无机材料学报 ›› 2014, Vol. 29 ›› Issue (6): 639-644.DOI: 10.3724/SP.J.1077.2014.13416 CSTR: 32189.14.SP.J.1077.2014.13416

王 燕, 王红宁, 陈若愚

收稿日期:2013-08-13

修回日期:2013-10-29

出版日期:2014-06-20

网络出版日期:2014-05-27

作者简介:王 燕(1989-), 女, 硕士研究生. E-mail: wangyan1989816@126.com

基金资助:WANG Yan, WANG Hong-Ning, CHEN Ruo-Yu

Received:2013-08-13

Revised:2013-10-29

Published:2014-06-20

Online:2014-05-27

About author:WANG Yan. E-mail: wangyan1989816@126.com

摘要:

采用SiO2水溶胶(ACS)为硅源, H3PO4为桥联剂, H2O2为活化剂在玻璃表面成功制备了一种性能优异的新型减反膜。利用FTIR、XRD、FESEM、TEM、AFM对薄膜结构、形成机理及性能进行了研究, 结果表明, 在成胶过程中, H2O2的导入有效修复了SiO2胶粒的表面羟基, 提高了SiO2的反应活性; 而在焙烧过程中, H3PO4通过其自身脱水形成的偏磷酸链状体分别与SiO2胶粒及玻璃基底表面的Si-OH进行了脱羟基缩聚, 构架了坚固的Si-O-P网络交联, 最终形成了稳定的磷硅酸盐凝胶网络结构, 提高了成膜质量。当n(H3PO4) : n(H2O2) : n(EtOH) : n(SiO2)= 0.49: 0.52: 30: 1时, 制备的SiO2减反膜在可见光区平均透光率高达98%, 硬度可达6H。

中图分类号:

王 燕, 王红宁, 陈若愚. 含Si-O-P键的减反膜结构及性能影响因素研究[J]. 无机材料学报, 2014, 29(6): 639-644.

WANG Yan, WANG Hong-Ning, CHEN Ruo-Yu. Structure of Antireflective Films with Si-O-P Bonds and Impact Factors on Its Performance[J]. Journal of Inorganic Materials, 2014, 29(6): 639-644.

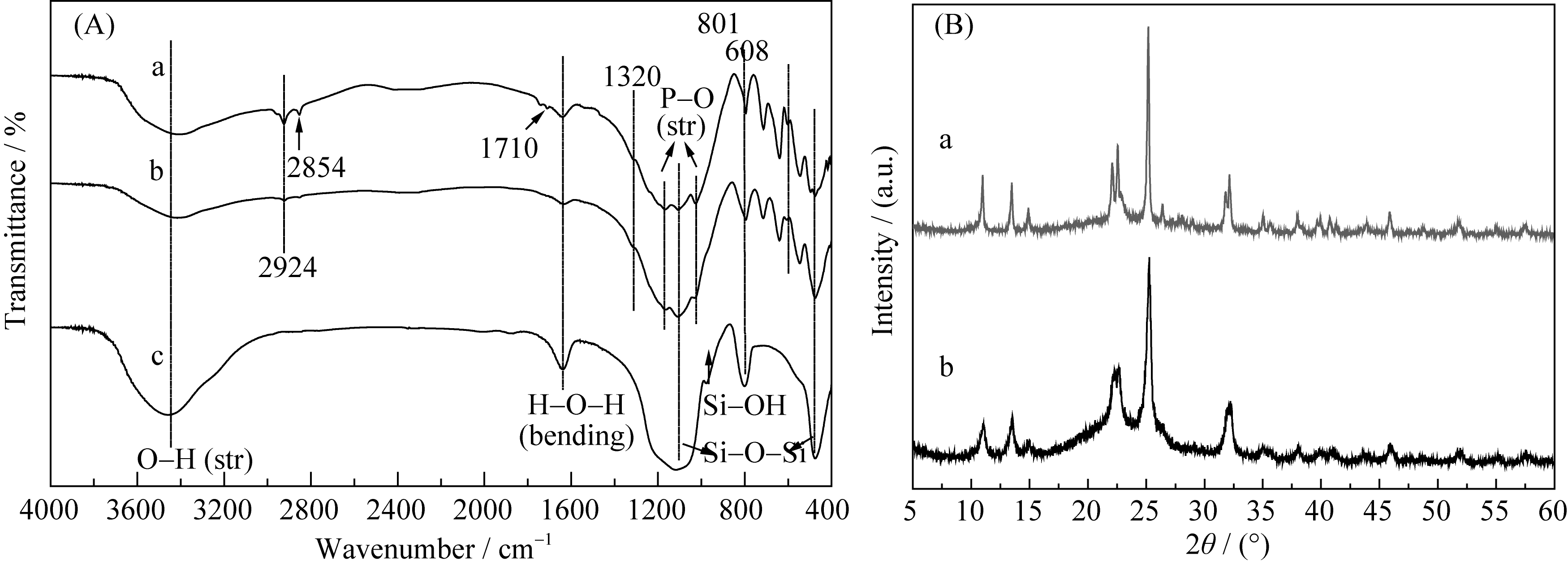

图1 在n(H2O2)﹕n(EtOH)﹕n(SiO2)=0.52﹕30﹕1), n(H3PO4/SiO2)分别为: (a) 0.98, (b) 0.49, (c) 0比例制备的SiO2凝胶的红外光谱图(A)和XRD图谱(B)

Fig. 1 FTIR spectra (A) and XRD patterns (B) of the SiO2 gels with different n(H3PO4/SiO2)(A) a-0, b-0.49, c-0.98; (B) a-0.49, b-0.98

| n(H3PO4/SiO2) | 0 | 0.16 | 0.33 | 0.49 | 0.65 | 0.82 | 0.98 |

|---|---|---|---|---|---|---|---|

| SBET /(m2•g-1) | 230.5 | 76.3 | 59.6 | 38.7 | 21.6 | 2.1 | / |

| Si-OH content/(bonds•nm-2) | 10.2 | 7.8 | 5.6 | 4.3 | 3.1 | 2.3 | / |

| Pencil hardness grade | 5B | F | 3H | 6H | 4H | 3H | H |

表1 在n(H2O2)﹕n(EtOH)﹕n(SiO2)=0.52﹕30﹕1, 以下同n(H3PO4/SiO2)比例制备SiO2凝胶的比表面积和Si-OH含量以及相应SiO2薄膜的铅笔硬度

Table 1 SBET and the Si-OH content of the SiO2 gels with different n(H3PO4)﹕n(H2O2)﹕n(EtOH)﹕n(SiO2)= 0.52﹕30﹕1) and pencil hardness grades of the corresponding SiO2 films

| n(H3PO4/SiO2) | 0 | 0.16 | 0.33 | 0.49 | 0.65 | 0.82 | 0.98 |

|---|---|---|---|---|---|---|---|

| SBET /(m2•g-1) | 230.5 | 76.3 | 59.6 | 38.7 | 21.6 | 2.1 | / |

| Si-OH content/(bonds•nm-2) | 10.2 | 7.8 | 5.6 | 4.3 | 3.1 | 2.3 | / |

| Pencil hardness grade | 5B | F | 3H | 6H | 4H | 3H | H |

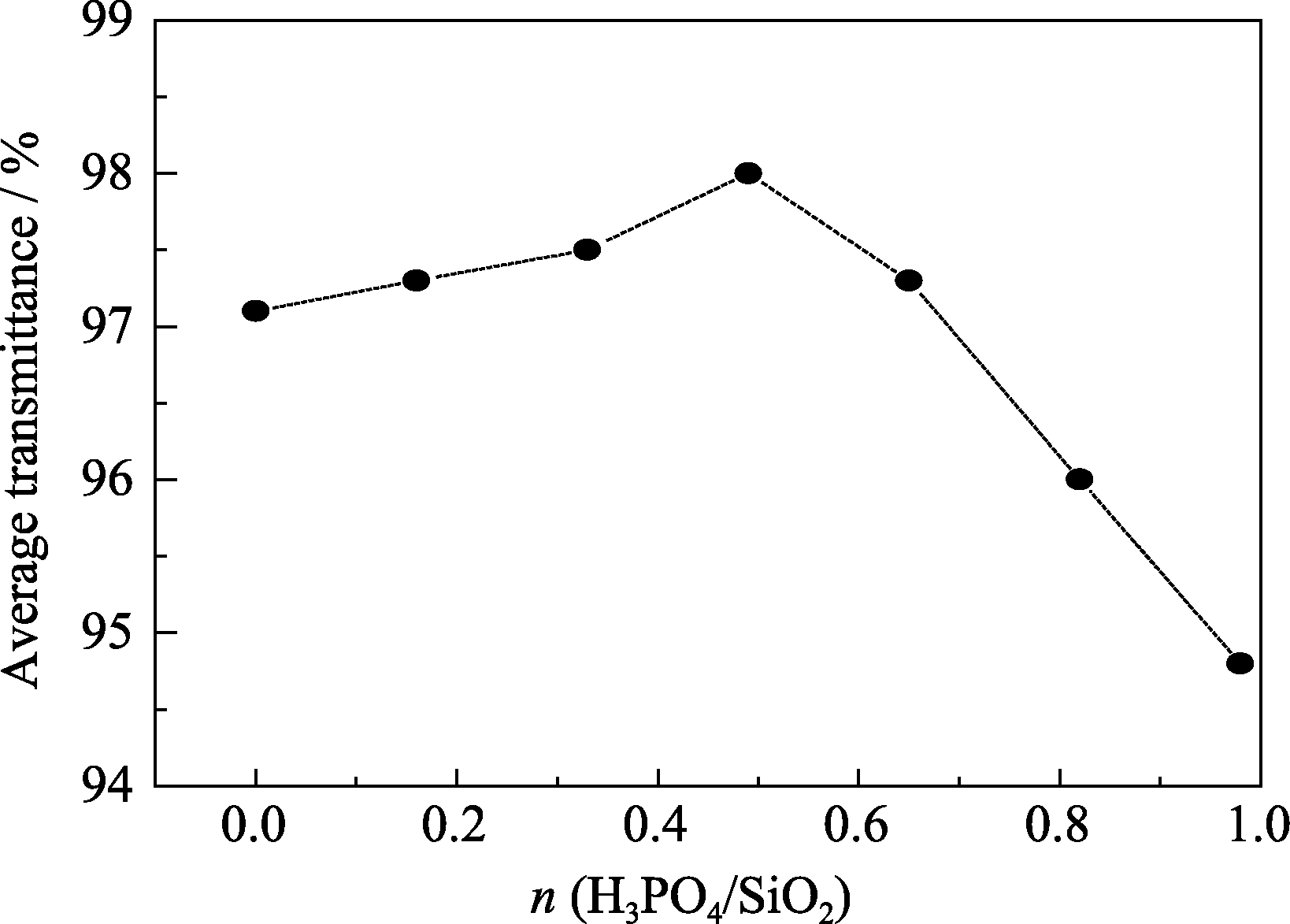

图3 在n(H2O2):n(EtOH):n(SiO2)=0.52:30:1, 以下同n(H3PO4/ SiO2)比例制备的SiO2薄膜在可见光区域的平均透光率

Fig. 3 Average transmittance in the visible light of the SiO2 films with different n(H3PO4/SiO2) (n(H2O2/EtOH/SiO2)= 0.52: 30: 1)

| n(H2O2/SiO2) | 0 | 0.26 | 0.39 | 0.52 | 0.64 | 0.77 | 0.90 | 1.03 |

|---|---|---|---|---|---|---|---|---|

| Pencil hardness grade | F | 3H | 3H | 6H | 6H | 5H | 5H | 5H |

| Average transmittance/% | 98.0 | 97.7 | 98.0 | 98.0 | 97.6 | 97.9 | 97.8 | 98.0 |

表2 在n(H2O2)﹕n(EtOH)﹕n(SiO2) = 0.49: 30: 1, 以下同n(H3PO4/SiO2)比例制备的SiO2薄膜的硬度及在可见光区的平均透光率

Table 2 Pencil hardness grades and the average transmittance in the visible light of the SiO2 films with different n(H2O2/SiO2) (n(H3PO4/EtOH/SiO2)= 0.49: 30: 1)

| n(H2O2/SiO2) | 0 | 0.26 | 0.39 | 0.52 | 0.64 | 0.77 | 0.90 | 1.03 |

|---|---|---|---|---|---|---|---|---|

| Pencil hardness grade | F | 3H | 3H | 6H | 6H | 5H | 5H | 5H |

| Average transmittance/% | 98.0 | 97.7 | 98.0 | 98.0 | 97.6 | 97.9 | 97.8 | 98.0 |

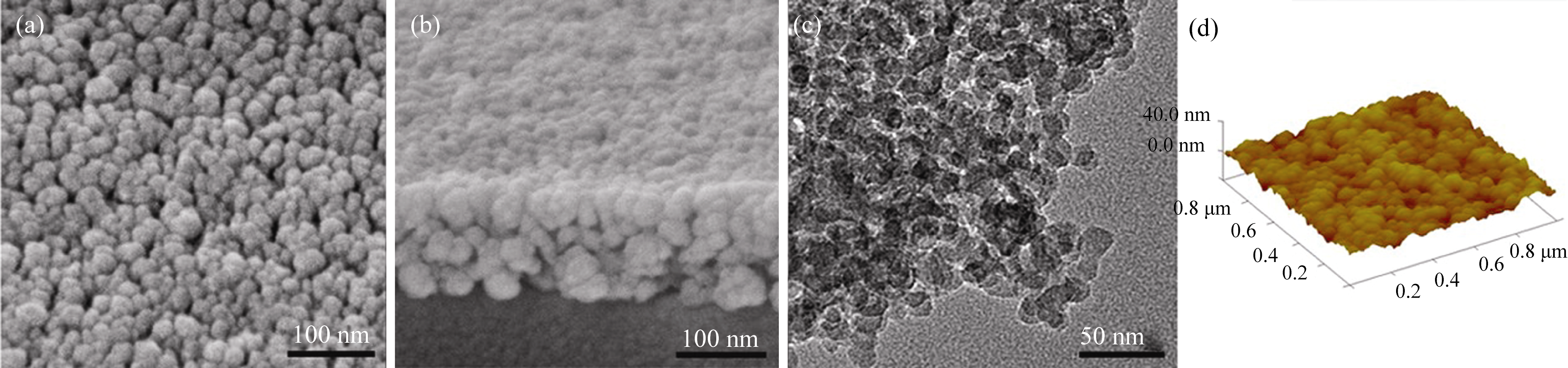

图5 SiO2薄膜的表面FESEM照片(a)、横截面FESEM照片(b)、TEM照片(c)和AFM照片(d)

Fig. 5 Surface FESEM (a), cross-sectional FESEM (b), TEM (c) and AFM (d) images of the SiO2 film

| [1] | FURBO S, SHAH L J. Thermal advantages for solar heating systems with a glass cover with antireflection surfaces. Sol. Energy, 2003, 74(6): 513-523. |

| [2] | ZHANG QIAN, JI RUO-NAN, ZHANG LIANG, et al. Synthesis and properties research of antireflection film for solar cells. Chemical Industry and Engineering Progress, 2012, 31(Sppl.): 347-349. |

| [3] | NOSTELL P, ROOS A, KARLSSON B. Optical and mechanical properties of Sol-Gel antireflective films for solar energy applications. Thin Solid Films, 1999, 351(1): 170-175. |

| [4] | WANG QUAN-ZHI, JING XI-LI, MA YI-HENG, et al. Refractive indexes distribution of anti-reflection coatings for high efficiency silicon solar cells. Laser and Infrared, 2011, 41(6): 669-672. |

| [5] | BAUTISTA M C, MORALES A. Silica antireflective films on glass produced by the Sol-Gel method.. Sol. Energy Mater. Sol.Cells, 2003, 80(2): 217-225. |

| [6] | BELLEVILLE P F, PRENÉ P, MENNECHEZ F, et al. Sol-Gel antireflective spin-coating process for large-size shielding windows. International symposium on optical science and technology .International Society for Optics and Photonics, 2002, 4804: 69-72. |

| [7] | RAUT H K, NAIR A S, DINACHALI S S, et al. Porous SiO2 anti-reflective coatings on large-area substrates by electrospinning and their application to solar modules. Sol. Energy Mater. Sol. Cells, 2013, 111: 9-15. |

| [8] | SHEN JUN, LIU YUAN, LI XIAO-GUANG. Surface modification and contamination resistance of Sol-Gel SiO2 derived. Journal of the Chinese Ceramic Society, 2010, 38(11): 2054-2058. |

| [9] | MAI X D, JUNE K L, WOO-SIK S, et al. Ultralow-n SiO2 Thin films synthesized using organic nanoparticles template.Bull. Korean Chem. Soc, 2010, 31(12): 3593-3599. |

| [10] | ZHAO Q N, LIU Y, HOU S H, et al. Preparation and characterization of nano-porous SiO2/TiO2-SiO2 thin films on glass substrates by Sol-Gel method. Key Eng. Mater. , 2013, 531: 651-654. |

| [11] | XU Y D, PENG CH, XIN CH F, et al. Preparation of silica antireflective films for solar energy application .Mater. Lett, 2013, 94(1): 89-91. |

| [12] | CHI F T, YAN L H, LV H B, et al. Novel pathways for the preparation of silica antireflective films: improvement in mechanical property. Mater. Lett , 2011, 65: 1095-1097. |

| [13] | WANG JIAN-WU, BAI YU-CHEN, YAO WEI, et al. Preparation and investigation of SiO2/TiO2 antireflective coatings with self- cle-an--ing and scratch-resistant Properties. Journal of Inorganic Materials, 2011, 26(7): 769-773. |

| [14] | LI X G, SHEN J. A scratch-resistant and hydrophobic broadband antireflective coating by Sol-Gel method. Thin Solid Films, 2011, 519: 6236-6240. |

| [15] | WU G M, WANG J, SHEN J, et al. Properties of Sol-Gel derived scratch-resistant nano-porous silica films by a mixed atmosphere treatment. J. Non-Cryst Solids, 2000, 275(3): 169-174. |

| [16] | WANG J, WU G M, SHEN J, et al. Scratch-resistant improvement of Sol-Gel derived nano-porous silica films. J. Sol-Gel Sci. Technol, 2000, 18: 219-224. |

| [17] | YE H P, ZHANG X X, ZHANG Y L, et al. Preparation of antireflective coatings with high transmittance and enhanced abrasion- resistance by a base/acid two-step catalyzed Sol-Gel process. Sol. Energy Mater. Sol. Cells, 2011, 95: 2347-2351. |

| [18] | KOZUKA H, YAMANO A, FUJITA M, et al. Aqueous dip-coating route to dense and porous silica thin films using silica nanocolloids with an aid of polyvinylpyrrolidone. J. Sol-Gel Sci. Technol, 2012, 61: 381-389. |

| [19] | ZHU JIAN-JUN, YAO JING, LV XIAO-MENG, et al. Synthesis and characterization of superhydrophobic mesoporous silica aerogels by ambient pressure drying .Journal of the Chinese Ceramic Society, 2009, 37(4): 512-515. |

| [20] | NISHIYAMA N, KAIHARA J, NISHIYAMA Y, et al. Vapor-phase synthesis of mesoporous SiO2-P2O5 thin films. Langmuir, 2007, 23: 4746-4748. |

| [21] | DAYANAND C, BHIKSHAMAIAH G, JAYA TYAGARAJU V, et al. Review structural investigations of phosphate glasses: a detailed infrared study of the x(PbO)-(1-x)P2O5 vitreous system .J. Mater. Sci, 1996, 31:1945-1967. |

| [22] | CUI SH, LIU Y, FAN M H, et al. Temperature dependent microstructure of MTES modified hydrophobic .Mater. Lett , 2011, 65: 606-609. |

| [23] | SALAME I I, BANDOSZ T J. Surface chemistry of activated carbons: combining the results of temperature-programmed desorption, boehm, and potentiometric titrations .J. Colloid Interf. Sci, 2001, 240: 252-258. |

| [24] | BOEHM H P. Some aspects of the surface chemistry of carbon blacks and other carbons. Carbon, 1994, 32(5): 759-769. |

| [25] | BOEHM H P. Chemical identification of surface groups. Adv.in Catal., 1966, 16: 179-274. |

| [26] | OUYANG ZHAO-HUI, WU LIN, LI KONG-BIAO, et al. Surface modification of nano-SiO2 in gas phase. Chemical Industry and Engineering Progress, 2005, 24(11): 1265-1268. |

| [27] | ISO 15184: 1998, Paints and varnishes: determination of film hardness by pencil test.. ISO, 1998. |

| [28] | CHEN ZH, WU L Y L, CHWA E, et al. Scratch resistance of brittle thin films on compliant substrates. Mater. Sci. Eng. A, 2008, 493: 292-298. |

| [29] | DAPUZZO M, ARONNE A, ESPOSITO S, et al. Sol-Gel synthesis of humidity-sensitive P2O5-SiO2 amorphous films .J. Sol-Gel Sci. Technol, 2000, 17: 247-254. |

| [30] | DUAN XIANG, WANG DE-PING, YAO AI-HUA, et al. Fabrication of hydroxyapatite with three-dimensional pore frame by colloidal template method. Journal of Inorganic Materials, 2009, 24(1): 161-165. |

| [1] | 程博, 安晓航, 李定华, 杨荣杰. ATH/ADP配比对EVA阻燃性能及机理转变的影响[J]. 无机材料学报, 2024, 39(5): 509-516. |

| [2] | 沈斌, 张旭, 熊怀, 李海元, 谢兴龙. 溶胶-凝胶SiO2减反膜的制备与光学性能研究[J]. 无机材料学报, 2024, 39(5): 525-530. |

| [3] | 陈梦杰, 王倩倩, 吴成铁, 黄健. 基于DFT的描述符预测生物陶瓷的降解性[J]. 无机材料学报, 2024, 39(10): 1175-1181. |

| [4] | 李乾利, 黎乃鑫, 李育成, 刘慎业, 程帅, 杨光, 任宽, 王峰, 赵景泰. 辐射光致发光材料及其应用研究进展[J]. 无机材料学报, 2023, 38(7): 731-749. |

| [5] | 张航, 韩坤原, 董兰兰, 李祥. DLP打印β-磷酸三钙/纳米黏土复合支架的制备与表征[J]. 无机材料学报, 2022, 37(10): 1116-1122. |

| [6] | 王影, 张文龙, 邢彦锋, 曹苏群, 戴新义, 李晶泽. 非晶态磷酸锂包覆钛酸锂电极在0.01~3.00 V电压范围的性能研究[J]. 无机材料学报, 2021, 36(9): 999-1005. |

| [7] | 杨言言, 李永国, 祝小雯, 杜晓, 马旭莉, 郝晓刚. 电活性镍钴双金属氧化物高选择性去除/回收水中磷酸盐离子[J]. 无机材料学报, 2021, 36(3): 292-298. |

| [8] | 费明婕, 张任平, 朱归胜, 俞兆喆, 颜东亮. 磷酸根掺杂MnFe2O4及其赝电容特性[J]. 无机材料学报, 2020, 35(10): 1137-1141. |

| [9] | 魏居孟, 吕强, 王奔驰, 潘家乐, 叶祥桔, 宋常春. 高可见光催化活性立方体浮雕状Ag3PO4的合成[J]. 无机材料学报, 2019, 34(7): 786-790. |

| [10] | 柯剑煌, 谢凯, 韩喻, 孙巍巍, 罗世强, 刘锦锋. 基于不同共溶剂体系对于高电压正极材料LiCoPO4的形貌控制[J]. 无机材料学报, 2019, 34(6): 618-624. |

| [11] | 强小虎,李彬彬,黄大建,周松毅. 氧化硼对聚磷酸钙纤维力学和降解性能的影响[J]. 无机材料学报, 2019, 34(2): 201-206. |

| [12] | 荚桂玉, 李怡雯, 王红宁, 陈若愚. 具有梯度渐变折射率的超疏水减反膜的制备及其性能[J]. 无机材料学报, 2018, 33(9): 1011-1016. |

| [13] | 王琦, 彭大春, 马倩, 何月德, 刘洪波. 炭包覆LiFePO4纳米片的制备及电化学性能研究[J]. 无机材料学报, 2018, 33(12): 1349-1354. |

| [14] | 李承斌, 岳红云, 王秋娴, 李静娴, 杨书廷. 锂离子电池陶瓷复合全固态电解质的制备和性能研究[J]. 无机材料学报, 2017, 32(8): 801-805. |

| [15] | 肖 雯, 刘玉梅, 任凯歌, 匙 峰, 李 焰, 智 伟, 翁 杰, 屈树新. 利用鸡胚模型半体内评价多孔磷酸钙骨修复材料血管化的研究[J]. 无机材料学报, 2017, 32(6): 649-654. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||