

MANTHIRAM A, CHUNG S H, ZU C X . Lithium-sulfur batteries: progress and prospects. Advanced Materials, 2015,27(12):1980-2006.

DOI URL |

| [7] |

CHENG X B, YAN C, CHEN X , et al. Implantable solid electrolyte interphase in lithium-metal batteries. Chem., 2017,2(2):258-270.

DOI URL |

| [8] | YE H, XIN S, YIN Y X , et al. Advanced porous carbon materials for high-efficient lithium metal anodes. Advanced Energy Materials, 2017,7(23): 1700530-1-9. |

| [9] |

CHEN J J, YUAN R M, FENG J M , et al. Conductive Lewis base matrix to recover the missing link of Li2S8 during the sulfur redox cycle in Li-S battery. Chemistry of Materials, 2015,27(6):2048-2055.

DOI URL |

| [10] |

YU S, FENG X R, ZHANG N , et al. Understanding conversion- type electrodes for lithium rechargeable batteries. Accounts of Chemical Research, 2018,51(2):273-281.

DOI URL |

| [11] |

EVERS S, NAZAR L F . New approaches for high energy density lithium-sulfur battery cathodes. Accounts of Chemical Research, 2013,46(5):1135-1143.

DOI URL |

| [12] |

JI L W, RAO M M, ZHENG H M , et al. Graphene oxide as a sulfur immobilizer in high performance lithium/sulfur cells. Journal of The American Chemical Society, 2011, 133( 46):18522-18525.

DOI URL |

| [13] |

QIN F R, WANG X W, ZHANG K , et al. High areal capacity cathode and electrolyte reservoir render practical Li-S batteries. Nano Energy, 2017,38:137-146.

DOI URL |

| [14] |

FU Y Z, SU Y S, MANTHIRAM A . Highly reversible lithium/ dissolved polysulfide batteries with carbon nanotube electrodes. Angewandte Chemie-International Edition, 2013,52(27):6930-6935.

DOI URL |

| [15] | CHUNG S H, HAN P, SINGHAL R , et al. Electrochemically stable rechargeable lithium-sulfur batteries with a microporous carbon nanofiber filter for polysulfide. Advanced Energy Materials, 2015, 5(18): 1500738-1-11. |

| [16] | LI Z, WU H B, LOU X W . Rational designs and engineering of hollow micro-/nanostructures as sulfur hosts for advanced lithium- sulfur batteries. Energy & Environmental Science, 2016,9(10):3061-3070. |

| [17] |

LUO S W, YAO M J, LEI S , et al. Freestanding reduced graphene oxide-sulfur composite films for highly stable lithium-sulfur batteries. Nanoscale, 2017,9(14):4646-4651.

DOI URL |

| [18] |

WANG H L, YANG Y, LIANG Y Y , et al. Graphene-wrapped sulfur particles as a rechargeable lithium-sulfur battery cathode material with high capacity and cycling stability. Nano Letters, 2011,11(7):2644-2647.

DOI URL |

| [19] |

CAO J, CHEN C, ZHAO Q , et al. A flexible nanostructured paper of a reduced graphene oxide-sulfur composite for high-performance lithium-sulfur batteries with unconventional configurations. Advanced Materials, 2016,28(43):9629-9636.

DOI URL |

| [20] | JEONG Y C, KIM J H, NAM S , et al. Rational design of nanostructured functional interlayer/separator for advanced Li-S batteries. Advanced Functional Materials, 2018, 28(38): 1707411-1-32. |

| [21] |

WANG P, ZHANG Z A, HONG B , et al. Multifunctional porous VN nanowires interlayer as polysulfides barrier for high performance lithium sulfur batteries. Journal of Electroanalytical Chemistry, 2019,832:475-479.

DOI URL |

| [22] |

XU G Y, YAN Q B, WANG S T , et al. A thin multifunctional coating on a separator improves the cyclability and safety of lithium sulfur batteries. Chemical Science, 2017,8(9):6619-6625.

DOI URL |

| [23] |

LAI Y Q, WANG P, QIN F R , et al. A carbon nanofiber@mesoporous δ-MnO2 nanosheet-coated separator for high-performance lithium- sulfur batteries. Energy Storage Materials, 2017,9:179-187.

DOI URL |

| [24] | PARK J, KIM E T, KIM C , et al. The importance of confined sulfur nanodomains and adjoining electron conductive pathways in subreaction regimes of Li-S batteries. Advanced Energy Materials, 2017, 7(19): 1700074-1-10. |

| [25] |

LIANG G M, WU J X, QIN X Y , et al. Ultrafine TiO2 decorated carbon nanofibers as multifunctional interlayer for high-performance lithium-sulfur battery. ACS Applied Materials & Interfaces, 2016,8(35):23105-23113.

DOI URL |

| [26] |

REHMAN S, GUO S J, HOU Y L . Rational design of Si/SiO2@hierarchical porous carbon spheres as efficient polysulfide reservoirs for high-performance Li-S battery. Advanced Materials, 2016,28(16):3167-3172.

DOI URL |

| [27] |

HUANG J Q, ZHANG Q, WEI F . Multi-functional separator/ interlayer system for high-stable lithium-sulfur batteries: progress and prospects. Energy Storage Materials, 2015,1:127-145.

DOI URL |

| [28] |

LIU M C, KONG L B, ZHANG P , et al. Porous wood carbon monolith for high-performance supercapacitors. Electrochimica Acta, 2012,60:443-448.

DOI URL |

| [29] |

ZHANG S, WU C L, WU W , et al. High performance flexible supercapacitors based on porous wood carbon slices derived from Chinese fir wood scraps. Journal of Power Sources, 2019,424:1-7.

DOI URL |

| [30] |

MA F W, SONG S J, WU G , et al. Facile selt-template large scale preparation of biomass-derived 3D hierarchical porous carbon for advanced supercapacitors. J. Mater. Chem. A, 2015,3(35):18154-18162.

DOI URL |

| [31] |

YUAN X Q, WU L S, HE X L , et al. Separator modified with N, S co-doped mesoporous carbon using egg shell as template for high performance lithium-sulfur batteries. Chemical Engineering Journal, 2017,320:178-188.

DOI URL |

| [32] |

ROSENMAN A, MARKEVICH E, SALITRA G , et al. Facile synthesis and very stable cycling of polyvinylidene dichloride derived carbon: sulfur composite cathode. Journal of The Electrochemical Society, 2016,163(9):A1829-A1835.

DOI URL |

| [33] | LIANG X, HART C, PANG Q , et al. A highly efficient polysulfide mediator for lithium-sulfur batteries. Nature Communications, 2015, 6: 5682-1-8. |

| [34] |

MALARD L M, PIMENTA M A, DRESSELHAUS G , et al. Raman spectroscopy in graphene. Physics Reports, 2009,473(5):51-87.

DOI URL |

| [35] |

WALLE M D, ZHANG Z, ZHANG M , et al. Hierarchical 3D nitrogen and phosphorous codoped graphene/carbon nanotubes- sulfur composite with synergistic effect for high performance of lithium-sulfur batteries. Journal of Materials Science, 2018,53(4):2685-2696.

DOI URL |

| [36] |

FERRARI A, ROBERTSON J . Interpretation of Raman spectra of disordered and amorphous carbon. Physical Review B (Condensed Matter), 2000,61(20):14095-14107.

DOI URL |

| [37] |

YANG S J, KIM T, IM J H , et al. MOF-derived hierarchically porous carbon with exceptional porosity and hydrogen storage capacity. Chemistry of Materials, 2012,24(3):464-470.

DOI URL |

| [38] |

OAKES L, CARTER R, PINT C L . Nanoscale defect engineering of lithium-sulfur battery composite cathodes for improved performance. Nanoscale, 2016,8(46):19368-19375.

DOI URL |

| [39] |

ZHU Z Q, CHENG F Y, CHEN J . Investigation of effects of carbon coating on the electrochemical performance of Li4Ti5O12/C nanocomposites. Journal of Materials Chemistry A, 2013,1(33):9484-9490.

DOI URL |

| [40] | LI Z, ZHANG J T, GUAN B Y , et al. A sulfur host based on titanium monoxide@carbon hollow spheres for advanced lithium- sulfur batteries. Nature Communications, 2016, 7: 13065-1-11. |

| [41] |

HUANG J Q, LIU X F, ZHANG Q , et al. Entrapment of sulfur in hierarchical porous graphene for lithium-sulfur batteries with high rate performance from -40 to 60 ℃. Nano Energy, 2013,2(2):314-321.

DOI URL |

| [42] | FU X, YANG R, LIU L , et al. Preparation of cellular 3-D graphite and its application in Li-S battery. New Chemical Materials, 2019,47(2):85-89. |

| [43] |

YANG S Y, YAN C, CAO Z X , et al. Preparation of hierarchical porous carbon/sulfur composite based on lotus-leaves and its property for Li-S batteries. Journal of Inorganic Materials, 2016,31(2):135-140.

DOI URL |

| [44] |

ZHU J D, GE Y Q, KIM D , et al. A novel separator coated by carbon for achieving exceptional high performance lithium-sulfur batteries. Nano Energy, 2016,20:176-184.

DOI URL |

| [45] |

FANG X, PENG H S . Revolution in electrodes: recent progress in rechargeable lithium-sulfur batteries. Small, 2015,11(13):1488-1511.

DOI URL |

| [46] |

SONG J, SU D, XIE X , et al. Immobilizing polysulfides with MXene-functionalized separators for stable lithium-sulfur batteries. ACS Appl. Mater. Interfaces, 2016,8(43):29427-29433.

DOI URL |

| [1] | 刘艳艳, 谢曦, 刘增乾, 张哲峰. MAX相陶瓷增强金属基复合材料: 制备、性能与仿生设计[J]. 无机材料学报, 2024, 39(2): 145-152. |

| [2] | 王新玲, 周娜, 田亚文, 周明冉, 韩静茹, 申远升, 胡执一, 李昱. SnS2/ZIF-8衍生二维多孔氮掺杂碳纳米片复合材料的锂硫电池性能研究[J]. 无机材料学报, 2023, 38(8): 938-946. |

| [3] | 李高然, 李红阳, 曾海波. 硼基材料在锂硫电池中的研究进展[J]. 无机材料学报, 2022, 37(2): 152-162. |

| [4] | 李婷婷, 张阳, 陈加航, 闵宇霖, 王久林. 锂硫电池S@pPAN正极用柔性黏结剂研究[J]. 无机材料学报, 2022, 37(2): 182-188. |

| [5] | 李华鑫, 陈俊勇, 肖洲, 乐弦, 余显波, 向军辉. 纳米材料形貌和性能调控的仿生自组装研究进展[J]. 无机材料学报, 2021, 36(7): 695-710. |

| [6] | 金高尧, 何海传, 吴杰, 张梦源, 李亚娟, 刘又年. 锂硫电池正极用钴掺杂空心多孔碳载体材料[J]. 无机材料学报, 2021, 36(2): 203-209. |

| [7] | 汤嘉伟, 王永邦, 马成, 杨海潇, 王际童, 乔文明, 凌立成. 甲基萘沥青基有序中孔炭的制备及电化学性能[J]. 无机材料学报, 2021, 36(10): 1031-1038. |

| [8] | 王佳宁, 靳俊, 温兆银. α-MoC1-x纳米晶富集碳球修饰隔膜对锂硫电池性能的影响[J]. 无机材料学报, 2020, 35(5): 532-540. |

| [9] | 李亚东, 李伟平, 王琴, 郑道光, 王建新. 碳纤维支撑柔性碳硫复合电极的制备、物性及电池性能研究[J]. 无机材料学报, 2019, 34(4): 373-378. |

| [10] | 佟威, 熊党生. 仿生超疏水表面的发展及其应用研究进展[J]. 无机材料学报, 2019, 34(11): 1133-1144. |

| [11] | 王宇晖, 靳 俊, 郭战胜, 温兆银. 锂硫电池循环过程中变形演化的直接观测[J]. 无机材料学报, 2017, 32(3): 247-251. |

| [12] | 柴二亚, 潘俊安, 袁国龙, 程豪, 安峰, 谢淑红. 聚苯胺包覆蛋白石页岩/硫复合材料的制备及其电化学性能[J]. 无机材料学报, 2017, 32(11): 1165-1170. |

| [13] | 杨书廷, 闫 崇, 曹朝霞, 史梦姣, 李艳蕾, 尹艳红. 以荷叶制备多级孔碳硫复合正极材料及性能研究[J]. 无机材料学报, 2016, 31(2): 135-140. |

| [14] | 许金妹, 刘新玲, 高彦峰. 多巴胺辅助牙本质沉积羟基磷灰石研究[J]. 无机材料学报, 2016, 31(1): 95-99. |

| [15] | 马国强, 温兆银, 王清松, 靳 俊, 吴相伟, 张敬超. CeO2纳米晶的添加对锂硫电池电化学性能的影响[J]. 无机材料学报, 2015, 30(9): 913-918. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||