Journal of Inorganic Materials ›› 2016, Vol. 31 ›› Issue (8): 860-864.DOI: 10.15541/jim20150654

• Orginal Article • Previous Articles Next Articles

SUN Jin-Xing, CHEN Bin, LIU Pei-Sheng

Received:2015-12-29

Revised:2016-02-20

Published:2016-08-20

Online:2016-07-20

About author:SUN Jin-Xing. E-mail: sjx476526525@163.com

CLC Number:

SUN Jin-Xing, CHEN Bin, LIU Pei-Sheng. Preparation of Light Weight Porous Ceramics and Sound Absorption Performance Research[J]. Journal of Inorganic Materials, 2016, 31(8): 860-864.

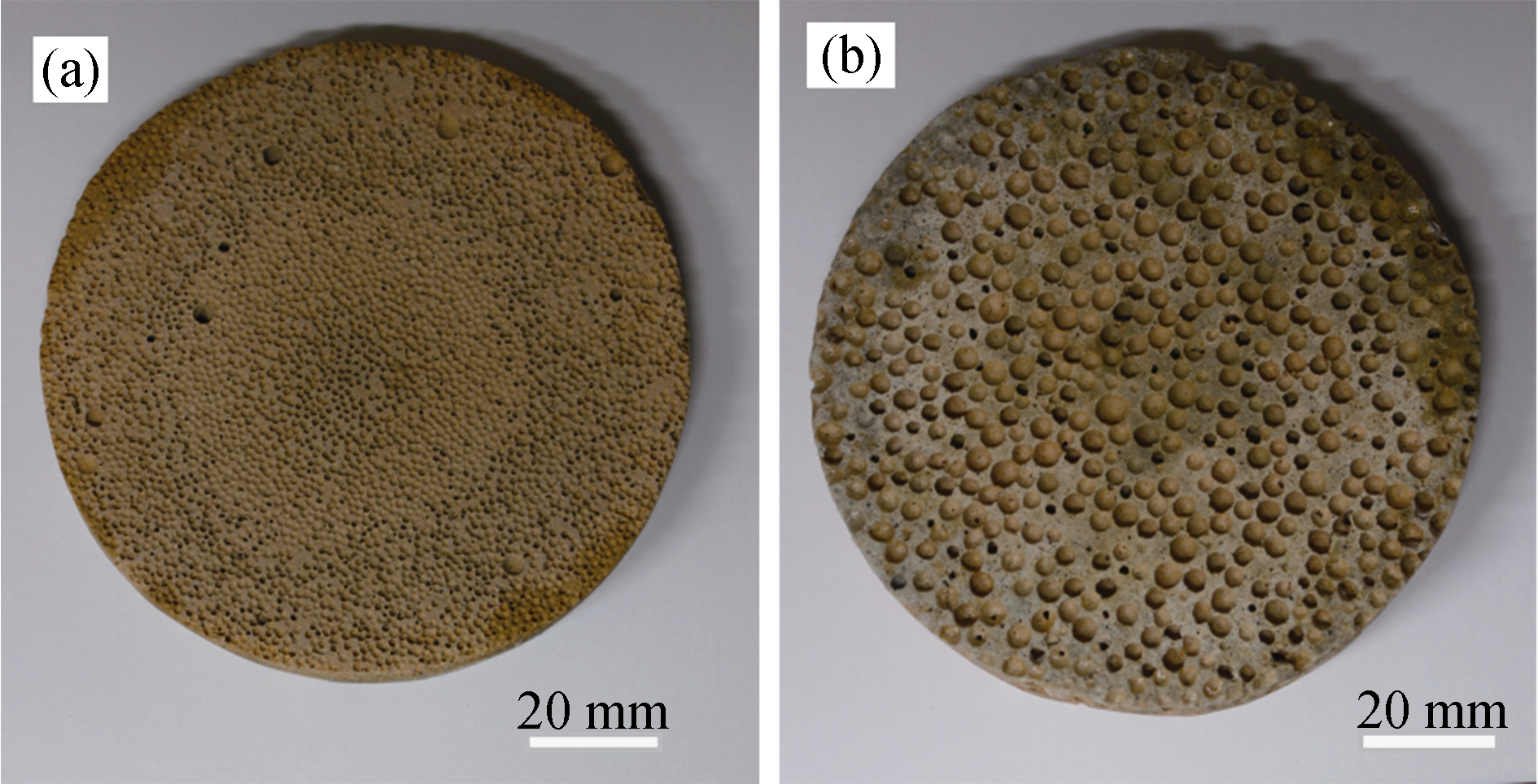

Fig. 1 Pictures of porous ceramics prepared from pore-forming agents with different pore sizes(a) Microporous ceramics (1-2 mm); (b) Macroporous ceramics (4-5 mm)

| [1] | LEI Y, PAN J, SHENG M P.Investigation of structural response and noise reduction of an acoustical enclosure using SEA method.Applied Acoustics, 2012, 73(12): 348-355. |

| [2] | MASAHIRO TOYODA, MIKITO TANNKA, DAIJII TAKAHASHI.Reduction of acoustic radiation by perforated board and honey comb layer systems.Applied Acoustics, 2007, 68(1): 71-78. |

| [3] | LIU J, HERRIN D W.Enhancing micro-perforated panel attenuation by partitioning the adjoining cavity.Applied Acoustics, 2010, 71: 120-127. |

| [4] | LOPEZ-HARO S A, GUTIERREZ M I, VERA A, et al. Modeling the thermo-acoustic effects of thermal-dependent speed of sound and acoustic absorption of biological tissues during focused ultrasound hyperthermia.Journal of Medical Ultrasonics, 2015, 42(4): 489-498. |

| [5] | RWAWIIRE SAMSON, TOMKOVA BLANKA, GLISCINSKA EULALIA, et al.Investigation of sound absorption properties of bark cloth non-woven fabric and composites.Autex Research Journal, 2015, 15(3): 173-180. |

| [6] | 毛东兴, 洪宗辉. 环境噪声控制工程, 2版. 北京: 高等教育出版社, 2010: 175. |

| [7] | XU WEIGANG, JIANG CHUNHAI, ZHANG JINSONG.Improvement in underwater acoustic absorption performance of open-celled SiC foam.Colloids and Surfaces A-Physicochemical and Engineering A Spects, 2015, 482: 568-574. |

| [8] | ZOU DAPENG, WILLIAMS KEVIN L, THORSOS ERIC I.Influence of temperature on acoustic sound speed and attenuation of seafloor sand sediment.IEEE Journal of Oceanic Engineering, 2014, 40(4): 969-980. |

| [9] | MICHEAL SCHEFFLER, PAOLO COLOMBO.Cellular Ceramics: Structure, Manufacturing, Properties and Applications. New York: John Wiley and Sons, 2006: 296-300. |

| [10] | GUO QIANGQIANG, XIANG HUIMIN, SUN XIN, et al.Preparation of porous YB4 ceramics using a combination of in-situ borothermal reaction and high temperature partial sintering.Journal of the European Ceramic Society, 2015, 35(13): 3411-3418. |

| [11] | HU HAILONG, ZENG YUPING, XIA YONGFENG, et al.High-strength porous Si3N4 ceramics prepared by freeze casting and silicon powder nitridation process.Materials Letters, 2014, 133: 285-288. |

| [12] | RANIER SEPULVEDA, AMELIA A PLUNK, DAVID C DUNAND.Microstructure of Fe2O3 scaffolds created by freeze- casting and sintering.Materials Letters, 2015, 142: 56-59. |

| [13] | SHI GUODONG, WU ZHANJUN, JIANGCHUNYU, et al. Porous alumina ceramics produced by physical vapor deposition assisted freeze-casting method.Materials Letters, 2015, 161: 580-582. |

| [14] | STUDART A R, GONZENBACH U T, TERVOORT E.Processing routes to macroporous ceramics: a review.Journal of the American Ceramic Society, 2006, 89(6): 1771-1789. |

| [15] | STEPHEN A BARR, ERIK LUIJTEN.Structural properties of materials created through freeze casting.Acta Materiallia, 2010, 58: 709-715. |

| [16] | ZHANG RUBING, HAN BINGYU, FANG DAINING, et al.Porous Y2SiO5 ceramics with a centrosymmetric structure produced by freeze casting.Ceramics International, 2015, 41(9): 11517-11522. |

| [17] | LIU CHUANBEI, LIU LAIBAO, TAN KEFENG, et al.Fabrication and characterization of porous cordierite ceramics prepared from ferrochromium slag.Ceramics International, 2015, 42(1): 734-742. |

| [18] | TAKAHIRO TOMITA, SHINJI KAWASAKI, KIYOSHI OKADA.Effect of viscosity on preparation of foamed silica ceramics by a rapid gelation foaming method.Journal of Porous Materials, 2005, 12(2): 123-129. |

| [19] | DESCAMPS M, RICHART O, HARDOUIN P, et al.Synthesis of macroporous β-tricalcium phosphate with controlled porous architectural.Ceramics International, 2008, 34: 1131-1137. |

| [20] | ANDRÉR STUDART, GONZENBACH URS T, ELENA TERVOORT, et al. Processing route to macroporous ceramics: a review.Journal of the American Ceramic Society, 2006, 89(6): 1771-1789. |

| [21] | XU CHANGMING, WANG SHIWEI, KATARINA FLODSTRÖM, et al. Cellular silica-based ceramics prepared by direct foaming at high temperature.Ceramics International, 2010, 36: 923-927. |

| [22] | LI LIUYUAN, WANG HONGJIE, SU SHAOCHANG, et al.Porous Si3N4 ceramics prepared by TBA-based gel-casting.Journal of Materials Science & Technology, 2015, 31(3): 295-299. |

| [23] | LIU XINLI, ZHANG HUIBIN, JIANG YAO, et al.Characterization and application of porous Ti3SiC2 ceramic prepared through reactive synthesis.Materials & Design, 2015, 79: 94-98. |

| [24] | DUAN CUIYUN, CUI GUANG, XU XINBANG, et al.Sound absorption characteristics of a high-temperature sintering porous ceramic material.Applied Acoustics, 2012, 73(9): 865-871. |

| [1] | WU Songze, ZHOU Yang, LI Runfeng, LIU Xiaoqian, LI Cuiwei, HUANG Zhenying. Reaction Sintered Porous Ceramics Using Iron Tailings: Preparation and Properties [J]. Journal of Inorganic Materials, 2023, 38(10): 1193-1199. |

| [2] | WANG Shiwei. Progress of Spontaneous Coagulation Casting of Ceramic Slurries Based on Hydrophobic Interaction [J]. Journal of Inorganic Materials, 2022, 37(8): 809-820. |

| [3] | ZHU Quan, HU Jianbao, YANG Jinshan, ZHOU Haijun, DONG Shaoming. Strong SiC Porous Ceramic Obtained by Sintering of Reticulated Aligned SiC Nanowires [J]. Journal of Inorganic Materials, 2021, 36(5): 547-551. |

| [4] | ZHANG Li, YANG Xianfeng, XU Xiewen, GUO Jinyu, ZHOU Zhe, LIU Peng, XIE Zhipeng. 3D Printed Zirconia Ceramics via Fused Deposit Modeling and Its Mechanical Properties [J]. Journal of Inorganic Materials, 2021, 36(4): 436-442. |

| [5] | DONG Longhao,ZHANG Haijun,ZHANG Jun,WU Wenhao,JIA Quanli. Carbon Nanotube Modified Sepiolite Porous Ceramics for High-efficient Oil/Water Separation [J]. Journal of Inorganic Materials, 2020, 35(6): 689-696. |

| [6] | XIE Yu-Zhou, PENG Chao-Qun, WANG Xiao-Feng, WANG Ri-Chu, LUO Feng. Porous Alumina Ceramic Prepared by HEMA-TBA Gelcasting System [J]. Journal of Inorganic Materials, 2017, 32(7): 731-738. |

| [7] | YUAN Wen-Yu, CHENG Lai-Fei,WU Heng, LIU Yong-Sheng. Effect of Silicon Source on Biomorphic SiC Fibers Converted from Natural Fibers [J]. Journal of Inorganic Materials, 2015, 30(2): 159-164. |

| [8] | LIU Gang, YAN Yan. Research Progress of Porous Ceramics Produced by Freeze Casting Technique [J]. Journal of Inorganic Materials, 2014, 29(6): 571-583. |

| [9] | WANG Hao, ZHOU Qing-Jun, JIAN Ke, SHAO Chang-Wei, ZHU Yi-Hua. Preparation of Ordered Porous Ceramic Joint on C/SiC Composites and Its Joining Technique [J]. Journal of Inorganic Materials, 2013, 28(7): 763-768. |

| [10] | PAN Jian-Mei, CHENG Xiao-Nong, YAN Xue-Hua, ZHANG Cheng-Hua, XU Gui-Fang. In situ Synthesis and Growth Mechanism of SiC Nanowires in SiCO Porous Ceramics [J]. Journal of Inorganic Materials, 2013, 28(5): 474-478. |

| [11] | SHEN Zhi-Xun, GE Min, CHEN Ming-Wei, QIAN Yang-Bao, ZHANG Wei-Gang. Oxidation Resistance and High Temperature Thermal Insulation of a Polymeric Precursor Derived BN/SiC Ceramics Foam [J]. Journal of Inorganic Materials, 2012, 27(12): 1306-1312. |

| [12] | LI Jun-Feng, LIN Hong, LI Jian-Bao. Influence Factors on the Porosity and Strength of SiC Porous Ceramic [J]. Journal of Inorganic Materials, 2011, 26(9): 944-948. |

| [13] | LIU Bin, DONG Yin-Sheng, LIN Ping-Hua, ZHANG Jun, SU Jing. Preparation of Polyphosphate Porous Bioceramics and in vitro Cytocompatibility [J]. Journal of Inorganic Materials, 2011, 26(7): 759-764. |

| [14] | LIN Ya-Mei, LI Cui-Wei, WANG Chang-An. Effects of Mullite Content on the Properties and Microstructure of Porous Anorthite/Mullite Composite Ceramics [J]. Journal of Inorganic Materials, 2011, 26(10): 1095-1100. |

| [15] | QI Hong, HAN Jing, JIANG Xiao-Luo, XING Wei-Hong, FAN Yi-Qun. Preparation and Hydrothermal Stability of Organic-inorganic Hybrid Silica Membrane [J]. Journal of Inorganic Materials, 2010, 25(7): 758-764. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||