Journal of Inorganic Materials ›› 2017, Vol. 32 ›› Issue (9): 973-979.DOI: 10.15541/jim20160661

• Orginal Article • Previous Articles Next Articles

ZHANG Xiao-Feng1, 2, ZHOU Ke-Song1, 2, LIU Min2, DENG Chun-Ming2, DENG Chang-Guang2, CHEN Huan-Tao2

Received:2016-11-28

Revised:2017-01-17

Published:2017-09-30

Online:2017-08-29

Supported by:CLC Number:

ZHANG Xiao-Feng, ZHOU Ke-Song, LIU Min, DENG Chun-Ming, DENG Chang-Guang, CHEN Huan-Tao. Thermal Shock Analysis of Surface Al-modified 7YSZ Nano-thermal Barrier Coatin[J]. Journal of Inorganic Materials, 2017, 32(9): 973-979.

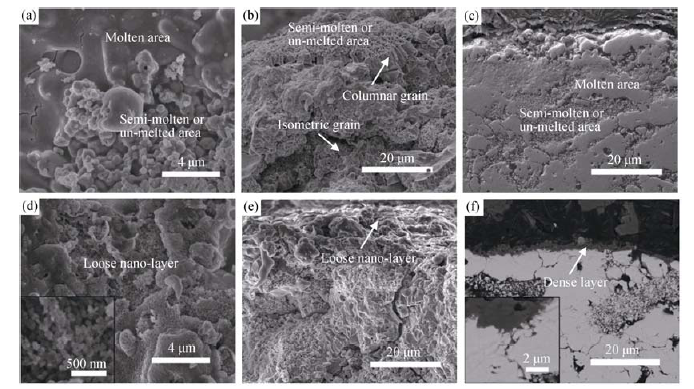

Fig. 2 7YSZ nano-TBC microgrsphy before and after Al-modification (a-c) As-sprayed TBC: surface, un-polished cross-section, polished cross-section; (d-f) Al-modified TBC at 200 Pa: surface, un-polished cross-section, polished cross-section

| [1] | SANCHEZ M, MORENO M N, SEGRERA S,et al.Method and process development of advanced atmospheric plasma spraying for thermal barrier coating. J. Therm. Spray Technol., 2012, 21(3): 400-408. |

| [2] | GUO H B, GONG S K, XU H B.Progress in thermal barrier coatings for advanced aeroengine.Materials China, 2009, 28(Z2): 18-26. |

| [3] | ZHANG Y J, SUN X F, JIN T,et al. Microstructure of air plasma sprayed YSZ nanostructured thermal barrier coatin. Acta Metallurgica Sinica, 2003, 39(4): 395-398. |

| [4] | ZHAI M L, LI D C, ZHAO Y X,et al.Comparative study on thermal shock behavior of thick thermal barrier coatings fabricated with nano-based YSZ suspension and agglomerated particle. Ceram. Int., 2016, 42(10): 12172-12179. |

| [5] | ZHANG C X, ZHOU C G, PENG H,et al.Influence of thermal shock on insulation effect of nano-multilayer thermal barrier coating. Surf. Coat. Technol., 2007, 201(14): 6340-6344. |

| [6] | WANG Y, BAI Y, LIU K,et al.Microstructural evolution of plasma sprayed submicron-/nano-zirconia-based thermal barrier coating. Applied Surf. Sci., 2016, 363(15): 101-112. |

| [7] | ZHANG X F, ZHOU K S, XU W,et al.In situ synthesis of α-alumina layer at top yttrium-stabilized zirconia thermal barrier coatings for oxygen barrie. Ceram. Int., 2014, 40: 12703-12708. |

| [8] | ZHANG X F, ZHOU K S, XU W,et al.In situ synthesis of α-alumina layer on thermal barrier coating for protection against CMAS (CaO-MgO-Al2O3-SiO2) corrosio. Surf. Coat. Technol., 2015, 261: 54-59. |

| [9] | ZHANG X F, ZHOU K S, LIU M,et al. Enhanced properties of Al-modified EB-PVD 7YSZ thermal barrier coating. Ceram. Int., 2016, 42: 13969-13975. |

| [10] | KAVEENDRAN B, WANG G S, HUANG L J,et al.In situ ( Al3Zr-Al2O3) metal matrix composite with novel reinforcement distributions fabricated by reaction hot pressin. J. Alloys Compd., 2013, 581: 16-22. |

| [11] | DREXLER J M, GLEDHILL A D, SHINODA K,et al. Jet engine coatings for resisting volcanic ash damag. Adv. Mater., 2011, 23: 2419-2424. |

| [12] | DIAZ P, RALPHA B, EDIRISINGHE M J.Transmission electron microscope characterization of a plasma-sprayed ZrO2-Y2O3-TiO2 thermal barrier coatin.Mater. Characterization, 1998, 41(2/3): 55-67. |

| [13] | POERSCHKE D L, LEVI C G.Effects of cation substitution and temperature on the interaction between thermal barrier oxides and molten CMA.J. Eur. Ceram. Soc., 2015, 35: 681-691. |

| [14] | LIU H F, LI S L, LI Q L,et al.Preparation and phase stability of La2O3, Y2O3 co-doped ZrO2 ceramic powder application for thermal barrier coatin. Journal of Inorganic Materials, 2009, 24(6): 1226-1230. |

| [15] | NEJATI M, RAHIMIPOUR M R, MPBASHERPOUR I,et al.Microstructural analysis and thermal shock behavior of plasma sprayed ceria-stabilized zirconia thermal barrier coatings with micro and nano Al2O3 as a third layer. Surf. Coat. Technol., 2015, 282: 129-138. |

| [16] | DOKUR M M, GOLLER G.Processing and characterization of CYSZ/Al2O3 and CYSZ/Al2O3+YSZ multilayered thermal barrier coating.Surf. Coat. Technol., 2014, 258: 804-813. |

| [17] | LIN F, YU Y G, JIANG X L, et al. Microstructures and properties of nanostrutured TBCs fabricated by plasma spraying. The Chinese Journal of Nonferrous Metals, 2006, 16(3): 482-487. |

| [18] | 张立德, 牟季美. 纳米材料学. 辽宁科学技术出版社, 1994: 67-69. |

| [19] | 孟红梅. 蒸镀、磁控溅射铝和铝合金薄膜的组织与性. 天津: 天津大学, 2007. |

| [20] | ZHANG X F, ZHOU K S, XU W,et al.Reaction mechanism and thermal insulation property of Al-deposited 7YSZ thermal barrier coatin. J. Mater. Sci. Technol., 2015, 31: 1006-1010. |

| [21] | HE M Y, EVANS A G, HUTCHINSON J W.The ratcheting of com-pressed thermally grown thin films on ductile substrate.Acta Mater., 2000, 48: 2593-2601. |

| [1] | AN Wenran, HUANG Jingqi, LU Xiangrong, JIANG Jianing, DENG Longhui, CAO Xueqiang. Effect of Heat-treatment Temperature on Thermal and Mechanical Properties of LaMgAl11O19 Coating [J]. Journal of Inorganic Materials, 2022, 37(9): 925-932. |

| [2] | WEI Hailang, CAO Xueqiang, DENG Longhui, JIANG Jianing. Thermodynamic Properties and Thermal Cycling Lifetimes of LaMeAl11O19/YSZ Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2022, 37(12): 1259-1266. |

| [3] | ZHU Jiatong, LOU Zhihao, ZHANG Ping, ZHAO Jia, MENG Xuanyu, XU Jie, GAO Feng. Preparation and Thermal Properties of Rare Earth Tantalates (RETaO4) High-Entropy Ceramics [J]. Journal of Inorganic Materials, 2021, 36(4): 411-417. |

| [4] | JI Xiaojuan,YU Yueguang,LU Xiaoliang. Effects of Impurities on Properties of YSZ Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2020, 35(6): 669-674. |

| [5] | FAN Jia-Feng,ZHANG Xiao-Feng,ZHOU Ke-Song,LIU Min,DENG Chang-Guang,DENG Chun-Ming,NIU Shao-Peng,DENG Zi-Qian. Influence of Al-modification on CMAS Corrosion Resistance of PS-PVD 7YSZ Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2019, 34(9): 938-946. |

| [6] | Bo-Le MA, Wen MA, Wei HUANG, Yu BAI, Rui-Ling JIA, Hong-Ying DONG. Thermophysical Property of Single-phase Strontium Zirconate Co-doped with Double Rare-earth Oxides as a Thermal Barrier Coating Material [J]. Journal of Inorganic Materials, 2019, 34(4): 394-400. |

| [7] | WANG Lin, DING Kun-Ying, LIN Xiao-Ping, LI Ze, ZHENG Run-Guo, YANG Lian-Wei. Defect Evolution and Microcracks of 8YSZ Double-layer Thermal Barrier Coatings by Water Immersion Ultrasound Macroscopic Detection [J]. Journal of Inorganic Materials, 2019, 34(12): 1265-1271. |

| [8] | LI Da-Chuan, ZHAO Hua-Yu, ZHONG Xing-Hua, TAO Shun-Yan. Research Progresses of Atmospheric Plasma Sprayed Splat [J]. Journal of Inorganic Materials, 2017, 32(6): 571-580. |

| [9] | SUN Xu-Xuan, CHEN Hong-Fei, YANG Guang, LIU Bin, GAO Yan-Feng. YSZ- Ti3AlC2 Thermal Barrier Coating and Its Self-healing Behavior under High Temperatures [J]. Journal of Inorganic Materials, 2017, 32(12): 1269-1274. |

| [10] | MA Rong-Bin, CHENG Xu-Dong, ZOU Jun, LI Qing-Yu, HUANG Xia. Toughness and Thermal Shock of SiC Fiber/Yttria-stabilized-zirconia Composite Thick Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2016, 31(2): 190-194. |

| [11] | ZHANG Xiao-Feng, ZHOU Ke-Song, ZHANG Ji-Fu, HAN Tao, Song Jin-Bing, LIU-Min. Erosion Failure Mechanism and Model Establishment of Thermal Barrier Coatings Based on Roughness [J]. Journal of Inorganic Materials, 2014, 29(3): 294-300. |

| [12] | YANG Bin, LI Lin-Yan, FAN Min-Guang, LI Bin, XU Sheng-Ming, WANG Jian-Long, LIN Xu-Ping. Synthesis and Thermophysical Properties of (La1-xMgx)2Ce2O7-x [J]. Journal of Inorganic Materials, 2014, 29(12): 1301-1305. |

| [13] | YANG Jia-Sheng, YU Jian-Hua, ZHONG Xing-Hua, ZHAO Hua-Yu, ZHOU Xia-Ming, TAO Shun-Yan, DING Chuan-Xian. Experimental and Numerical Investigation of Residual Stresses in Plasma-sprayed Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2013, 28(12): 1381-1386. |

| [14] | HUA Jia-Jie, ZHANG Li-PENG, LIU Zi-Wei, WANG Yong-Zhe, LIN Chu-Cheng, ZENG Yi, ZHENG Xue-Bing. Progress of Research on the Failure Mechanism of Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2012, 27(7): 680-686. |

| [15] | MA Wen, SONG Feng-Yu, DONG Hong-Ying, XU Ping, LUN Wen-Shan, ZHENG Xue-Bin. Thermophysical Properties of Y2O3 and Gd2O3 Co-doped SrZrO3 Thermal Barrier Coating Material [J]. Journal of Inorganic Materials, 2012, 27(2): 209-213. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||