无机材料学报 ›› 2021, Vol. 36 ›› Issue (8): 883-892.DOI: 10.15541/jim20200727 CSTR: 32189.14.10.15541/jim20200727

杜傲宸1,2( ), 杜琪源3, 刘欣2,4, 杨益民1,2, 夏晨阳1, 邹军3, 李江2,4(

), 杜琪源3, 刘欣2,4, 杨益民1,2, 夏晨阳1, 邹军3, 李江2,4( )

)

收稿日期:2020-12-18

修回日期:2021-01-24

出版日期:2021-08-20

网络出版日期:2021-03-12

通讯作者:

李 江, 研究员. E-mail: lijiang@mail.sic.ac.cn

作者简介:杜傲宸(1995-), 男, 硕士研究生. E-mail: duaochen@foxmail.com

DU Aochen1,2( ), DU Qiyuan3, LIU Xin2,4, YANG Yimin1,2, XIA Chenyang1, ZOU Jun3, LI Jiang2,4(

), DU Qiyuan3, LIU Xin2,4, YANG Yimin1,2, XIA Chenyang1, ZOU Jun3, LI Jiang2,4( )

)

Received:2020-12-18

Revised:2021-01-24

Published:2021-08-20

Online:2021-03-12

Contact:

LI Jiang, professor. E-mail: lijiang@mail.sic.ac.cn

About author:DU Aochen (1995-), male, Master candidate. E-mail: duaochen@foxmail.com

Supported by:摘要:

Ce:YAG透明陶瓷可与蓝光LEDs/LDs复合, 用于大功率白光LEDs/LDs。本研究通过调整Ce:YAG透明陶瓷的厚度和Ce3+的掺杂浓度, 将组装器件的发射光谱和色坐标从冷白区调整到暖白区。以高纯(≥99.99%)商业粉体α-Al2O3、Y2O3、CeO2为原料, 采用固相反应法制备了(CexY1-x)3Al5O12 (x=0.0005、0.0010、0.0030、0.0050、0.0070和0.0100)透明陶瓷。陶瓷素坯在1750 ℃真空烧结20 h(真空度5.0×10-5 Pa), 之后在马弗炉中退火1450 ℃×10 h。不同掺杂浓度Ce:YAG陶瓷(厚度分别为0.2、0.4、1.0 mm)在800 nm处的直线透过率均大于79%。Ce:YAG荧光陶瓷的热导率随着测试温度和掺杂浓度的增加而降低。采用有限元方法模拟不同厚度的Ce:YAG陶瓷和LED组装的热分布, 比较了三种封装方式的热分布。将Ce:YAG荧光陶瓷与LEDs/LDs复合, 制备出色坐标分别为(0.3319, 0.3827)和(0.3298, 0.3272)的白光, 发光效率分别为122.4和201.5 lm/W。将Ce:YAG荧光陶瓷和10、50 W商用蓝光LED芯片组合成熟灯具, 可用于商业用途。Ce:YAG透明陶瓷在大功率照明和显示的彩色转换材料应用领域极具潜力。

中图分类号:

杜傲宸, 杜琪源, 刘欣, 杨益民, 夏晨阳, 邹军, 李江. 高光效、大功率LEDs/LDs用Ce:YAG透明陶瓷[J]. 无机材料学报, 2021, 36(8): 883-892.

DU Aochen, DU Qiyuan, LIU Xin, YANG Yimin, XIA Chenyang, ZOU Jun, LI Jiang. Ce:YAG Transparent Ceramics Enabling High Luminous Efficacy for High-power LEDs/LDs[J]. Journal of Inorganic Materials, 2021, 36(8): 883-892.

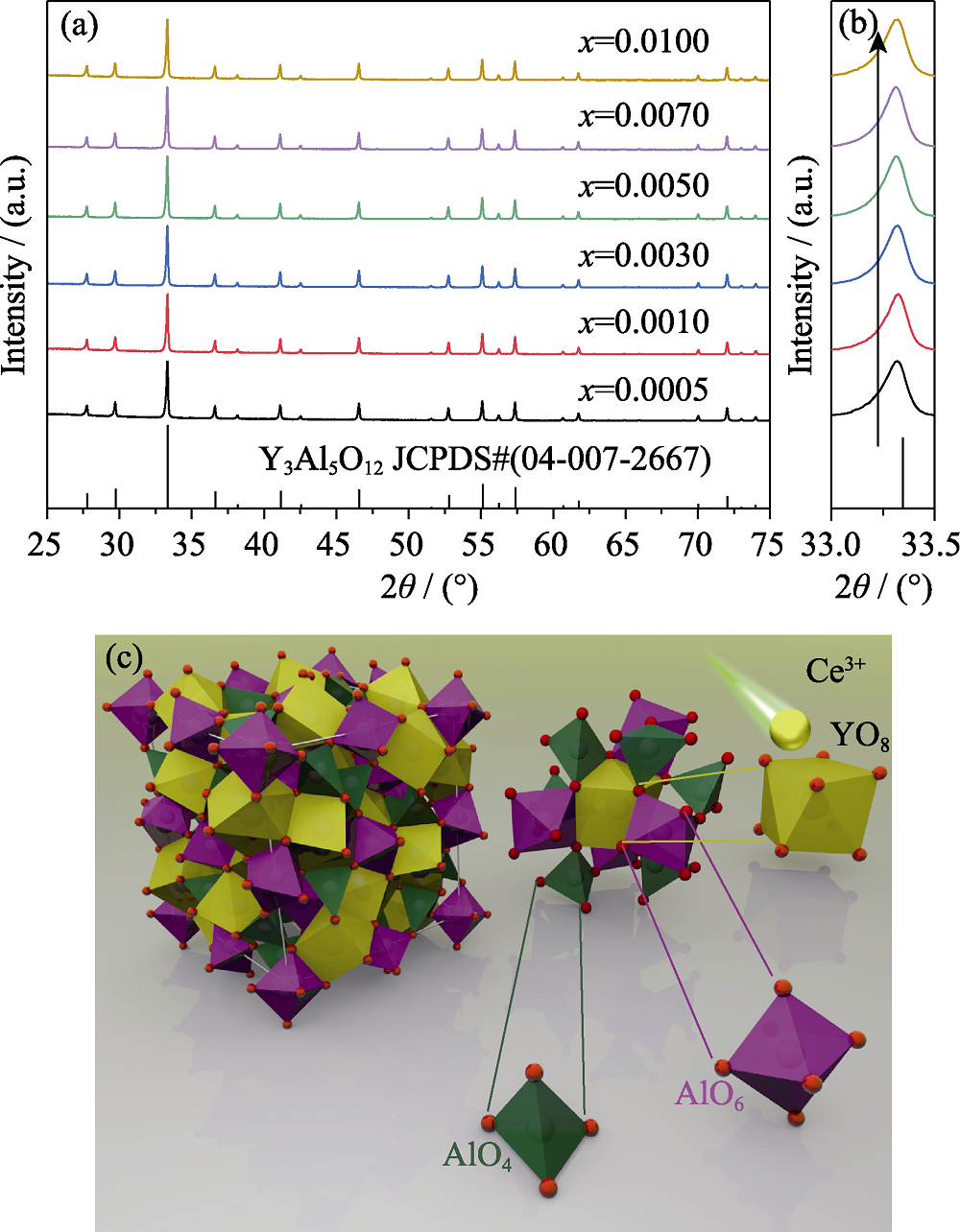

Fig. 2 XRD patterns (a) of (CexY1-x)3Al5O12 transparent ceramics smashed into powder, expanded view (b) of 2θ diffraction peaks between 33.0° and 32.5°, and illustration of Ce:YAG crystalline structure and the coordinated environments (c) of YO8 dodecahedron, AlO4 tetrahedra, and AlO6 octahedra based on JCPDS #04-007-2667

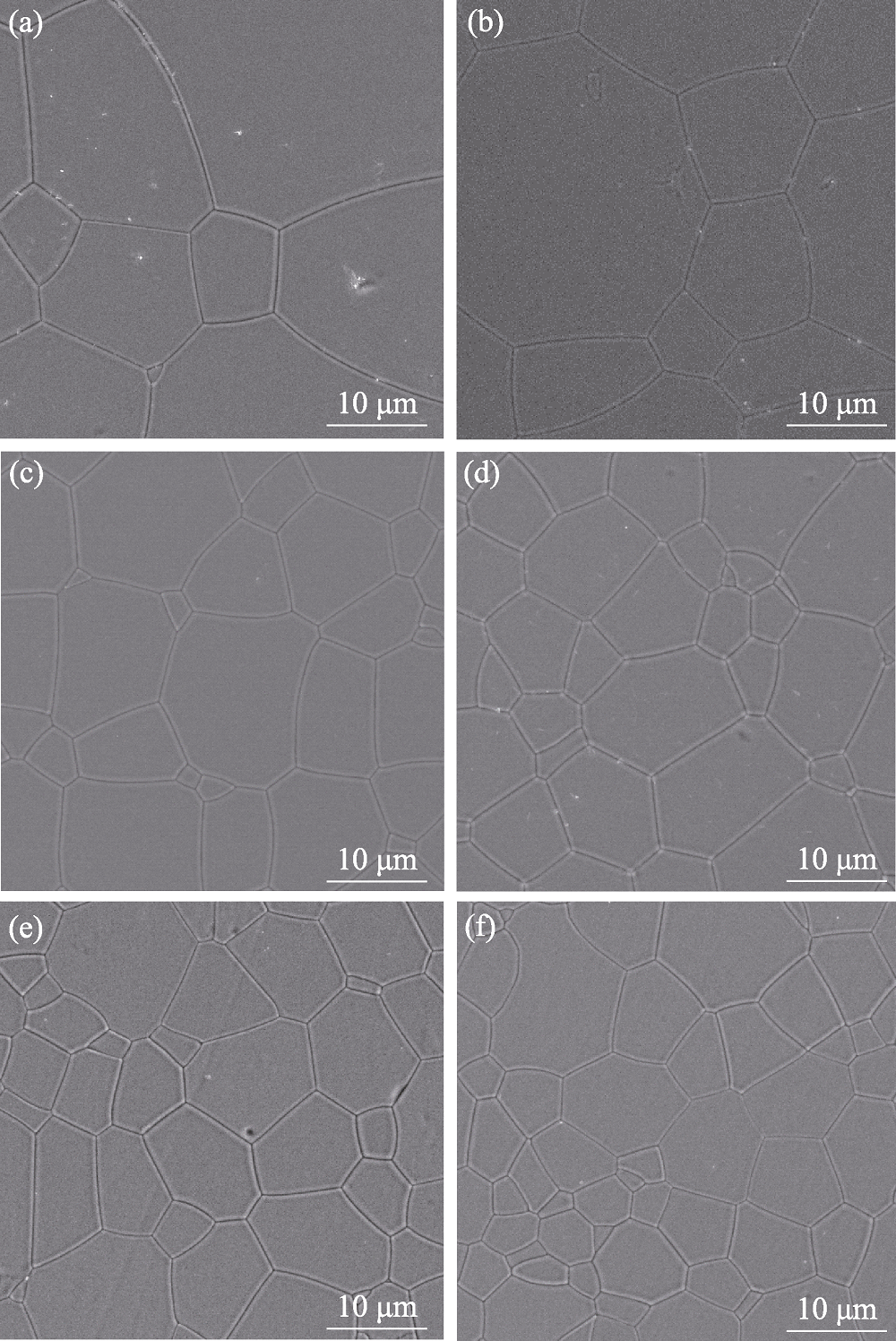

Fig. 3 FESEM images of the thermally etched surfaces of (CexY1-x)3Al5O12 ceramics with different doping concentrations (a) x=0.0005; (b) x=0.0010; (c) x=0.0030; (d) x=0.0050; (e) x=0.0070; (f) x=0.0100

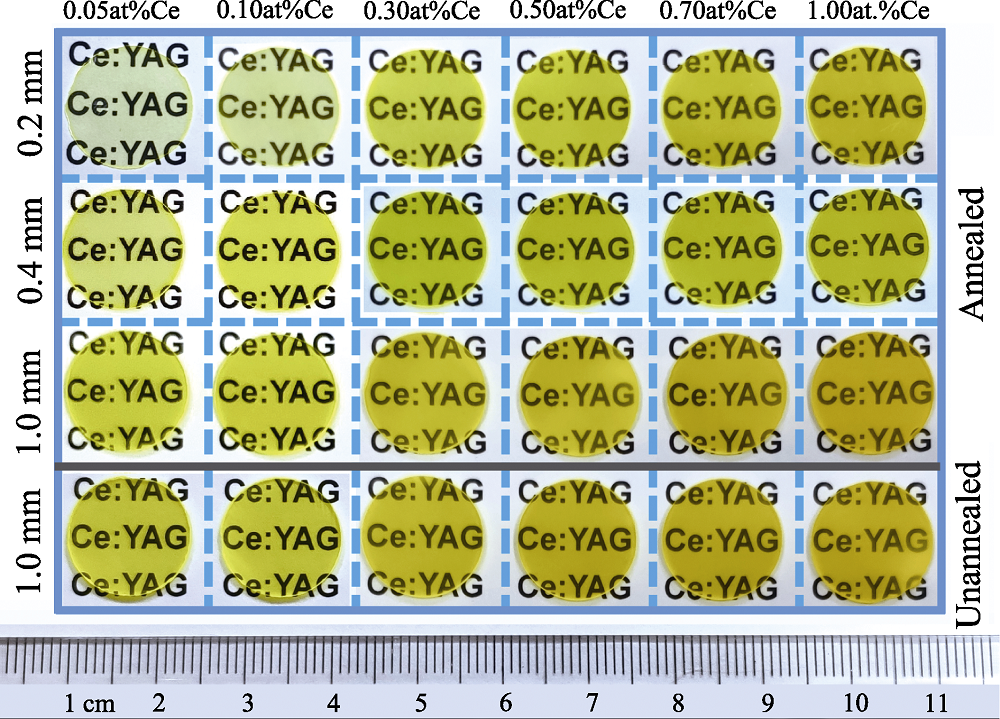

Fig. 4 Photographs of all (CexY1-x)3Al5O12 ceramics with orthogonally designed parameters under sunlight. All conditions (thickness and concentration) were independent and resulted in the great difference in color from light yellow to deep yellow (x=0.0005, 0.0010, 0.0030, 0.0050, 0.0070 and 0.0100, d=0.2, 0.4 and 1.0 mm)

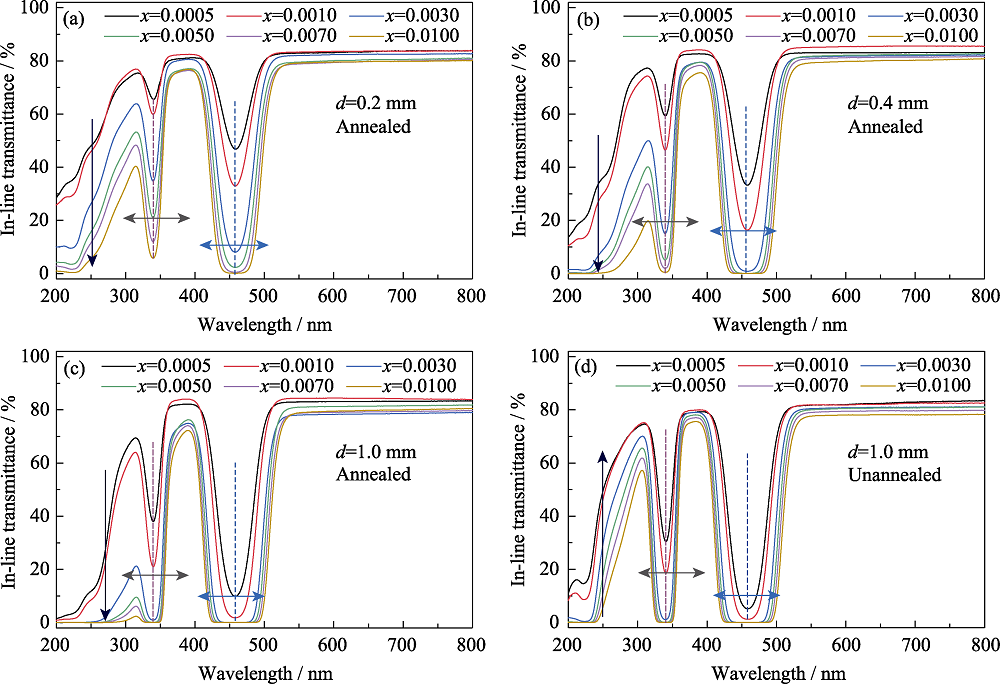

Fig. 5 In-line transmittance curves for annealed and unannealed (CexY1-x)3Al5O12 ceramics (x=0.0005, 0.0010, 0.0030, 0.0050, 0.0070 and 0.0100, d=0.2, 0.4 and 1.0 mm)

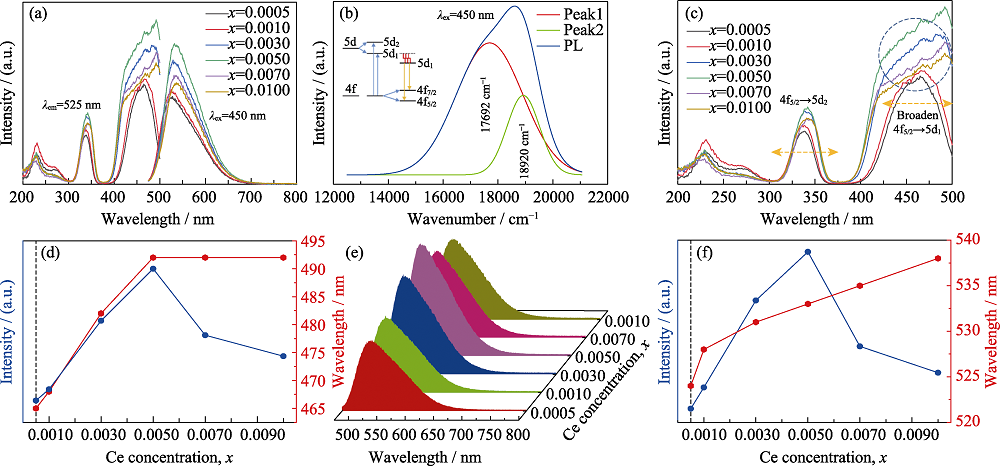

Fig. 6 PLE and PL spectra (a) of (CexY1-x)3Al5O12 ceramics, Gaussian deconvolution (b) of the 0.5at%Ce:YAG ceramic with inset showing energy-level scheme of Ce3+, PLE (λem=525 nm) (c) and PL (λex=450 nm) (e) of the prepared Ce:YAG ceramics as the function of Ce3+ doping concentration, the detailed peak positions and emission intensities of PLE (d) and PL (f) spectra of the Ce:YAG ceramics (x=0.0005, 0.0010, 0.0030, 0.0050, 0.0070 and 0.0100)

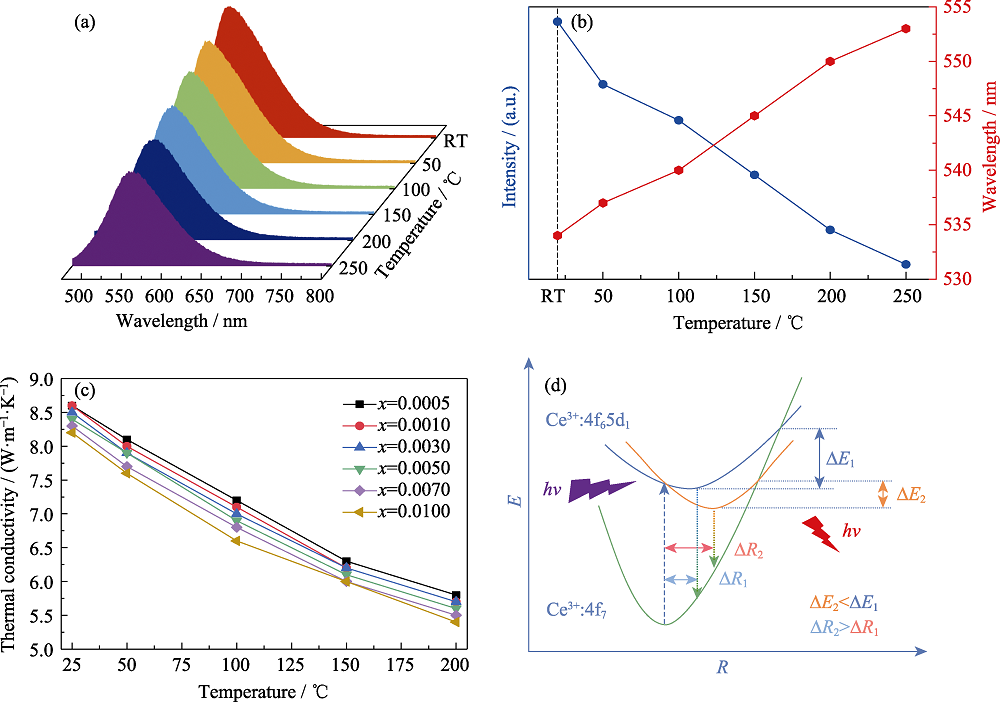

Fig. 7 Thermal quenching behavior (a) for photoluminescence 0.50at%Ce:YAG ceramic phosphor, detailed peak positions and emission intensities of PL spectra (b) of 0.5at%Ce:YAG ceramic, thermal conductivity (c) of (CexY1-x)3Al5O12 ceramics at different temperatures, and configurational coordination diagrams (d) illustrating the thermally quenching of 5d-4f luminescence of Ce3+

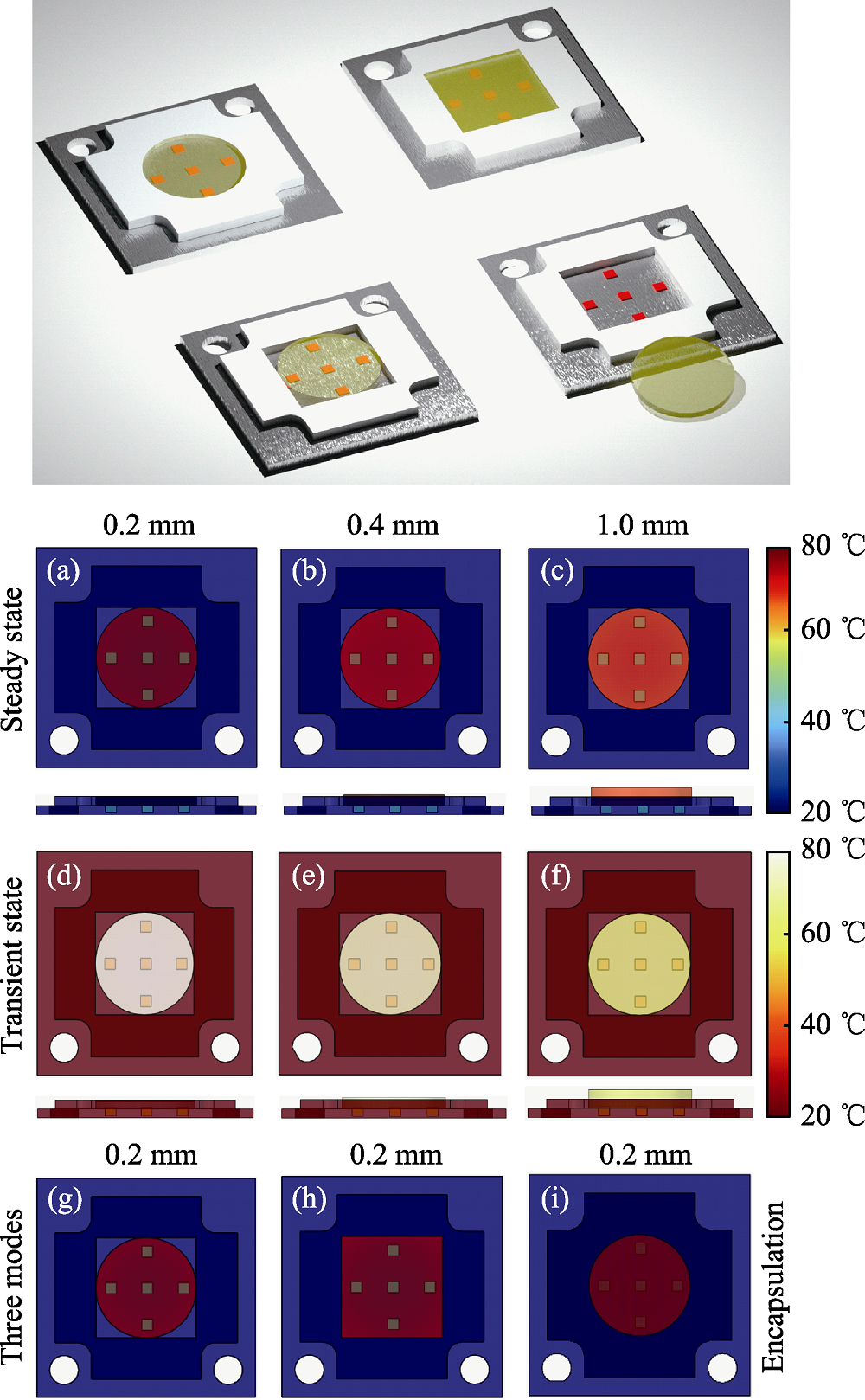

Fig. 8 Simplified three-dimensional model view of assemblage and white LEDs encapsulation model (TOP figure), thermal distribution of 0.5at%Ce:YAG transparent ceramics, thickness 0.2 mm (a, d), 0.4 mm (b, e), 1.0 mm (c, f) respectively, during steady thermal state or transient thermal state, and (g-i) three common packaging methods and heat dissipation

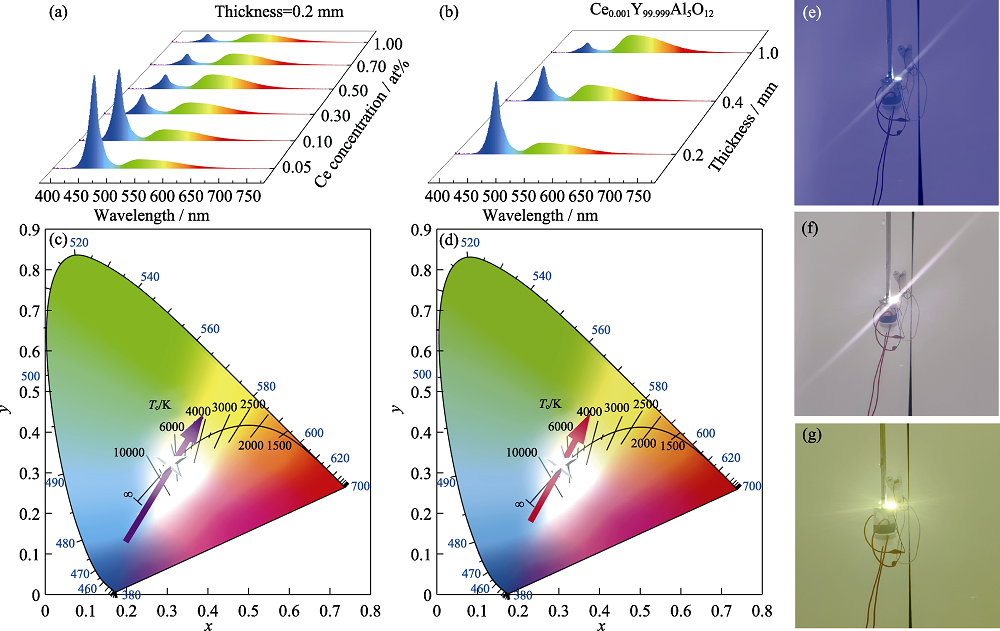

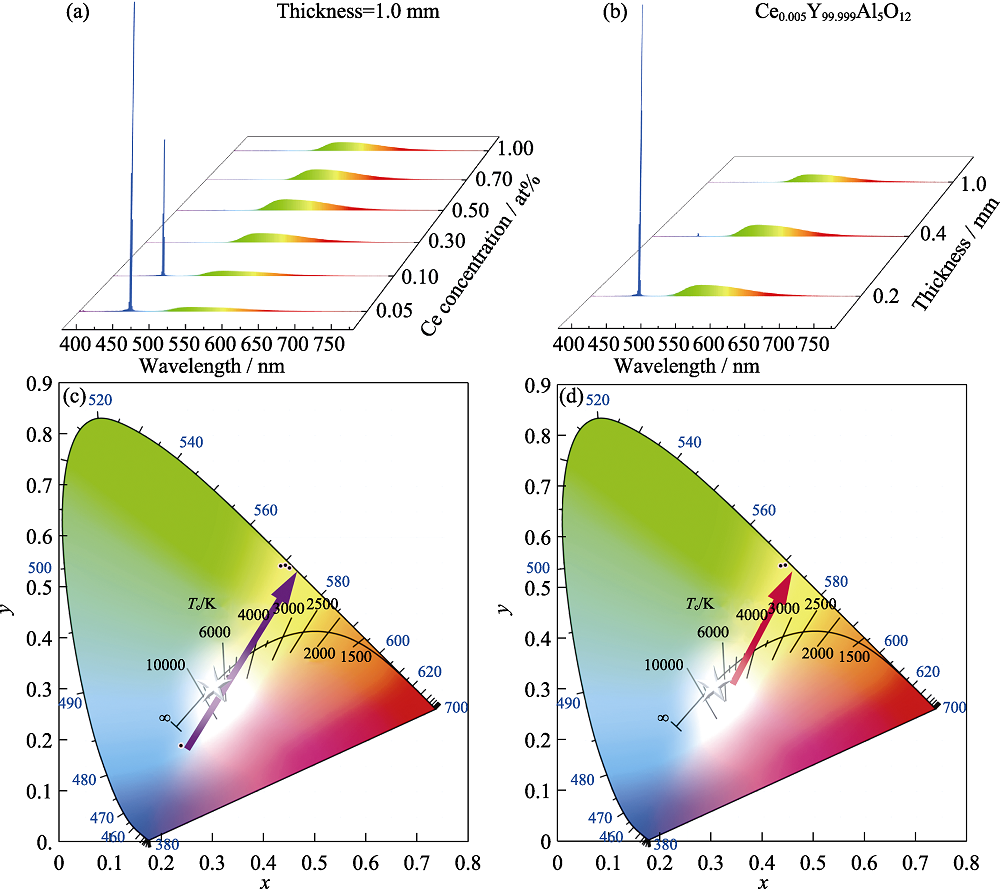

Fig. 9 EL spectra of Ce:YAG ceramics with different doping concentrations (a) and thickness (b), CIE of the LEDs with Ce:YAG ceramics of different doping concentrations (c) and thicknesses (d), the pictures of the LEDs with Ce:YAG ceramics with the increase of doping concentrations and thickness, which changes from blue to yellow (e-g)

Fig. 10 EL spectra of Ce:YAG ceramics with different doping concentrations (a) and thicknesses (b), CIE of the LDs with Ce:YAG ceramics of different doping concentrations (c) and thicknesses (d)

| LEDs/LDs | x | Thickness/mm | LE/(lm·W-1) | CIE | CCT/K | CRI |

|---|---|---|---|---|---|---|

| LED | 0.0005 | 1.0 | 122.4 | (0.3319, 0.3827) | 5528 | 62.8 |

| LED | 0.0010 | 0.4 | 115.5 | (0.3021, 0.3217) | 7196 | 68.8 |

| LED | 0.0030 | 0.2 | 83.7 | (0.3166, 0.3442) | 6216 | 67.1 |

| LD | 0.0010 | 1.0 | 201.5 | (0.3298, 0.3272) | 7415 | 65.1 |

| LD | 0.0050 | 0.2 | 170.3 | (0.3146, 0.3169) | 7264 | 65.4 |

Table 1 White light emission parameters of Ce:YAG packaged devices ((CexY1-x)3Al5O12)

| LEDs/LDs | x | Thickness/mm | LE/(lm·W-1) | CIE | CCT/K | CRI |

|---|---|---|---|---|---|---|

| LED | 0.0005 | 1.0 | 122.4 | (0.3319, 0.3827) | 5528 | 62.8 |

| LED | 0.0010 | 0.4 | 115.5 | (0.3021, 0.3217) | 7196 | 68.8 |

| LED | 0.0030 | 0.2 | 83.7 | (0.3166, 0.3442) | 6216 | 67.1 |

| LD | 0.0010 | 1.0 | 201.5 | (0.3298, 0.3272) | 7415 | 65.1 |

| LD | 0.0050 | 0.2 | 170.3 | (0.3146, 0.3169) | 7264 | 65.4 |

| [1] |

ZHENG F, MAO Y W, YANG B B, et al. Laser lighting device based on YAG:Ce3+ phosphor composite Eu3+ doped phosphor-in- glasses. Chinese Journal of Luminescence , 2019, 40(7):842-848.

DOI URL |

| [2] |

ZHANG J F, GU G R, DI X X, et al. Optical characteristics of Ce,Eu:YAG single crystal grown by Czochralski method. Journal of Rare Earths , 2019, 37(2):145-150.

DOI URL |

| [3] |

SHAO X C, ZHOU S M, TANG Y R, et al. Luminescence characteristics of Ce:YAG ceramic phosphors with Gd3+ doping for white light-emitting diodes. Journal of Inorganic Materials , 2018, 33(10):1119-1123.

DOI URL |

| [4] |

WANG Z X, LIN H, ZHANG D W, et al. Deep-red emitting Mg2TiO4:Mn4+ phosphor ceramics for plant lighting. Journal of Advanced Ceramics , 2020, 10(1):88-97.

DOI URL |

| [5] |

CHEN S L, JIANG B X, WANG Y, et al. Fabrication of Ce-doped (Gd2Y)Al5O12/Y3Al5O12 composite-phase scintillation ceramic. Journal of Rare Earths , 2019, 37(9):978-983.

DOI URL |

| [6] |

ZHENG Z H, ZHANG X, XU X K, et al. Thickness and surface roughness effect on lighting performance of Ce3+:YAG transparent ceramics based high power LED and LD lighting prototype devices. Chinese Journal of Luminescence , 2020, 41(11):1411-1420.

DOI URL |

| [7] |

HUA H, FENG S W, YANG Z Y, et al. YAGG:Ce transparent ceramics with high luminous efficiency for solid-state lighting application. Journal of Advanced Ceramics , 2019, 8(3):389-398.

DOI URL |

| [8] |

LIU X, ZHOU H Y, HU Z W, et al. Transparent Ce:GdYAG ceramic color converters for high-brightness white LEDs and LDs. Optical Materials , 2019, 88(7):97-102.

DOI URL |

| [9] | CHO J, SCHUBERT E F, KIM J K, Efficiency droop in light-emitting diodes: challenges and countermeasures. Laser & Photonics Reviews , 2013, 7(3):408-421. |

| [10] | BERGH A, CRAFORD G, DUGGAL A, et al. The promise and challenge of solid-state lighting. Physics Today , 2001, 54(12):42-47. |

| [11] |

CAO Y F, HAN T, YANG J Y, et al. Tunable-spectrum Mn2+ doped garnet transparent ceramics for high-color rendering laser lighting. International Journal of Applied Ceramic Technology , 2021, 18:716-723.

DOI URL |

| [12] | LI S X, WANG L, HIROSAKI N, et al. Color conversion materials for high-brightness laser-driven solid-state lighting. Laser & Photonics Reviews , 2018, 12(12):1800173-1800203. |

| [13] |

PAN G H, WU H J, HE S, et al. Dye-embedded YAG:Ce3+@SiO2 composite phosphors toward warm wLEDs through radiative energy transfer: preparation, characterization and luminescence properties. Nanoscale , 2018, 10(47):22237-22251.

DOI URL |

| [14] |

SONG Y H, JI E K, JEONG B W, et al. High power laser-driven ceramic phosphor plate for outstanding efficient white light conversion in application of automotive lighting. Scientific Reports , 2016, 6(1):31206-31213.

DOI URL |

| [15] |

LIN Z B, LIN H, XU J, et al. Highly thermal-stable warm w-LED based on Ce:YAG PiG stacked with a red phosphor layer. Journal of Alloys and Compounds , 2015, 649(1):661-665.

DOI URL |

| [16] |

WANG L, WEI R, ZHENG P, et al. Realizing high-brightness and ultra-wide-color-gamut laser-driven back lighting by using laminated phosphor-in-glass (PiG) films. Journal of Materials Chemistry C , 2020, 8(5):1746-1754.

DOI URL |

| [17] |

YAO Q, ZHANG L, ZHANG J, et al. Simple mass-preparation and enhanced thermal performance of Ce:YAG transparent ceramics for high power white LEDs. Ceramics International , 2019, 45(5):6356-6362.

DOI URL |

| [18] |

WAETZIG K, KUNZER M and KINSKI I, Influence of sample thickness and concentration of Ce dopant on the optical properties of YAG:Ce ceramic phosphors for white LEDs. Journal of Materials Research , 2014, 29(19):2318-2324.

DOI URL |

| [19] |

LIU G H, ZHOU Z Z, SHI Y, et al. Ce:YAG transparent ceramics for applications of high power LEDs: thickness effects and high temperature performance. Materials Letters , 2015, 139(1):480-482.

DOI URL |

| [20] |

SHANG M M, FAN J, LIAN H Z, et al. A double substitution of Mg2+-Si4+/Ge4+ for Al(1)(3+)-Al(2)3+ in Ce3+-doped garnet phosphor for white LEDs. Inorganic Chemistry , 2014, 53(14):7748-7755.

DOI URL |

| [21] |

AO G, TANG Y R, YI X Z, et al. Red emission generation in Ce3+/Mn2+ co-doping Y3Al5O12 phosphor ceramics for warm white lighting emitting diodes. Journal of Alloys and Compounds , 2019, 798(17):695-699.

DOI URL |

| [22] |

KANG J, ZHANG L, LI Y B, et al. Luminescence declining behaviors in YAG:Ce transparent ceramics for high power laser lighting. Journal of Materials Chemistry C , 2019, 7(45):14357-14365.

DOI URL |

| [23] |

XIA Z G, MEIJERINK A. Ce3+-doped garnet phosphors: composition modification, luminescence properties and applications. Chemical Society Reviews , 2017, 46(1):275-299.

DOI URL |

| [24] | LIU S, SUN P, LIU Y F, et al. Warm white light with a high color-rendering index from a Single Gd3Al4GaO12:Ce3+ transparent ceramic for high-power LEDs and LDs. ACS Applied Materials & Interfaces , 2018, 11(2):2130-2139. |

| [25] | TOLMACHEV R P, TOLMACHEV A V, Thermostimulated luminescence from single crystals of modified lithium gadolinium orthoborate Li6-xNaxGd(BO3)3:Ce. Technical Physics Letters , 2004, 30(12):8-14. |

| [26] |

ZHANG W, LU T C, WEI N, et al. Effect of annealing on the optical properties of Nd:YAG transparent ceramics. Optical Materials , 2012, 34(4):685-690.

DOI URL |

| [27] |

ZHANG W, LU T, MA B Y, et al. Improvement of optical properties of Nd:YAG transparent ceramics by post-annealing and post hot isostatic pressing. Optical Materials , 2013, 35(12):2405-2410.

DOI URL |

| [28] |

STEVENSON A J, BITTEL B C, LEH C G, et al. Color center formation in vacuum sintered Nd3xY3-3xAl5O12 transparent ceramics. Applied Physics Letters , 2011, 98(5):051906-051909.

DOI URL |

| [29] |

SONG Z, LIU X L, HE L Z, et al. Correlation between the energy level structure of cerium-doped yttrium aluminum garnet and luminescent behavior at varying temperatures. Materials Research Express , 2016, 3(5):055501-055509.

DOI URL |

| [30] |

SUN P, HU P, LIU Y F, et al. Broadband emissions from Lu2Mg2Al2Si2O12:Ce3+ plate ceramic phosphors enable a high color- rendering index for laser-driven lighting. Journal of Materials Chemistry C , 2020, 8(4):1405-1412.

DOI URL |

| [31] |

PAN Z F, CHEN J C, WU H Q, et al. Red emission enhancement in Ce3+/Mn2+ co-doping suited garnet host MgY2Al4SiO12 for tunable warm white LED. Optical Materials , 2017, 72(5):257-264.

DOI URL |

| [32] |

YEH C W, CHEN W T, LIU R S, et al. Origin of thermal degradation of Sr2-xSi5N8:Eux phosphors in air for light-emitting diodes. Journal of the American Chemical Society , 2012, 134(34):14108-14117.

DOI URL |

| [33] |

ZHANG L L, ZHANG S, HAO Z D, et al. A high efficiency broad-band near-infrared Ca2LuZr2Al3O12:Cr3+ garnet phosphor for blue LED chips. Journal of Materials Chemistry C , 2018, 6(18):4967-4976.

DOI URL |

| [34] |

GU C, WANG X J, XIA C, et al. A new CaF2-YAG:Ce composite phosphor ceramic for high-power and high-color-rendering WLEDs. Journal of Materials Chemistry C , 2019, 7(28):8569-8574.

DOI URL |

| [35] |

KIM J S, PARK Y H, KIM S M, et al. Temperature-dependent emission spectra of M2SiO4:Eu2+(M=Ca, Sr, Ba) phosphors for green and greenish white LEDs. Solid State Communications , 2005, 133(7):445-448.

DOI URL |

| [36] |

WANG Y H, DING J Y, WANG Y C, et al. Structural design of new Ce3+/Eu2+-doped or co-doped phosphors with excellent thermal stabilities for WLEDs. Journal of Materials Chemistry C , 2019, 7(7):1792-1820.

DOI URL |

| [1] | 李乾利, 黎乃鑫, 李育成, 刘慎业, 程帅, 杨光, 任宽, 王峰, 赵景泰. 辐射光致发光材料及其应用研究进展[J]. 无机材料学报, 2023, 38(7): 731-749. |

| [2] | 柳琪, 朱璨, 谢贵震, 王俊, 张东明, 邵刚勤. Ce掺杂SrMgF4超结构多晶体的吸收/光致发光光谱[J]. 无机材料学报, 2022, 37(8): 897-902. |

| [3] | 关旭峰, 李桂芳, 卫云鸽. Na1-xMxCaEu(WO4)3 (M=Li, K)红色荧光粉的微观结构与热猝灭特性研究[J]. 无机材料学报, 2022, 37(6): 676-682. |

| [4] | 张国庆, 秦鹏, 黄富强. 空间限域铅离子与钙钛矿纳米晶间的可逆转换与信息存储应用[J]. 无机材料学报, 2022, 37(4): 445-451. |

| [5] | 彭星淋, 李淑星, 刘泽华, 姚秀敏, 解荣军, 黄政仁, 刘学建. 大功率固态照明用荧光陶瓷研究进展[J]. 无机材料学报, 2021, 36(8): 807-819. |

| [6] | 邵秀晨, 周圣明, 唐燕如, 易学专, 郝德明, 陈杰. Ce:YAG荧光陶瓷掺杂Gd对白光LED发光性能的影响[J]. 无机材料学报, 2018, 33(10): 1119-1123. |

| [7] | 李桂芳, 杨 倩, 卫云鸽. 复合钙钛矿型NaLaMgWO6: Eu3+红色荧光材料的制备及发光性能研[J]. 无机材料学报, 2017, 32(9): 936-942. |

| [8] | 鄢波, 彭泽洋, 吕斌, 刘薇. 圆偏振光诱导CdTe量子点再生长及其对光致发光的影响[J]. 无机材料学报, 2017, 32(12): 1321-1326. |

| [9] | 卓世异, 刘 熙, 高 攀, 严成锋, 施尔畏. N-B-Al共掺荧光4H-SiC施主受主对发光性能研究[J]. 无机材料学报, 2017, 32(1): 51-55. |

| [10] | 杨修春. 离子交换和热处理对贵金属掺杂硅酸盐玻璃光致发光的影响[J]. 无机材料学报, 2016, 31(10): 1039-1045. |

| [11] | 杨丰桕, 陆梦晨, 张 欣, 张 延, 王连军, 江 莞. 一种简单的水热法制备油溶性PbSe量子点[J]. 无机材料学报, 2015, 30(7): 774-778. |

| [12] | 张 延, 刘 升, 许虹杰, 王连军, 江 莞. LED用荧光玻璃的制备及性能研究[J]. 无机材料学报, 2015, 30(6): 588-592. |

| [13] | 韩 斌, 王义飞, 刘 茜, 黄 庆. 微波法合成Ba3Si6O12N2:Eu2+绿色氮氧化物 荧光粉及其光学性能研究[J]. 无机材料学报, 2015, 30(3): 330-336. |

| [14] | 郭 鹏, 彭林志, 张为海, 刘 雷, 熊 娟. Pr掺杂Mg2SnO4纳米颗粒的制备及其光致发光性能[J]. 无机材料学报, 2015, 30(11): 1172-1176. |

| [15] | 陈小波, 杨 雯, 段良飞, 张力元, 杨培志. 周期性梯度富硅SiNx薄膜的微结构与发光特性[J]. 无机材料学报, 2014, 29(12): 1270-1274. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||