无机材料学报 ›› 2023, Vol. 38 ›› Issue (7): 815-822.DOI: 10.15541/jim20220714 CSTR: 32189.14.10.15541/jim20220714

收稿日期:2022-11-28

修回日期:2023-01-04

出版日期:2023-01-11

网络出版日期:2023-01-11

通讯作者:

杨东旺, 助理研究员. E-mail: ydongwang@whut.edu.cn;作者简介:姚 磊(1989-), 男, 博士研究生. E-mail: yaolei1644@whut.edu.cn

基金资助:

YAO Lei( ), YANG Dongwang(

), YANG Dongwang( ), YAN Yonggao, TANG Xinfeng(

), YAN Yonggao, TANG Xinfeng( )

)

Received:2022-11-28

Revised:2023-01-04

Published:2023-01-11

Online:2023-01-11

Contact:

YANG Dongwang, research assistant. E-mail: ydongwang@whut.edu.cn;About author:YAO Lei (1989-), male, PhD candidate. E-mail: yaolei1644@whut.edu.cn

Supported by:摘要:

通过自蔓延高温合成(SHS)及其衍生方法可以超快速地制备热电材料粉体或块体, 并获得优异的热电性能。但是在采用SHS技术制备方钴矿材料的过程中, 易出现非稳态SHS反应, 使得反应后的坯体中产生杂相。本工作采用激光诱导点火和坯体预热相结合的方法, 分别研究了激光点火的功率密度η和预热温度T0对方钴矿材料自蔓延高温合成过程的影响, 总结了方钴矿CoSb3燃烧模式的变化规律, 并获得了制备单相的工艺窗口。研究结果表明, 当激光点火功率密度η固定时, 随着预热温度T0升高, 方钴矿的SHS反应存在“反应中止→非稳态螺旋燃烧→稳态燃烧→非稳态螺旋燃烧”的转变过程; 在η=3.75 J·mm-2, 250 ℃≤T0<370 ℃条件下, 可以获得单相CoSb3。

中图分类号:

姚磊, 杨东旺, 鄢永高, 唐新峰. 激光诱导方钴矿自蔓延高温合成过程研究[J]. 无机材料学报, 2023, 38(7): 815-822.

YAO Lei, YANG Dongwang, YAN Yonggao, TANG Xinfeng. Laser-induced Self-propagating High-temperature Synthesis of Skutterudite[J]. Journal of Inorganic Materials, 2023, 38(7): 815-822.

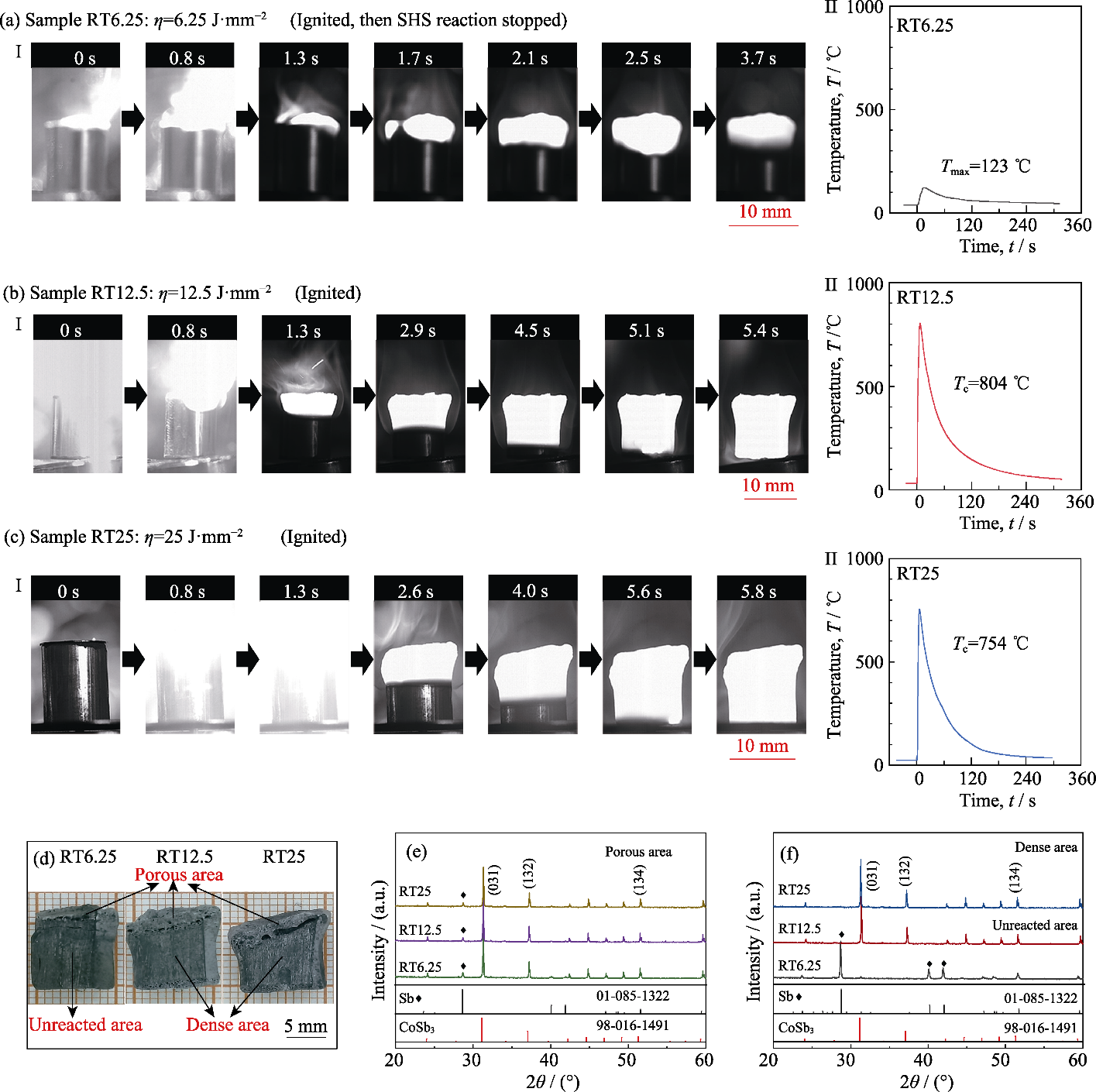

图1 室温条件下激光诱导方钴矿SHS反应过程

Fig. 1 Laser-induced skutterudite SHS reaction process at room temperature (a-c) I. SHS processes and II. time-dependent temperature curves of sample RT6.25, RT12.5 and RT25, respectively; (d) Section photographs of RT6.25, RT12.5 and RT25; (e, f) XRD patterns of powders in (e) porous and (f) dense areas

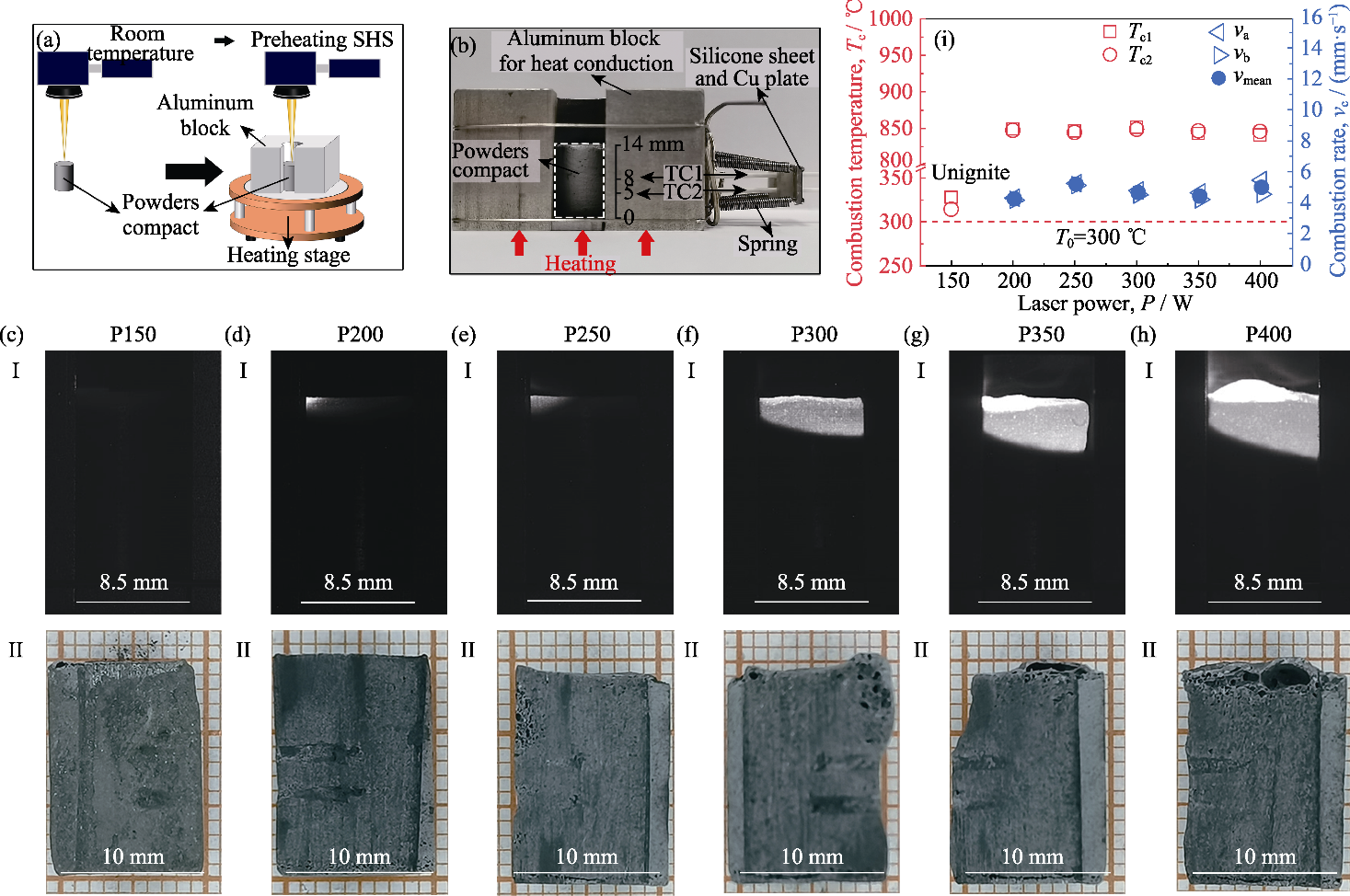

图2 (a)室温和预热SHS实验设备示意图; (b)预热模块的实物图; (c~h)样品Px(x=150, 200, 250, 300, 350, 400)的I. 燃烧波前沿(t=0.95 s)和II. SHS实验后坯体截面照片; (i)CoSb3体系中燃烧温度和燃烧速度随激光点火功率密度变化的趋势

Fig. 2 (a) Schematic diagram of room temperature and preheating SHS experiment; (b) Physical picture of the preheating module; (c-h) I. combustion wave front (t=0.95 s) and II. section photographs of powders compacts after SHS for sample Px(x=150, 200, 250, 300, 350, 400); (i) Trend graph of combustion temperature and combustion velocity changed with power density of ignition laser in CoSb3 system

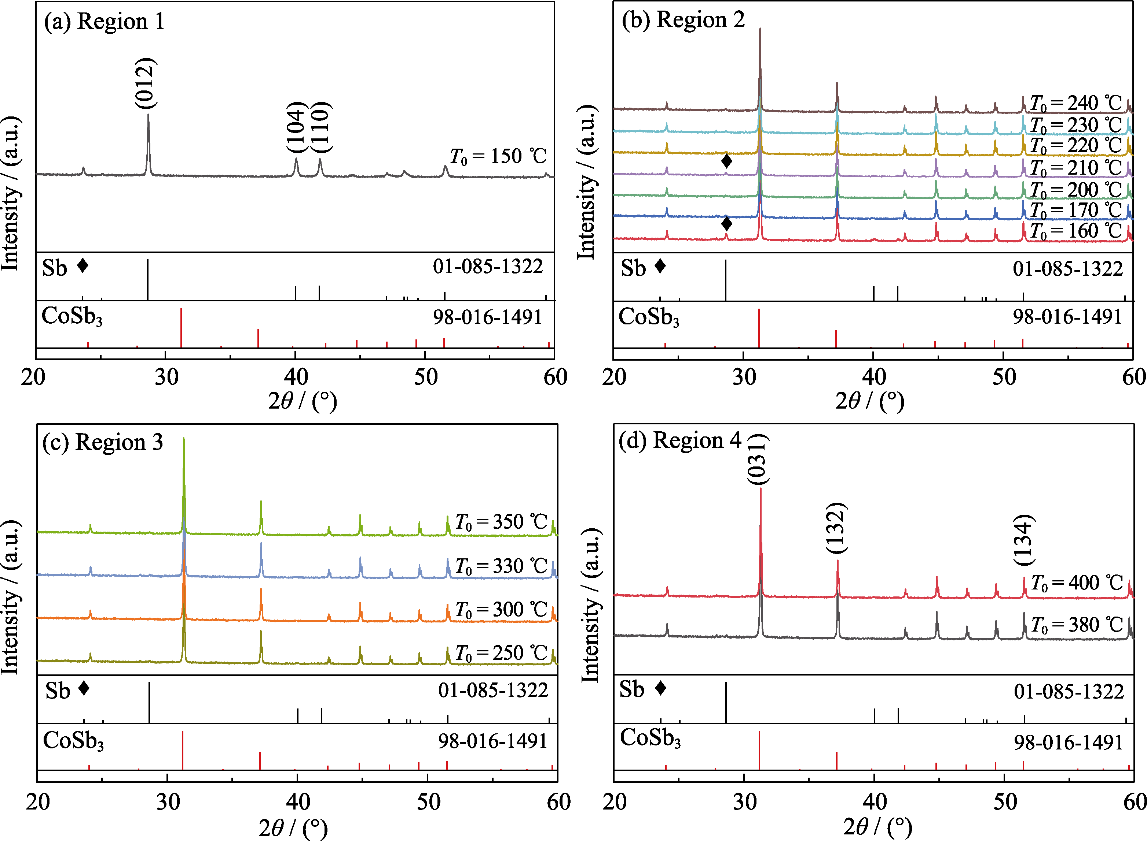

图3 不同预热温度时CoSb3体系中四种典型SHS反应现象

Fig. 3 Four typical SHS performances in CoSb3 system with different preheating temperatures (a) T0=150 ℃; (b) T0=160 ℃; (c) T0=300 ℃; (d) T0=400 ℃

图4 (a) CoSb3体系中燃烧温度随预热温度变化趋势图和(b)区域3附近燃烧速率的变化趋势

Fig. 4 (a) Trend graph of combustion temperature changed with preheating temperature in CoSb3 system and (b) variation trend of combustion rate around region 3

图5 不同预热温度区间SHS实验后坯体粉末的XRD谱图

Fig. 5 XRD patterns of compact powders after SHS in different preheating temperature ranges (a) T0≤150 ℃; (b) 150 ℃<T0<250 ℃; (c) 250 ℃≤T0<370 ℃; (d) T0≥370 ℃

| Sample | Ignition time, t/s | Laser power, P/W | Scan rate, vL/ (mm·s-1) | Scan spacing, d/mm | Energy density, η/(J·mm-2) |

|---|---|---|---|---|---|

| RT6.25 | 0.81 | 500 | 800 | 0.10 | 6.25 |

| RT12.5 | 1.31 | 500 | 400 | 0.10 | 12.5 |

| RT25 | 2.56 | 500 | 400 | 0.05 | 25 |

表S1 室温自蔓延样品的激光点火工艺参数

Table S1 Laser ignition process for SHS samples at room temperature

| Sample | Ignition time, t/s | Laser power, P/W | Scan rate, vL/ (mm·s-1) | Scan spacing, d/mm | Energy density, η/(J·mm-2) |

|---|---|---|---|---|---|

| RT6.25 | 0.81 | 500 | 800 | 0.10 | 6.25 |

| RT12.5 | 1.31 | 500 | 400 | 0.10 | 12.5 |

| RT25 | 2.56 | 500 | 400 | 0.05 | 25 |

| Sample | Preheating temperature, T/℃ | Ignition time, t/s | Laser power, P/W | Energy density, η/(J·mm-2) | Sample | Preheating temperature, T/℃ | Ignition time, t/s | Laser power, P/W | Energy density, η/(J·mm-2) |

|---|---|---|---|---|---|---|---|---|---|

| P150 | 300 | 0.95 | 150 | 1.88 | T210 | 210 | 0.95 | 300 | 3.75 |

| P200 | 300 | 0.95 | 200 | 2.50 | T220 | 220 | 0.95 | 300 | 3.75 |

| P250 | 300 | 0.95 | 250 | 3.13 | T230 | 230 | 0.95 | 300 | 3.75 |

| P300 | 300 | 0.95 | 300 | 3.75 | T240 | 240 | 0.95 | 300 | 3.75 |

| P350 | 300 | 0.95 | 350 | 4.38 | T250 | 250 | 0.95 | 300 | 3.75 |

| P400 | 300 | 0.95 | 400 | 5.00 | T330 | 330 | 0.95 | 300 | 3.75 |

| T150 | 150 | 0.95 | 300 | 3.75 | T350 | 350 | 0.95 | 300 | 3.75 |

| T160 | 160 | 0.95 | 300 | 3.75 | T380 | 380 | 0.95 | 300 | 3.75 |

| T170 | 170 | 0.95 | 300 | 3.75 | T400 | 400 | 0.95 | 300 | 3.75 |

| T200 | 200 | 0.95 | 300 | 3.75 |

表S2 预热状态下自蔓延样品的激光点火工艺参数

Table S2 Laser ignition process of SHS samples under preheating condition

| Sample | Preheating temperature, T/℃ | Ignition time, t/s | Laser power, P/W | Energy density, η/(J·mm-2) | Sample | Preheating temperature, T/℃ | Ignition time, t/s | Laser power, P/W | Energy density, η/(J·mm-2) |

|---|---|---|---|---|---|---|---|---|---|

| P150 | 300 | 0.95 | 150 | 1.88 | T210 | 210 | 0.95 | 300 | 3.75 |

| P200 | 300 | 0.95 | 200 | 2.50 | T220 | 220 | 0.95 | 300 | 3.75 |

| P250 | 300 | 0.95 | 250 | 3.13 | T230 | 230 | 0.95 | 300 | 3.75 |

| P300 | 300 | 0.95 | 300 | 3.75 | T240 | 240 | 0.95 | 300 | 3.75 |

| P350 | 300 | 0.95 | 350 | 4.38 | T250 | 250 | 0.95 | 300 | 3.75 |

| P400 | 300 | 0.95 | 400 | 5.00 | T330 | 330 | 0.95 | 300 | 3.75 |

| T150 | 150 | 0.95 | 300 | 3.75 | T350 | 350 | 0.95 | 300 | 3.75 |

| T160 | 160 | 0.95 | 300 | 3.75 | T380 | 380 | 0.95 | 300 | 3.75 |

| T170 | 170 | 0.95 | 300 | 3.75 | T400 | 400 | 0.95 | 300 | 3.75 |

| T200 | 200 | 0.95 | 300 | 3.75 |

图S4 样品Tx(x=150, 160, 300, 400)在热电偶TC1(黑色)和TC2(红色)处温度随时间的变化关系曲线

Fig. S4 Time-dependent temperature graphs of sample Tx(x=150, 160, 170, 200, 210, 220, 230, 240, 250, 330, 350, 380, 400) at the thermocouple TC1 (black) and TC2 (red)

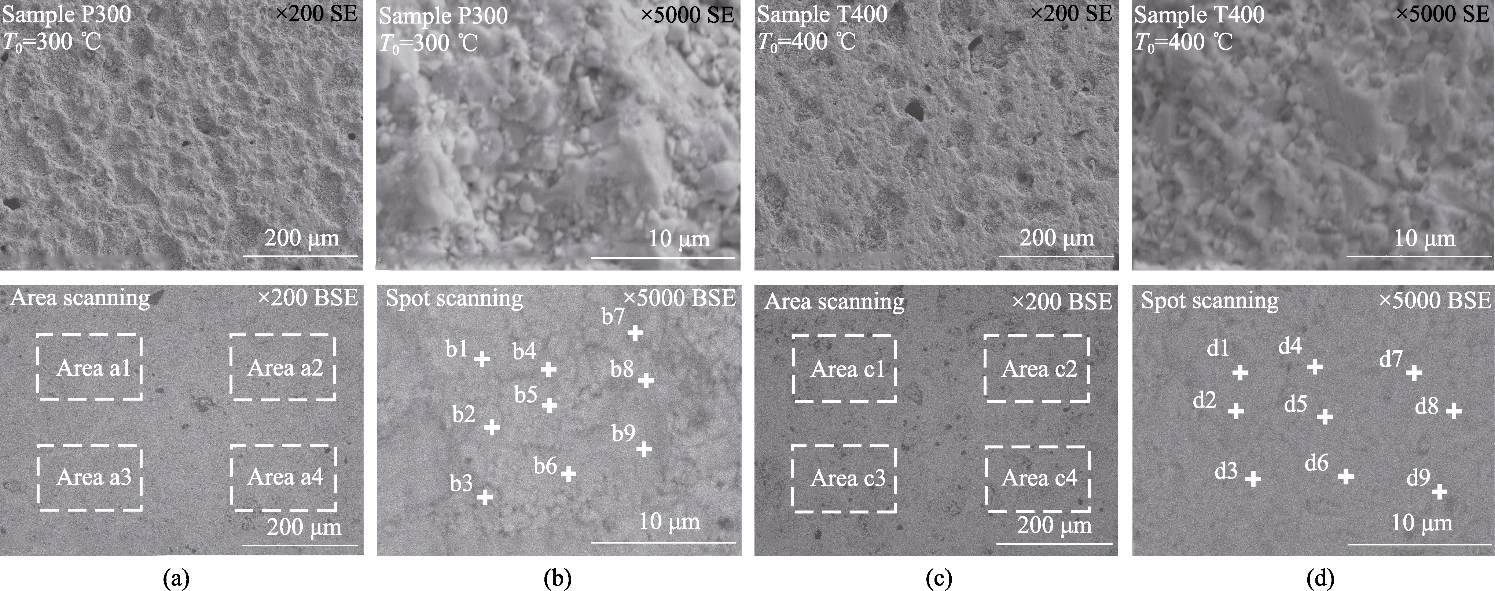

图S5 (a, b)样品P300和(c, d)样品T400的二次电子像、背散射电子像((a, c)×200, (b, d) ×5000)

Fig. S5 SE, BSE images ((a, c)×200, (b, d) ×5000) of (a, b) sample P300 and (c, d) sample T400

| Sample P300 (Fig. S5(a)) | Sample T400 (Fig. S5(c)) | |||||

|---|---|---|---|---|---|---|

| Area | Co/% | Sb/% | Area | Co/% | Sb/% | |

| Area a1 | 18.24 | 81.76 | Area c1 | 20.11 | 79.89 | |

| Area a2 | 17.54 | 82.46 | Area c2 | 18.77 | 81.23 | |

| Area a3 | 17.99 | 82.01 | Area c3 | 20.91 | 79.09 | |

| Area a4 | 18.14 | 81.86 | Area c4 | 19.12 | 80.88 | |

| Mean value | 17.98 | 82.02 | Mean value | 19.73 | 80.27 | |

| Sample P300 (Fig. S5(b)) | Sample T400 (Fig. S5(d)) | |||||

| Spot | Co/% | Sb/% | Spot | Co/% | Sb/% | |

| Spot b1 | 15.69 | 84.31 | Spot d1 | 19.87 | 80.13 | |

| Spot b2 | 19.65 | 80.35 | Spot d2 | 19.19 | 80.81 | |

| Spot b3 | 14.22 | 85.78 | Spot d3 | 19.76 | 80.24 | |

| Spot b4 | 17.23 | 82.77 | Spot d4 | 19.82 | 80.18 | |

| Spot b5 | 18.87 | 81.13 | Spot d5 | 21.77 | 78.23 | |

| Spot b6 | 21.34 | 78.66 | Spot d6 | 22.09 | 77.91 | |

| Spot b7 | 18.58 | 81.42 | Spot d7 | 21.68 | 78.32 | |

| Spot b8 | 16.64 | 83.36 | Spot d8 | 18.56 | 81.44 | |

| Spot b9 | 20.75 | 79.25 | Spot d9 | 18.58 | 81.42 | |

| Mean value | 18.11 | 81.89 | Mean value | 20.15 | 79.85 | |

表S3 样品P300、T400的矩形选区分析和选点分析结果(原子分数)

Table S3 Area scanning and spot scanning results (Atomic percent) of samples P300 and T400

| Sample P300 (Fig. S5(a)) | Sample T400 (Fig. S5(c)) | |||||

|---|---|---|---|---|---|---|

| Area | Co/% | Sb/% | Area | Co/% | Sb/% | |

| Area a1 | 18.24 | 81.76 | Area c1 | 20.11 | 79.89 | |

| Area a2 | 17.54 | 82.46 | Area c2 | 18.77 | 81.23 | |

| Area a3 | 17.99 | 82.01 | Area c3 | 20.91 | 79.09 | |

| Area a4 | 18.14 | 81.86 | Area c4 | 19.12 | 80.88 | |

| Mean value | 17.98 | 82.02 | Mean value | 19.73 | 80.27 | |

| Sample P300 (Fig. S5(b)) | Sample T400 (Fig. S5(d)) | |||||

| Spot | Co/% | Sb/% | Spot | Co/% | Sb/% | |

| Spot b1 | 15.69 | 84.31 | Spot d1 | 19.87 | 80.13 | |

| Spot b2 | 19.65 | 80.35 | Spot d2 | 19.19 | 80.81 | |

| Spot b3 | 14.22 | 85.78 | Spot d3 | 19.76 | 80.24 | |

| Spot b4 | 17.23 | 82.77 | Spot d4 | 19.82 | 80.18 | |

| Spot b5 | 18.87 | 81.13 | Spot d5 | 21.77 | 78.23 | |

| Spot b6 | 21.34 | 78.66 | Spot d6 | 22.09 | 77.91 | |

| Spot b7 | 18.58 | 81.42 | Spot d7 | 21.68 | 78.32 | |

| Spot b8 | 16.64 | 83.36 | Spot d8 | 18.56 | 81.44 | |

| Spot b9 | 20.75 | 79.25 | Spot d9 | 18.58 | 81.42 | |

| Mean value | 18.11 | 81.89 | Mean value | 20.15 | 79.85 | |

| [1] | BERETTA D, NEOPHYTOU N, HODGES J M, et al. Thermoelectrics: from history, a window to the future. Materials Science & Engineering R-Reports, 2019, 138: 210. |

| [2] | POURKIAEI S M, AHMADI M H, SADEGHZADEH M, et al. Thermoelectric cooler and thermoelectric generator devices: a review of present and potential applications, modeling and materials. Energy, 2019, 186: 115849. |

| [3] | JAZIRI N, BOUGHAMOURA A, MULLER J, et al. A comprehensive review of thermoelectric generators: technologies and common applications. Energy Reports, 2020, 6: 264. |

| [4] |

CHEN L D, XIONG Z, BAI S Q. Recent progress of thermoelectric nano-composites. Journal of Inorganic Materials, 2010, 25(6):561.

DOI URL |

| [5] |

ZHANG Q H, BAI S Q, CHEN L D. Technologies and applications of thermoelectric devices: current status, challenges and prospects. Journal of Inorganic Materials, 2019, 34(3):279.

DOI URL |

| [6] | HU T Z, CAO W Q, YANG D W, et al. Ultra-fast fabrication of bulk ZrNiSn thermoelectric material through self-propagating high-temperature synthesis combined with in-situ quick pressing. Scripta Materialia, 2019, 165: 140. |

| [7] | SU X L, FU F, YAN Y G, et al. Self-propagating high-temperature synthesis for compound thermoelectrics and new criterion for combustion processing. Nature Communications, 2014, 5: 4908. |

| [8] | ZHANG J, ZHU T, ZHANG C, et al. In-situ formed nano-pore induced by ultrasonication boosts the thermoelectric performance of Cu2Se compounds. Journal of Alloys and Compounds, 2021, 881: 160639. |

| [9] | LIANG T, SU X, YAN Y, et al. Panoscopic approach for high- performance Te-doped skutterudite. NPG Asia Materials, 2017, 9: e352. |

| [10] |

YANG D W, LUO T T, SU X L, et al. Unveiling the intrinsic low thermal conductivity of BiAgSeS through entropy engineering in SHS kinetic process. Journal of Inorganic Materials, 2021, 36(9):991.

DOI |

| [11] |

LIU R, TAN X, REN G K, et al. Enhanced thermoelectric performance of Te-doped Bi2Se3-xTex bulks by self-propagating high-temperature synthesis. Crystals, 2017, 7(9):257.

DOI URL |

| [12] |

ZHENG G, SU X L, LIANG T, et al. High thermoelectric performance of mechanically robust n-type Bi2Te3-xSex prepared by combustion synthesis. Journal of Materials Chemistry A, 2015, 3(12):6603.

DOI URL |

| [13] | IVANOV O, YAPRINTSEV M, VASIL'EV A, et al. Microstructure and thermoelectric properties of the medium-entropy block- textured BiSbTe1.5Se1.5 alloy. Journal of Alloys and Compounds, 2021, 872: 159743. |

| [14] |

SHENOY S, BHAT D K. Enhanced bulk thermoelectric performance of Pb0.6Sn0.4Te: effect of magnesium doping. Journal of Physical Chemistry C, 2017, 121(38):20696.

DOI URL |

| [15] | YAPRINTSEVA E, VASIL'EV A, YAPRINTSEV M, et al. Thermoelectric properties of medium-entropy PbSbTeSe alloy prepared by reactive spark plasma sintering. Materials Letters, 2022, 309: 131416. |

| [16] | DELGADO A, CORDOVA S, LOPEZ I, et al. Mechanically activated combustion synthesis and shockwave consolidation of magnesium silicide. Journal of Alloys and Compounds, 2016, 658: 422. |

| [17] | ZHANG Q, SU X L, YAN Y G, et al. Phase segregation and superior thermoelectric properties of Mg2Si1-xSbx (0≤x≤0.025) prepared by ultrafast self-propagating high-temperature synthesis. ACS Applied Materials & Interfaces, 2016, 8(5):3268. |

| [18] | ZHANG Q, SU X L, YAN Y G, et al. Ultrafast and low-cost preparation of Mg2(Si0.3Sn0.7)(1-y)Sby with superior thermoelectric performance by self-propagating high-temperature synthesis. Scripta Materialia, 2019, 162: 507. |

| [19] | ZHANG Q, FAN J F, FAN W H, et al. Energy-efficient synthesis and superior thermoelectric performance of Sb-doped Mg2Si0.3Sn0.7 solid solutions by rapid thermal explosion. Materials Research Bulletin, 2020, 128: 110885. |

| [20] | XING Y F, LIU R H, LIAO J C, et al. High-efficiency half-Heusler thermoelectric modules enabled by self-propagating synthesis and topologic structure optimization. Energy & Environmental Science, 2019, 12(11):3390. |

| [21] |

XING Y F, LIU R H, SUN Y Y, et al. Self-propagation high- temperature synthesis of half-Heusler thermoelectric materials: reaction mechanism and applicability. Journal of Materials Chemistry A, 2018, 6(40):19470.

DOI URL |

| [22] | HU T Z, YANG D W, SU X L, et al. Interpreting the combustion process for high-performance ZrNiSn thermoelectric materials. ACS Applied Materials & Interfaces, 2018, 10(1):864. |

| [23] | KRUSZEWSKI M J, CYMERMAN K, ZYBALA R, et al. High homogeneity and ultralow lattice thermal conductivity in Se/Te- doped skutterudites obtained by self-propagating high-temperature synthesis and pulse plasma sintering. Journal of Alloys and Compounds, 2022, 909: 164796. |

| [24] |

LIANG T, SU X L, YAN Y G, et al. Ultra-fast synthesis and thermoelectric properties of Te doped skutterudites. Journal of Materials Chemistry A, 2014, 2(42):17914.

DOI URL |

| [25] |

SHI X, YANG J, SALVADOR J R, et al. Multiple-filled skutterudites: high thermoelectric figure of merit through separately optimizing electrical and thermal transports. Journal of the American Chemical Society, 2011, 133(20):7837.

DOI PMID |

| [26] |

TANG Y, GIBBS Z M, AGAPITO L A, et al. Convergence of multi-valley bands as the electronic origin of high thermoelectric performance in CoSb3skutterudites. Nature Materials, 2015, 14(12):1223.

DOI |

| [27] | ROGL G, BURSIK J, GRYTSIV A, et al. Nanostructuring as a tool to adjust thermal expansion in high ZT skutterudites. Acta Materialia, 2018, 145: 359. |

| [28] |

ZHAO W Y, LIU Z Y, SUN Z G, et al. Superparamagnetic enhancement of thermoelectric performance. Nature, 2017, 549(7671):247.

DOI URL |

| [29] |

ZHOU J, JIE Q, WU L J, et al. Nanostructures and defects in nonequilibrium-synthesized filled skutterudite CeFe4Sb12. Journal of Materials Research, 2011, 26(15): 1842.

DOI URL |

| [30] |

TAN G J, LIU W, WANG S Y, et al. Rapid preparation of CeFe4Sb12 skutterudite by melt spinning: rich nanostructures and high thermoelectric performance. Journal of Materials Chemistry A, 2013, 1(40):12657.

DOI URL |

| [31] | YAN Y, KE H, YANG J, et al. Fabrication and thermoelectric properties of n-type CoSb2.85Te0.15 using selective laser melting. ACS Applied Materials & Interfaces, 2018, 10(16):13669. |

| [32] |

ZHANG Y B, LI C R, DU Z M, et al. The thermodynamic assessment of the Co-Sb system. Calphad-Computer Coupling of Phase Diagrams and Thermochemistry, 2008, 32(1):56.

DOI URL |

| [33] |

PARK K H, LIM Y S, SEO W S, et al. Effects of heat treatment on the thermoelectric properties of Yb-filled skutterudites. Journal of the Korean Physical Society, 2013, 63(9):1764.

DOI URL |

| [34] |

SESSELMANN A, SKOMEDAL G, MIDDLETON H, et al. the influence of synthesis procedure on the microstructure and thermoelectric properties of p-type skutterudite Ce0.6Fe2Co2Sb12. Journal of Electronic Materials, 2016, 45(3):1397.

DOI URL |

| [35] | ALINEJAD B, CASTELLERO A, BARICCO M. Full dense CoSb3 single phase with high thermoelectric performance prepared by oscillated cooling method. Scripta Materialia, 2016, 113: 110. |

| [36] |

GENG H Y, OCHI S, GUO J Q. Solidification contraction-free synthesis for the Yb0.15Co4Sb12 bulk material. Applied Physics Letters, 2007, 91(2):022106.

DOI URL |

| [37] | LI Z, FENG G, WANG S, et al. High-efficiency joining of Cf/Al composites and TiAl alloys under the heat effect of laser-ignited self-propagating high-temperature synthesis. Journal of Materials Science & Technology, 2016, 32(11):1111. |

| [38] | RESNINA N, BELYAEV S, VORONKOV A, et al. Martensitic transformation and mechanical behavior of porous Ti-50.0at% Ni alloy, fabricated by self-propagating high temperature synthesis at different temperature. Strasbourg:3rd International Symposium on Shape Memory Materials for Smart Systems/E-MRS Spring Meeting, 2010: 11-16. |

| [39] |

KILIC M, KIRIK I, OKUMUS M. Microstructure examination of functionally graded NiTi/NiAl/Ni3Al intermetallic compound produced by self-propagating high-temperature synthesis. Kovove Materialy-Metallic Materials, 2017, 55(2):97.

DOI URL |

| [40] |

ROGACHEV A S, BARAS F. Dynamical and statistical properties of high-temperature self-propagating fronts: an experimental study. Physical Review E, 2009, 79(2):026214.

DOI URL |

| [41] |

KESKIN B, BASSANI P, BAKAN F, et al. Synthesis and microstructure investigation of Ni40Ti50Cu10 intermetallic shape memory alloys by self-propagating combustion method. Transactions of the Indian Institute of Metals, 2022, 75(11):2749.

DOI |

| [42] | SONG M S, HUANG B, ZHANG M X, et al. Study of formation behavior of TiC ceramic obtained by self-propagating high- temperature synthesis from Al-Ti-C elemental powders. International Journal of Refractory Metals & Hard Materials, 2009, 27(3):584. |

| [1] | 张叶, 曾宇平. 自蔓延高温合成氮化硅多孔陶瓷的研究进展[J]. 无机材料学报, 2022, 37(8): 853-864. |

| [2] | 杨东旺, 罗婷婷, 苏贤礼, 吴劲松, 唐新峰. 基于熵工程及SHS动力学的BiAgSeS本征低热导率起源探究[J]. 无机材料学报, 2021, 36(9): 991-998. |

| [3] | 张骐昊, 廖锦城, 唐云山, 顾明, 刘睿恒, 柏胜强, 陈立东. 方钴矿热电材料/Ti88Al12界面稳定性研究[J]. 无机材料学报, 2018, 33(8): 889-894. |

| [4] | 宗鹏安, 陈立东. Ce0.85Fe3CoSb12/rGO热电纳米复合材料的制备及其力学性能[J]. 无机材料学报, 2017, 32(1): 33-38. |

| [5] | 姚 铮, 仇鹏飞, 李小亚, 陈立东. n型填充方钴矿热电材料的快速制备研究[J]. 无机材料学报, 2016, 31(12): 1375-1382. |

| [6] | 丁 娟, 刘睿恒, 顾 辉, 陈立东 . YbyCo4Sb12/Yb2O3热电复合材料的高温稳定性研究[J]. 无机材料学报, 2014, 29(2): 209-214. |

| [7] | 吴 汀, 柏胜强, 史 迅, 陈立东. 高填充量BaxEuyCo4Sb12方钴矿热电性能研究[J]. 无机材料学报, 2013, 28(2): 224-228. |

| [8] | 魏 平, 董春垒, 赵文俞, 张清杰. 纳米SiO2包覆提高填充方钴矿热电材料热稳定性[J]. 无机材料学报, 2010, 25(6): 577-582. |

| [9] | 秦丙克,李小雷,李尚升,宿太超,马红安,贾晓鹏. Ba填充方钴矿化合物的高压合成及热电性能[J]. 无机材料学报, 2010, 25(1): 23-26. |

| [10] | 王建华,刘玉存,刘登程,郭 豪. 镍源对自蔓延高温合成Ni0.35Zn0.65Fe2O4的影响[J]. 无机材料学报, 2009, 24(5): 973-977. |

| [11] | 刘桃香,唐新峰,邓书康,宋 晨,张清杰. Ca和Sm双原子共填充方钴矿化合物的制备及热电性能[J]. 无机材料学报, 2008, 23(4): 710-714. |

| [12] | 文衍宣,肖 卉,甘永乐,粟海锋,王 凡. 自蔓延高温合成锂离子电池正极材料LiCoO2[J]. 无机材料学报, 2008, 23(2): 286-290. |

| [13] | 糜建立,赵新兵,朱铁军,曹高劭. Te掺杂方钴矿CoSb3的溶剂热合成及电学性能[J]. 无机材料学报, 2007, 22(5): 869-872. |

| [14] | 张廷安,豆志河. 自蔓延冶金法制备 TiB2微粉的生长机理研究[J]. 无机材料学报, 2006, 21(3): 583-590. |

| [15] | 傅仁利,陈克新,周和平,费雷拉J.M.F. 规则结晶形态氮化铝颗粒的自蔓延高温合成[J]. 无机材料学报, 2004, 19(6): 1402-1406. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||