无机材料学报 ›› 2025, Vol. 40 ›› Issue (6): 711-718.DOI: 10.15541/jim20240517 CSTR: 32189.14.jim20240517

杨燕1,2( ), 张发强1, 马名生1(

), 张发强1, 马名生1( ), 王墉哲1, 欧阳琪1, 刘志甫1(

), 王墉哲1, 欧阳琪1, 刘志甫1( )

)

收稿日期:2024-12-12

修回日期:2025-02-19

出版日期:2025-06-20

网络出版日期:2025-02-25

通讯作者:

刘志甫, 研究员. E-mail: liuzf@mail.sic.ac.cn;作者简介:杨 燕(1994-), 女, 博士. E-mail: yan.yang@hongxing799.com

YANG Yan1,2( ), ZHANG Faqiang1, MA Mingsheng1(

), ZHANG Faqiang1, MA Mingsheng1( ), WANG Yongzhe1, OUYANG Qi1, LIU Zhifu1(

), WANG Yongzhe1, OUYANG Qi1, LIU Zhifu1( )

)

Received:2024-12-12

Revised:2025-02-19

Published:2025-06-20

Online:2025-02-25

Contact:

LIU Zhifu, professor. E-mail: liuzf@mail.sic.ac.cn;About author:YANG Yan (1994-), female, PhD. E-mail: yan.yang@hongxing799.com

Supported by:摘要:

ZnAl2O4及ZnAl2O4基陶瓷由于具有优良的微波介电、热学和力学性能, 从而备受研究人员关注。本工作系统研究了不同组成比例的5% CuO-TiO2-Nb2O5(CTN)三元复合氧化物烧结助剂对ZnAl2O4微波介电陶瓷烧结行为和性能的影响。当5% CTN烧结助剂中Cu、Ti、Nb元素的摩尔分数分别为0.625~0.875、0~0.250、0.125~0.625时, ZnAl2O4陶瓷的烧结温度可从1400 ℃以上降低至1000 ℃以下。烧结助剂CN(Cu : Nb=1 : 1, 摩尔比)和CTN(Cu : Ti : Nb=4 : 1 : 3, 摩尔比)可分别将ZnAl2O4陶瓷的烧结温度降低至975和1000 ℃, 同时陶瓷具有优良的介电性能(介电常数εr=11.36, 品质因数Q׃=8245 GHz; εr=9.52, Q׃=22249 GHz)和抗弯强度(200和161 MPa), 有望用于制备铜电极低温共烧陶瓷(LTCC)材料。ZnAl2O4+CTN体系的低温烧结是一种活化烧结机制。晶界处存在含Cu、Ti、Nb元素的纳米级非晶态界面膜, 在ZnAl2O4陶瓷烧结过程中为传质过程提供了快速扩散路径。Ti和Cu离子的化合价改变以及氧空位变化, 降低了ZnAl2O4陶瓷的烧结温度。此外, 晶界上发生的系列反应发挥了活化晶界的作用, 进一步促进烧结致密化。本工作为设计具有优良性能、CuO-TiO2-Nb2O5复合氧化物助烧的ZnAl2O4陶瓷LTCC材料提供了一种参考。

中图分类号:

杨燕, 张发强, 马名生, 王墉哲, 欧阳琪, 刘志甫. 基于CuO-TiO2-Nb2O5复合氧化物烧结助剂的ZnAl2O4陶瓷低温烧结研究[J]. 无机材料学报, 2025, 40(6): 711-718.

YANG Yan, ZHANG Faqiang, MA Mingsheng, WANG Yongzhe, OUYANG Qi, LIU Zhifu. Low Temperature Sintering of ZnAl2O4 Ceramics with CuO-TiO2-Nb2O5 Composite Oxide Sintering Aid[J]. Journal of Inorganic Materials, 2025, 40(6): 711-718.

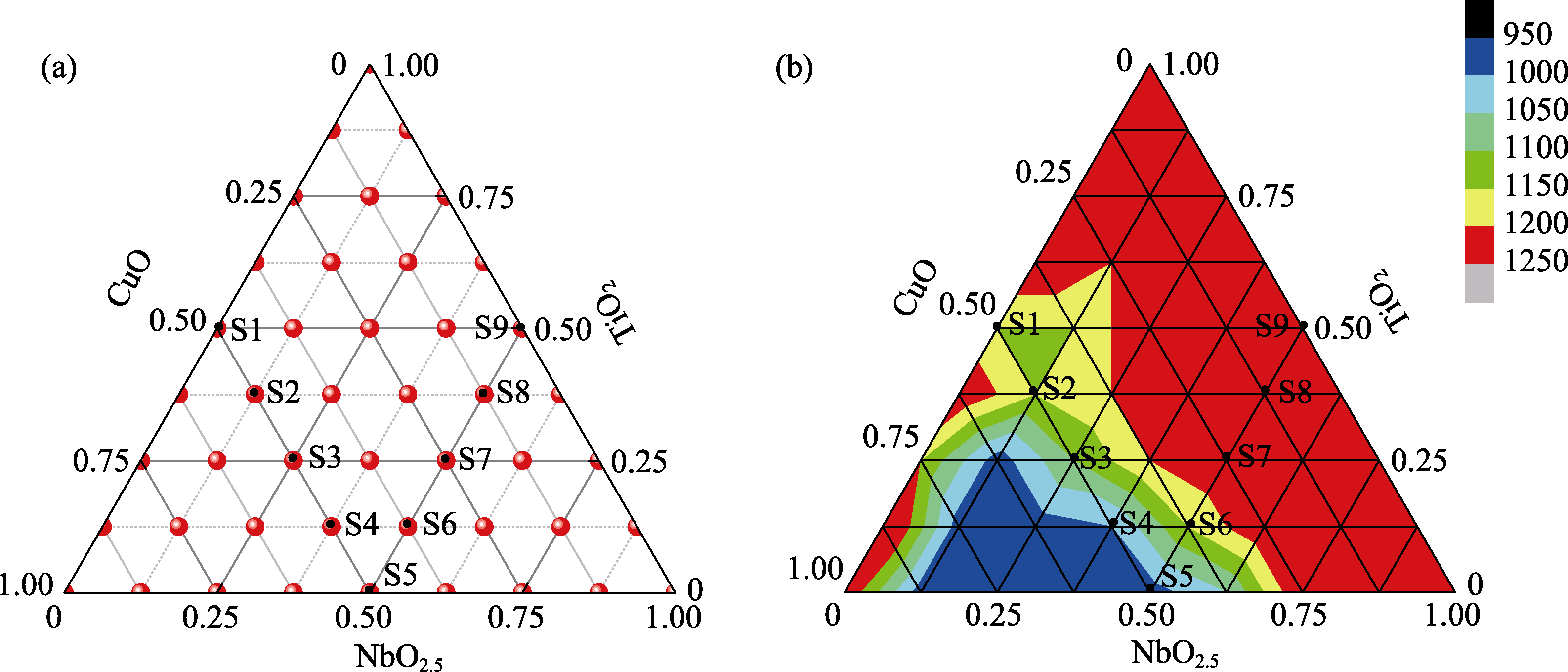

Fig. 1 (a) Compositions of CTN additives for ZnAl2O4; (b) Nephogram of sintering temperature of ZnAl2O4 ceramics with 5% CTN additives and different compositions Colorful figures are available on website

| Sample ID | Sintering temperature/℃ | Molar fraction | ||

|---|---|---|---|---|

| Cu | Ti | Nb | ||

| S1 | 1150 | 0.500 | 0.500 | 0 |

| S2 | 1150 | 0.500 | 0.375 | 0.125 |

| S3 | 1100 | 0.500 | 0.250 | 0.250 |

| S4 | 1000 | 0.500 | 0.125 | 0.375 |

| S5 | 975 | 0.500 | 0 | 0.500 |

| S6 | 1150 | 0.375 | 0.125 | 0.500 |

| S7 | 1250 | 0.250 | 0.250 | 0.500 |

| S8 | 1250 | 0.125 | 0.375 | 0.500 |

| S9 | 1250 | 0 | 0.500 | 0.500 |

Table 1 Sintering temperatures of ZnAl2O4 ceramics mixed 5% CTN additives with different formulas

| Sample ID | Sintering temperature/℃ | Molar fraction | ||

|---|---|---|---|---|

| Cu | Ti | Nb | ||

| S1 | 1150 | 0.500 | 0.500 | 0 |

| S2 | 1150 | 0.500 | 0.375 | 0.125 |

| S3 | 1100 | 0.500 | 0.250 | 0.250 |

| S4 | 1000 | 0.500 | 0.125 | 0.375 |

| S5 | 975 | 0.500 | 0 | 0.500 |

| S6 | 1150 | 0.375 | 0.125 | 0.500 |

| S7 | 1250 | 0.250 | 0.250 | 0.500 |

| S8 | 1250 | 0.125 | 0.375 | 0.500 |

| S9 | 1250 | 0 | 0.500 | 0.500 |

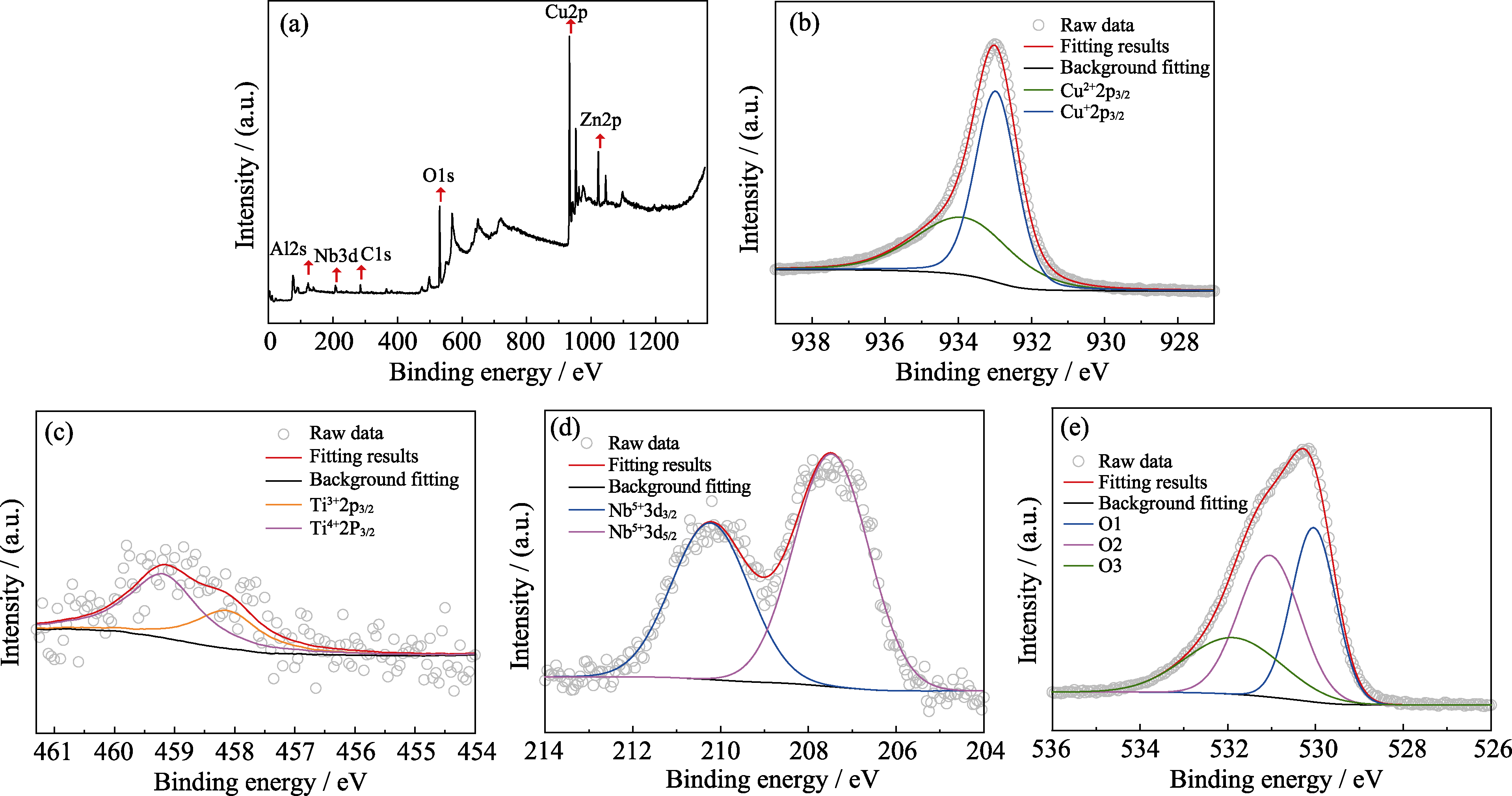

Fig. 4 XPS spectra of sample S4 sintered at 1000 ℃ for 2 h (a) and (b-e) detailed XPS spectra of Cu ion (b), Ti ion (c), Nb ion (d) and O1s (e) Colorful figures are available on website

| Sample ID | Sintering temperature/℃ | Density/(g·cm-3) | εr(@10 GHz) | Q׃/GHz | CTE/(×10-6, ℃-1) (25-350 ℃) | Flexural strength/MPa |

|---|---|---|---|---|---|---|

| S1 | 1150 | 4.46±0.17 | 10.18 | 17811 | 7.66 | 246±34 |

| S2 | 1150 | 4.49±0.02 | 9.00 | 41673 | 7.34 | 230±10 |

| S3 | 1100 | 4.49±0.01 | 10.10 | 17150 | 7.65 | 233±10 |

| S4 | 1000 | 4.54±0.03 | 9.52 | 22249 | 7.49 | 161±25 |

| S5 | 975 | 4.50±0.04 | 11.36 | 8245 | 7.56 | 200±14 |

| S6 | 1150 | 4.54±0.01 | 9.67 | 30021 | 7.45 | 186±10 |

| S7 | 1250 | 4.17±0.02 | - | - | 7.47 | 215±20 |

| S8 | 1250 | 4.19±0.02 | - | - | 7.53 | 199±8 |

| S9 | 1250 | 3.51±0.03 | - | - | 7.29 | 195±17 |

Table S1 Properties of ZnAl2O4 ceramics with different formulas of CTN additives

| Sample ID | Sintering temperature/℃ | Density/(g·cm-3) | εr(@10 GHz) | Q׃/GHz | CTE/(×10-6, ℃-1) (25-350 ℃) | Flexural strength/MPa |

|---|---|---|---|---|---|---|

| S1 | 1150 | 4.46±0.17 | 10.18 | 17811 | 7.66 | 246±34 |

| S2 | 1150 | 4.49±0.02 | 9.00 | 41673 | 7.34 | 230±10 |

| S3 | 1100 | 4.49±0.01 | 10.10 | 17150 | 7.65 | 233±10 |

| S4 | 1000 | 4.54±0.03 | 9.52 | 22249 | 7.49 | 161±25 |

| S5 | 975 | 4.50±0.04 | 11.36 | 8245 | 7.56 | 200±14 |

| S6 | 1150 | 4.54±0.01 | 9.67 | 30021 | 7.45 | 186±10 |

| S7 | 1250 | 4.17±0.02 | - | - | 7.47 | 215±20 |

| S8 | 1250 | 4.19±0.02 | - | - | 7.53 | 199±8 |

| S9 | 1250 | 3.51±0.03 | - | - | 7.29 | 195±17 |

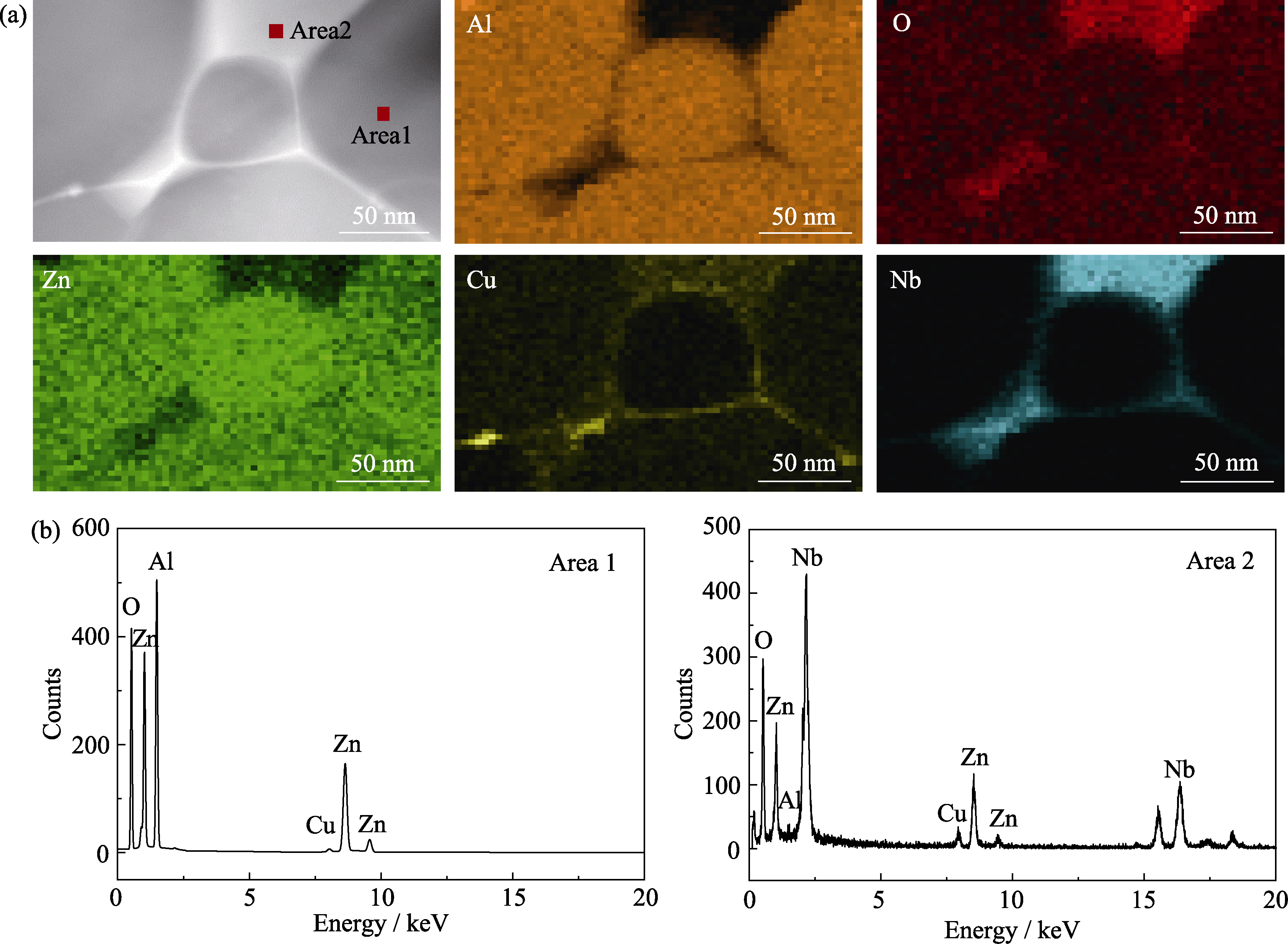

Fig. S4 EDS element mappings of sample S5 sintered at 975 ℃ for 2 h (a) and EDS spectra of the grain phase (Area 1) and the adjacent second phase (Area 2) (b)

| Element | Al (K) | Zn(K) | O (K) | Nb (K) | Cu (K) | |

|---|---|---|---|---|---|---|

| Atomic/% | Area 1 | 28.63 | 13.50 | 57.47 | 0.00 | 0.38 |

| Area 2 | 1.44 | 4.43 | 88.90 | 4.04 | 1.17 | |

| Uncertainty/% | Area 1 | 0.31 | 0.42 | 0.49 | 100.00 | 0.05 |

| Area 2 | 0.11 | 0.43 | 1.14 | 0.78 | 0.19 | |

Table S2 EDS analysis results for the grain (Area 1) and the adjacent second phase (Area 2)

| Element | Al (K) | Zn(K) | O (K) | Nb (K) | Cu (K) | |

|---|---|---|---|---|---|---|

| Atomic/% | Area 1 | 28.63 | 13.50 | 57.47 | 0.00 | 0.38 |

| Area 2 | 1.44 | 4.43 | 88.90 | 4.04 | 1.17 | |

| Uncertainty/% | Area 1 | 0.31 | 0.42 | 0.49 | 100.00 | 0.05 |

| Area 2 | 0.11 | 0.43 | 1.14 | 0.78 | 0.19 | |

| [1] | NAGATSUMA T, DUCOURNAU G, RENAUD C C. Advances in terahertz communications accelerated by photonics. Nature Photonics, 2016, 10: 371. |

| [2] | MA M S, WANG Y, NAVARRO-CÍA M, et al. The dielectric properties of some ceramic substrate materials at terahertz frequencies. Journal of the European Ceramic Society, 2019, 39: 4424. |

| [3] | TAJIMA T, SONG H J, YAITA M. Compact THz LTCC receiver module for 300 GHz wireless communications. IEEE Microwave and Wireless Components Letters, 2016, 26: 291. |

| [4] | CHEN X, ZHANG W, BAI S, et al. Densification and characterization of SiO2-B2O3-CaO-MgO glass/Al2O3 composites for LTCC application. Ceramics International, 2013, 39: 6355. |

| [5] | ARCARO S, CESCONETO FR, PEREIRA F R, et al. Synthesis and characterization of LZS/Α-Al2O3 glass-ceramic composites for applications in the LTCC technology. Ceramics International, 2014, 40: 5269. |

| [6] | SEBASTIAN M T, JANTUNEN H. Low loss dielectric materials for LTCC applications: a review. International Materials Reviews, 2008, 53: 57. |

| [7] | ZHOU J. Towards rational design of low-temperature co-fired ceramic (LTCC) materials. Journal of Advanced Ceramics, 2012, 1: 89. |

| [8] | RABE T, GEMEINERT M, SCHILLER W A. Development of advanced low temperature cofired ceramics (LTCC). Key Engineering Materials, 2004, 264-268: 1181. |

| [9] | SHIGENO K, KATSUMURA H, KAGATA H, et al. Low temperature sintering of alumina by CuO-TiO2-Nb2O5 additives. Key Engineering Materials, 2006, 320: 181. |

| [10] | SHIGENO K, KOJIMA E, FUJIMORI H. Improvement in the low-temperature sintering performance and characteristics of alumina with CuO-TiO2-Nb2O5 additive by controlling the firing atmosphere. Journal of the Japan Society of Powder and Powder Metallurgy, 2016, 63: 701. |

| [11] | YANG Y, MA M S, ZHANG F Q, et al. Low-temperature sintering of Al2O3 ceramics doped with 4CuO-TiO2-2Nb2O5 composite oxide sintering aid. Journal of the European Ceramic Society, 2020, 40: 5504. |

| [12] | LEI W, LU W Z, ZHU J H, et al. Microwave dielectric properties of ZnAl2O4-TiO2 spinel-based composites. Materials Letters, 2007, 61: 4066. |

| [13] | SURENDRAN K P, SANTHA N, MOHANAN P, et al. Temperature stable low loss ceramic dielectrics in (1-x)ZnAl2O4-xTiO2 system for microwave substrate applications. European Physical Journal B, 2004, 41: 301. |

| [14] | QIN T Y, ZHONG C W, QIN Y, et al. Low-temperature sintering mechanism and microwave dielectric properties of ZnAl2O4-LMZBS composites. Journal of Alloys and Compounds, 2019, 797: 744. |

| [15] | ROSHNI S B, SEBASTIAN M T, SURENDRAN K P. Can zinc aluminate-titania composite be an alternative for alumina as microelectronic substrate? Scientific Reports, 2017, 7: 40839. |

| [16] | WU J M, LU W Z, LEI W, et al. Preparation of ZnAl2O4-based microwave dielectric ceramics and GPS antenna by aqueous gel casting. Materials Research Bulletin, 2011, 46: 1485. |

| [17] | THOMAS S, SEBASTIAN M T. Effect of B2O3-Bi2O3-SiO2- ZnO glass on the sintering and microwave dielectric properties of 0.83ZnAl2O4-0.17TiO2. Materials Research Bulletin, 2008, 43: 843. |

| [18] | YANG Y, MA M S, WANG Y Z, et al. Low-temperature sintering of ZnAl2O4 ceramics with 4CuO-TiO2-2Nb2O5 composite oxide sintering aid. Ferroelectrics, 2022, 586: 190. |

| [19] | COURTNEY W E. Analysis and evaluation of a method of measuring the complex permittivity and permeability microwave insulators. IEEE Transaction on Microwave Theory and Techniques, 1970, 18: 476. |

| [20] | HAKKI B W, COLEMAN P D. A dielectric resonator method of measuring inductive capacitance in the millimeter range. IEEE Transaction on Microwave Theory and Techniques, 1960, 8: 402. |

| [21] | DIFEO M, RAMAJO L, CASTRO M. Influence of CuO addition on dielectric and piezoelectric properties of (Bi0.5Na0.5) TiO3- BaTiO3 lead-free piezoceramics. Journal of Advanced Dielectrics, 2021, 11: 2140004. |

| [22] | MCLNTYRE N S, COOK M G. X-ray photoelectron studies on some oxides and hydroxides of cobalt, nickel, and copper. Analytical Chemistry, 1975, 47: 2208. |

| [23] | SUZANA M, FRANCISCO P, MASTERARO V R. Activity and characterization by XPS, HRTEM, Raman spectroscopy, and BET surface area of CuO/CeO2-TiO2 catalysts. The Journal of Physical Chemistry B, 2001, 105: 10515. |

| [24] | SANJINÉS R, TANG H, BERGER H, et al. Electronic structure of anatase TiO2 oxide. Journal of Applied Physiology, 1994, 75: 2945. |

| [25] | MOREAU P, OUVRARD G, GRESSIER P, et al. Electronic structures and charge transfer in lithium and mercury intercalated titanium disulfides. Journal of Physics and Chemistry of Solids, 1996, 57: 1117. |

| [26] | UEKAWA N, WATANABE M, KANEKO K. Mixed-valence formation in highly oriented Ti-doped iron oxide film. Journal of the Chemical Society, Faraday Transaction, 1995, 91: 2161. |

| [27] | WERFEL F, BRUMMER O. Corundum structure oxides studied by XPS. Physical Scripta, 1983, 28: 92. |

| [28] | LU F H, FANG F X, CHEN Y S. Eutectic reaction between copper oxide and titanium dioxide. Journal of the European Ceramic Society, 2001, 21: 1093. |

| [29] | YOSHIDA H, YAMAMOTO T. Densification behavior of Ti-doped polycrystalline alumina in a nitrogen-hydrogen atmosphere. Materials Transactions, 2009, 50: 1032. |

| [30] | PULLAR R C, PENN S J, WANG X, et al. Dielectric loss caused by oxygen vacancies in titania ceramics. Journal of the European Ceramic Society, 2009, 29: 419. |

| [31] | POLLAK R A, STOLZ H J, RAIDER S I, et al. Chemical composition and interface chemistry of very thin Nb2O5 films prepared by RF plasma oxidation. Oxidation of Metals, 1983, 20: 185. |

| [32] | OU G, XU YS, WEN B, et al. Tuning defects in oxides at room temperature by lithium reduction. Nature Communications, 2018, 9: 1302. |

| [33] | CHEN, X B, LIU L, YU P Y, et al. Increasing solar absorption for photocatalysis with black hydrogenated titanium dioxide nanocrystals. Science, 2011, 331: 746. |

| [34] | HU W B, LIU Y, WITHERS R L, et al. Electron-pinned defect- dipoles for high-performance colossal permittivity materials. Nature Materials, 2013, 12: 821. |

| [35] | THIRUMAL M, MURUGAN G S, VARMA K B R, et al. Ba3ZnTa2-xNbxO9 and Ba3MgTa2-xNbxO9: synthesis, structural and dielectric studies. Materials Research Bulletin, 2000, 35: 2423. |

| [36] | NIE J Y, CHAN J M, QIN M D, et al. Liquid-like grain boundary complexion and sub-eutectic activated sintering in CuO-doped TiO2. Acta Materials, 2017, 130: 329. |

| [37] | KINGERY W D, BOWEN H K, UHLMANN D R. Introduction to Ceramics, 2nd edition. New York: John Wiley and Sons, 1976: 478-482. |

| [38] | GUPTA V K, YOON D H, MEYER H M, et al. Thin intergranular films and solid state activated sintering in nickel- doped tungsten. Acta Materials, 2007, 55: 3131. |

| [39] | LUO J, WANG H, CHIANG Y M. Origin of solid-state activated sintering in Bi2O3-doped ZnO. Journal of the American Ceramic Society, 1999, 82: 916. |

| [1] | 胡智超, 杨鸿宇, 杨鸿程, 孙成礼, 杨俊, 李恩竹. P-V-L键理论在微波介质陶瓷性能调控中的应用[J]. 无机材料学报, 2025, 40(6): 609-626. |

| [2] | 何国强, 张恺恒, 王震涛, 包健, 席兆琛, 方振, 王昌昊, 王威, 王鑫, 姜佳沛, 李祥坤, 周迪. Ba(Nd1/2Nb1/2)O3: 一种被低估的K40微波介质陶瓷[J]. 无机材料学报, 2025, 40(6): 639-646. |

| [3] | 唐莹, 李洁, 相怀成, 方维双, 林慧兴, 杨俊峰, 方亮. Rattling效应: 一种影响微波介质陶瓷谐振频率温度系数的新机制[J]. 无机材料学报, 2025, 40(6): 656-666. |

| [4] | 姜昆, 李乐天, 郑木鹏, 胡永明, 潘勤学, 吴超峰, 王轲. PZT陶瓷的低温烧结研究进展[J]. 无机材料学报, 2025, 40(6): 627-638. |

| [5] | 尹长志, 成名飞, 雷微程, 蔡弋炀, 宋小强, 付明, 吕文中, 雷文. Ga3+掺杂对SrAl2Si2O8陶瓷晶体结构及微波介电性能的影响[J]. 无机材料学报, 2025, 40(6): 704-710. |

| [6] | 江强, 施立志, 陈政燃, 周志勇, 梁瑞虹. 高于居里温度极化的硬性PZT压电陶瓷的制备及叠层驱动器性能研究[J]. 无机材料学报, 2024, 39(10): 1091-1099. |

| [7] | 彭萍, 谭礼涛. CuO掺杂(Ba,Ca)(Ti,Sn)O3陶瓷的结构与压电性能[J]. 无机材料学报, 2024, 39(10): 1100-1106. |

| [8] | 柯鑫, 谢炳卿, 王忠, 张敬国, 王建伟, 李占荣, 贺会军, 汪礼敏. 第三代半导体互连材料与低温烧结纳米铜材的研究进展[J]. 无机材料学报, 2024, 39(1): 17-31. |

| [9] | 罗淑文, 马名生, 刘峰, 刘志甫. Ca-B-Si体系LTCC材料腐蚀行为及腐蚀机理[J]. 无机材料学报, 2023, 38(5): 553-560. |

| [10] | 李海涛, 李 谦, 闫焉服, 许荣辉. ZnO掺杂对Ca0.25(Li0.43Sm0.57)0.75TiO3陶瓷烧结性能和微波介电性能的影响[J]. 无机材料学报, 2015, 30(4): 369-373. |

| [11] | 方爱华, 谢晓明, 黄富强, 江绵恒. 机械合金化合成高临界场Sm0.85Nd0.15FeAsO0.85F0.15超导体[J]. 无机材料学报, 2012, 27(4): 439-444. |

| [12] | 刘 林, 方有维, 邓新峰, 庄文东, 唐 斌, 张树人. (Ba1-xSrx)La4Ti4O15(x=0.8~0.95)陶瓷的微结构及微波介电性能研究[J]. 无机材料学报, 2012, 27(3): 281-284. |

| [13] | 姚晓刚, 林慧兴, 姜少虎, 陈 玮, 罗 澜. Al2O3掺杂对Ba4Sm9.33Ti18O54陶瓷显微结构和介电性能的影响[J]. 无机材料学报, 2012, 27(12): 1266-1270. |

| [14] | 刘 昊, 沈春英, 卢正东, 丘 泰. (1-x)(Mg0.9Co0.1)TiO3-x(Ca0.61La0.26)TiO3陶瓷的微波介电性能[J]. 无机材料学报, 2011, 26(6): 664-668. |

| [15] | 晁小练, 杨祖培, 安伟伟. MnO2对BiFeO3掺杂PZT-PFW-PMN陶瓷的电性能与温度特性研究[J]. 无机材料学报, 2010, 25(12): 1242-1246. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||