Journal of Inorganic Materials ›› 2020, Vol. 35 ›› Issue (10): 1112-1116.DOI: 10.15541/jim20190578

Special Issue: 结构陶瓷论文精选(2020)

Previous Articles Next Articles

YANG Shaohui1( ),YAN Shufang1,2(

),YAN Shufang1,2( ),LI Shijiang1,CHEN Weidong1,2,DU Pei1,MA Wen1,2

),LI Shijiang1,CHEN Weidong1,2,DU Pei1,MA Wen1,2

Received:2019-11-14

Revised:2019-12-26

Published:2020-10-20

Online:2020-01-20

About author:YANG Shaohui (1996-) male, Master candidate. E-mail:18447071525@163.com

Supported by:CLC Number:

YANG Shaohui, YAN Shufang, LI Shijiang, CHEN Weidong, DU Pei, MA Wen. Effect of Phase Duty Cycle on the Properties of ZrH1.8 Surface Micro-arc Oxidized Ceramic Layer[J]. Journal of Inorganic Materials, 2020, 35(10): 1112-1116.

| No. | Anode voltage/V | Cathode voltage/V | Frequency/ Hz | Duty cycle |

|---|---|---|---|---|

| Ⅰ | 350 | 120 | 100 | 40%-50%-60% |

| Ⅱ | 350 | 120 | 100 | 50%-60%-40% |

| Ⅲ | 350 | 120 | 100 | 60%-50%-40% |

Table 1 Electrical parameters of micro-arc oxidation

| No. | Anode voltage/V | Cathode voltage/V | Frequency/ Hz | Duty cycle |

|---|---|---|---|---|

| Ⅰ | 350 | 120 | 100 | 40%-50%-60% |

| Ⅱ | 350 | 120 | 100 | 50%-60%-40% |

| Ⅲ | 350 | 120 | 100 | 60%-50%-40% |

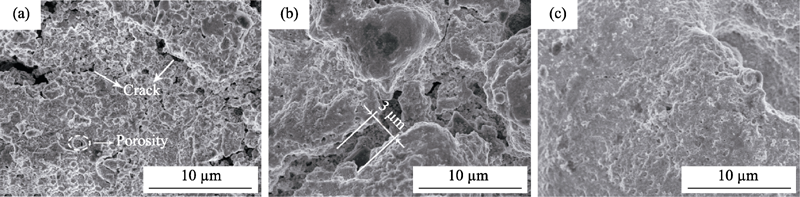

Fig. 2 Micromorphology of ZrH1.8 micro-arc oxidation ceramic layer under different phase duty cycles (a) 40%-50%-60%; (b) 50%-60%-40%; (c) 60%-50%-40%

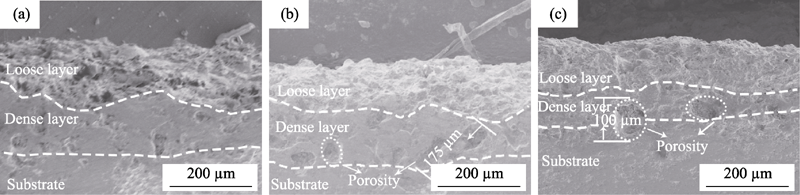

Fig. 3 Cross-micromorphology of ZrH1.8 micro-arc oxidation ceramic layers under different phase duty cycle modes (a) 40%-50%-60%; (b) 50%-60%-40%; (c) 60%-50%-40%

| No. | Duty cycle/% | Thickness /μm | HPRF |

|---|---|---|---|

| Ⅰ | 40%-50%-60% | 162.6 | 12.5 |

| Ⅱ | 50%-60%-40% | 175.9 | 7.1 |

| Ⅲ | 60%-50%-40% | 158.7 | 10.5 |

Table 2 Thicknesses and permeation reduction factors of micro-arcoxidation ceramic layers under different phase duty cycle modes

| No. | Duty cycle/% | Thickness /μm | HPRF |

|---|---|---|---|

| Ⅰ | 40%-50%-60% | 162.6 | 12.5 |

| Ⅱ | 50%-60%-40% | 175.9 | 7.1 |

| Ⅲ | 60%-50%-40% | 158.7 | 10.5 |

| [1] |

KUPRIN A S, BELOUS V A, VOYEVODIN V N .et al. Irradiation resistance of vacuum arc chromium coatings for zirconium alloy fuel claddings. Journal of Nuclear Materials , 2018,510:163-167.

DOI URL |

| [2] |

HU X, TERRANI K A, WIRTH B D . Hydrogen desorption kinetics from zirconium hydride and zirconium metal in vacuum. Journal of Nuclear Materials, 2014,448:87-95.

DOI URL |

| [3] |

VESHCHUNOV M S, SHESTAK V E . Models for hydrogen uptake and release kinetics by zirconium alloys at high temperatures. Nuclear Engineering and Design, 2012,252:96-107.

DOI URL |

| [4] | 马浩然, 付晓刚, 秦博 . 氢化锆高温氢释放的阻止方法研究. 原子能科学技术, 2016,50(11):2023-2026. |

| [5] | 陈伟东, 闫淑芳, 刘向东 , 等. 氢化锆与O2反应制备氢渗透阻挡层的研究. 稀有金属, 2014,38(01):71-76. |

| [6] |

ZHANG Y, LIN X, CHEN W , et al. Synthesis of Y2O3-ZrO2-SiO2 composite coatings on carbon fiber reinforced resin matrix composite by an electro-plasma process. Applied Surface Science, 2016,371:504-511.

DOI URL |

| [7] |

JUNICHIRO Y, TOHRU A, SABURO M . Elucidating the hydrgen- entry-obstruction mechanism of a newly developed aluminum- based coating in high-pressure gaseous hydrogen. International Journal of Hydrogen Energy, 2015,40(32):10329-10339.

DOI URL |

| [8] |

CHENG Y, WU F, MATYKINA E , et al. The influences of microdischarge types and silicate on the morphologies and phase compositions of plasma electrolytic oxidation coatings on Zircaloy-2. Corrosion Science , 2012,59:307-315.

DOI URL |

| [9] |

HSIAO C H, TENG H P, LU F H . Formation of zirconia coatings on ZrN-coated substrates by plasma electrolytic oxidation. Surface and Coatings Technology, 2015,269:295-301.

DOI URL |

| [10] |

TREVOR W C, SAMUEL C T . A review of recent work on discharge characteristics during plasma electrolytic oxidation of various metals. International Materials Reviews, 2019,64(3):127-162.

DOI URL |

| [11] |

MALINOV SCHI V, MARIN A, NEGREA D , et al. Characterization of Al2 O3/ZrO2, composite coatings deposited on Zr-2.5Nb alloy by plasma electrolytic oxidation. Applied Surface Science, 2018,451:169-179.

DOI URL |

| [12] | 刘俊超, 朱彦海, 唐明奇 , 等. 电参数对锻铝合金微弧氧化涂层生长特性的影响. 表面技术, 2011,40(3):71-74. |

| [13] | VAHID D, BEN L L, DAVIDW. et al. Effect of duty cycle and applied current frequency on plasma electrolytic oxidation (PEO) coating growth behavior. Surface & Coatings Technology , 2013,226:100-107. |

| [14] |

YAN G Q, CHEN W D, ZHONG X K , et al. Properties of oxide coating on the surface of ZrH1.8 prepared by microarc oxidation with different positive voltages. Rare Metals, 2013,32(2):169-173.

DOI URL |

| [15] | 陈伟东, 闫淑芳, 闫国庆 , 等. 氧化气氛对氢化锆表面防氢渗透层的影响. 稀有金属, 2013,37(3):418-421. |

| [16] | WANG L, CHEN L, YAN Z , et al. Optical emission spectroscopy studies of discharge mechanism and plasma characteristics during plasma electrolytic oxidation of magnesium in different electrolytes. Surface & Coatings Technology , 2010,205(6):1651-1658. |

| [17] |

CHENG Y, MATYKINA E, SKELDON P , et al. Characterization of plasma electrolytic oxidation coatings on Zircaloy-4 formed in different electrolytes with AC current regime. Electrochimica Acta, 2011,56(24):8467-8476.

DOI URL |

| [18] | 潘明强, 狄士春 . 微弧氧化火花放电等离子体源的形成机制研究. 稀有金属材料与工程, 2011,40(S2):333-338. |

| RUDNEV V S, NEDOZOROV P M, USTINOV A Y , et al. Obtaining ZrO + CeOx + TiO/Ti compositions by plasma-electrolytic oxidation of titanium and investigating their properties. Protection of Metals & Physical Chemistry of Surfaces, 2011,47(5):621-628. |

| [1] | DU Jiaheng, FAN Xinli, XIAO Dongqin, YIN Yiran, LI Zhong, HE Kui, DUAN Ke. Electrophoretic Coating of Magnesium Oxide on Microarc-oxidized Titanium and Its Biological Properties [J]. Journal of Inorganic Materials, 2023, 38(12): 1441-1448. |

| [2] | WANG Zhihu,ZHANG Jumei,BAI Lijing,ZHANG Guojun. Mg(OH)2 Film on Micro-arc Oxidation Ceramic Coating of AZ31 Magnesium Alloy: Preparation and Corrosion Resistance [J]. Journal of Inorganic Materials, 2020, 35(6): 709-716. |

| [3] | DU Pei, YAN Shu-Fang, CHEN Wei-Dong, LI Shi-Jiang, MA Wen. Graphene Concentration on Micro-arc Oxidation Ceramic Layer of ZrH1.8 Surface [J]. Journal of Inorganic Materials, 2019, 34(11): 1175-1180. |

| [4] | ZHANG Peng-Fei, YAN Shu-Fang, CHEN Wei-Dong, LI Shi-Jiang, GENG Yan-Hua, Wang Hong-Xing. Anode Voltage on Hydrogen Permeation Barrier Performance of Zirconium Hydride with Micro-arc Oxidation [J]. Journal of Inorganic Materials, 2018, 33(7): 793-797. |

| [5] | ZHANG Peng-Fei, YAN Shu-Fang, CHEN Wei-Dong, LI Shi-Jiang, ZHAO Li, WANG Hong-Xing. Influence of Reaction Time on Hydrogen Resistance Film on the Surface of ZrH1.8 in Aluminate System [J]. Journal of Inorganic Materials, 2018, 33(3): 284-288. |

| [6] | LI Hang, LU Song-Tao, QIN Wei, WU Xiao-Hong. Current Density on Microstructure and Thermal Control Performances of MgO-ZnO Ceramic Coatings [J]. Journal of Inorganic Materials, 2017, 32(12): 1292-1298. |

| [7] | YE Zuo-Yan, LIU Dao-Xin, LI Chong-Yang, ZHANG Xiao-Hua, ZANG Xiao-Ming, LEI Ming-Xia. Effect of Sealing Treatments on the Corrosion Behavior of Micro-arc Oxidation Coating on Aluminum Alloy in Acid NaCl Solution [J]. Journal of Inorganic Materials, 2015, 30(6): 627-632. |

| [8] | YU Jie, WEI Dong-Bo, WANG Yan, Lü Peng-Xiang, DI Shi-Chun. Structure and Property of Micro-arc Oxidation Coating Modified by Laser Melting and Solidifying on Aluminum Alloy [J]. Journal of Inorganic Materials, 2013, 28(8): 859-863. |

| [9] | Lü Peng-Xiang, WEI Dong-Bo, GUO Cheng-Bo, LI Zhao-Long, DI Shi-Chun. Study on Scanning Micro-arc Oxidation Technology Applied to 2024 Aluminum Alloy [J]. Journal of Inorganic Materials, 2013, 28(4): 381-386. |

| [10] | WANG Xiao-Bo, TIAN Xiu-Bo, GONG Chun-Zhi, YANG Shi-Qin. Na2CO3-induced Gas Evolution Reaction and Morphology Modulation on Magnesium Alloy during Micro-arc Oxidation [J]. Journal of Inorganic Materials, 2011, 26(7): 721-725. |

| [11] |

WU Zhen-Dong,JIANG Zhao-Hua,YAO Zhong-Ping,ZHANG Xue-Lin.

nfluence of Treatment Time on Structure and Property of Ceramic Coatings Formed on LY12 Aluminum Alloy by Micro-arc Oxidation [J]. Journal of Inorganic Materials, 2007, 22(3): 555-559. |

| [12] | XIN Shi-Gang,SONG Li-Xin,ZHAO Rong-Gen,HU Xing-Fang. Microstructure and Adhesion Strength of Al-Si-O \\Micro-arc Oxidation Coating [J]. Journal of Inorganic Materials, 2006, 21(2): 493-498. |

| [13] | XIN Shi-Gang, SONG Li-Xin, ZHAO Rong-Gen, HU Xing-Fang. Phase Composition and Properties of the Micro-arc Oxidation Coating on Aluminium Matrix Composite [J]. Journal of Inorganic Materials, 2006, 21(1): 223-229. |

| [14] | HAN Yong,XU Ke-Wei. Structural Characterization of Micro-arc Oxidation Formed Titanium Dioxide Films Containing Ca and P [J]. Journal of Inorganic Materials, 2001, 16(5): 951-956. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||