无机材料学报 ›› 2022, Vol. 37 ›› Issue (3): 338-346.DOI: 10.15541/jim20210606 CSTR: 32189.14.10.15541/jim20210606

周红莉1( ), 蔡志勇1, 王小锋1(

), 蔡志勇1, 王小锋1( ), 曾婧2, 冯艳1, 彭超群1, 王日初1

), 曾婧2, 冯艳1, 彭超群1, 王日初1

收稿日期:2021-10-02

修回日期:2021-12-02

出版日期:2022-03-20

网络出版日期:2021-12-24

通讯作者:

王小锋, 副教授. E-mail: wangxiaofeng@csu.edu.cn

作者简介:周红莉(1996-), 女, 硕士研究生. E-mail: summertimezhl@163.com

ZHOU Hongli1( ), CAI Zhiyong1, WANG Xiaofeng1(

), CAI Zhiyong1, WANG Xiaofeng1( ), ZENG Jin2, FENG Yan1, PENG Chaoqun1, WANG Richu1

), ZENG Jin2, FENG Yan1, PENG Chaoqun1, WANG Richu1

Received:2021-10-02

Revised:2021-12-02

Published:2022-03-20

Online:2021-12-24

Contact:

WANG Xiaofeng, associate professor. E-mail: wangxiaofeng@csu.edu.cn

About author:ZHOU Hongli (1996-), female, Master candidate. E-mail: summertimezhl@163.com

Supported by:摘要:

石膏是雕像、建筑和铸造模具(合金和陶瓷)的常用材料。采用直写成型(Direct Ink Writing, DIW)打印石膏可避免其他3D打印技术(如Binder Jetting, PBBJ等)中存在水化反应不充分等问题, 获得高强度3D打印石膏。为了延缓水化反应获得充足的打印操作时间, 本研究通过添加缓凝剂和增稠剂, 研制了一种适用于直写成型的石膏浆料, 并打印了多种石膏三维结构(如蜘蛛网和木材堆积结构等)。结果表明, 质量分数为0.6%柠檬酸(Citric Acid, CA)的缓凝效果最好, 极大地减少了石膏流动性的经时损失。质量分数为0.3%羟丙基甲基纤维素(Hydroxypropyl Methylcellulose, HPMC)的增稠效果最好, 使石膏浆料具有良好的打印性能。CA的选择性吸附使得石膏晶体定向生长, 延长水化反应时间, 但一定程度降低石膏强度。HPMC加速石膏浆料中絮凝结构形成, 导致其粘度和剪切弹性模量升高。直写成型3D石膏件的抗压强度约为20 MPa, 远高于PBBJ等方法制备的石膏件的抗压强度。

中图分类号:

周红莉, 蔡志勇, 王小锋, 曾婧, 冯艳, 彭超群, 王日初. 石膏的直写成型:可打印石膏浆料的研制[J]. 无机材料学报, 2022, 37(3): 338-346.

ZHOU Hongli, CAI Zhiyong, WANG Xiaofeng, ZENG Jin, FENG Yan, PENG Chaoqun, WANG Richu. Direct Ink Writing of Gypsum: Developing a Printable Gypsum Paste[J]. Journal of Inorganic Materials, 2022, 37(3): 338-346.

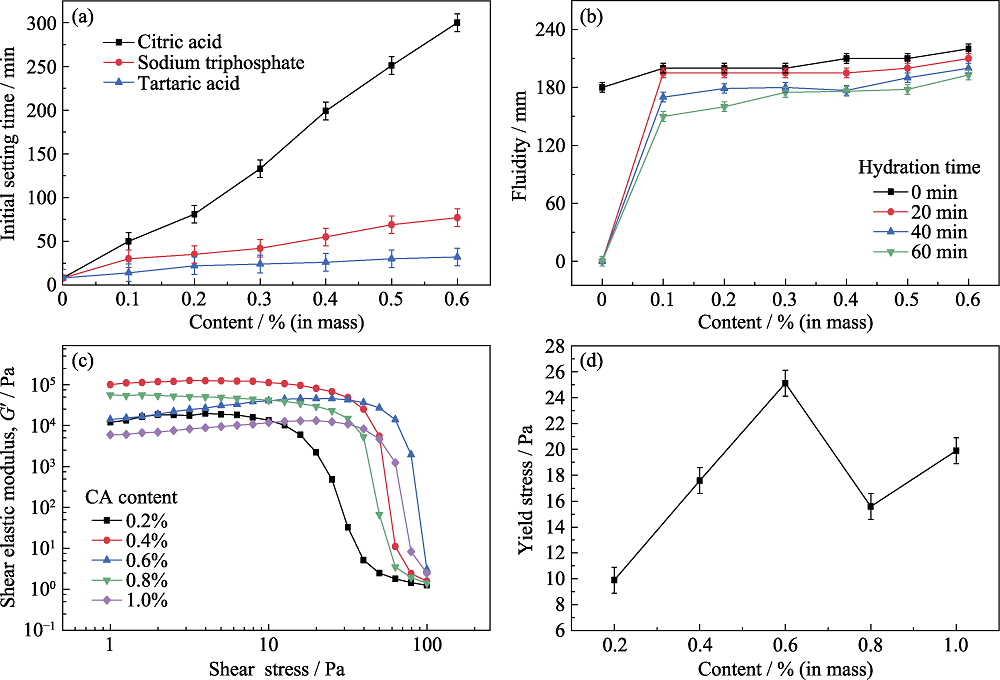

Fig. 1 Effect of retarders on gypsum paste (a) Setting time vs content of retarder; (b) Fluidity vs content of citric acid (CA) in the gypsum paste; (c) Shear elastic modulus vs shear stress; (d) Yield stress vs content of CA

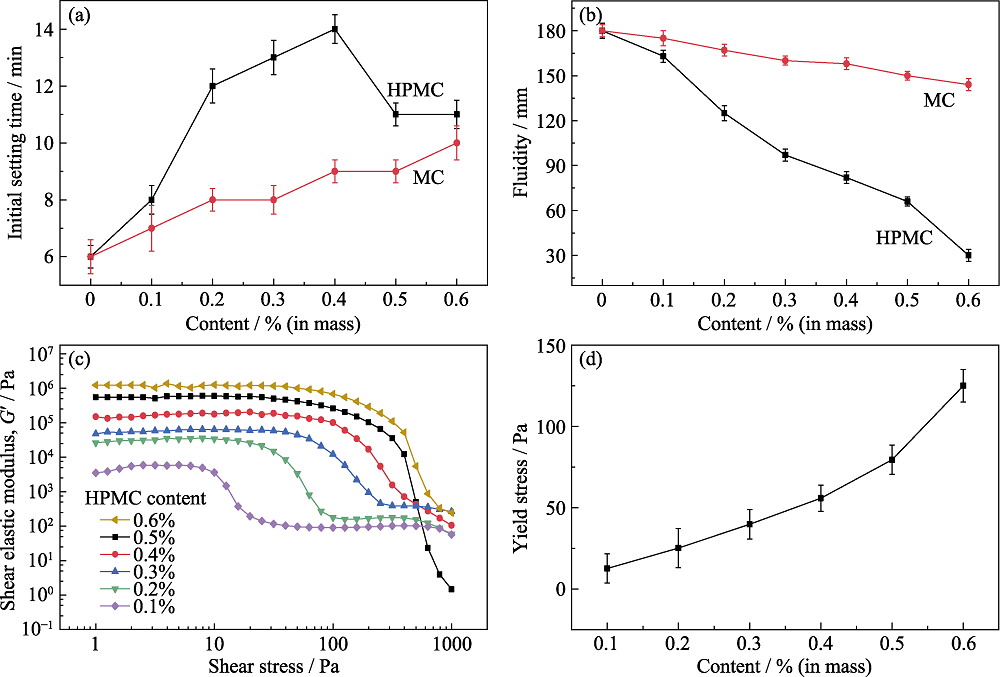

Fig. 2 Effect of thickener on gypsum paste (a) Setting time vs content of thickeners; (b) Fluidity vs content of thickener; (c) Shear modulus of elasticity of HPMC with different dosage; (d) Yield stress vs content of HPMC

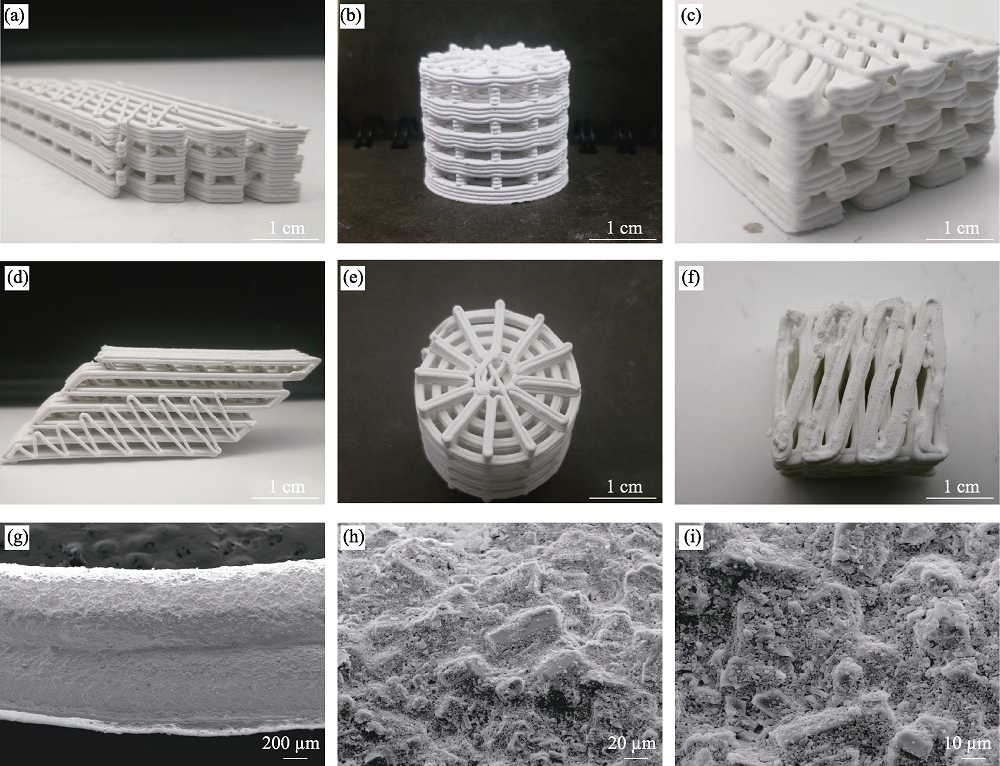

Fig. 3 Structures and microstructures of printed 3D gypsum (a, d) Scaffold structure with three horizontal lines and three vertical lines appearing alternately and periodically in the Z-axis, the cross angle is 60°; (b, e) Spider structure consisting of alternate layers of radial and circular rods; (c, f) Scaffold structure with three horizontal lines and three vertical lines appearing alternately and periodically in the Z-axis, the cross angle is 45°; (g-i) Microstructure of printed gypsum parts

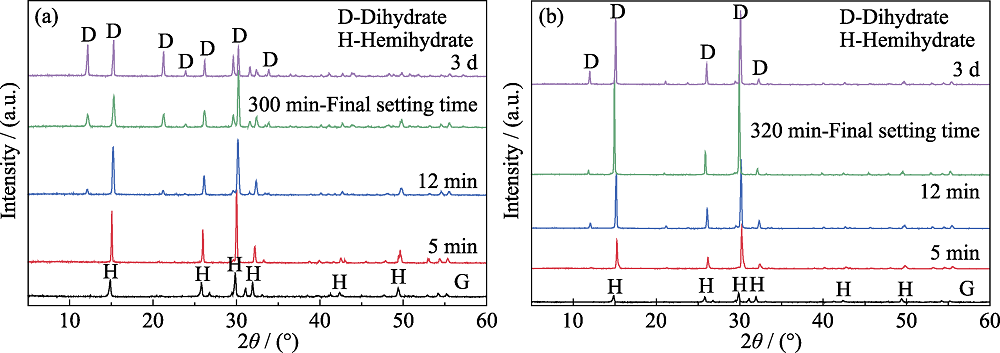

Fig. 5 XRD patterns at different hydration time for gypsum pastes with different agents (a) 0.6% (in mass) citric acid gypsum at different hydration time; (b) 0.6% (in mass) citric acid and 0.3% (in mass) HPMC at different hydration time

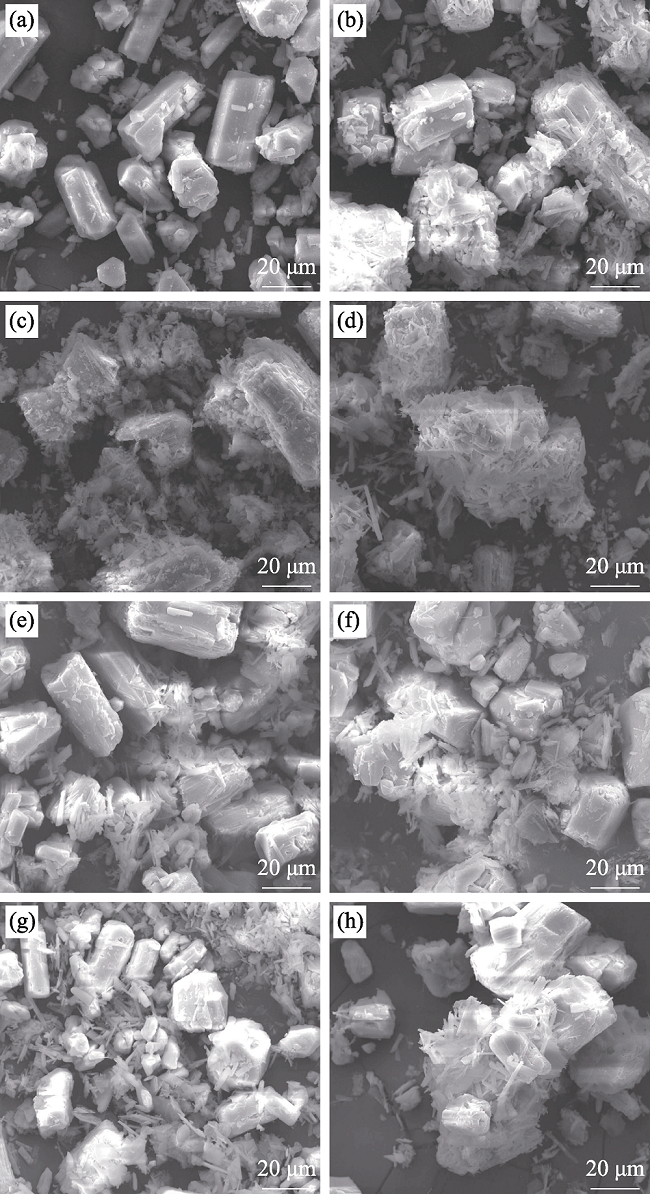

Fig. 6 SEM images of gypsum at different hydration time (a-d) Gypsum with 0.6% (in mass) CA at different hydration time ((a) 5 min, (b) 12 min, (c) 20 min, (d) 300 min (final setting time)); (e-f) Gypsum with 0.6% (in mass) CA and 0.3% (in mass) HPMC at different hydration time ((e) 5 min, (f) 12 min, (g) 20 min, (h) 320 min (final setting time))

| [1] |

ZHANG J X, ZHANG Y, LIU J K, et al. Research on the properties of high-strength gypsum based tile adhesive in interior decoration. E3S Web of Conferences, 2020, 165(5): 05015.

DOI URL |

| [2] |

PHONGTHORN J, PANUWAT J. Utilization of several industrial wastes as raw material for calcium sulfoaluminate cement. Materials, 2019, 12(20): 3319-3331.

DOI URL |

| [3] |

PHETRATTANARANGSI T, PUNCREOBUTR C, KHAMKONGKAEO A, et al. The behavior of gypsum-bonded investment in the gold jewelry casting process. Thermochimica Acta, 2017, 657: 144-150.

DOI URL |

| [4] |

WEISE J, HILBERS J, HANDELS F, et al. New core technology for light metal casting. Advanced Engineering Materials, 2019, 21(4): 1800608.

DOI URL |

| [5] |

MA CHANGLIANG, ZHANG YUE, ZHANG HUANYUE, et al. Manufacturing of herringbone gear model by 3D printing assisted investment casting. IOP Conference Series Earth and Environmental Science, 2019, 332(4): 042045.

DOI URL |

| [6] | MA Y, TANG B, YAO Q M, et al. Common defects and their solutions in plaster investment precision casting. Special Casting, 2020, 41(7): 664-666. |

| [7] | SHEN Y, ZHENG G, FENG C M. Research progress in investment casting precision casting technology. Precision Forming Engineering, 2019(01): 54-62. |

| [8] |

HEAD D, VANORIO T. Effects of changes in rock microstructures on permeability: 3-D printing investigation. Geophysical Research Letters, 2016, 43(14): 7494-7502.

DOI URL |

| [9] |

LIGON S C, LISKA R, STAMPFL J, et al. Polymers for 3D printing and customized additive manufacturing. Chemical Reviews, 2017, 117(15): 10212-10290.

DOI URL |

| [10] |

AMBROSI A, PUMERA M. 3D-printing technologies for electrochemical applications. Chemical Society Reviews, 2016, 45(10): 2740-2755.

DOI URL |

| [11] |

HISHAM H H, ARIFIN S S, AYA A, et al. 3D printable conductive materials for the fabrication of electrochemical sensors: a mini review. Electrochemistry Communications, 2018, 96: 27-31.

DOI URL |

| [12] | CIMA M, LEXINGTON, SACHS E M, et al. Three-dimensional Printing Techniques. U.S., Patent, 5387380, 1995.2.7. |

| [13] |

CASTILHO M, RODRIGUES J, PIRES I, et al. Fabrication of individual alginate-TCP scaffolds for bone tissue engineering by means of powder printing. Biofabrication, 2015, 7(1): 15004-15023.

DOI URL |

| [14] |

JARIWALA S H, LEWIS G S, BUSHMAN Z J, et al. 3D printing of personalized artificial bone scaffolds. 3D Printing and Additive Manufacturing, 2015, 2(2): 56-64.

DOI URL |

| [15] |

SNYDER T J, ANDREWS M, WEISLOGEL M, et al. 3D systems' technology overview and new applications in manufacturing, engineering, science, and education. 3D Printing and Additive Manufacturing, 2014, 1(3): 169-176.

DOI URL |

| [16] | LIU H B, MENG F J, HUA S Z. 4D mapping of the fracture evolution in a printed gypsum-like core by using X-ray CT scanning. Advances in Civil Engineering, 2021, 2021: 1-12. |

| [17] |

SONG R, WANG Y, ISHUTOV S, et al. A comprehensive experimental study on mechanical behavior, microstructure and transport properties of 3D-printed rock analogs. Rock Mechanics and Rock Engineering, 2020, 53(12): 5745-5765.

DOI URL |

| [18] |

JAVAN R, ELLENBOGEN A L, GREEK N, et al. A prototype assembled 3D-printed phantom of the glenohumeral joint for fluoroscopic-guided shoulder arthrography. Skeletal Radiology, 2019, 48(5): 791-802.

DOI URL |

| [19] |

BUDA M, BRATOS M, SORENSEN J A. Accuracy of 3-dimensional computer-aided manufactured single-tooth implant definitive casts. Journal of Prosthetic Dentistry, 2018, 120(6): 913-918.

DOI URL |

| [20] |

RODRÍGUEZ-GONZÁLEZ P, FERNÁNDEZ-ABIA A I, CASTRO- SASTRE M A, et al. Heat treatments for improved quality binder jetted molds for casting aluminum alloys. Additive Manufacturing, 2020, 36: 101524.

DOI URL |

| [21] |

WU Z J, ZHANG B, WENG L, et al. A new way to replicate the highly stressed soft rock: 3D printing exploration. Rock Mechanics and Rock Engineering, 2020, 53(1): 467-476.

DOI URL |

| [22] | ASADI-EYDIVAND M, SOLATI-HASHJIN M, SHAFIEI S S, et al. Structure, properties, and in vitro behavior of heat-treated calcium sulfate scaffolds fabricated by 3D printing. PLOS ONE, 2016, 11(3): e151216. |

| [23] |

SELVARAJ S B, SINGAMNENI S. Pre-moisturized β-hemihydrate for 3d printed molds. Materials and Manufacturing Processes, 2015, 31(8): 1102-1112.

DOI URL |

| [24] |

SHAHARIAR H, KIM I, BHAKTA R, et al. Direct-write printing process of conductive paste on fiber bulks for wearable textile heaters. Smart Materials and Structures, 2020, 29(8): 085018.

DOI URL |

| [25] |

FIOCCO L, ELSAYED H, BADOCCO D, et al. Direct ink writing of silica-bonded calcite scaffolds from preceramic polymers and fillers. Biofabrication, 2017, 9(2): 025012.

DOI URL |

| [26] |

LIU C B, GAO J M, TANG Y B, et al. Preparation and characterization of gypsum-based materials used for 3D robocasting. Journal of Materials Science, 2018, 53(24): 16415-16422.

DOI URL |

| [27] |

ZHANG Y Y, YANG J S, CAO X Y. Effects of several retarders on setting time and strength of building gypsum. Construction and Building Materials, 2020, 240: 117927.

DOI URL |

| [28] |

HILL J, PLANK J. Retardation of setting of plaster of paris by organic acids: understanding the mechanism through molecular modeling. Journal of Computational Chemistry, 2004, 25(12): 1438-1448.

DOI URL |

| [29] |

GENSOWSKI K, TEPNER S, SCHWEIGERT S, et al. Conductive highly filled suspensions for an electrochemical dispensing approach to pattern full-area thin metal layers by physical vapour deposition. Scientific Reports, 2020, 10(1): 27-31.

DOI URL |

| [30] |

HOWARD A BARNES. The yield stress—a review or ‘παντα ρει’—everything flows? Journal of Non-Newtonian Fluid Mechanics, 1999, 81(1): 133-178.

DOI URL |

| [31] |

LIU C B, GAO J M, CHEN X M, et al. Effect of polysaccharides on setting and rheological behavior of gypsum-based materials. Construction and Building Materials, 2021, 267: 120922.

DOI URL |

| [32] |

CAMARINI G, PINTO M C C, MOURA A G D, et al. Effect of citric acid on properties of recycled gypsum plaster to building components. Construction and Building Materials, 2016, 124: 383-390.

DOI URL |

| [33] |

LIU C B, GAO J M, TANG Y B, et al. Early hydration and microstructure of gypsum plaster revealed by environment scanning electron microscope. Materials Letters, 2019, 234: 49-52.

DOI URL |

| [34] |

SINGH M, GARG M. Retarding action of various chemicals on setting and hardening characteristics of gypsum plaster at different pH. Cement and Concrete Research, 1997, 27(6): 947-950.

DOI URL |

| [35] | QU J D, LI B Z, PENG J H. Influence of retarders on the microstructure of hardened building gypsum paste and the mechanism of its strength loss. Advanced Materials Research, 2011, 250(253): 313-320. |

| [36] |

BÜLICHEN D, PLANK J. Water retention capacity and working mechanism of methyl hydroxypropyl cellulose (MHPC) in gypsum plaster-which impact has sulfate? Cement and Concrete Research, 2013, 46: 66-72.

DOI URL |

| [37] | THOMPSON B R, HOROZOV T S, STOYANOV S D, et al. Hierarchically porous composites fabricated by hydrogel templating and viscous trapping techniques. Materials & Design, 2018, 137: 384-393. |

| [38] | MENG X L, WANG Q Q, WANG Y L. Effect of retarder on properties of FGD gypsum. Shandong Chemical Industry, 2019, 49(4): 17-18. |

| [39] |

MAGALLANES-RIVERA R X, ESCALANTE-GARCÍA J I, GOROKHOVSKY A. Hydration reactions and microstructural characteristics of hemihydrate with citric and malic acid. Construction and Building Materials, 2009, 23(3): 1298-1305.

DOI URL |

| [40] |

LANZÓN M, GARCÍA-RUIZ P A. Effect of citric acid on setting inhibition and mechanical properties of gypsum building plasters. Construction and Building Materials, 2012, 28(1): 506-511.

DOI URL |

| [1] | 周港怀, 刘耀, 石原, 刘绍军. 活性氧化铝催化剂载体的光固化浆料制备与成型[J]. 无机材料学报, 2022, 37(3): 297-302. |

| [2] | 付云飞, 朱伯铨, 李享成, 陈平安. 含镁铝尖晶石的铝酸钙水泥的合成与流变特性[J]. 无机材料学报, 2017, 32(8): 884-890. |

| [3] | 谢雨洲, 彭超群, 王小锋, 王日初, 罗 丰. HEMA-TBA凝胶体系制备多孔氧化铝陶瓷[J]. 无机材料学报, 2017, 32(7): 731-738. |

| [4] | 鲁 元, 李京龙, 杨建锋, 李 鹏. 热处理温度对双连续β-氮化硅增强铝基复合材料性能的影响[J]. 无机材料学报, 2015, 30(3): 277-281. |

| [5] | 王小锋, 孙月花, 彭超群, 王日初, 张 斗, 马 超. 直写成型用悬浮液的设计[J]. 无机材料学报, 2015, 30(11): 1139-1147. |

| [6] | 舒 夏, 李 军, 张海龙, 董满江, 岛井骏臧, 王士维. 水溶性共聚物为交联剂的凝胶注成型AlN陶瓷的研究[J]. 无机材料学报, 2014, 29(3): 327-330. |

| [7] | 罗真兰, 王海波, 苏俭生. 镍与绿茶EGCG对舌鳞癌细胞毒性的影响[J]. 无机材料学报, 2012, 27(2): 179-184. |

| [8] | 蔡坤鹏, 李亚运, 孙振新, 孙竞博, 李 勃, 周 济. 三维TiO2陶瓷网络的直写无模成型及结构设计对其光催化性能的调制作用[J]. 无机材料学报, 2012, 27(1): 102-106. |

| [9] | 孙竞博, 李 勃, 蔡坤鹏, 周济, 李龙土. 利用浆料直写无模成型技术制备自支撑 TiO2 光降解器件[J]. 无机材料学报, 2011, 26(3): 300-304. |

| [10] | 肖 奇, 高 兰, 张 响. 高可见光响应型单斜介孔BiVO4的合成与表征[J]. 无机材料学报, 2011, 26(12): 1256-1260. |

| [11] | 孙竞博,李 勃,黄学光,蔡坤鹏,周 济,李龙土. 基于光敏浆料的直写精细无模三维成型[J]. 无机材料学报, 2009, 24(6): 1147-1150. |

| [12] | 高 兰,马会茹,刘秧生,官建国. 硫酸改性TiO2粒子的表征与电流变性能研究[J]. 无机材料学报, 2009, 24(6): 1121-1124. |

| [13] | 吴 昊,桑绍柏,李 炜,蒲 健,李 箭. 流延法制备SOFC阳极支撑体基片[J]. 无机材料学报, 2008, 23(1): 82-86. |

| [14] | 汤枫秋,黄校先,张玉峰,郭景坤. 盐离子对纳米氧化锆浆料流变性能的影响[J]. 无机材料学报, 1999, 14(2): 239-244. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||