Journal of Inorganic Materials ›› 2017, Vol. 32 ›› Issue (6): 587-595.DOI: 10.15541/jim20160480

• Orginal Article • Previous Articles Next Articles

YUAN Guan-Ming1, XUE Zheng1, CUI Zheng-Wei1, DONG Zhi-Jun1, LI Xuan-Ke1, ZHANG Zhong-Wei2, WANG Jun-Shan2

Received:2016-08-29

Revised:2016-10-14

Published:2017-06-20

Online:2017-05-27

About author:YUAN Guan-Ming. E-mail: yuanguanming@wust.edu.cn

Supported by:CLC Number:

YUAN Guan-Ming, XUE Zheng, CUI Zheng-Wei, DONG Zhi-Jun, LI Xuan-Ke, ZHANG Zhong-Wei, WANG Jun-Shan. Controlled Preparation and Thermal Conductivity of Highly Oriented Graphite Blocks[J]. Journal of Inorganic Materials, 2017, 32(6): 587-595.

| Pitch binder | ρ/ (g·cm-3) | σ/ (μΩ·m) | α/ (mm2·s-1) | λ/ (W·m-1·K-1) |

|---|---|---|---|---|

| WG | 1.76 | 2.02 | 294.01 | 388.1 |

| NP | 1.78 | 1.62 | 309.74 | 413.5 |

| MP | 1.83 | 1.27 | 385.66 | 529.3 |

| SC | 1.78 | 1.31 | 363.01 | 484.6 |

| AR | 1.91 | 1.45 | 395.52 | 551.6 |

Table 1 Physical properties of graphite blocks made with different pitch binders

| Pitch binder | ρ/ (g·cm-3) | σ/ (μΩ·m) | α/ (mm2·s-1) | λ/ (W·m-1·K-1) |

|---|---|---|---|---|

| WG | 1.76 | 2.02 | 294.01 | 388.1 |

| NP | 1.78 | 1.62 | 309.74 | 413.5 |

| MP | 1.83 | 1.27 | 385.66 | 529.3 |

| SC | 1.78 | 1.31 | 363.01 | 484.6 |

| AR | 1.91 | 1.45 | 395.52 | 551.6 |

| Pitch binder | Softening point/℃ | Ash content/% | Volatile content/% | Carbon yield/% | TI/% | QI/% |

|---|---|---|---|---|---|---|

| WG | 110 | 0.12 | 48.65 | 50.56 | 31.5 | 11.2 |

| NP | 82 | 0.004 | 55.31 | 44.65 | 1.3 | 1.0 |

| MP | 275 | 0.02 | 21.67 | 78.24 | 69.4 | 42.5 |

| SC | 280 | 0.03 | 19.52 | 80.25 | 67.8 | 20.6 |

| AR | 266 | 0.001 | 22.03 | 77.95 | 66.9 | 50.8 |

Table 2 Basic physical properties of different pitch binders

| Pitch binder | Softening point/℃ | Ash content/% | Volatile content/% | Carbon yield/% | TI/% | QI/% |

|---|---|---|---|---|---|---|

| WG | 110 | 0.12 | 48.65 | 50.56 | 31.5 | 11.2 |

| NP | 82 | 0.004 | 55.31 | 44.65 | 1.3 | 1.0 |

| MP | 275 | 0.02 | 21.67 | 78.24 | 69.4 | 42.5 |

| SC | 280 | 0.03 | 19.52 | 80.25 | 67.8 | 20.6 |

| AR | 266 | 0.001 | 22.03 | 77.95 | 66.9 | 50.8 |

| Pitch binder | d002 | La/ nm | Lc/ nm | g/ % |

|---|---|---|---|---|

| WG | 0.3367 | 73.1 | 20.4 | 84.88 |

| NP | 0.3365 | 86.4 | 24.5 | 87.21 |

| MP | 0.3357 | 316.7 | 25.0 | 96.51 |

| SC | 0.3366 | 79.2 | 22.7 | 86.05 |

| AR | 0.3356 | 475 | 26.5 | 97.67 |

Table 3 Microcrystal parameters of the different pitch binder-derived graphite particles after 2800℃ graphitization treatment

| Pitch binder | d002 | La/ nm | Lc/ nm | g/ % |

|---|---|---|---|---|

| WG | 0.3367 | 73.1 | 20.4 | 84.88 |

| NP | 0.3365 | 86.4 | 24.5 | 87.21 |

| MP | 0.3357 | 316.7 | 25.0 | 96.51 |

| SC | 0.3366 | 79.2 | 22.7 | 86.05 |

| AR | 0.3356 | 475 | 26.5 | 97.67 |

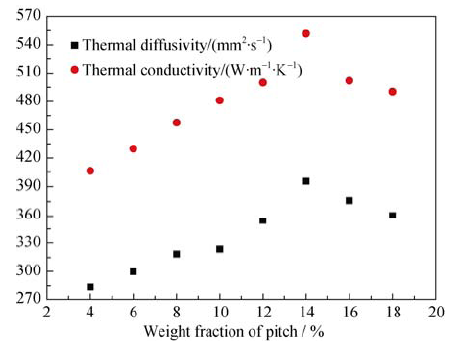

Fig. 6 Room-temperature thermal conductivity and thermal diffusivity of graphite blocks heat treated at 2800℃ versus initial weight fraction of mesophase pitch

| Thermal property | Particle sizes of graphite flakes/ mesh | |||

|---|---|---|---|---|

| 80-40 | 40-32 | +32 | +20 | |

| α/(mm2·s-1) | 343.8 | 360.8 | 395.5 | 366.1 |

| λ/(W·m-1·K-1) | 484.7 | 514.2 | 551.6 | 510.7 |

Table 4 Room-temperature thermal diffusivity and thermal conductivity of graphite blocks prepared with different particle- sized graphite flakes

| Thermal property | Particle sizes of graphite flakes/ mesh | |||

|---|---|---|---|---|

| 80-40 | 40-32 | +32 | +20 | |

| α/(mm2·s-1) | 343.8 | 360.8 | 395.5 | 366.1 |

| λ/(W·m-1·K-1) | 484.7 | 514.2 | 551.6 | 510.7 |

| Hot-pressing temperature/℃ | ρ/ (g·cm-3) | α/(mm2·s-1) | λ/(W·m-1·K-1) |

|---|---|---|---|

| 300 | 1.66 | 331.36 | 412.5 |

| 500 | 1.91 | 395.52 | 551.6 |

| 650 | 1.95 | 415.13 | 607.1 |

Table 5 Influence of hot-pressing temperature on the physical properties of graphite blocks

| Hot-pressing temperature/℃ | ρ/ (g·cm-3) | α/(mm2·s-1) | λ/(W·m-1·K-1) |

|---|---|---|---|

| 300 | 1.66 | 331.36 | 412.5 |

| 500 | 1.91 | 395.52 | 551.6 |

| 650 | 1.95 | 415.13 | 607.1 |

| Dopants | ρ/(g·cm-3) | σ/(μΩ·m) | α/(mm2·s-1) | λ/(W·m-1·K-1) |

|---|---|---|---|---|

| Undoped | 1.91 | 1.45 | 395.52 | 551.6 |

| 5wt% Si | 1.79 | 1.90 | 307.21 | 412.4 |

| 5wt% Ti | 1.89 | 1.52 | 296.60 | 420.4 |

| 3wt%Si+ 5wt%Ti | 1.65 | 2.25 | 229.20 | 283.6 |

Table 6 Physical properties of 2800℃ treated graphite blocks before and after doping

| Dopants | ρ/(g·cm-3) | σ/(μΩ·m) | α/(mm2·s-1) | λ/(W·m-1·K-1) |

|---|---|---|---|---|

| Undoped | 1.91 | 1.45 | 395.52 | 551.6 |

| 5wt% Si | 1.79 | 1.90 | 307.21 | 412.4 |

| 5wt% Ti | 1.89 | 1.52 | 296.60 | 420.4 |

| 3wt%Si+ 5wt%Ti | 1.65 | 2.25 | 229.20 | 283.6 |

| [1] | NORLEY J.The role of natural graphite in electronics cooling.Electronics Cooling, 2001, 7: 50-51. |

| [2] | QIU H P, SONG Y Z, LIU L, et al.Thermal conductivity and microstructure of Ti-doped graphite.Carbon, 2003, 41(5): 973-978. |

| [3] | LUEDTKE A.Thermal management materials for high performance applications.Advanced Engineering Materials, 2004, 6(3): 142-144. |

| [4] | ZWEBEN C.High-performance thermal management materials.Advanced Packaging, 2006, 15(2): 1-5. |

| [5] | PIERSON H O.Handbook of Carbon, Diamond and Fullerenes. 1st Edition. Park Ridge NJ: Noyes Publications, 1993: 50-67. |

| [6] | KUGA Y, SHIRAHIGE M, FUJIMOTO T, et al.Production of natural graphite particles with high electrical conductivity by grinding in alcoholic vapors.Carbon, 2004, 42(2): 293-300. |

| [7] | WANG H Y, YOSHIO M.Electrochemical performance of raw natural graphite flakes as an anode material for lithium-ion batteries at the elevated temperature.Materials Chemistry and Physics, 2003, 79(1): 76-80. |

| [8] | BONNISSEL M, LUO L, TONDEUR D.Compacted exfoliated natural graphite as heat conduction medium.Carbon, 2001, 39(14): 2151-2161. |

| [9] | GENG Y, WANG S J, KIM J K.Preparation of graphite nanoplatelets and graphene sheets.Journal of Colloid and Interface Science, 2009, 336(2): 592-598. |

| [10] | LIU Z J, GUO Q G, SHI J L, et al.Preparation of doped graphite with high thermal conductivity by a liquid mixing process.Carbon, 2007, 45(9): 1914-1916. |

| [11] | LIU Z J, GUO Q G, SHI J L, et al.Graphite blocks with high thermal conductivity derived from natural graphite flake.Carbon, 2008, 46(3): 414-421. |

| [12] | PRIETO R, MOLINA J M, NARCISOA J, et al.Fabrication and properties of graphite flakes/metal composites for thermal management applications.Scripta Materialia, 2008, 59(1): 11-14. |

| [13] | TAKAHASHI H, KURODA H, AKAMATU H.Correlation between stacking order and crystallite dimensions in carbons.Carbon, 1965, 2(4): 432-433. |

| [14] | BACON G E.A method for determining the degree of orientation of graphite.Journal of Applied Chemistry, 1956, 6(11): 477-481. |

| [15] | TASSONE G.Bacon anisotropy factor measurements on PyC by X-ray diffractometry.Carbon, 1970, 8(3): 387-388. |

| [16] | FUJIMOTO H.Theoretical X-ray scattering intensity of carbons with turbostratic stacking and AB stacking structures.Carbon, 2003, 41(8): 1585-1592. |

| [17] | YUAN G M, LI X K, DONG Z J, et al.Graphite blocks with preferred orientation and high thermal conductivity.Carbon, 2012, 50(1): 175-182. |

| [18] | CHEN G H, WANG H Q, ZHAO W F.Fabrication of highly ordered polymer/graphite flake composite with eminent anisotropic electrical property.Polymer Advanced Technology, 2008, 19(8): 1113-1117. |

| [19] | HORR N E, BOURGERETT E C, OBERLIN A.Mesophase powders (carbonization and graphitization).Carbon, 1994, 32(6): 1035-1044. |

| [20] | MARSH H, MENENDEZ R. Carbons from pyrolysis of pitches, coals, and their blends. Fuel Process Technology, 1988, 20(1/2/3): 269-296. |

| [1] | HE Fei, LI Ya, LUO Jin, FANG Min-Han, HE Xiao-Dong. Development of SiO2/C and SiC/C Composites Featuring Aerogel Structures [J]. Journal of Inorganic Materials, 2017, 32(5): 449-458. |

| [2] | TAN Man-Lin, SHANG Xu-Ran, MA Qing, WANG Xiao-Wei, FU Dong-Ju, LI Dong-Shuang, ZHANG Wei-Li, CHEN Jian-Jun, ZHANG Hua-Yu. Down-conversion Photoluminescence Properties of YVO4: Eu3+@SiO2 Core-shell Structures for Solar Cell Applications [J]. Journal of Inorganic Materials, 2016, 31(10): 1110-1116. |

| [3] | TAN Man-Lin, MA Dong-Cao, FU Dong-Ju, MA Qing, LI Dong-Shuang, WANG Xiao-Wei, ZHANG Wei-Li, CHEN Jian-Jun, ZHANG Hua-Yu. Properties of Silver Nanostructures Incorporated Perovskite Based Thin Films for Solar Cell Applications [J]. Journal of Inorganic Materials, 2016, 31(9): 908-914. |

| [4] | HE Fei, YU Wan-Jun, FANG Min-Han, HE Xiao-Dong, LI Ming-Wei. An Overview on Silica Aerogels Synthesized by Siloxane Co-precursors [J]. Journal of Inorganic Materials, 2015, 30(12): 1243-1253. |

| [5] | JIANG Jin-Long, WANG Qiong, HUANG Hao, ZHANG Xia, WANG Yu-Bao, GENG Qing-Fen. Microstructure Evolution Induced by Ultraviolet Light Irradiation in Ti-Si Codoped Diamond-like Carbon films [J]. Journal of Inorganic Materials, 2014, 29(9): 941-946. |

| [6] | FENG Wen-Po,QI Yuan-Ming, TANG Ke-Yong. Effects of GumArabic on Properties of Collagen-hydroxyapatite Composite [J]. Journal of Inorganic Materials, 2011, 26(1): 38-42. |

| [7] | LI Zai-Ying, DING Shi-Hua, SONG Tian-Xiu. Influence of Properties of Bi2(Zn1/3Nb2/3)2O7 Ceramics Doped with Na-Ni [J]. Journal of Inorganic Materials, 2010, 25(8): 825-828. |

| [8] | XIANG Jun,SHEN Xiang-Qian,ZHU Yong-Wei. Preparation and Magnetic Properties of Spinel-type Ferrite Fibres [J]. Journal of Inorganic Materials, 2008, 23(5): 1005-1010. |

| [9] | HU Hai,XIAO Wen-Jun,YUAN Jian,SHI Jian-Wei,SHANGGUAN Wen-Feng. Photocatalytic Activities of TiO2 and TiO2/Al2O3 Films Coated on Foam Nickel Substrates [J]. Journal of Inorganic Materials, 2007, 22(2): 363-368. |

| [10] | SONG Rui-Feng,YU Huai-Zhi,HUO Cheng-Song. Optical Properties and Microscopic Structures of Heat Isostatic Press(HIP)Processed Chemical Vapor Deposition Zinc Sulphide [J]. Journal of Inorganic Materials, 2002, 17(4): 872-876. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||