无机材料学报 ›› 2018, Vol. 33 ›› Issue (7): 728-734.DOI: 10.15541/jim20170445 CSTR: 32189.14.10.15541/jim20170445

师建军1, 张宗波2, 冯志海1, 张大海1, 王筠1, 徐彩虹2

收稿日期:2017-09-18

修回日期:2017-11-14

出版日期:2018-07-10

网络出版日期:2018-06-19

作者简介:师建军(1984-), 男, 高级工程师. E-mail: shijj2016@yeah.net

基金资助:SHI Jian-Jun1, ZHANG Zong-Bo2, FENG Zhi-Hai1, ZHANG Da-Hai1, WANG Yun1, XU Cai-Hong2

Received:2017-09-18

Revised:2017-11-14

Published:2018-07-10

Online:2018-06-19

About author:SHI Jian-Jun. E-mail: shijj2016@yeah.net

摘要:

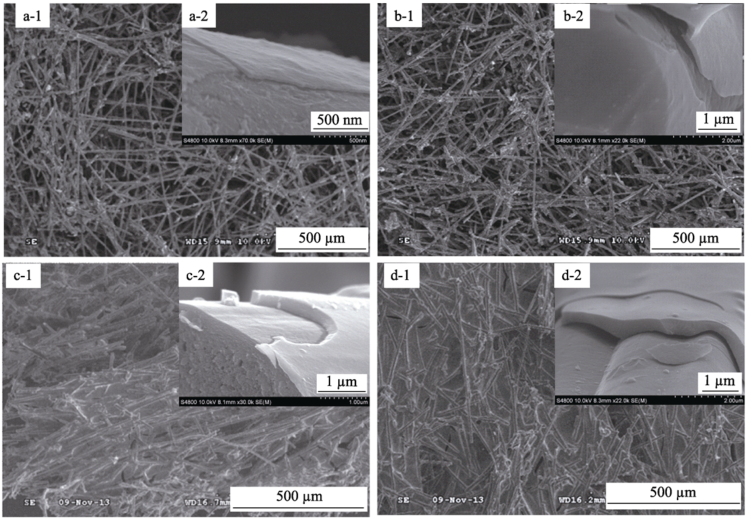

以全氢聚硅氮烷(PHPS)为原料, 采用浸渍-热转化方法, 在低密度碳粘接碳纤维复合材料(CBCF)中短切碳纤维表面成功包覆硅氧氮(SiON)涂层。采用扫描电子显微镜(SEM)、能量色散X射线光谱(EDS)等分析测试手段对碳纤维表面的SiON涂层进行了形貌和物相分析, 结果表明: 涂层主要由Si、O、N元素组成, 在PHPS浓度为3wt%和5wt%条件下制备的涂层均匀、致密, 随着PHPS浓度的提高, 涂层厚度增加, 但易发生结块。当PHPS浓度为10wt%和20wt%时, 制备的SiON涂层出现结块并且存在裂纹。采用热重分析和等温氧化实验对纯CBCF和SiON涂层改性的CBCF复合材料抗氧化性能进行考核, 结果显示碳纤维表面包覆SiON涂层能够显著提高CBCF复合材料的抗氧化性, 随着PHPS浓度增大, 低密度CBCF复合材料抗氧化性能显著提高。

中图分类号:

师建军, 张宗波, 冯志海, 张大海, 王筠, 徐彩虹. 低密度碳粘接碳纤维复合材料(CBCF)抗氧化改性研究[J]. 无机材料学报, 2018, 33(7): 728-734.

SHI Jian-Jun, ZHANG Zong-Bo, FENG Zhi-Hai, ZHANG Da-Hai, WANG Yun, XU Cai-Hong. Modification of Oxidation Resistance for Low Density Carbon-bonded Carbon Fiber (CBCF) Composite[J]. Journal of Inorganic Materials, 2018, 33(7): 728-734.

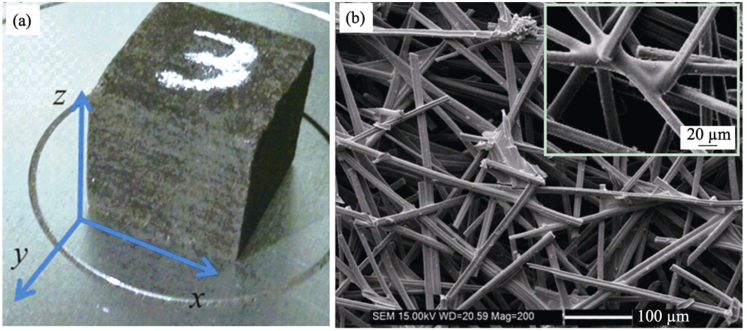

图1 高孔隙率碳粘接碳纤维复合材料(CBCF)外观照片(a)和SEM照片(b)

Fig. 1 Optical picture (a) and SEM micrograph (b) of high porosity carbon-bonded carbon fiber (CBCF) composite

| Samples | Contents of elements/wt%(at%) | |||

|---|---|---|---|---|

| Si | O | N | C | |

| CBCF | 0.72(0.32) | 5.76(4.41) | 0.73(0.64) | 92.79(94.64) |

| PHPS3 | 13.65(6.47) | 5.81(4.83) | 2.97(2.82) | 77.56(85.88) |

| PHPS5 | 13.76(6.64) | 13.15(11.14) | 1.67(1.62) | 71.41(80.60) |

| PHPS10 | 13.51(6.41) | 6.56(5.45) | 2.59(2.46) | 77.34(85.65) |

| PHPS20 | 13.72(6.65) | 5.71(4.78) | 2.51(2.43) | 78.06(86.15) |

表1 CBCF中碳纤维表面各元素含量

Table 1 Contents of elements on the surface of uncoated and coated carbon fiber

| Samples | Contents of elements/wt%(at%) | |||

|---|---|---|---|---|

| Si | O | N | C | |

| CBCF | 0.72(0.32) | 5.76(4.41) | 0.73(0.64) | 92.79(94.64) |

| PHPS3 | 13.65(6.47) | 5.81(4.83) | 2.97(2.82) | 77.56(85.88) |

| PHPS5 | 13.76(6.64) | 13.15(11.14) | 1.67(1.62) | 71.41(80.60) |

| PHPS10 | 13.51(6.41) | 6.56(5.45) | 2.59(2.46) | 77.34(85.65) |

| PHPS20 | 13.72(6.65) | 5.71(4.78) | 2.51(2.43) | 78.06(86.15) |

图5 不同PHPS浓度下CBCF中碳纤维表面涂层的SEM照片

Fig. 5 SEM images of the coatings on carbon fiber surface in cured CBCF composite at different concentrations of PHPS (a) PHPS3; (b) PHPS5; (c) PHPS10; (d) PHPS20

| Samples | CBCF | PHPS3 | PHPS5 | PHPS10 | PHPS20 |

|---|---|---|---|---|---|

| Density/(g•cm-3) | 0.22 | 0.23 | 0.25 | 0.29 | 0.33 |

| Coating thickness/µm | 0 | 0.26 | 0.32 | 0.33 | 0.41 |

表2 不同PHPS浓度制备的涂层厚度和CBCF复合材料密度

Table 2 Coating thickness and volume densities of the CBCFs prepared at different concentrations of PHPS

| Samples | CBCF | PHPS3 | PHPS5 | PHPS10 | PHPS20 |

|---|---|---|---|---|---|

| Density/(g•cm-3) | 0.22 | 0.23 | 0.25 | 0.29 | 0.33 |

| Coating thickness/µm | 0 | 0.26 | 0.32 | 0.33 | 0.41 |

| Samples | CBCF | PHPS3 | PHPS5 | PHPS10 | PHPS20 | PHPS100 |

|---|---|---|---|---|---|---|

| W */% | 0 | 6.0 | 14.5 | 26.2 | 57.6 | - |

| Td5/℃ | 442 | 644 | 649 | 650 | 653 | - |

| Td10/℃ | 506 | 656 | 659 | 660 | 667 | - |

| Residue/ (1000℃, %) | 0 | 8.6 | 17.8 | 30.8 | 52.5 | 105.4 |

表3 不同PHPS浓度下制备的SiON涂层包覆CBCF复合材料在空气中的热失重数据

Table 3 TGA data of CBCF composites coated by SiON coatings prepared with different PHPS concentrations at air

| Samples | CBCF | PHPS3 | PHPS5 | PHPS10 | PHPS20 | PHPS100 |

|---|---|---|---|---|---|---|

| W */% | 0 | 6.0 | 14.5 | 26.2 | 57.6 | - |

| Td5/℃ | 442 | 644 | 649 | 650 | 653 | - |

| Td10/℃ | 506 | 656 | 659 | 660 | 667 | - |

| Residue/ (1000℃, %) | 0 | 8.6 | 17.8 | 30.8 | 52.5 | 105.4 |

| [1] | BURCHELL T D.Porous Carbon Frbier-Carbon Binder Composites. Carbon Materials for Advanced Technologies; Elsevier Science, 1999: 169-204. |

| [2] | DAVIES I J, RAWLINGS R D.Microstructural investigation of low-density carbon-carbon composites. Journal of Materials Science, 1994, 29(2): 338-344. |

| [3] | DAVIES I J, RAWLINGS R D.Mechanical properties in compression of low density carbon/carbon composites. Composites, 1994, 25(3): 229-236. |

| [4] | LIU C, HAN J, ZHANG X,et al.Lightweight carbon-bonded carbon fiber composites prepared by pressure filtration technique. Carbon, 2013, 59: 551-554. |

| [5] | WRENN G E, ABBATIELLO L A, LEWIS J. Method for Fabricating Light Weight Carbon-bonded Carbon Fiber Composites. US 07/063,059.1989-4-4. |

| [6] | MARBÁN G, FUERTES A B, NEVSKAIA D M. Dry formation of low-density NomexTM rejects-based activated carbon fiber composites. Carbon, 2000, 38(15): 2167-2170. |

| [7] | AGRAWAL P, CHAVEZ-GARCIA J F, PHAM J. Fracture in phenolic impregnated carbon ablator. Journal of Spacecraft and Rockets, 2013, 50(4): 735-741. |

| [8] | AHMED A S, RAWLINGS R D, ELLACOTT S D,et al.Oxidation and thermal degradation resistance of silicon carbide coated low density carbon-carbon composite. Advances in Applied Ceramics, 2013, 112(1): 23-32. |

| [9] | NATALI M, KENNY J M, TORRE L.Science and technology of polymeric ablative materials for thermal protection systems and propulsion devices: a review. Progress in Materials Science, 2016, 84: 192-275. |

| [10] | BESSIRE B K, LAHANKAR S A, MINTON T K.Pyrolysis of phenolic impregnated carbon ablator (PICA). ACS Applied Materials & Interfaces, 2015, 7(3): 1383-1395. |

| [11] | GADIOU R, SERVERIN S, GIBOT P,et al.The synthesis of SiC and TiC protective coatings for carbon fibers by the reactive replica process. Journal of the European Ceramic Society, 2008, 28(11): 2265-2274. |

| [12] | HALBIG M C, MCGUFFIN-CAWLEY J D, ECKEL A J,et al.Oxidation kinetics and stress effects for the oxidation of continuous carbon fibers within a microcracked C/SiC ceramic matrix composite. Journal of the American Ceramic Society, 2008, 91(2): 519-526. |

| [13] | FRANK E, STEUDLE L M, INGILDEEV D,et al.Carbon fibers: precursor systems, processing, structure, and properties. Angewandte Chemie International Edition, 2014, 53(21): 5262-5298. |

| [14] | SUJAK K, WŁOCHOWICZ A, WYSOCKI M. IR spectroscopic analysis of changes in the molecular structure of pitch carbon fibre precursor during oxidation. Acta Polymerica, 1984, 35(9): 580-584. |

| [15] | LI HE-JUN, XUE HUI FU QIAN-GANG,et al. Research status and prospect of anti-oxidation coatings for carbon/carbon composite.Journal of Inorgainc Materials, 2010, 25(4): 337-343. |

| [16] | GAO PENG-ZHAO, WANG HONG-JIE, JIN ZHI- HAO.Influence of SiO2 coating preparation process on the oxidation resistance of 3D carbon fiber braids. Journal of Inorganic Materials, 2003, 18(4): 849-854. |

| [17] | XU B, HONG C, QU Q,et al.Preparation of a multi-composition coating for oxidation protection of modified carbon-bonded carbon fiber composites by a rapid sintering method. Surface and Coatings Technology, 2015, 270: 109-116. |

| [18] | XU B, HONG C, ZHOU S,et al.High-temperature erosion resistance of ZrB2-based ceramic coating for lightweight carbon/carbon composites under simulated atmospheric re-entry conditions by high frequency plasma wind tunnel test. Ceramics International, 2016, 42(8): 9511-9518. |

| [19] | AHMED A S, RAWLINGS R D, ELLACOTT S D,et al.Oxidation and thermal degradation resistance of silicon carbide coated low density carbon-carbon composite. Advances in Applied Ceramics, 2013, 112(1): 23-32. |

| [20] | AHMED A S, CHLUP Z, DLOUHY I,et al.Mechanical properties of low-density SiC-coated carbon-bonded carbon fiber composites. International Journal of Applied Ceramic Technology, 2012, 9(2): 401-412. |

| [21] | DAVIES I J, RAWLINGS R D.Mechanical properties in compression of CVI-densified porous carbon/carbon composite. Composites Science and Technology, 1999, 59(1): 97-104. |

| [22] | BAXTER R I, RAWLINGS R D, IWASHITA N,et al.Effect of chemical vapor infiltration on erosion and thermal properties of porous carbon/carbon composite thermal insulation.Carbon, 2000, 38(3): 441-449. |

| [23] | ZHANG X, XU B, HONG C,et al.Carbon-bonded carbon fiber composites containing uniformly distributed silicon carbide. RSC Advances, 2014, 4: 6591-6596. |

| [24] | SMEACETTO F, FERRARIS M, SALVO M,et al.Protective coatings for carbon bonded carbon fibre composites. Ceramics International, 2008, 34(5): 1297-1301. |

| [25] | DUMBACHER D L.X-37 Flight Demonstrator Porject: Capabilities for Future Space Transportation Systems Development. Vancouver,Canada: 2004. |

| [26] | GRANTZ A C.X-37B Orbital Test Vehicle and Derivatives. California: Long Beach, 2011. |

| [27] | ZHANG ZONG-BO, XIAO FENG-YAN, LUO YONG-MING,et al.Research progress in perhydropolysilazane coatings.Paint & Coating Industry, 2014, 43(4): 74-79. |

| [28] | GÜNTHNER M, KRAUS T, KRENKEL W,et al.Particle-filled PHPS silazane-based coatings on steel. International Journal of Applied Ceramic Technology, 2009, 6(3): 373-380. |

| [29] | FUNAYAMA O, TASHIRO Y, KAMO A,et al.Conversion mechanism of perhydropolysilazane into silicon nitride-based ceramics. Journal of Materials Science, 1994, 29(18): 4883-4888. |

| [30] | PENG Z, FU X, ZHU N,et al.Preparation and growth mechanism of clustered one-dimensional SiOx amorphous nanowires by catalytic pyrolysis of a polymer precursor. Journal of Non-Crystalline Solids, 2009, 355(43/44): 2156-2159. |

| [31] | MONTI M, DAL BIANCO B, BERTONCELLO R,et al.New protective coatings for ancient glass: silica thin-films from perhydropolysilazane. Journal of Cultural Heritage, 2008, 9(Supplement): 143-145. |

| [32] | XIAO FENG-YAN, ZHANG ZONG-BO, ZENG FAN,et al.Preparation and characterization of SiOx coating from perhydro- polysilazane.Rare Metal Materials and Engineering, 2013, 42(S1): 151-154. |

| [33] | QI GONG-JIN, ZHANG CHANG-RUI, HU HAI-FENG,et al.Synthesis and characterization of perhydropolysilazane.Journal of National University of Defense Technology, 2005, 27(6): 14-19. |

| [34] | BARROSO G S, KRENKEL W, MOTZ G.Low thermal conductivity coating system for application up to 1000℃ by simple PDC processing with active and passive fillers. Journal of the European Ceramic Society, 2015, 35(12): 3339-3348. |

| [35] | GÜNTHNER M, SCHÜTZ A, GLATZEL U,et al.High performance environmental barrier coatings, part I: Passive filler loaded SiCN system for steel. Journal of the European Ceramic Society, 2011, 31(15): 3003-3010. |

| [1] | 王文婷, 徐敬军, 马科, 李美栓, 李兴超, 李同起. 原位反应/热压合成Ti2AlC-20TiB2复合材料在1000~1300 ℃空气中的高温氧化行为[J]. 无机材料学报, 2025, 40(1): 31-38. |

| [2] | 蔡飞燕, 倪德伟, 董绍明. 高熵碳化物超高温陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 591-608. |

| [3] | 刘国昂, 王海龙, 方成, 黄飞龙, 杨欢. B4C含量对(Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C陶瓷力学性能及抗氧化性能的影响[J]. 无机材料学报, 2024, 39(6): 697-706. |

| [4] | 郑斌, 康凯, 张青, 叶昉, 解静, 贾研, 孙国栋, 成来飞. 前驱体转化陶瓷法制备Ti3SiC2陶瓷及其热稳定性研究[J]. 无机材料学报, 2024, 39(6): 733-740. |

| [5] | 张幸红, 王义铭, 程源, 董顺, 胡平. 超高温陶瓷复合材料研究进展[J]. 无机材料学报, 2024, 39(6): 571-590. |

| [6] | 周云凯, 刁亚琪, 王明磊, 张宴会, 王利民. 聚苯胺改性Ti3C2(OH)2抗氧化性的第一性原理计算研究[J]. 无机材料学报, 2024, 39(10): 1151-1158. |

| [7] | 舒朝琴, 朱敏, 朱钰方. 熔盐法制备含钴氯磷灰石及其抗氧化性能和细胞相容性研究[J]. 无机材料学报, 2022, 37(11): 1225-1235. |

| [8] | 王皓轩, 刘巧沐, 王一光. 高熵过渡金属碳化物陶瓷的研究进展[J]. 无机材料学报, 2021, 36(4): 355-364. |

| [9] | 张亚晨, 孟佳, 蔡坤, 盛晓晨, 乐军, 宋力昕. 基于声发射技术的Si-Cr-Ti高温抗氧化涂层弯曲失效机理研究[J]. 无机材料学报, 2021, 36(11): 1185-1192. |

| [10] | 余汉青, 董志军, 袁观明, 丛野, 李轩科, 罗永明. B-C掺杂SiC纤维的制备及其性能研究[J]. 无机材料学报, 2019, 34(5): 493-501. |

| [11] | 陈婷, 查剑锐, 张筱君, 江伟辉, 江莞, 刘健敏, 吴倩. 硅烷偶联剂对制备硅酸锆薄膜及其抗氧化性能的影响[J]. 无机材料学报, 2017, 32(11): 1154-1158. |

| [12] | 张 旭, 董志军, 袁观明, 丛 野, 李轩科. 陶瓷前驱体配比对Si-Zr-B掺杂沥青基炭材料抗氧化性能的影响[J]. 无机材料学报, 2016, 31(12): 1311-1319. |

| [13] | 曹希文, 罗凌虹, 徐 序, 程 亮, 石纪军, 余 辉. MnCo2O4涂层对SUS430合金连接体的表面改性研究[J]. 无机材料学报, 2016, 31(1): 63-68. |

| [14] | 雷卓研, 王 志, 范恒冰, 马文斌, 陈 健, 王 旭. 氧化硼-磷酸浸渍对中间相炭微球复合材料抗氧化及力学性能的影响[J]. 无机材料学报, 2015, 30(7): 769-773. |

| [15] | 毛金元, 刘 敏, 毛 杰, 邓春明, 曾德长, 徐 林. 等离子喷涂制备ZrB2-MoSi2复合涂层及其抗氧化性能[J]. 无机材料学报, 2015, 30(3): 282-286. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||