Journal of Inorganic Materials ›› 2025, Vol. 40 ›› Issue (7): 765-771.DOI: 10.15541/jim20240498

• RESEARCH ARTICLE • Previous Articles Next Articles

CHAI Runyu1,2( ), ZHANG Zhen3(

), ZHANG Zhen3( ), WANG Menglong1,2, XIA Changrong2,3,4(

), WANG Menglong1,2, XIA Changrong2,3,4( )

)

Received:2024-11-29

Revised:2025-01-26

Published:2025-07-20

Online:2025-02-25

Contact:

ZHANG Zhen, PhD. E-mail: zhenge@ustc.edu.cn;About author:CHAI Runyu (2000-), male, Master candidate. E-mail: sa22226007@mail.ustc.edu.cn

Supported by:CLC Number:

CHAI Runyu, ZHANG Zhen, WANG Menglong, XIA Changrong. Preparation of Ceria Based Metal-supported Solid Oxide Fuel Cells by Direct Assembly Method[J]. Journal of Inorganic Materials, 2025, 40(7): 765-771.

| Slurry | Electrolyte | Anode | |

|---|---|---|---|

| Powder | GDC | 45 | 12 |

| NiO | 0 | 28 | |

| Solvent | Ethanol | 25.5 | 28.5 |

| 2-Butanone | 14 | 16 | |

| Dispersant | Triethanolamine | 1.5 | 1.5 |

| Plasticizer | PEG-400 | 4 | 4 |

| Dibutyl phthalate | 5 | 5 | |

| Binder | PVA | 5 | 5 |

Table 1 Composition of casting slurries (in mass, %)

| Slurry | Electrolyte | Anode | |

|---|---|---|---|

| Powder | GDC | 45 | 12 |

| NiO | 0 | 28 | |

| Solvent | Ethanol | 25.5 | 28.5 |

| 2-Butanone | 14 | 16 | |

| Dispersant | Triethanolamine | 1.5 | 1.5 |

| Plasticizer | PEG-400 | 4 | 4 |

| Dibutyl phthalate | 5 | 5 | |

| Binder | PVA | 5 | 5 |

Fig. 4 SEM images of MS-SOFC (a) Cross-section; (b) Cross-sectional junction between anode and electrolyte; (c) Surface of electrolyte; (d) Bond between the nickel mesh and the cell; (e) Bond between the nickel mesh and the cell after operation at 550 ℃ for 100 h

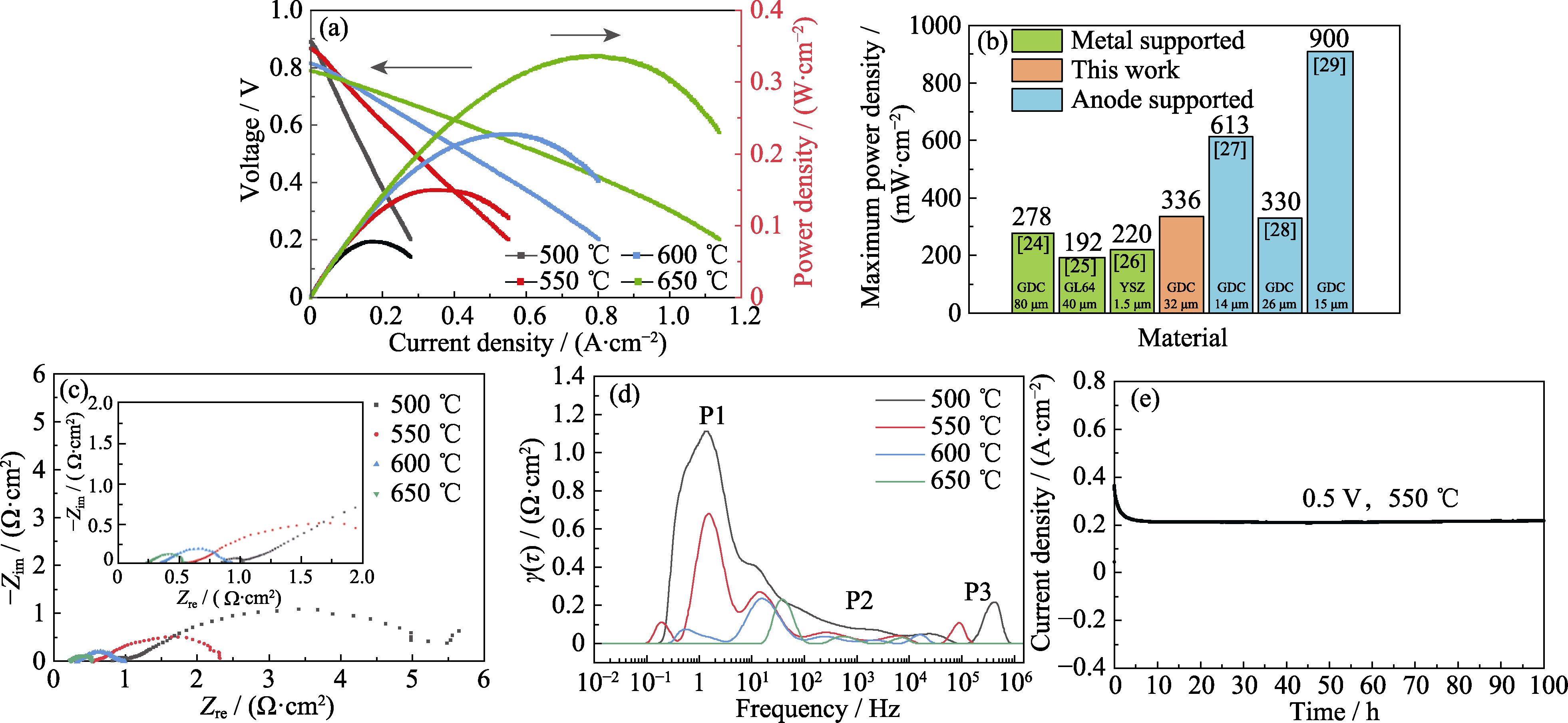

Fig. 5 Electrochemical performance of MS-SOFC (a) I-V-P curves of the cell at 500-650 ℃; (b) Performance of MS-SOFC in this study and other literature[24-29] at 650 ℃, and corresponding electrolyte materials used and their thickness; (c) Nyquist plots of a single cell at 500-650 ℃; (d) DRT curves of a single cell at 500-650 ℃; (e) Stability performance of the cell running at 550 ℃ and 0.5 V for 100 h. Colorful figures are available on website

| [1] | MANDEEP S, DARIO Z, ELISABETTA C. Solid oxide fuel cell: decade of progress, future perspectives and challenges. International Journal of Hydrogen Energy, 2021, 46: 27643. |

| [2] | MOLENDA J, KUPECKI J, BARON R, et al. Status report on high temperature fuel cells in Poland-recent advances and achievements. International Journal of Hydrogen Energy, 2017, 42: 4366. |

| [3] | VINCHHI P, KHANDLA M, CHAUDHARY K, et al. Recent advances on electrolyte materials for SOFC: a review. Inorganic Chemistry Communications, 2023, 152: 110724. |

| [4] | JAISWAL N, TANWAR K, SUMAN R, et al. A brief review on ceria based solid electrolytes for solid oxide fuel cells. Journal of Alloys and Compounds, 2019, 781: 984. |

| [5] | DAS S, BHASKAR R, NARAYANAN K B. Multifunctional applications of gadolinium-doped cerium oxide (Ce1-xGdxO2-∂) ceramics: a review. Journal of Rare Earths, 2024, 42: 1817. |

| [6] | ZHANG J, LENSER C, MENZLER N H, et al. Comparison of solid oxide fuel cell (SOFC) electrolyte materials for operation at 500 ℃. Solid State Ionics, 2020, 344: 115138. |

| [7] | LIU Y, SHAO Z P, MORI T, et al. Development of nickel based cermet anode materials in solid oxide fuel cells-now and future. Materials Reports: Energy, 2021, 1: 100003. |

| [8] | XU N, CHEN M, HAN M. Oxidation behavior of a Ni-Fe support in SOFC anode atmosphere. Journal of Alloys and Compounds, 2018, 765: 757. |

| [9] | AHMAD M Z, AHMAD S H, CHEN R S, et al. Review on recent advancement in cathode material for lower and intermediate temperature solid oxide fuel cells application. International Journal of Hydrogen Energy, 2022, 47: 1103. |

| [10] | XU H, HAN Y, ZHU J, et al. Status and progress of metal- supported solid oxide fuel cell: towards large-scale manufactory and practical applications. Energy Reviews, 2024, 3: 100051. |

| [11] | LI K, WANG X, JIA L, et al. High performance Ni-Fe alloy supported SOFCs fabricated by low cost tape casting-screen printing- cofiring process. International Journal of Hydrogen Energy, 2014, 39: 19747. |

| [12] | TIMURKUTLUKA B, TIMURKUTLUK C, MAT M D, et al. A review on cell/stack designs for high performance solid oxide fuel cells. Renewable and Sustainable Energy Reviews, 2016, 56: 1101. |

| [13] | SHAIGAN N, QU W, IVEY D G, et al. A review of recent progress in coatings, surface modifications and alloy. Journal of Power Sources, 2010, 195: 1529. |

| [14] | ZAJAC W, SUESCUN L, SWIERCZEK K, et al. Structural and electrical properties of grain boundaries in Ce0.85Gd0.15O1.925 solid electrolyte modified by addition of transition metal ions. Journal of Power Sources, 2009, 194: 2. |

| [15] | DWIVEDI S. Solid oxide fuel cell: materials for anode, cathode and electrolyte. International Journal of Hydrogen Energy, 2020, 45: 23988. |

| [16] | KROMP A, NIELSEN A, BLENNOW P, et al. Break-down of losses in high performing metal-supported solid oxide fuel cells. Fuel Cells, 2013, 13: 598. |

| [17] | TSAI C H, HWANG C S, CHANG C L, et al. Performances of plasma sprayed metal-supported solid oxide fuel cell and stack. Fuel Cells, 2018, 18: 800. |

| [18] | ZHOU J, MA Z, ZHANG L, et al. Study of CO2 and H2O direct co-electrolysis in an electrolyte-supported solid oxide electrolysis cell by aqueous tape casting technique. International Journal of Hydrogen Energy, 2019, 44: 28939. |

| [19] | CHENG J, ZHA S, FANG X, et al. On the green density, sintering behavior and electrical property of tape cast Ce0.9Gd0.1O1.95 electrolyte films. Materials Research Bulletin, 2002, 37: 2437. |

| [20] | ZHOU Y, XIN X, LI J, et al. Performance and degradation of metal-supported solid oxide fuel cells with impregnated electrodes. International Journal of Hydrogen Energy, 2014, 39: 2279. |

| [21] | HUANGA Q, WANG B, QU W, et al. Impedance diagnosis of metal-supported SOFCs with SDC as electrolyte. Journal of Power Sources, 2009, 191: 297. |

| [22] | LEE S, JANG Y, SHIN H, et al. Reliable sealing design of metal- based solid oxide fuel cell stacks for transportation applications. International Journal of Hydrogen Energy, 2019, 44: 30280. |

| [23] | TAO H, REN Q, ZHANG Y, et al. High-performance and stable proton ceramic fuel cells prepared via a co-tape casting process. International Journal of Hydrogen Energy, 2024, 57: 1498. |

| [24] | ZHANG M, SONG C, LIU M, et al. Study on the performance of GDC electrolytes fabricated by atmospheric plasma spraying and vacuum plasma spraying. Ceramics International, 2024, 50: 44391. |

| [25] | CHEN Z, ZHANG X, LIANG Y, et al. Breakthrough in atmospheric plasma spraying of high-density composite electrolytes: deposition behavior and performance of plasma-sprayed GDC-LSGM on porous metal-supported solid oxide fuel cells. International Journal of Hydrogen Energy, 2024, 72: 614. |

| [26] | LEE K, KANG J, LEE J, et al. Evaluation of metal-supported solid oxide fuel cells (MS-SOFCs) fabricated at low temperature (-1000 ℃) using wet chemical coating processes and a catalyst wet impregnation method. International Journal of Hydrogen Energy, 2018, 43: 3786. |

| [27] | FU C, LIU Q, CHAN S, et al. Effects of transition metal oxides on the densification of thin-film GDC electrolyte and on the performance of intermediate-temperature SOFC. International Journal of Hydrogen Energy, 2010, 35: 11200. |

| [28] | XIA C, LIU M. Low-temperature SOFCs based on Gd0.1Ce0.9O1.95 fabricated by dry pressing. Solid State Ionics, 2001, 144: 249. |

| [29] | FU C, CHAN S, LIU Q, et al. Fabrication and evaluation of Ni-GDC composite anode prepared by aqueous-based tape casting method for low-temperature solid oxide fuel cell. International Journal of Hydrogen Energy, 2010, 35: 301. |

| [30] | HUANG J, SULLIVAN N, ZAKUTAYEV A, et al. How reliable is distribution of relaxation times (DRT) analysis? A dual regression- classification perspective on DRT estimation, interpretation, and accuracy. Electrochimica Acta, 2023, 443: 141879. |

| [31] | XIA J, WANG C, WANG X, et al. A perspective on DRT applications for the analysis of solid oxide cell electrodes. Electrochimica Acta, 2020, 349: 136328. |

| [32] | SCHICHLEIN H, MÜLLER A C, VOIGTS M, et al. Deconvolution of electrochemical impedance spectra for the identifcation of electrode reaction mechanisms in solid oxide fuel cells. Journal of Applied Electrochemistry, 2002, 32: 875. |

| [33] | OSINKIN D A. Identification of gas diffusion phenomena on highly active Ni-ceramic anodes using the DRT technique. Journal of Power Sources, 2023, 571: 233085. |

| [1] | ZHENG Qifan, LI Chaoqun, BAN Xiaokuan, ZHAN Zhongliang, CHEN Chusheng. Preparation and Property of GDC-LSF Dual-phase Composite Membrane with Straight Pores and Sandwich Structure [J]. Journal of Inorganic Materials, 2021, 36(5): 497-501. |

| [2] | Wei WANG, Li-Li YUAN, Qian-Yuan QIU, Ming-Yang ZHOU, Mei-Lin LIU, Jiang LIU. A Direct Carbon Solid Oxide Fuel Cell Stack Based on a Single Electrolyte Plate Fabricated by Tape Casting Technique [J]. Journal of Inorganic Materials, 2019, 34(5): 509-514. |

| [3] | ZHANG Yu-Yue, LIN Jie, MIAO Guo-Shuan, GAO Jian-Feng, CHEN Chu-Sheng, XIA Chang-Rong, ZHAN Zhong-Liang, WANG Shao-Rong. Phase Inversion Tape Casting and Electrochemical Performance of Solid Oxide Fuel Cell Anode [J]. Journal of Inorganic Materials, 2015, 30(12): 1291-1294. |

| [4] | LUO Ting, SHI Jian, WANG Shao-Rong, ZHAN Zhong-Liang. Optimization of the Solid Oxide Fuel Cell Anode by Tape Casting [J]. Journal of Inorganic Materials, 2014, 29(2): 203-208. |

| [5] | LI Wei, XIONG Zhao-Xian, XUE Hao. Preparation and Electrical Properties of CaCu3Ti4O12 Thin Ceramic Sheets via Water-based Tape Casting [J]. Journal of Inorganic Materials, 2014, 29(11): 1228-1232. |

| [6] | SANG Shao-Bai,LI Wei,PU Jian,LI Jian. Al2O3-based Compressive Seals for Planar Intermediate Temperature Solid Oxide Fuel Cells [J]. Journal of Inorganic Materials, 2008, 23(4): 841-846. |

| [7] | GAO Feng,ZHANG Chang-Song,ZHAO Ming,WANG Wei-Min,TIAN Chang-Sheng. Microstructure and Piezoelectric Properties of (Na0.85K0.15)0.5Bi0.5TiO3Lead-free Ceramics Prepared by Tape Casting Processing [J]. Journal of Inorganic Materials, 2006, 21(5): 1134-1140. |

| [8] | HUANG He-Ji,ZHOU He-Ping,WANG Yu-Di. Application of Infrared Analysis in Testing the Dispersant Property of AlN Tape Casting Slurry [J]. Journal of Inorganic Materials, 2002, 17(2): 380-384. |

| [9] | CAO Jun,ZHANG Qing-Xue,ZHUANG Han-Rui,WU Feng-Ying. Tape Casting Process of Aluminium Nitride Substrate [J]. Journal of Inorganic Materials, 2001, 16(2): 269-276. |

| [10] | CAO Jun,ZHUANG Han-Rui,WU Feng-Ying. Electrokinetic Behavior of Hydrophobic Aluminium Nitride Powder [J]. Journal of Inorganic Materials, 2000, 15(3): 551-555. |

| [11] | CHEN Ming,WEN Ting-Lian,HUANG Zhen,WANG Ping-Chu,TU Heng-Yong,LU Zhi-Yi. Study on Isostatic Pressing YSZ Membrane Fabricated by Tape Casting [J]. Journal of Inorganic Materials, 1999, 14(5): 745-750. |

| [12] | ZENG Yu-Ping,JIANG Dong-Liang,Grail Peter. Aqueous Tape casting of Bio activity A/W-Al2O 3 with Low Temperature Sintering [J]. Journal of Inorganic Materials, 1999, 14(4): 569-574. |

| [13] | HE Lian-Xing,WEN Ting-Llian,LU Zhi-Yi. Study of Sintering Technique and Properties of Tape-casting Electrolyte for Ceramic Fuel Cell [J]. Journal of Inorganic Materials, 1998, 13(2): 243-246. |

| [14] | ZENG Yuping,JIANG Dongliang,TAN Shouhong,GUO Jingkun. Fabrication and Properties of Multilayer Al2O3-TiC Composite Ceramic [J]. Journal of Inorganic Materials, 1997, 12(6): 802-808. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||