Journal of Inorganic Materials ›› 2015, Vol. 30 ›› Issue (2): 141-146.DOI: 10.15541/jim20140323

• Orginal Article • Previous Articles Next Articles

GUO Xing-Zhong, CAI Xiao-Bo, SONG Jie, YANG Hui

Received:2014-06-24

Revised:2014-08-16

Published:2015-02-20

Online:2015-01-27

About author:GUO Xing-Zhong. E-mail: msewj01@zju.edu.cn

Supported by:CLC Number:

GUO Xing-Zhong, CAI Xiao-Bo, SONG Jie, YANG Hui. Preparation and Characterization of Macroporous Mayenite Monoliths[J]. Journal of Inorganic Materials, 2015, 30(2): 141-146.

| (CaCl2/AlCl3) /(g·g-1) | (EtOH/H2O) /(mL·mL-1) | EGa /mL | FAb /mL | POc /mL | PEOd /g | |

|---|---|---|---|---|---|---|

| CA01 | 1.044 / 2.000 | 3.00 / 3.00 | 0.40 | 0.50 | 1.50 | 0 |

| CA02 | 1.044 / 2.000 | 3.00 / 3.00 | 0.40 | 0.50 | 1.50 | 0.100 |

| CA03 | 1.044 / 2.000 | 3.00 / 3.00 | 0.40 | 0.50 | 1.50 | 0.200 |

| CA04 | 1.044 / 2.000 | 3.00 / 3.00 | 0.40 | 0.50 | 1.50 | 0.400 |

| CA05 | 1.044 / 2.000 | 3.50 / 2.50 | 0.40 | 0.50 | 1.50 | 0.200 |

| CA06 | 1.044 / 2.000 | 4.00 / 2.00 | 0.40 | 0.50 | 1.50 | 0.200 |

| CA07 | 1.044 / 2.000 | 2.50 / 3.50 | 0.40 | 0.50 | 1.50 | 0.200 |

| CA08 | 1.044 / 2.000 | 2.00 / 4.00 | 0.40 | 0.50 | 1.50 | 0.200 |

Table 1 Starting compositions of samples

| (CaCl2/AlCl3) /(g·g-1) | (EtOH/H2O) /(mL·mL-1) | EGa /mL | FAb /mL | POc /mL | PEOd /g | |

|---|---|---|---|---|---|---|

| CA01 | 1.044 / 2.000 | 3.00 / 3.00 | 0.40 | 0.50 | 1.50 | 0 |

| CA02 | 1.044 / 2.000 | 3.00 / 3.00 | 0.40 | 0.50 | 1.50 | 0.100 |

| CA03 | 1.044 / 2.000 | 3.00 / 3.00 | 0.40 | 0.50 | 1.50 | 0.200 |

| CA04 | 1.044 / 2.000 | 3.00 / 3.00 | 0.40 | 0.50 | 1.50 | 0.400 |

| CA05 | 1.044 / 2.000 | 3.50 / 2.50 | 0.40 | 0.50 | 1.50 | 0.200 |

| CA06 | 1.044 / 2.000 | 4.00 / 2.00 | 0.40 | 0.50 | 1.50 | 0.200 |

| CA07 | 1.044 / 2.000 | 2.50 / 3.50 | 0.40 | 0.50 | 1.50 | 0.200 |

| CA08 | 1.044 / 2.000 | 2.00 / 4.00 | 0.40 | 0.50 | 1.50 | 0.200 |

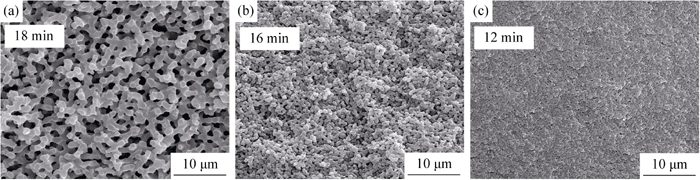

Fig. 2 SEM images of dried gels prepared with high volume ratios of ethanol to water (a) 1/1, (b) 7/5, (c) 2/1. Time inserted each image indicates the length of gelation time

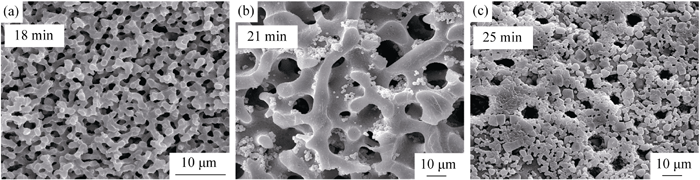

Fig. 3 SEM images of dried gels prepared with low volume ratios of ethanol to water (a) 1/1, (b) 5/7, (c) 1/2. Time inserted each image indicates the length of gelation time

| [1] | HOSONO H, ABE Y.Occurrence of superoxide radical ion in crystalline calcium aluminate 12CaO·7Al2O3 prepared via solid- state reactions.Inorg. Chem., 1987, 26(8): 1192-1195. |

| [2] | JEEVARATNAM J, GLASSER F P, GLASSER L S.Anion substitution and structure of 12CaO·7A12O3.J. Am. Ceram. Soc., 1964, 47(2): 105-106. |

| [3] | LI J, HUANG F, WANG L, et al.High density hydroxyl anions in a microporous crystal: [Ca24Al28O64]4+·4(OH-).Chem. Mater., 2005, 17: 2771-2774. |

| [4] | HAYASHI K, HIRANO M, MATSUISHI S, et al.J. Microporous crystal 12CaO·7Al2O3 encaging abundant O- radicals.J. Am. Chem. Soc., 2002, 124(5): 738-739. |

| [5] | HAYASHI K, MATSUISHI S, KAMIYA T, et al.Light-induced conversion of an insulating refractory oxide into a persistent electronic conductor.Nature, 2002, 419: 462-465. |

| [6] | MIYAKAWA M, HAYASHI K, HIRANO M, et al.Fabtication of highly conductive 12CaO·7Al2O3 thin films encaging hydride ions by proton implantation.Adv. Mater., 2003, 15(13): 1100-1103. |

| [7] | MATSUISHI S, TODA Y, MIYAKAWA M, et al.High-density electron anions in a nanoporous single crystal.Science, 2003, 301: 626-629. |

| [8] | TODA Y, MATSUISHI S, HAYASHI K, et al.Field emission of electron anions clathrated in subnanometer-sized cages in [Ca24Al28O64]4+·4(e-).Adv. Mater., 2004, 16(8): 685-689. |

| [9] | LI Z, YANG J, HOU J G, et al.Is mayenite without clathrated oxygen an inorganic electride.Angew. Chem., Int. Ed., 2004, 43: 6479-6482. |

| [10] | SUSHKO P V, SHLUGER A L, HIRANO M, et al.From insulator to electride: a theoretical model of nanoporous oxide 12CaO·7Al2O3.J. Am. Chem. Soc., 2007, 129(4): 942-951. |

| [11] | TODA Y, YANAGI H, IKENAGA E, et al.Work function of a room-temperature, stable electride [Ca24Al28O64]4+·4(e-).Adv. Mater., 2007, 19: 3564-3569. |

| [12] | MATSUISHI S, NOMURA T, HIRANO M, et al.Direct synthesis of powdery inorganic electride [Ca24Al28O64]4+·4(e-) and determination of oxygen stoichiometry.Chem. Mater., 2009, 21: 2589-2591. |

| [13] | KURASHIGE K, TODA Y, MATSTUISHI S, et al.Czochralski growth of 12CaO·7Al2O3 crystals.Cryst. Growth Design, 2006, 6(7): 1602-1605. |

| [14] | ZAHEDI M, RAY A K, BARRATT D S.Preparation and crystallization of Sol-Gel C12A7 thin films.J. Phys. D: Appl. Phys., 2008, 41: 035404-035408. |

| [15] | NAKANISHI K, TANAKA N.Sol-Gel with phase separation hierarchically porous materials optimized for high-performance liquid chromatography separations.Acc. Chem. Res., 2007, 40(9): 863-873. |

| [16] | KITADA A, HASEGAWA G, KOBAYASHI Y, et al.Selective preparation of macroporous monoliths of conductive titanium oxides TinO2n-1 (n = 2, 3, 4, 6).J. Am. Chem. Soc., 2012, 134: 10894-10898. |

| [17] | NAKANISHI K.Pore structure control of silica gels based on phase separation.J. Porous Mater., 1997, 4(2): 67-112. |

| [18] | HASEGAWA G, KANAMORI K, NAKANISHI K, et al.Facile preparation of hierarchically porous TiO2 monoliths.J. Am. Ceram. Soc., 2010, 93(10): 3110-3115. |

| [19] | KONISHI J, FUJITA K, OIWA S, et al.Crystalline ZrO2 monoliths with well-defined macropores and mesostructured skeletons prepared by combining the alkoxy-derived Sol-Gel process accompanied by phase separation and the solvothermal process.Chem. Mater., 2008, 20(6): 2165-2173. |

| [20] | GASH A E, TILLOTSON T M, SATCHER J H, et al.Use of epoxides in the Sol-Gel synthesis of porous iron(III) oxide monoliths from Fe(III) salts.Chem. Mater., 2001, 13: 999-1007. |

| [21] | GASH A E, SATCHER J H, SIMPSON R L, et al.Strong akaganeite aerogel monoliths using epoxides: synthesis and characterization.Chem. Mater., 2003, 15: 3268-3275. |

| [22] | TOKUDOME Y, FUJITA K, NAKANISHI K, et al.Synthesis of monolithic Al2O3 with well-defined macropores and mesostructured skeletons via the Sol-Gel process accompanied by phase separation.Chem. Mater., 2007, 19(14): 3393-3398. |

| [23] | HASEGAWA G, ISHIHARA Y, KANAMORI K, et al.Facile preparation of monolithic LiFePO4/Carbon Composites with well-defined macropores for a lithium-ion battery.Chem. Mater., 2011, 23: 5208-5216. |

| [24] | KIDO Y, NAKANISHI K, MIYASAKA A, et al.Synthesis of monolithic hierarchically porous iron-based xerogels from iron(III) salts via an epoxid-mediated Sol-Gel process.Chem. Mater., 2012, 24: 2071-2077. |

| [25] | GUO X Z, LI W Y, ZHU Y, et al.Macroporous SiO2 monoliths prepared via Sol-Gel process accompanied by phase separation.Acta Phys.-Chim. Sin., 2013, 29(3): 646-652. |

| [26] | GUO X Z, LÜLIN Y X, YANG H. Preparation of macroporous zirconia monoliths via Sol-Gel process accompanied by phase separation.J. Chin. Ceram. Soc., 2014, 42(1): 6-10. |

| [27] | GUO X Z, LI W Y, NAKANISHI K, et al.Preparation of mullite monoliths with well-defined macropores and mesostructured skeletons via the Sol-Gel process accompanied by phase separation. J. Eur. Ceram. Soc., 2013, 33(10): 1967-1974. |

| [28] | GUO X Z, NAKANISHI K, KANAMORI K, et al.Preparation of macroporous cordierite monoliths via the Sol-Gel process accompanied by phase separation.J. Eur. Ceram. Soc., 2014, 34: 817-823. |

| [29] | XU Z J, GAN L H, PANG Y C, et al.Preparation of Al2O3 bulk aerogels by non-supercritical fluid drying.Acta Phys. -Chim. Sin., 2005, 21(2): 221-224. |

| [30] | SAEKI S, KUWAHARA N, NAKATA M, et al.Upper and lower critical solution temperatures in poly (ethylene glycol) solutions.Polymer, 1976, 17(8): 685-689. |

| [31] | SUN J Q, GONG L, SHEN J, et al.Sol-Gel preparation of porous C12A7-Cl- crystals.Acta Phys.-Chim. Sin., 2010, 26(3): 795-798. |

| [1] | GUO Ziyu, ZHU Yunzhou, WANG Li, CHEN Jian, LI Hong, HUANG Zhengren. Effect of Zn2+ Catalyst on Microporous Structure of Porous Carbon Prepared from Phenolic Resin/Ethylene Glycol [J]. Journal of Inorganic Materials, 2025, 40(5): 466-472. |

| [2] | SHEN Bin, ZHANG Xu, XIONG Huai, LI Haiyuan, XIE Xinglong. Preparation and Optical Properties of Sol-Gel SiO2 Antireflective Films [J]. Journal of Inorganic Materials, 2024, 39(5): 525-530. |

| [3] | DAI Le, LIU Yang, GAO Xuan, WANG Shuhao, SONG Yating, TANG Mingmeng, DMITRY V Karpinsky, LIU Lisha, WANG Yaojin. Self-polarization Achieved by Compositionally Gradient Doping in BiFeO3 Thin Films [J]. Journal of Inorganic Materials, 2024, 39(1): 99-106. |

| [4] | JIA Yuna, CAO Xu, JIAO Xiuling, CHEN Dairong. Preparation of Alumina Ceramic Continuous Fibers with Inorganic Acidic Aluminum Sol as Precursor [J]. Journal of Inorganic Materials, 2023, 38(11): 1257-1264. |

| [5] | MAN Xin, WU Nan, ZHANG Mu, HE Hongliang, SUN Xudong, LI Xiaodong. Lu2O3-MgO Nano-powder: Synthesis and Fabrication of Composite Infrared Transparent Ceramics [J]. Journal of Inorganic Materials, 2021, 36(12): 1263-1269. |

| [6] | YANG Conggang, MI Le, FENG Aihu, YU Yang, SUN Dazhi, YU Yun. Synthesis and Performance of KH-560 Modified SiO2 Insulation Coating [J]. Journal of Inorganic Materials, 2021, 36(12): 1343-1348. |

| [7] | ZHU Ben-Bi,ZHANG Wang,ZHANG Zhi-Jian,ZHANG Jian-Zhong,IMRAN Zada,ZHANG Di. Photothermal Enhanced Photocatalytic Properties of Titanium Dioxide (B)/Glass Fiber Cloth [J]. Journal of Inorganic Materials, 2019, 34(9): 961-966. |

| [8] | Shao-Dan ZHANG, Wei-Wei BAO, Hai-Ping MA. Near-infrared Reflective Pigments Based on Cu 2+ and Tb 3+ Codoped BaZrO3: Preparation and Performance [J]. Journal of Inorganic Materials, 2019, 34(6): 599-604. |

| [9] |

LIU Qian, ZHOU Zhen-Zhen.

Progress in Activated-synthesis of Si-based Oxynitrides Materials at Low Temperatures [J]. Journal of Inorganic Materials, 2018, 33(2): 129-137. |

| [10] | LI Jia-Ke, HAN Xiao-Qi, LIU Xin, WANG Yan-Xiang, GUO Ping-Chun, YANG Zhi-Sheng. Preparation of High Specific Surface Area Micro/Meso-porous SiOC Ceramics by the Low Temperature Phase Separation Method [J]. Journal of Inorganic Materials, 2018, 33(12): 1360-1364. |

| [11] | ZHAO Hui-Yue, WANG Xiao-Dong, FENG Jian-Bin, LIU Yuan, HUANG Ji-Chen, SHEN Jun. Environmental Stable SiO2 Antireflective Coating Modified via NH3/HTMS Vapor Phase Treatment [J]. Journal of Inorganic Materials, 2018, 33(11): 1219-1224. |

| [12] | HE Fei, LI Ya, LUO Jin, FANG Min-Han, HE Xiao-Dong. Development of SiO2/C and SiC/C Composites Featuring Aerogel Structures [J]. Journal of Inorganic Materials, 2017, 32(5): 449-458. |

| [13] | LU Shu-Juan, WANG Chang, ZHAO Bo-Wen, WANG Hao, LIU Jing-Bing, YAN Hui. Electrochromic Properties of PEG-modified Tungsten Oxide Thin Films [J]. Journal of Inorganic Materials, 2017, 32(2): 185-190. |

| [14] | CHEN Ting, ZHA Jian-Rui, ZHANG Xiao-Jun, JIANG Wei-Hui, JIANG Wan, LIU Jian-Min, WU Qian. Silane Coupling Agent on Synthesis and Antioxidation Property of Zircon Film [J]. Journal of Inorganic Materials, 2017, 32(11): 1154-1158. |

| [15] | ZHENG Lei, LI Jin, LIU Hong-Bo. Carbon Aerogels Prepared Based on Sol-Gel Reaction of Cellulose Colloid with AEP and Its Adsorption of Copper Ions in Aqueous Solution [J]. Journal of Inorganic Materials, 2017, 32(11): 1159-1164. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||