Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (10): 1111-1118.DOI: 10.15541/jim20250016

• RESEARCH ARTICLE • Previous Articles Next Articles

AI Yizhaotong1( ), REN Jiulong2, QIANG Linya3, ZHANG Xiaozhen3, YANG Kai2(

), REN Jiulong2, QIANG Linya3, ZHANG Xiaozhen3, YANG Kai2( ), GAO Yanfeng2

), GAO Yanfeng2

Received:2025-01-13

Revised:2025-02-17

Published:2025-10-20

Online:2025-03-25

Contact:

YANG Kai, professor. E-mail: kaiyang_yk@shu.edu.cnAbout author:AI Yizhaotong (1993-), female, engineer. E-mail: aiyizhaotong@mail.sic.ac.cn

CLC Number:

AI Yizhaotong, REN Jiulong, QIANG Linya, ZHANG Xiaozhen, YANG Kai, GAO Yanfeng. Friction and Wear Properties of Al2O3-GdAlO3 (GAP) Amorphous Ceramic Coatings under High Load Capacity[J]. Journal of Inorganic Materials, 2025, 40(10): 1111-1118.

| Sample | Arc current/A | Primary plasma gas (Ar)/slpm | Secondary plasma gas (Ar)/slpm | Power/ kW | Carrier gas (Ar)/slpm | Powder feed rate/(g·min-1) | Spray distance/cm |

|---|---|---|---|---|---|---|---|

| NiCr bondcoat | 590-610 | 55-60 | 7.5-8.0 | 40-50 | 3.5 | 10 | 120 |

| Al2O3-GAP topcoat | 640-660 | 45-50 | 8.5-9.0 | 45-50 | 4.0 | 30 | 110 |

Table 1 Spray coating parameters for NiCr bondcoat and Al2O3-GAP ceramic topcoat

| Sample | Arc current/A | Primary plasma gas (Ar)/slpm | Secondary plasma gas (Ar)/slpm | Power/ kW | Carrier gas (Ar)/slpm | Powder feed rate/(g·min-1) | Spray distance/cm |

|---|---|---|---|---|---|---|---|

| NiCr bondcoat | 590-610 | 55-60 | 7.5-8.0 | 40-50 | 3.5 | 10 | 120 |

| Al2O3-GAP topcoat | 640-660 | 45-50 | 8.5-9.0 | 45-50 | 4.0 | 30 | 110 |

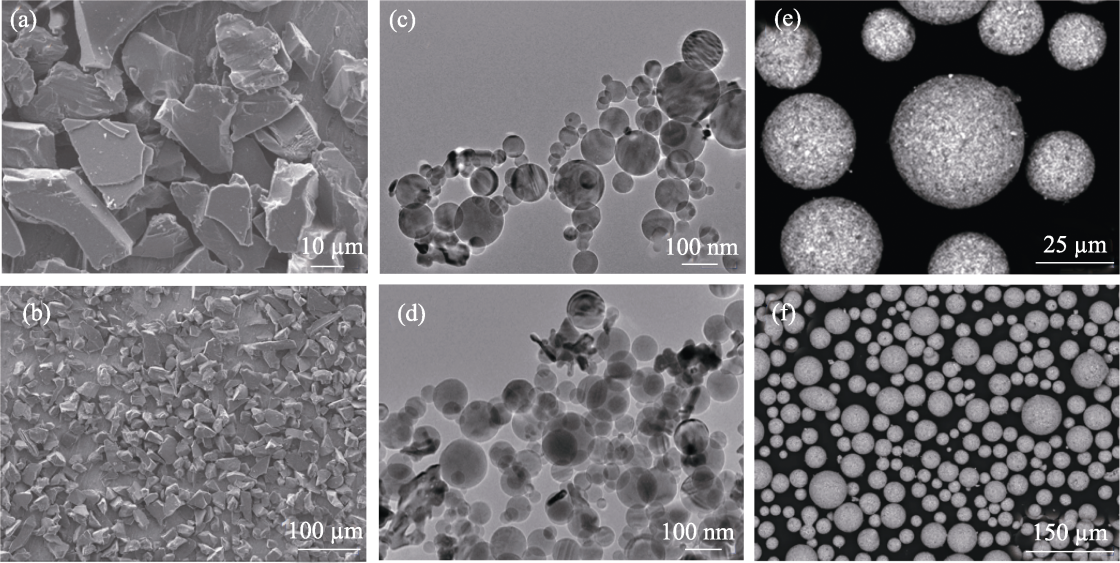

Fig. 2 Morphologies of different powder samples (a, b) SEM images of Al2O3 spray powder prepared by the melting and crushing method; (c, d) TEM images of mixed powder composed of nanoscale or submicron Al2O3 and Gd2O3 raw materials; (e, f) SEM images of sprayed Al2O3/Gd2O3 powder after heat treatment at 900 ℃

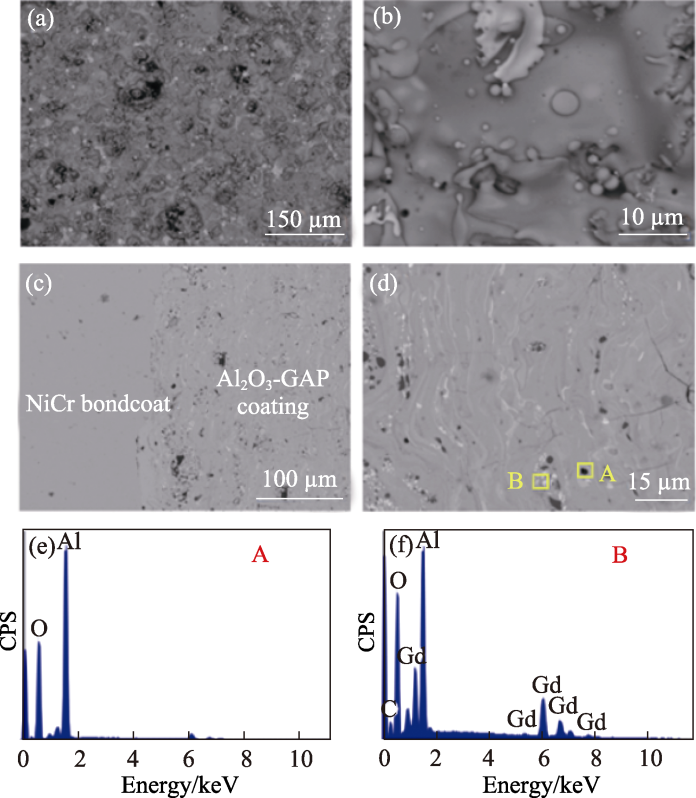

Fig. 4 Morphology and EDS analysis of as-sprayed Al2O3-GAP amorphous coating (a, b) Surface morphology of the coating; (c, d) Cross-sectional morphology of the coating; (e, f) EDS elemental analysis of the coating

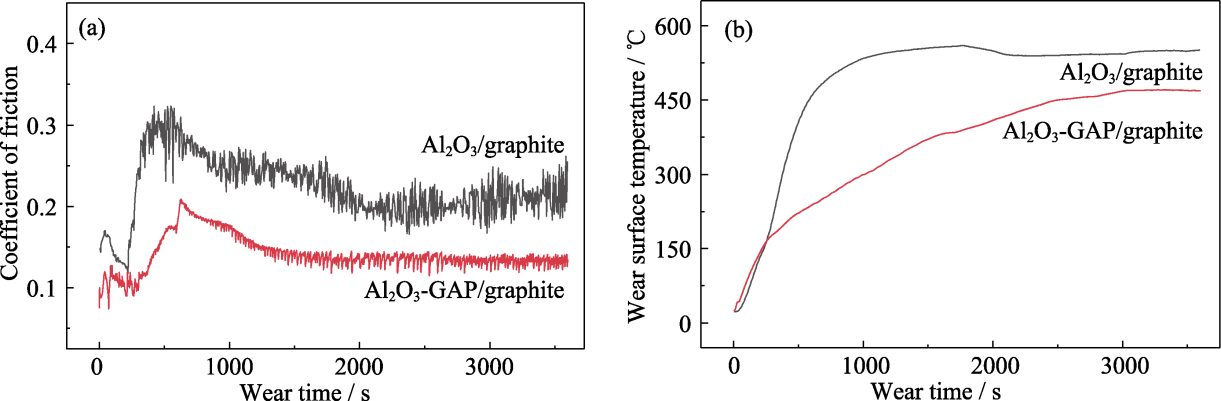

Fig. 5 Coefficients of friction (a) and wear surface temperatures (b) of sprayed Al2O3 coating and Al2O3-GAP amorphous coating under conditions of 2000 N@500 r/min

| Coating system | Coefficient of friction | Wear surface temperature/℃ | |||

|---|---|---|---|---|---|

| Average | Maximum | Minimum | Average | Maximum | |

| Al2O3 | 0.236 | 0.305 | 0.127 | 513.14 | 553.80 |

| Al2O3-GAP | 0.146 | 0.213 | 0.067 | 438.54 | 464.20 |

Table 2 Coefficients of friction and wear surface temperatures of Al2O3 and Al2O3-GAP coatings

| Coating system | Coefficient of friction | Wear surface temperature/℃ | |||

|---|---|---|---|---|---|

| Average | Maximum | Minimum | Average | Maximum | |

| Al2O3 | 0.236 | 0.305 | 0.127 | 513.14 | 553.80 |

| Al2O3-GAP | 0.146 | 0.213 | 0.067 | 438.54 | 464.20 |

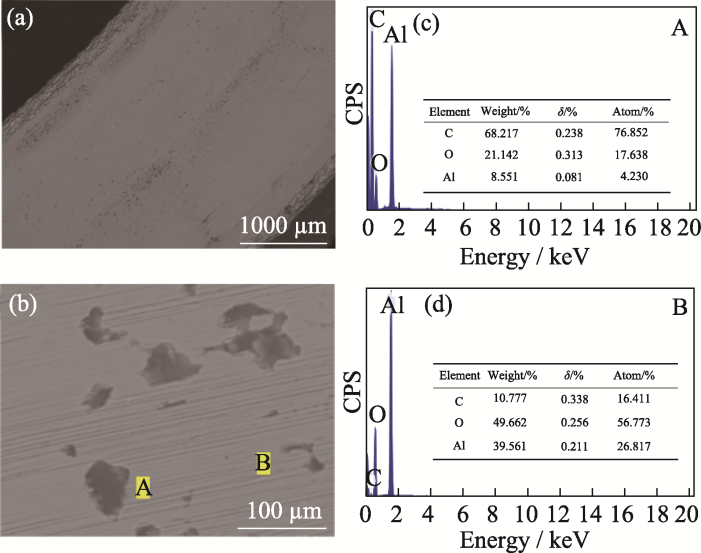

Fig. 6 Wear surface morphology and EDS analysis of Al2O3 coating under conditions of 2000 N@500 r/min (a) SEM image of the overall worn surface of coating wear ring; (b) Magnified view of a worn region in (a); (c, d) EDS elemental analysis

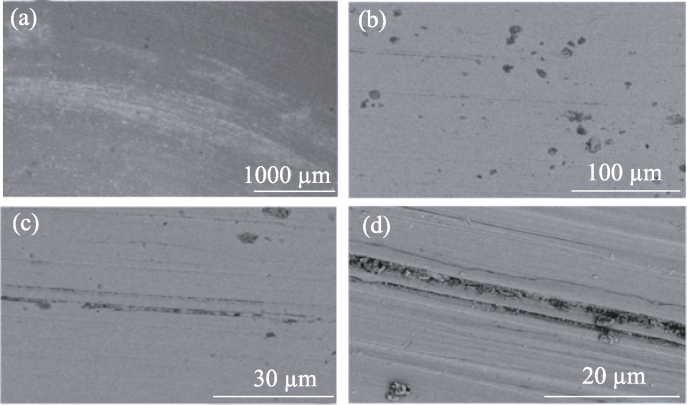

Fig. 7 Wear surface morphology of Al2O3-GAP amorphous coating under conditions of 2000 N@500 r/min (a) A typical wear scar region of the coating; (b) Magnified view of an abrasive wear characteristic region selected from (a); (c) Magnified view of a typical dark ‘scratch’ region selected from (b); (d) Further magnified view of the region in (c)

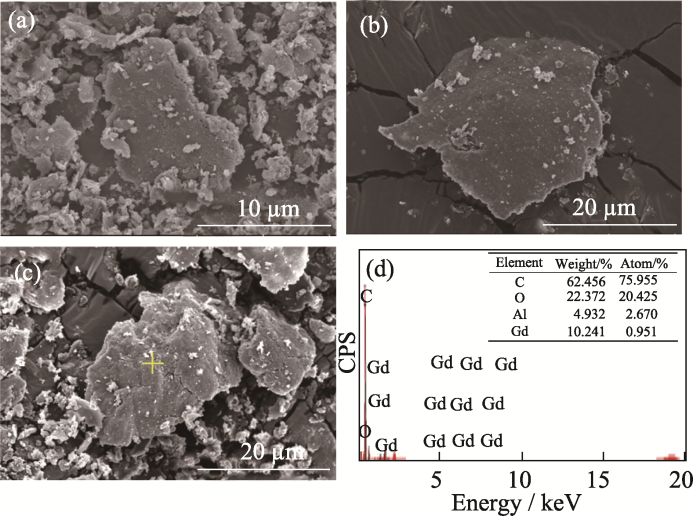

Fig. 8 Morphology and EDS analysis of wear debris from Al2O3-GAP/graphite under conditions of 2000 N@500 r/min (a-c) SEM images of wear debris with different sizes and shapes; (d) EDS elemental analysis of the wear debris in (c)

| [1] | LIU M, PENG Q, HUANG Y, et al. Influencing factors and process optimization of Al-25Si coating prepared by inner-hole supersonic atmospheric plasma spraying. Surface and Coatings Technology, 2023, 464: 129456. |

| [2] | LASHMI P G, ANANTHAPADMANABHAN P V, UNNIKRISHNAN G, et al. Present status and future prospects of plasma sprayed multilayered thermal barrier coating systems. Journal of the European Ceramic Society, 2020, 40(8): 2731. |

| [3] | CHELLAGANESH D, KHAN M A, JAPPES J W. Thermal barrier coatings for high temperature applications - a short review. Materials Today: Proceedings, 2021, 45: 1529. |

| [4] | ZHU C N, SU Y S, ZHANG D, et al. Effect of Al2O3 coating thickness on microstructural characterization and mechanical properties of continuous carbon fiber reinforced aluminum matrix composites. Materials Science and Engineering: A, 2020, 793: 139839. |

| [5] | CHEN Y, YANG Y, CHU Z, et al. Microstructure and properties of Al2O3-ZrO2 composite coatings prepared by air plasma spraying. Applied Surface Science, 2018, 431: 93. |

| [6] | HARIDASA N, VARUN K R, VENKATESH M K, et al. Thermal cycle behaviour of plasma sprayed thermal barrier coatings on cast iron substrate for the application of liner of internal combustion engine. Results in Surfaces and Interfaces, 2024, 17: 100297. |

| [7] | DENG W, LI S, HOU G, et al. Comparative study on wear behavior of plasma sprayed Al2O3 coatings sliding against different counterparts. Ceramics International, 2017, 43(9): 6976. |

| [8] | YIN Z, TAO S, ZHOU X, et al. Particle in-flight behavior and its influence on the microstructure and mechanical properties of plasma-sprayed Al2O3 coatings. Journal of the European Ceramic Society, 2008, 28(6): 1143. |

| [9] | FAN Y, MATEJKA V, KRATOŠOVÁ G, et al. Role of Al2O3 in semi-metallic friction materials and its effects on friction and wear performance. Tribology Transactions, 2008, 51(6): 771. |

| [10] | ZHU J H, LIU H Z, LIU L, et al. Preparation and characterisation of electroformed Cu/nano Al2O3 composite. Materials Science and Technology, 2007, 23(6): 665. |

| [11] | TINGAUD O, BERTRAND P, BERTRAND G. Microstructure and tribological behavior of suspension plasma sprayed Al2O3 and Al2O3-YSZ composite coatings. Surface and Coatings Technology, 2010, 205(4): 1004. |

| [12] | YIN Z, TAO S, ZHOU X, et al. Preparation and characterization of plasma-sprayed Al/Al2O3 composite coating. Materials Science and Engineering: A, 2008, 480(1): 580. |

| [13] | TAO S, YIN Z, ZHOU X, et al. Sliding wear characteristics of plasma-sprayed Al2O3 and Cr2O3 coatings against copper alloy under severe conditions. Tribology International, 2010, 43(1/2): 69. |

| [14] | KRISHNAN R, DASH S, KESAVAMOORTHY R, et al. Laser surface modification and characterization of air plasma sprayed alumina coatings. Surface and Coatings Technology, 2006, 200(8): 2791. |

| [15] | SARIKAYA O. Effect of some parameters on microstructure and hardness of alumina coatings prepared by the air plasma spraying process. Surface and Coatings Technology, 2005, 190(2/3): 388. |

| [16] | YILMAZ R, KURT A O, DEMIR A, et al. Effects of TiO2 on the mechanical properties of the Al2O3-TiO2 plasma sprayed coating. Journal of the European Ceramic Society, 2007, 27(2): 1319. |

| [17] | QIANG L, ZHANG X, AI Y, et al. Crystallization behavior and thermal stability mechanism of plasma sprayed Al2O3-GAP amorphous ceramic coatings. Journal of the European Ceramic Society, 2022, 42(12): 5108. |

| [18] | RONG J, YANG K, ZHUANG Y, et al. Non-isothermal crystallization kinetics of Al2O3-YAG amorphous ceramic coating deposited via plasma spraying. Journal of the American Ceramic Society, 2018, 101(7): 2888. |

| [19] | MA W, ZHANG J, SU H, et al. Theoretical prediction and experimental comparison for eutectic growth of Al2O3/GdAlO3 faceted eutectics. Journal of the European Ceramic Society, 2019, 39(13): 3837. |

| [20] | CHEN Y T, LIN S H, HSIEH W H. Differential scanning calorimetric determination of the thermal properties of amorphous Co60Fe20B20 and Co40Fe40B20 thin films. Applied Physics Letters, 2013, 102(5): 051905. |

| [21] | ZHANG Y, CHEN J, CHEN G L, et al. Glass formation mechanism of minor yttrium addition in CuZrAl alloys. Applied Physics Letters, 2006, 89(13): 131904. |

| [22] | LU Y, HUANG Y, WEI X, et al. Close correlation between transport properties and glass-forming ability of an FeCoCrMoCBY alloy system. Intermetallics, 2012, 30: 144. |

| [23] | SALEHI M, SHABESTARI S G, BOUTORABI S M. Nano-crystal development and thermal stability of amorphous Al-Ni-Y-Ce alloy. Journal of Non-crystalline Solids, 2013, 375: 7. |

| [24] | ZHOU X, ZHOU H, ZHAO Z, et al. A study of non-isothermal primary crystallization kinetics and soft magnetic property of Co65Fe4Ni2Si15B14 amorphous alloy. Journal of Alloys and Compounds, 2012, 539: 210. |

| [25] | ZHANG Z, YANG K, RONG J, et al. Study on process optimization of sprayable powders and deposition performance of amorphous Al2O3-YAG coatings. Coatings, 2020, 10(12): 1158. |

| [26] | ZHANG Z, AI Y, ZHONG X, et al. Formation mechanism of Al2O3-YAG amorphous ceramic coating deposited via atmospheric plasma spraying. International Journal of Applied Ceramic Technology, 2022, 19(3): 1518. |

| [27] | ZHANG Z, YANG K, AI Y, et al. Crystallization behavior of novel Al2O3-YAG amorphous ceramic coating deposited by atmospheric plasma spraying. Journal of Thermal Spray Technology, 2022, 31(3): 462. |

| [1] | LI Jie, LUO Zhixin, CUI Yang, ZHANG Guangheng, SUN Luchao, WANG Jingyang. CMAS Corrosion Resistance of Y3Al5O12/Al2O3 Ceramic Coating Deposited by Atmospheric Plasma Spraying [J]. Journal of Inorganic Materials, 2024, 39(6): 671-680. |

| [2] | Yan-Zhe ZHOU, Min LIU, Kun YANG, Wei ZENG, Jin-Bing SONG, Chun-Ming DENG, Chang-Guang DENG. Microstructure and Property of MoSi2-30Al2O3 Electrothermal Coating Prepared by Atmospheric Plasma Spraying [J]. Journal of Inorganic Materials, 2019, 34(6): 646-652. |

| [3] | LI Da-Chuan, ZHAO Hua-Yu, ZHONG Xing-Hua, TAO Shun-Yan. Research Progresses of Atmospheric Plasma Sprayed Splat [J]. Journal of Inorganic Materials, 2017, 32(6): 571-580. |

| [4] | SUN Xu-Xuan, CHEN Hong-Fei, YANG Guang, LIU Bin, GAO Yan-Feng. YSZ- Ti3AlC2 Thermal Barrier Coating and Its Self-healing Behavior under High Temperatures [J]. Journal of Inorganic Materials, 2017, 32(12): 1269-1274. |

| [5] | YU Fang-Li, BAI Yu, WU Xiu-Ying, Wang Hai-Jun, WU Jiu-Hui. Corrosion Resistance and Anti-wear Property of Nickel Based Abradable Sealing Coating Deposited by Plasma Spraying [J]. Journal of Inorganic Materials, 2016, 31(7): 687-693. |

| [6] | MAO Jin-Yuan, LIU Min, MAO Jie, DENG Chun-Min, ZENG De-Chang, XU Lin. Oxidation-resistance of ZrB2-MoSi2 Composite Coatings Prepared by Atmospheric Plasma Spraying [J]. Journal of Inorganic Materials, 2015, 30(3): 282-286. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||