Journal of Inorganic Materials ›› 2014, Vol. 29 ›› Issue (9): 905-911.DOI: 10.15541/jim20140019

• Orginal Article • Previous Articles Next Articles

WANG Jing1, WU Xia2, DENG Chao-Yong2, ZHU Kong-Jun1, NAN Ce-Wen3

Received:2014-01-08

Revised:2014-03-09

Published:2014-09-17

Online:2014-08-21

Supported by:CLC Number:

WANG Jing, WU Xia, DENG Chao-Yong, ZHU Kong-Jun, NAN Ce-Wen. Research Progress of Film/Bulk Oxide Magnetoelectric Composites[J]. Journal of Inorganic Materials, 2014, 29(9): 905-911.

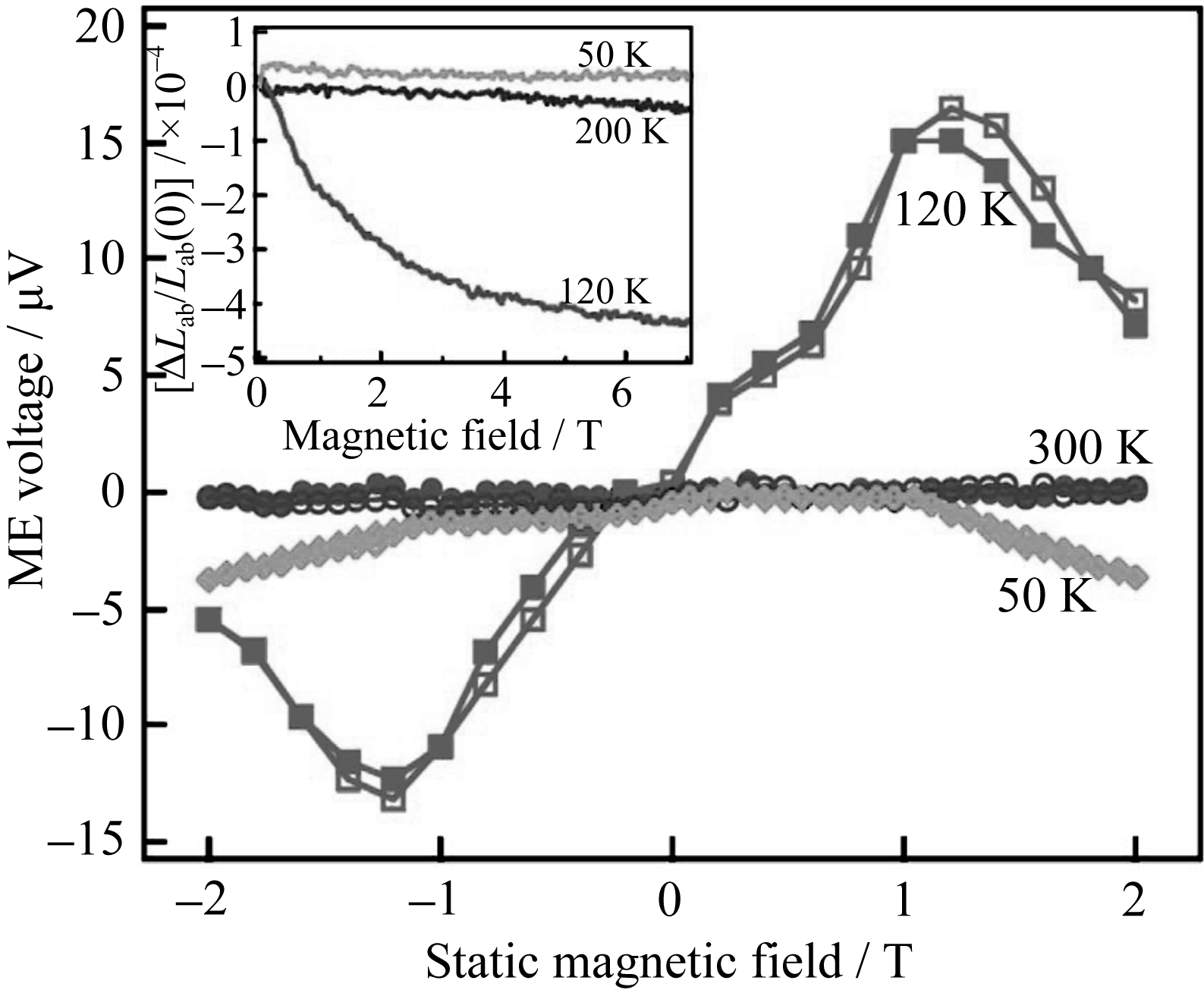

Fig. 1 ME voltage of PZT/LSMO vs static magnetic field at different temperatures. The inset shows the magnetostrictive strain of LSMO at different temperatures[14]

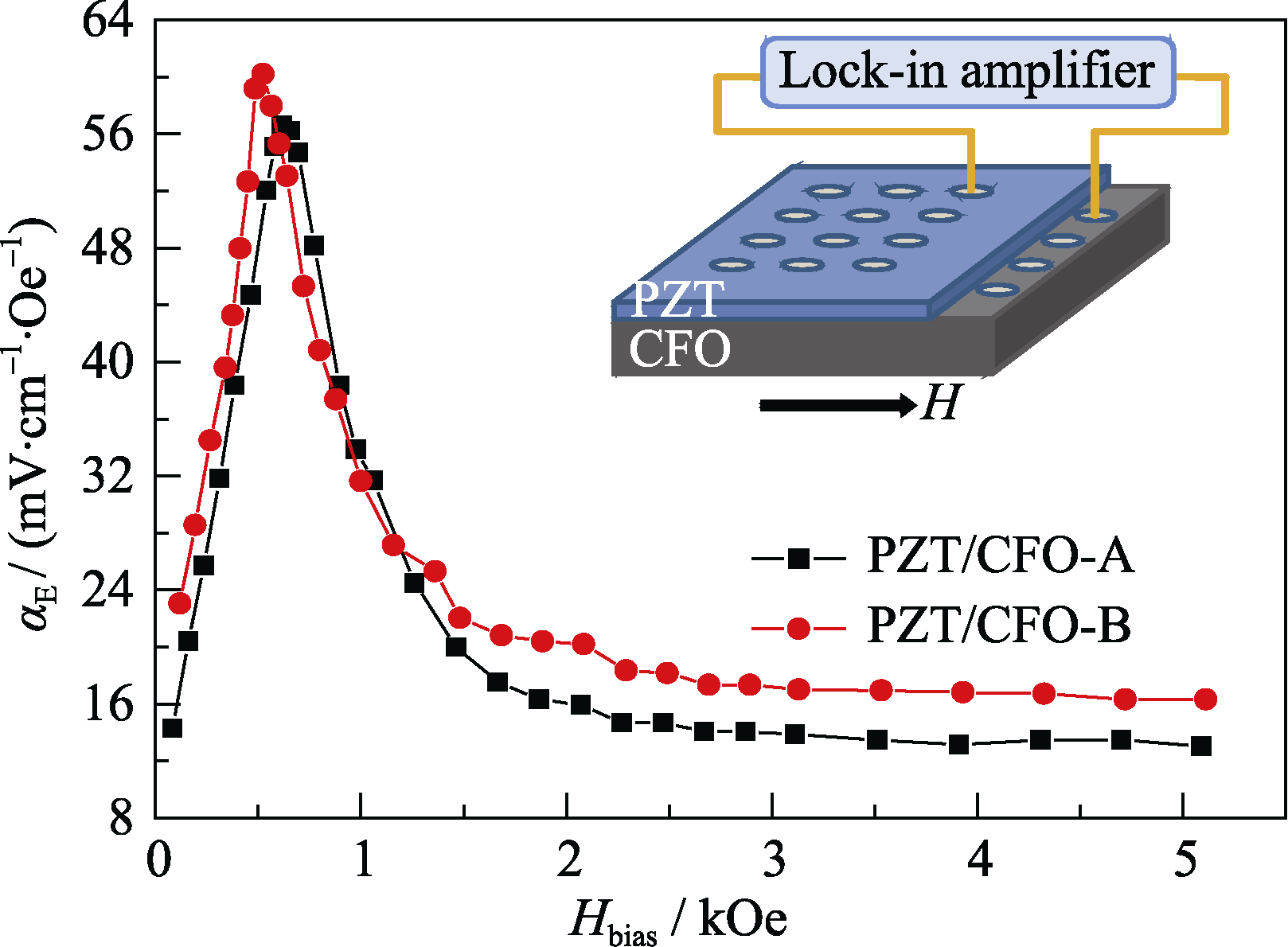

Fig. 3 Magnetic bias dependence of the in-plane magnetoelectric coefficient αE of PZT/CFO-A and PZT/CFO-B samples, The inset is a schematic of measurement [16]

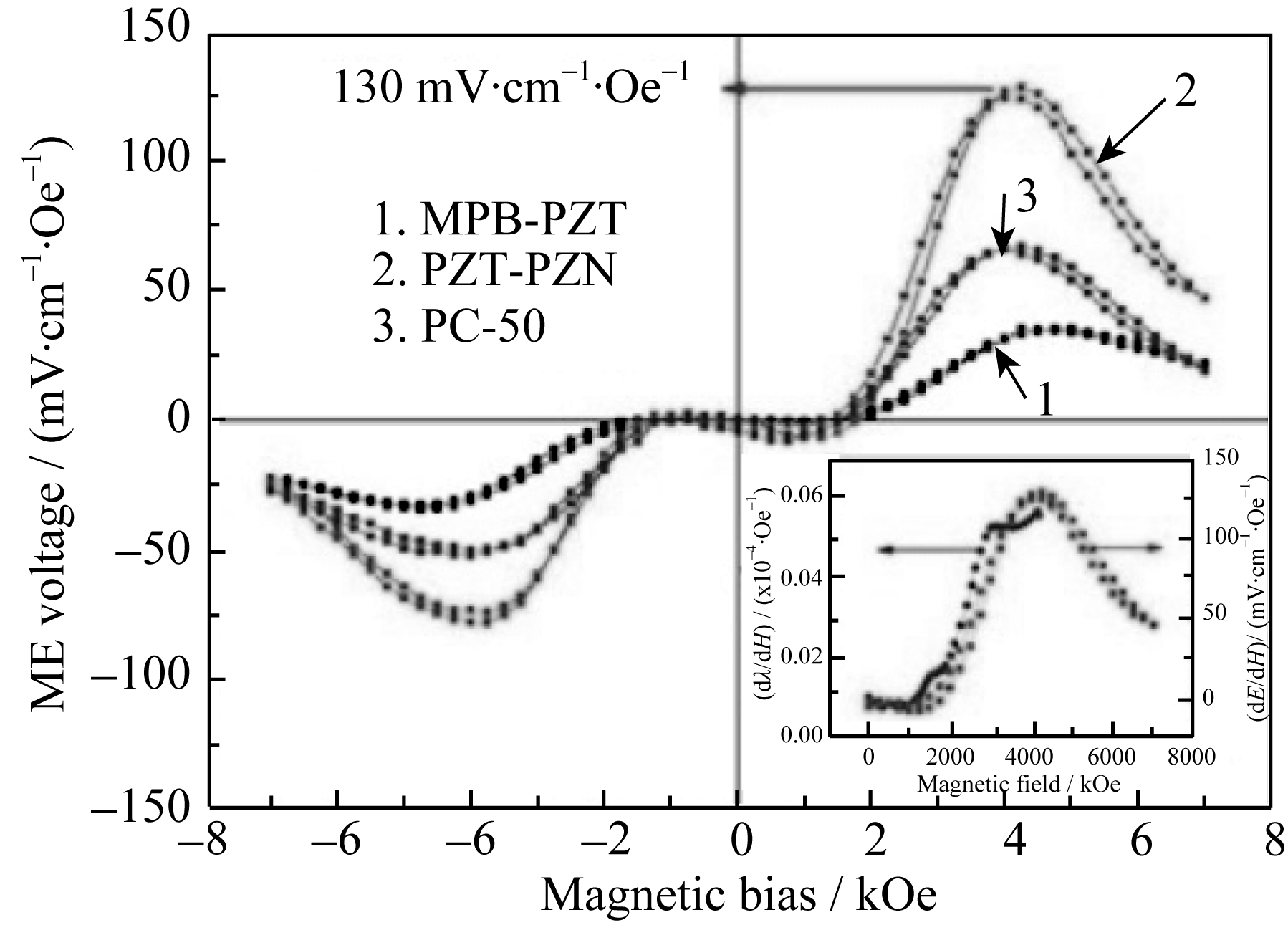

Fig. 4 Magnetoelectric voltage coefficient of MPB-PZT/Ag/CFO, PZT-PZN/Ag/CFO and PZT/Ag/CFO as a function of applied magnetic bias. The inset shows dE/dH and |dλ11/dH| with applied magnetic field[20]

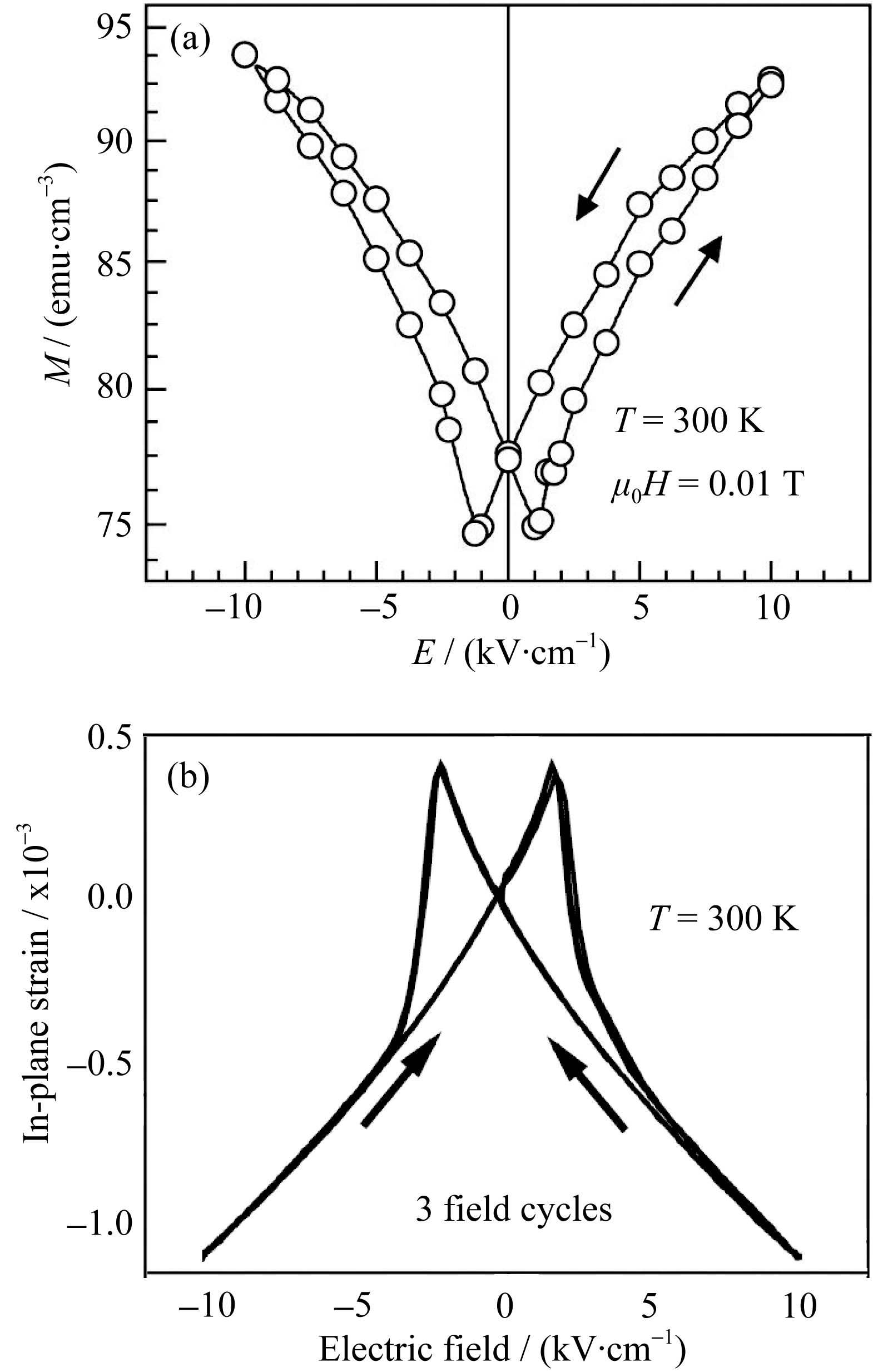

Fig. 6 Dependence of (a) the magnetization of LSMO film and (b) in-plane strain of PMN-PT on the electric field applied to the substrate (recorded for three cycles)[26-27]

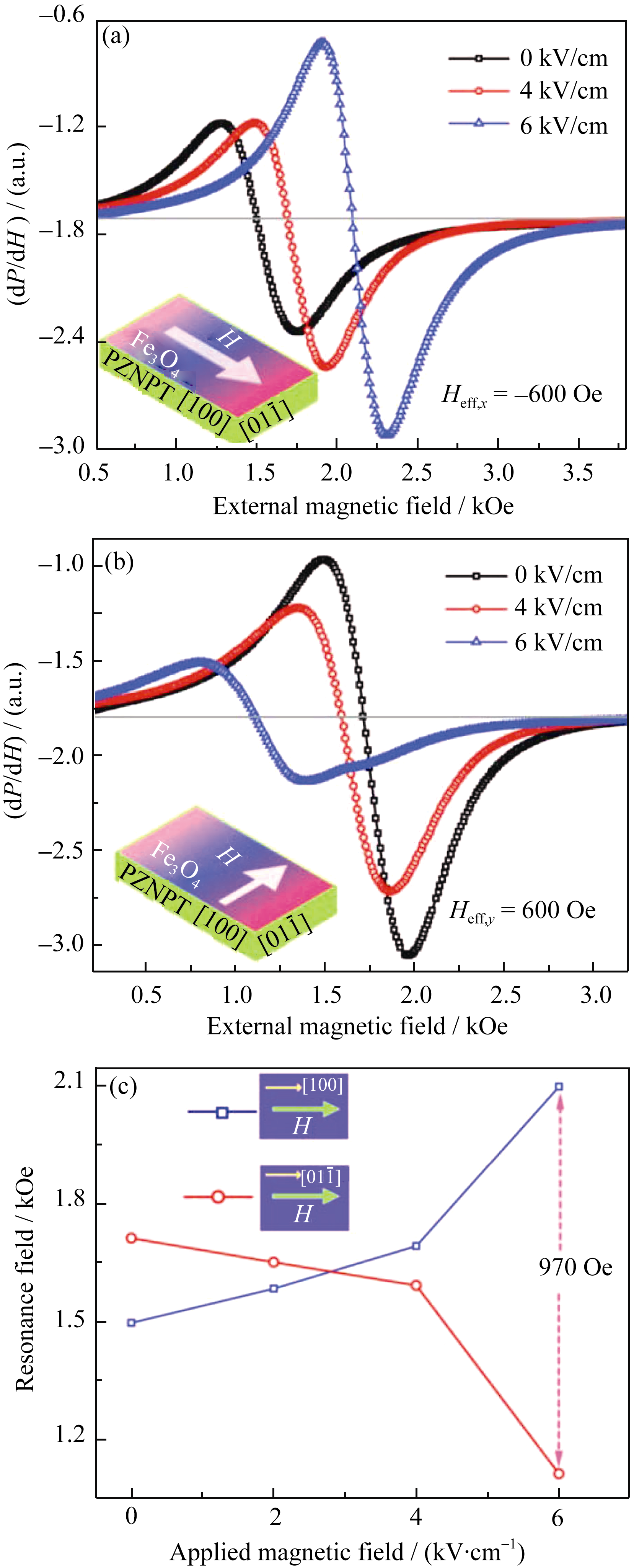

Fig. 7 FMR absorption spectra at different electric fields while the external magnetic fields was applied along (a) [100] and (b)[01 ] directions of PZN-PT, comparison of FMR absorption peak along [100] and [01 ] at different electric fields (c)[33]

| [1] | EERENSTEIN W, MATHUR N D, SCOTT J F. Multiferroic and magnetoelectric materials. Nature, 2006, 442(7104): 759-765. |

| [2] | SPALDIN N A, FIEBIG M. The renaissance of magnetoelectric multiferroics. Science, 2005, 309(5733): 391-392. |

| [3] | HILL N A. Why are there so few magnetic ferroelectrics?J. Phys. Chem. B, 2000, 104(29): 6694-6709. |

| [4] | MA J, HU J M, LI Z., et al. Recent progress in multiferroic magnetoelectric composites: from bulk to thin films. Adv. Mater., 2011, 23(9): 1062-1087. |

| [5] | NAN C W, BICHURIN M I, DONG S X, et al. Multiferroic magnetoelectric composites: historical perspective, status, and future directions. J. Appl. Phys. , 2008, 103(3): 031101-1-35. |

| [6] | VAN RUN A M J G, TERRELL D R, SCHOLING J H. An in situ grown electric magnetoelectric composite material: part II physical properties. J. Mater. Sci., 1974, 9: 1710-1714. |

| [7] | DEVAN R S, CHOUGULE B K. Effect of composition on coupled electric, magnetic, and dielectric properties of two phase particulate magnetoelectric composite. J. Appl. Phys., 2007, 101(1): 014109. |

| [8] | DEVAN R S, KANAMADI C M, LOKARE S A, et al. Electrical properties and magnetoelectric effect measurement in xNi0.8Cu0.2Fe2O4- (1-x)Ba0.9Pb0.1Ti0.9Zr0.1O3 composites. Smart Mater. Struct., 2006, 15(6): 1877-1881. |

| [9] | LI Y J, CHEN X M, LIN Y Q, et al. Magnetoelectric effect of Ni0.8Zn0.2Fe2O4/Sr0.5Ba0.5Nb2O6 composites. J. Eur. Ceram. Soc., 2006, 26(13): 2839-2844. |

| [10] | JIANG Q H, SHEN Z J, ZHOU J P, et al. Magnetoelectric composites of nickel ferrite and lead zirconnate titanate prepared by spark plasma sintering. J. Eur. Ceram. Soc., 2007, 27(1): 279-284. |

| [11] | AGRAWAL S, CHENG J P, GUO R Y, et al. Magnetoelectric properties of microwave sintered particulate composites. Mater. Lett., 2009, 63(26): 2198-2200. |

| [12] | ZHAI J, XING Z, DONG S, et al. Magnetoelectric laminate composites: an overview. J. Am. Ceram. Soc., 2008, 91(2): 351-358. |

| [13] | ZURBUCHEN M A, WU T, SAHA S, et al. Multiferroic composite ferroelectric-ferromagnetic films. Appl. Phys. Lett., 2005, 87(23): 232908. |

| [14] | WU T, ZURBUCHEN M A, SAHA S, et al. Observation of magnetoelectric effect in epitaxial ferroelectric film/manganite crystal heterostructures. Phys. Rev. B, 2006, 73(13): 134416. |

| [15] | WANG J, ZHANG Y, MA J, et al. Magnetoelectric behavior of BaTiO3 films directly grown on CoFe2O4 ceramics. J. Appl. Phys., 2008, 104(1): 014101. |

| [16] | WANG J, WANG L, LIU G, et al. Substrate effect on the magnetoelectric behavior of Pb(Zr0.52Ti0.48)O3 film-on-CoFe2O4 bulk ceramic composites prepared by direct solution spin coating. J. Am. Ceram. Soc., 2009, 92(11): 2654-2660. |

| [17] | WANG J, LI Z, SHEN Y, et al. Enhanced magnetoelectric coupling in Pb(Zr0.52Ti0.48)O3 film-on-CoFe2O4 bulk ceramic composite with LaNiO3 bottom electrode. J. Mater. Sci., 2013, 48(3): 1021-1026. |

| [18] | WANG J, LI Z, SHEN Y, et al. Modulation of magnetoelectric effect of Pb(Zr,Ti)O3-film-on-CoFe2O4 ceramic composites by LaNiO3 interface layer. J. Chin. Ceram. Soc., 2013, 41(10): 1313-1317. |

| [19] | PARK C S, KHACHATURYAN A, PRIYA S. Giant magnetoelectric coupling in laminate thin film structure grown on magnetostrictive substrate. Appl. Phys. Lett., 2012, 100(19): 192904. |

| [20] | OH N K, HAN G, YOON W H, et al. 2-2 structured magnetoelectric composites by aerosol deposition. J. Am. Ceram. Soc., 2012, 95(3): 855-858. |

| [21] | RYU J, BAEK C W, LEE Y S, et al. Enhancement of multiferroic properties in BiFeO3-Ba(Cu1/3Nb2/3)O3: film fabricated by aerosol deposition. J. Am. Ceram. Soc., 2011, 94(2): 355-358. |

| [22] | CHOPDEKAR R V, SUZUKI Y. Magnetoelectric coupling in epitaxial CoFe2O4 on BaTiO3. Appl. Phys. Lett., 2006, 89(18): 182506. |

| [23] | LEE M K, NATH T K, EOM C B, et al. Strain modification of epitaxial perovskite oxide thin films using structural transitions of ferroelectric BaTiO3 substrate. Appl. Phys. Lett., 2000, 77(22): 3547-3549. |

| [24] | SAHOO S, POLISETTY S, DUAN C G, et al. Ferroelectric control of magnetism in BaTiO3/Fe heterostructures via interface strain coupling. Phys. Rev. B, 2007, 76(9): 092108. |

| [25] | TIAN H F, QU T L, LUO L B, et al. Strain induced magnetoelectric coupling between magnetite and BaTiO3. Appl. Phys. Lett., 2008, 92(6): 063507. |

| [26] | DORR K, THIELE C, BILANI O, et al. Dynamic strain in magnetic films on piezoelectric crystals. J. Magn. Magn. Mater., 2007, 310(2): 1182-1184. |

| [27] | DORR K, THIELE C, KIM J W, et al. Approaches towards ferroelectric control of thin film magnetism. Phil. Mag. Lett., 2007, 87(3/4): 269-278. |

| [28] | EERENSTEIN W, WIORA M, PRIETO J L, et al. Giant sharp and persistent converse magnetoelectric effects in multiferroic epitaxial heterostructures. Nat. Mater., 2007, 6(5): 348-351. |

| [29] | LIU M, OBI O, LOU J, et al. Spin-spray deposited multiferroic composite Ni0.23Fe2.77O4/Pb(Zr,Ti)O3 with strong interface adhesion. Appl. Phys. Lett., 2008, 92(15): 152504. |

| [30] | REN S Q, WUTTIG M. Magnetoelectric nano-Fe3O4/CoFe2O4 parallel to PbZr0.53Ti0.47O3 composite. Appl. Phys. Lett., 2008, 92(8): 083502. |

| [31] | YANG J J, ZHAO Y G, TIAN H F, et al. Electric field manipulation of magnetization at room temperature in multiferroic CoFe2O4/Pb(Mg1/3Nb2/3)0.7Ti0.3O3 heterostructures. Appl. Phys. Lett., 2009, 94(21): 212504. |

| [32] | BRANDLMAIER A, GEPRAGS S, WEILER M, et al. In situ manipulation of magnetic anisotropy in magnetite thin films. Phys. Rev. B, 2008, 77(10): 104445. |

| [33] | LIU M, OBI O, CAI Z, et al. Electrical tuning of magnetism in Fe3O4/PZN-PT multiferroic heterostructures derived by reactive magnetron sputtering. J. Appl. Phys., 2010, 107(7): 073916. |

| [34] | LIU M, OBI O, LOU J, et al. Giant electric field tuning of magnetic properties in multiferroic ferrite/ferroelectric heterostructures. Adv. Funct. Mater., 2009, 19(11): 1826-1831. |

| [35] | LIU M, OBI O, LOU J, et al. Strong magnetoelectric coupling in ferrite/ferroelectric multiferroic heterostructures derived by low temperature spin-spray deposition. J. Phys. D: Appl. Phys., 2009, 42(4): 045007. |

| [36] | PETTIFORD C, LOU J, RUSSELL L, et al. Strong magnetoelectric coupling at microwave frequencies in metallic magnetic film/lead zirconate titanate multiferroic composites. Appl. Phys. Lett., 2008, 92(12): 122506. |

| [37] | WEILER M, BRANDLMAIER A, GEPRAGS S, et al. Voltage controlled inversion of magnetic anisotropy in a ferromagnetic thin film at room temperature. New J. Phys., 2009, 11: 013021. |

| [38] | LI Z, WANG J, LIN Y, et al. A magnetoelectric memory cell with coercivity state as writing data bit. Appl. Phys. Lett., 2010, 96(16): 162505. |

| [39] | MOUTIS N, SUAREZ-SANDOVAL D, NIARCHOS D. Voltage-induced modification in magnetic coercivity of patterned Co50Fe50 thin film on piezoelectric substrate. J. Magn. Magn. Mater., 2008, 320(6): 1050-1055. |

| [40] | WANG J, HU J, WANG H, et al. Electric-field modulation of magnetic properties of Fe films directly grown on BiScO3-PbTiO3 ceramics. J. Appl. Phys., 2010, 107(8): 083901. |

| [41] | WANG J, MA J, LI Z, et al. Switchable voltage control of the magnetic coercive field via magnetoelectric effect. J. Appl. Phys., 2011, 110(4): 043919. |

| [42] | WANG J, WANG H, JIANG H, et al. Large electric-field modulation of magnetic properties in Fe films on BiScO3-PbTiO3 ceramics. J. Nanomater., 2010, 2010: 142750. |

| [1] | ZHANG Hui, MA Yong-Jun, WANG Yi-Cheng, WEN Dan-Dan, YE Fei, BAI Fei-Ming. Preparation of 1-3 Dimensional PZT-NFO Nanocomposite Films by Off-axis Magnetron Sputtering [J]. Journal of Inorganic Materials, 2014, 29(4): 371-376. |

| [2] | LI Ting-Xian, ZHANG Ming, HU Zhou, LI Kuo-She, YU Dun-Bo, YAN Hui. Preparation and Strong Magnetoelectric Effect of Multiferroic BaTiO3/La2/3Sr1/3MnO3 Composite Film [J]. Journal of Inorganic Materials, 2012, 27(3): 291-295. |

| [3] | XUAN Min-Jie, LIU Xin-Yu, YUAN Chang-Lai, XU Ji-Wen, MA Jia-Feng. Fabrication and Properties of the Potassium Sodium Niobate/Cobalt Copper Ferritemultiferroic Magnetoelectric Composites [J]. Journal of Inorganic Materials, 2012, 27(10): 1042-1046. |

| [4] | GAO Jian-Sen,ZHANG Ning. Magnetoelectric Effect in Laminate Composites Tb1-xDyxFe2-y-BaTi0.99Cr0.01O3-δ [J]. Journal of Inorganic Materials, 2009, 24(2): 367-370. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||