Journal of Inorganic Materials ›› 2018, Vol. 33 ›› Issue (4): 373-379.DOI: 10.15541/jim20170206

• Orginal Article • Previous Articles Next Articles

XU Jian-Xin1, SHAN Ying-Chun1, WANG Guang1, XU Jiu-Jun1, WANG Liang1, LI Jiang-Tao2

Received:2017-04-28

Revised:2017-06-20

Published:2018-04-30

Online:2018-03-27

About author:XU Jian-Xin. E-mail: xujianxinxjx@163.com

Supported by:CLC Number:

XU Jian-Xin, SHAN Ying-Chun, WANG Guang, XU Jiu-Jun, WANG Liang, LI Jiang-Tao. Nucleation Density on the Synthesis of AlON Powder and Preparation of Transparent Ceramics[J]. Journal of Inorganic Materials, 2018, 33(4): 373-379.

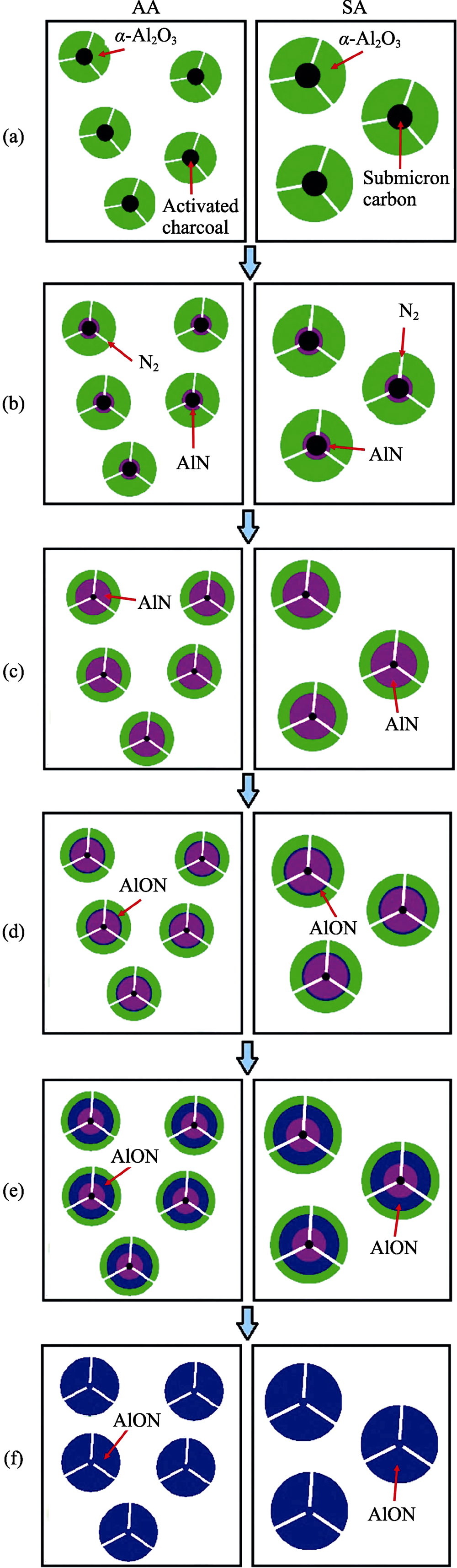

Fig. 10 Formation process of AlON powder synthesized by carbothermal reduction and nitridation(a) Mixture of Al2O3 and C; (b) Heated to 1550℃; (c) Held at 1550℃ for 60 min; (d) ≥1700℃; (e) After holding at 1750℃ for a period of time (<60 min); (f) Held at 1750℃ for 60 min

| [1] | JIANG DONG-LIANG.Transparent ceramics: one of the most impoetant field of research and development of inorganic materials.Journal of Inorganic Materials, 2009, 24(5): 873-881. |

| [2] | JIN X, LIAN G, JING S,et al. Highly transparent AlON pressurelessly sintered from powder synthesized by a novel carbothermal nitridation method. J. Am. Ceram. Soc., 2012, 95(9): 2801-2807. |

| [3] | SONG K X, WU S Y, CHEN X M.Effects of Y2O3 addition on microwave dielectric characteristics of Al2O3 ceramics.Mater. Lett., 2007, 61(16): 3357-3360. |

| HARTNETT T M, BERNSTEIN S D, MAGUIRE E A,et al. Op- tical properties of AlON (aluminum oxynitride).Infrared. Phys. Technol., 1998, 39(4): 203-211. | |

| [4] | KRELL A, HUTZLER T, KLIMKE J.Transmission physics and consequences for materials selection, manufacturing, and applications.J. Eur. Ceram. Soc., 2009, 29(2): 207-221. |

| [5] | LIAO L L, TAN S H, JIANG D L.Liquid-phase sintering of SiC with Al-B4C-C as sintering aids.Journal of Inorganic Materials, 2002, 17(2): 265-270. |

| [6] | WEINGARTEN N S, BYRD E F C. Special quasirandom structures of AlON.Comput. Mater. Sci., 2015, 96(PartA): 312-318. |

| [7] | TU B, WANG H, LIU X,et al. First-principles study on site preference of aluminum vacancy and nitrogen atoms in γ-AlON. J. Am. Ceram. Soc., 2013, 96(6): 1937-1943. |

| [8] | ZHANG N, LIANG B, WANG X Y,et al. The pressureless sintering and mechanical properties of AlON ceramic. Mater. Sci. Eng. A, 2011, 528(19): 6259-6262. |

| [9] | LEI JING-XUAN, SHI YING, XIE JIAN-JUN,et al. Effect of carbon sources on synthesis of AlON powder and fabrication of transparent ceramics. Journal of Materials Engineering, 2015, 43(8): 37-42. |

| [10] | YAO XIU-MIN, LIANG HAN-QIN, LIU XUE-JIAN,et al. Effect of carbon source and adding ratio on the microstructure and properties of solid-state sintering silicon carbide. Journal of Inorganic Materials, 2013, 28(9): 1009-1013. |

| [11] | SHAN YING-CHUN, XU JIAN-XIN, GUAN CHUN-LONG,et al. Effects of milling time on phase assemblages of AlON powders synthesized by CTRN. Journal of Functional Materials, 2014, 45(4): 112-115. |

| [12] | LIU JING, LIU JUN, LI JIANG,et al. Influence of ball milling speed on microstructure and optical transparency of Nd: YAG ceramics. Journal of Inorganic Materials, 2015, 30(6): 581-587. |

| [13] | LIU XUE-JIAN, YUAN XIAN-YANG, ZHANG FANG,et al. Fabrication of aluminum oxynitride transparent ceramics by carbothermal reduction nitridation processin. Journal of Inorganic Materials, 2010, 25(7): 678-682. |

| [14] | LIU Q, JIANG N, LI J,et al. Highly transparent AlON ceramics sintered from powder synthesized by carbothermal reduction nitridation. Ceram. Int., 2016, 42(7): 8290-8295. |

| [15] | OFFERMAN S E, DIJK N H V, SIETSMA J,et al. Grain nucleation and growth during phase transformations. Science, 2002, 298(5595): 1003-1005. |

| [16] | LEE S Y, FEIGELSON R S.Reduced optical losses in MOCVD grown lithium niobate thin films on sapphire by controlling nucleation density.J. Cryst. Growth, 1998, 186(4): 594-606. |

| [17] | EASTON M, STJOHN D.An analysis of the relationship between grain size, solute content, and the potency and number density of nucleant particles.Metall. Mater. Trans. A, 2005, 36(7): 1911-1920. |

| [18] | LEE Y C, DAHLE A K, STJOHN D H,et al. The effect of grain refinement and silicon content on grain formation in hypoeutectic Al-Si alloys. Mater. Sci. Eng. A, 1999, 259(1): 43-52. |

| [19] | CORBIN N D.Aluminum oxynitride spinel: a review.J. Eur. Ceram. Soc., 1989, 5(3): 143-154. |

| [1] | JIN Xihai, DONG Manjiang, KAN Yanmei, LIANG Bo, DONG Shaoming. Fabrication of Transparent AlON by Gel Casting and Pressureless Sintering [J]. Journal of Inorganic Materials, 2023, 38(2): 193-198. |

| [2] | LU Chenhui, GE Wanyin, SONG Panpan, ZHANG Panfeng, XU Meimei, ZHANG Wei. Luminescence Property of Eu Doped SiAlON Phosphors for White LEDs [J]. Journal of Inorganic Materials, 2023, 38(1): 97-104. |

| [3] | ZHANG Zhou, WANG Hao, TU Bing-Tian, XU Peng-Yu, WANG Wei-Min, FU Zheng-Yi. Characterization and Evaluation on Mechanical Property of Mg0.27Al2.58O3.73N0.27 Transparent Ceramic [J]. Journal of Inorganic Materials, 2018, 33(9): 1006-1010. |

| [4] | GU Hui. Correlation of Intergranular Amorphous Structures on Multi-levelled Phase Relationship in Sialon Ceramics: Retrospect and Prospect [J]. Journal of Inorganic Materials, 2018, 33(2): 147-152. |

| [5] | SONG Yun-Fei, WANG Shao-Hua, DENG Cheng-Ji, ZHU Hong-Xi, LIU Jian-Peng, DING Jun, YU Chao. Effects and Oxidation Kinetics of Holding Time on the β-Sialon Bonded MgAl2O4-C Composites [J]. Journal of Inorganic Materials, 2017, 32(5): 495-501. |

| [6] | PENG Ben, QIU Gui-Bo, YUE Chang-Sheng, ZHANG Mei, GUO Ming. Controllable Synthesis of One-dimensional β-SiAlON Materials [J]. Journal of Inorganic Materials, 2014, 29(7): 706-710. |

| [7] | LI Yan-Yun, LI Song-Mei, LIU Jian-Hua, YU Mei. Preparation and Anti-mildew Properties of TPN-SDS-layered Double Hydroxide Nanohybrids [J]. Journal of Inorganic Materials, 2014, 29(5): 515-522. |

| [8] | YUAN Xian-Yang, ZHANG Fang, LIU Xue-Jian, ZHANG-Zhao, WANG Shi-Wei. Fabrication of Transparent AlON Ceramics by Solid-state Reaction Sintering [J]. Journal of Inorganic Materials, 2011, 26(5): 499-502. |

| [9] | LIU Xue-Jian, YUAN Xian-Yang, ZHANG Fang, HUANG Zheng-Ren, WANG Shi-Wei. Fabrication of Aluminum Oxynitride Transparent Ceramics by Carbothermal Reduction Nitridation Processing [J]. Journal of Inorganic Materials, 2010, 25(7): 678-682. |

| [10] | HAO Hong-Shun, XU Li-Hua, ZHAI Wei, ZHANG Zuo-Shun, ZHANG Xiao-Meng, XIE Zhi-Peng. Development of Sialon Ecomaterials Drived from Solid Waste of Containing Silican and Aluminum [J]. Journal of Inorganic Materials, 2010, 25(11): 1121-1127. |

| [11] | LIU Xue-Jian,LI Hui-Li,HUANG Zheng-Ren,WANG Shi-Wei,JIANG Dong-Liang. Preparation of Aluminum Oxynitride Powders by Solid-State Reaction [J]. Journal of Inorganic Materials, 2009, 24(6): 1159-1162. |

| [12] | YUE Chang-Sheng,GUO Ming,ZHANG Mei,WANG Xi-Dong,ZHANG Zhi-An,PENG Ben. Controllable Synthesis of High-purity β-SiAlON Powder [J]. Journal of Inorganic Materials, 2009, 24(6): 1163-1167. |

| [13] | LI Peng-Liang,ZHOU Jing-En,XI Sheng-Qi. Cubic AlN Synthesized by High Energy Ball Milling and Its Phase Conversion at High Temperature [J]. Journal of Inorganic Materials, 2006, 21(4): 821-827. |

| [14] | LIU Guang-Hua,CHEN Ke-Xin,ZHOU He-Ping,GUO Jun-Ming,NING Xiao-Shan. Fabrication of Yb α-SiAlON Ceramics by SPS with Crystal Seeds Prepared through Combustion Synthesis [J]. Journal of Inorganic Materials, 2005, 20(3): 659-665. |

| [15] | YANG Shi-E,LU Zhan-Ling,FAN Zhi-Qin,YAO Ning,ZHANG Bing-Lin. Highly Adherent Diamond Film Deposited onto WC-Co Cemented Carbide Substrate [J]. Journal of Inorganic Materials, 2005, 20(1): 235-238. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||