无机材料学报 ›› 2017, Vol. 32 ›› Issue (10): 1035-1041.DOI: 10.15541/jim20170005 CSTR: 32189.14.10.15541/jim20170005

马 剑, 张波萍, 陈建银

收稿日期:2017-01-04

修回日期:2017-04-23

出版日期:2017-10-20

网络出版日期:2017-09-21

作者简介:马 剑(1990-),男,硕士研究生. E-mail address: majian9026@163.com

基金资助:MA Jian, ZHANG Bo-Ping, CHEN Jian-Yin

Received:2017-01-04

Revised:2017-04-23

Published:2017-10-20

Online:2017-09-21

About author:MA Jian. E-mail address: majian9026@163.com

Supported by:摘要:

采用传统固相烧结法制备了0.7BiFeO3-0.3BaTiO3-xBi2O3(0≤x≤0.05)无铅压电陶瓷, 研究了Bi补偿量x和冷却方式对其相结构、微观形貌和综合电学性能的影响。结果表明:所有样品均为菱方相(R)和伪立方相(PC)两相共存, 0≤x≤0.01样品为纯的钙钛矿结构, 且x=0.01样品的两相比例CR/CPC接近1; x>0.01样品中出现富Bi杂相Bi25FeO40。与冷却方式相比, 优化Bi补偿量更有利于提升BFBT-xBi2O3陶瓷的压电性能。随着x增大, d33先增大后减小, 在x=0.01时获得最优值。由于较小的晶粒、较合适的CR/CPC以及较大的残余应变, 水冷BFBT-0.01Bi2O3陶瓷获得了最优的压电性能(d33水冷=141 pC/N、kp=27%)和高TC=507℃。研究结果表明, BFBT基陶瓷有希望成为兼具高压电性能和高TC的无铅压电材料体系之一。

中图分类号:

马 剑, 张波萍, 陈建银. Bi过量以及冷却方式对BiFeO3-BaTiO3陶瓷的相结构及电学性能的影响[J]. 无机材料学报, 2017, 32(10): 1035-1041.

MA Jian, ZHANG Bo-Ping, CHEN Jian-Yin. Excess Bi and Cooling Method on Phase Structure and Electrical Properties of BiFeO3-BaTiO3 Lead-free Ceramics[J]. Journal of Inorganic Materials, 2017, 32(10): 1035-1041.

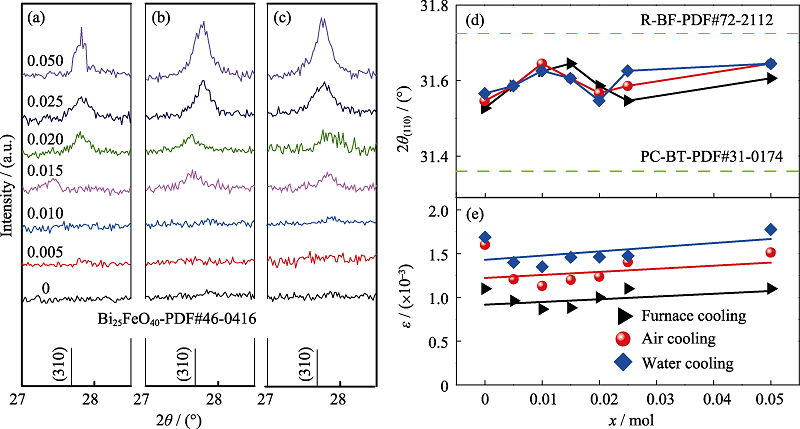

图2 炉冷、空冷、水冷BF-BT-xBi2O3陶瓷在2θ=27°~28.5°的XRD图谱(a~c), 2θ(110)角度(d)以及残余应变ε(e)随x的变化关系

Fig. 2 (a-c) Enlarged XRD patterns in the 2θ range of 27°-28.5°, and (d) the 2θ(110)value and (e) the residual strain ε as a function of x for BFBT-xBi2O3 ceramics by furnace cooling, air cooling and water cooling

| Cooling method | Space group | Lattice parameters/nm | α=β=γ/(°) | Rwp/% | CR/CPC | d33/(pC·N-1) | ||

|---|---|---|---|---|---|---|---|---|

| a | b | c | ||||||

| C-PDF#31-0174 | PM-3M | 0.4031 | 0.4031 | 0.4031 | 90.00 | - | - | |

| R-PDF#72-2112 | R-3M | 0.3952 | 0.3952 | 0.3952 | 90.00 | - | - | |

| Furnace cooling | PM-3M | 0.3999 | 0.3999 | 0.3999 | 90.00 | 13.2 | 51/49 | 122 |

| R-3M | 0.3999 | 0.3999 | 0.3999 | 89.80 | ||||

| Air cooling | PM-3M | 0.4029 | 0.4029 | 0.4029 | 90.00 | 9.8 | 54/46 | 130 |

| R-3M | 0.4027 | 0.4027 | 0.4027 | 90.00 | ||||

| Water cooling | PM-3M | 0.4040 | 0.4040 | 0.4040 | 90.00 | 10.7 | 60/40 | 141 |

| R-3M | 0.4030 | 0.4030 | 0.4030 | 90.01 | ||||

表1 BF-BT-0.01Bi2O3陶瓷的精修晶格参数和相比例

Table 1 Rietveld refined lattice parameters and phase ratio of the BFBT-0.01Bi2O3 ceramics

| Cooling method | Space group | Lattice parameters/nm | α=β=γ/(°) | Rwp/% | CR/CPC | d33/(pC·N-1) | ||

|---|---|---|---|---|---|---|---|---|

| a | b | c | ||||||

| C-PDF#31-0174 | PM-3M | 0.4031 | 0.4031 | 0.4031 | 90.00 | - | - | |

| R-PDF#72-2112 | R-3M | 0.3952 | 0.3952 | 0.3952 | 90.00 | - | - | |

| Furnace cooling | PM-3M | 0.3999 | 0.3999 | 0.3999 | 90.00 | 13.2 | 51/49 | 122 |

| R-3M | 0.3999 | 0.3999 | 0.3999 | 89.80 | ||||

| Air cooling | PM-3M | 0.4029 | 0.4029 | 0.4029 | 90.00 | 9.8 | 54/46 | 130 |

| R-3M | 0.4027 | 0.4027 | 0.4027 | 90.00 | ||||

| Water cooling | PM-3M | 0.4040 | 0.4040 | 0.4040 | 90.00 | 10.7 | 60/40 | 141 |

| R-3M | 0.4030 | 0.4030 | 0.4030 | 90.01 | ||||

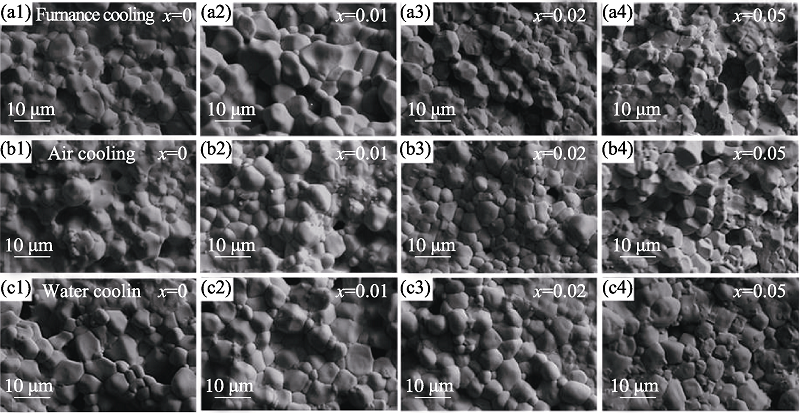

图4 炉冷(a1)~(a4)、空冷(b1~b4)、水冷(c1)~(c4)BF-BT-xBi2O3陶瓷的SEM照片

Fig. 4 SEM images of the BFBT-xBi2O3 ceramics sintered at 1020℃ for 4 h then by furnace cooling (a1)-(a4), air cooling (b1)-(b4) and water cooling (c1)-(c4)

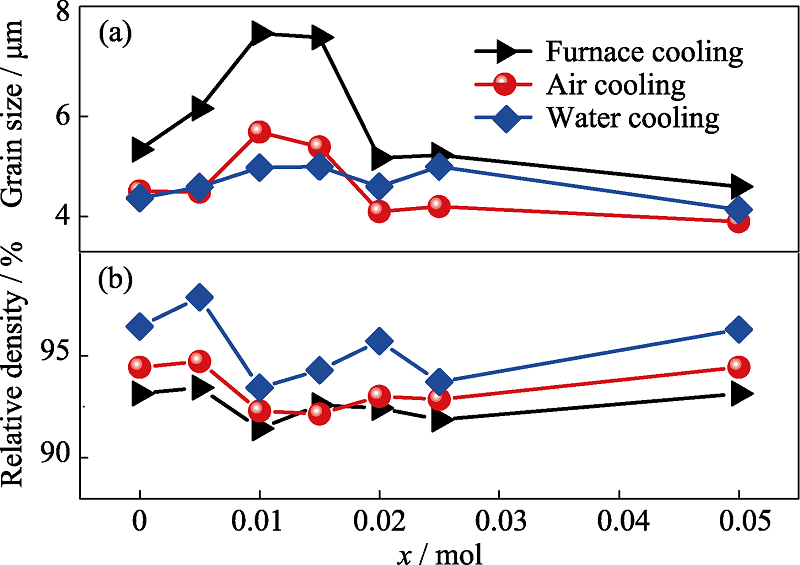

图5 炉冷、空冷、水冷BF-BT-xBi2O3陶瓷的平均晶粒尺寸(a)和相对密度(b)

Fig. 5 Average grain size (a) and relative density (b) for the BFBT-xBi2O3 ceramics by furnace cooling, air cooling and water cooling

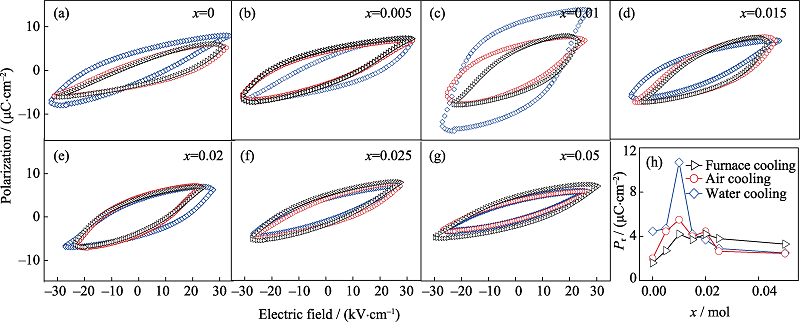

图6 炉冷、空冷、水冷BF-BT-0.01Bi2O3陶瓷的电滞回线

Fig. 6 Ferroelectric hysteresis loops (a-g) and Pr (h) as a function of x for the BFBT-xBi2O3 ceramics by furnace cooling, air cooling and water cooling

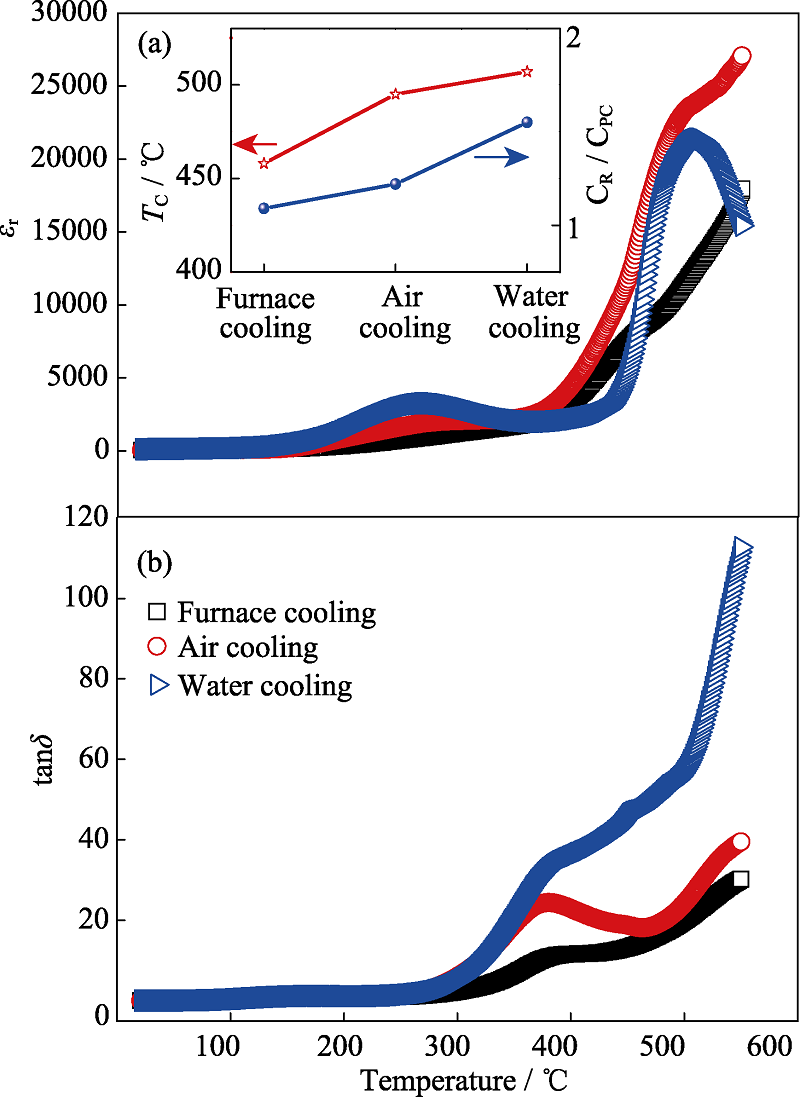

图7 炉冷、空冷、水冷BF-BT-0.01Bi2O3陶瓷的介电常数 εr(a)与介电损耗tanδ(b)

Fig. 7 Temperature dependences of dielectric constant εr (a) and dielectric loss tanδ (b) for the BFBT-0.01Bi2O3 ceramics by furnace cooling, air cooling and water coolingThe inset is TC and CR/CPC under different cooling modes

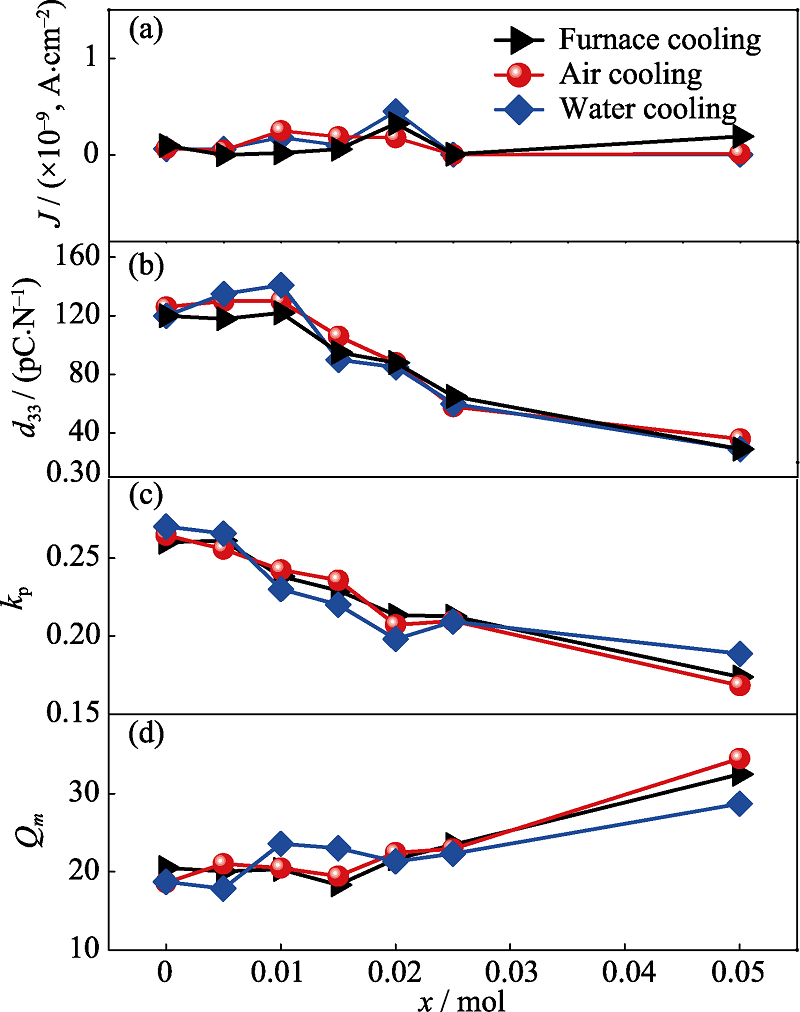

图8 炉冷、空冷、水冷BF-BT-xBi2O3陶瓷的漏电流密度J、压电系数d33、平面机电耦合系数kp和机械品质因数Qm随x变化关系

Fig. 8 Leakage current density J(a), piezoelectric coefficient d33(b), planar electromechanical coupling coefficient kp(c) and mechanical quality factor Qm(d) as a function of x for the BFBT- xBi2O3 ceramics by furnace cooling, air cooling and water cooling

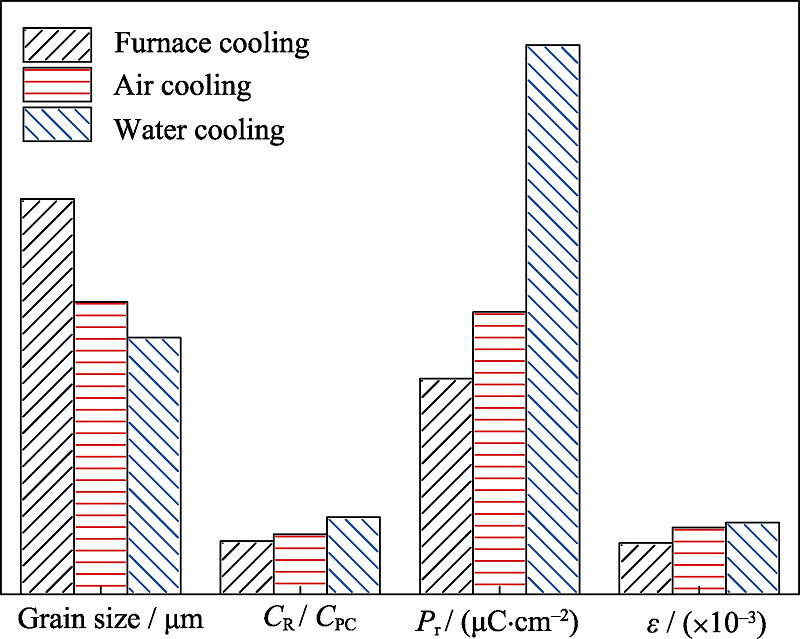

图9 炉冷、空冷、水冷BF-BT-0.01Bi2O3陶瓷的平均晶粒尺寸、CR/CPC、Pr以及残余应变ε

Fig. 9 Average grain size, CR/CPC, Pr, and residual strain ε of the BFBT-0.01Bi2O3 ceramics sintered at 1020℃ for 4 h then by furnace cooling, air cooling and water cooling

| Compositions | Pr/(μC·cm-2) | EC/(kV·cm-1) | d33/(pC·N-1) | TC/℃ | Ref. |

|---|---|---|---|---|---|

| 0.7BiFeO3-0.3BaTiO3-0.01Bi2O3 | 10.7 | 16.1 | 141 | 507 | This work |

| 0.65BiFeO3-0.35BaTiO3 | 30.6 | 27.9 | 104 | 414 | [25] |

| 0.7BiFeO3-0.3BaTiO3 | 26.0 | 33.0 | 134 | 510 | [21] |

| 0.75BiFeO3-0.25BaTiO3-Mn | 22.9 | 39.3 | 116 | 619 | [10] |

| 0.8BiFeO3-0.2BaTiO3-0.15wt% SiO2 | - | - | 86 | 628 | [26] |

| 0.705BiFeO3-0.275BaTiO3-0.02Bi0.5Na0.5TiO3-1mol%MnO2 | 27.4 | - | 140 | - | [18] |

| 0.715BiFeO3-0.275BaTiO3-0.01Bi(Mg0.5Zr0.5)O3 - MnO2 | 9.0 | 27.0 | 130 | 575 | [23] |

表2 BFBT基陶瓷的电学性能

Table 2 Electrical properties of the BF-BT based ceramics

| Compositions | Pr/(μC·cm-2) | EC/(kV·cm-1) | d33/(pC·N-1) | TC/℃ | Ref. |

|---|---|---|---|---|---|

| 0.7BiFeO3-0.3BaTiO3-0.01Bi2O3 | 10.7 | 16.1 | 141 | 507 | This work |

| 0.65BiFeO3-0.35BaTiO3 | 30.6 | 27.9 | 104 | 414 | [25] |

| 0.7BiFeO3-0.3BaTiO3 | 26.0 | 33.0 | 134 | 510 | [21] |

| 0.75BiFeO3-0.25BaTiO3-Mn | 22.9 | 39.3 | 116 | 619 | [10] |

| 0.8BiFeO3-0.2BaTiO3-0.15wt% SiO2 | - | - | 86 | 628 | [26] |

| 0.705BiFeO3-0.275BaTiO3-0.02Bi0.5Na0.5TiO3-1mol%MnO2 | 27.4 | - | 140 | - | [18] |

| 0.715BiFeO3-0.275BaTiO3-0.01Bi(Mg0.5Zr0.5)O3 - MnO2 | 9.0 | 27.0 | 130 | 575 | [23] |

| [1] | ZHU L F, ZHANG B P, ZHAO L, et al.Large piezoelectric effect of (Ba, Ca)TiO3-xBa(Sn, Ti)O3 lead-free ceramics.J. Eur. Ceram. Soc., 2016, 36(4): 1017-1024. |

| [2] | MA N, ZHANG B P, YANG W G, et al.Phase structure and nano-domain in high performance of BaTiO3 piezoelectric ceramics.J. Eur. Ceram. Soc., 2012, 32(5): 1059-1066. |

| [3] | DAI Z H, AKISHIGE Y. Electrical properties of multiferroic BiFeO3 ceramics synthesized by spark plasma sintering. J. Phys. D:Appl. Phys., 2010, 43: 445403-1-5. |

| [4] | TADEJ R, KOSEC M, BUDIC B, et al.Strong ferroelectric domain-wall pinning in BiFeO3 ceramics.J. Appl. Phys., 2010, 108: 074107. |

| [5] | TADEJ R, BENCAN A, MALI C B, et al.BiFeO3 ceramics: processing, electrical and electromechanical properties.J. Am. Ceram. Soc., 2014, 97(7): 1993-2011. |

| [6] | ISMAILZADE I H, ISMAILOV R M, ALEKBEROV A I, et al.Investigation of the magnetoelectric (ME)H effect in solid solutions of the systems BiFeO3-BaTiO3 and BiFeO3-PbTiO3.Phys. Status Solidi. A, 1981, 1(68): k81-k85. |

| [7] | GAO L, HUANG Y, HU Y, et al.Dielectric and ferroelectric properties of (1-x)BaTiO3-xBi0.5Na0.5TiO3 ceramics.Ceram. Int., 2007, 33(6): 1041-1046. |

| [8] | WANG T H, TUC S, DING Y, et al.Phase transition and ferroelectric properties of xBiFeO3-(1-x)BaTiO3 ceramics.Curr. Appl. Phys., 2011, 11(3): S240-S243. |

| [9] | YANG H, ZHOU C, LIU X, et al.Piezoelectric properties and temperature stabilities of Mn-and Cu-modified BiFeO3-BaTiO3 high temperature ceramics.J. Eur. Ceram. Soc., 2013, 33(6): 1177-1183. |

| [10] | LEONTSEV S O, EITELR E.Dielectric and piezoelectric properties in Mn-modified (1-x)BiFeO3-xBaTiO3 ceramics.J. Am. Ceram. Soc. 2009, 92(12): 2957-2961. |

| [11] | ZHOU C R, FETEIRAA, SHAN X, et al.Remarkably high- temperature stable piezoelectric properties of Bi(Mg0.5Ti0.5)O3 modified BiFeO3-BaTiO3 ceramics. Appl. Phys.Lett., 2012, 101(3): 2901. |

| [12] | ZHOU Q, ZHOU C R, YANG H B, et al.Dielectric, ferroelectric, and piezoelectric properties of Bi(Ni1/2Ti1/2)O3-modified BiFeO3- BaTiO3 ceramics with high curie temperature.J. Am. Ceram. Soc., 2012, 95(12): 3889-3893. |

| [13] | SHAN X, ZHOU C R, CEN Z Y, et al.Bi(Zn1/2Ti1/2)O3 modified BiFeO3-BaTiO3 lead-free piezoelectric ceramics with high temperature stability.Ceram. Int., 2013, 39(6): 6707-6712. |

| [14] | ZHANG Q, ZHU X H, XU YH, et al.Effect of La3+ substitution on the phase transitions, microstructure and electrical properties of Bi1-xLaxFeO3 ceramics.J. Alloys Compd., 2013, 546: 57-62. |

| [15] | KAWAE T, TERAUCHI Y, TSUDA H, M, et al. Improved leakage and ferroelectric properties of Mn and Ti co-doped BiFeO3 thin films.Appl. Phys. Lett., 2009, 94(11): 112904. |

| [16] | WU M S, HUANG Z B, HAN C X, et al.Enhanced multiferroic properties of BiFeO3 ceramics by Ba and high valence Nb co- doping.Soild. State. Commun., 2012, 152(24): 2142-2146. |

| [17] | AZOUGH F, FREER R, THRALL M, et al.Microstructure and properties of Co-, Ni-, Zn-, Nb- and W- modified multiferroic BiFeO3 ceramics.J. Eur. Ceram. Soc., 2010, 30(3): 727-736. |

| [18] | LI Y, JIANG N, LAM K H, et al.Structure, ferroelectric, piezoelectric, and ferromagnetic properties of BiFeO3-BaTiO3-Bi0.5Na0.5TiO3 lead-Free multiferroic ceramics.J. Am. Ceram. Soc., 2014, 97(11): 3602-3608. |

| [19] | CHEN J G, CHENG J R.Enhanced thermal stability of lead-free high temperature 0.75BiFeO3-0.25BaTiO3 ceramics with excess Bi content.J. Alloys Compd., 2014, 589: 115-119. |

| [20] | LEE M H, KIM D J, PARK J S, et al.High-performance lead-free piezoceramics with high curie temperatures.Adv. Mater., 2015, 27(43): 6976-6982. |

| [21] | WEI Y, WANG X, ZHU J, et al.Dielectric, ferroelectric and piezoelectric properties of BiFeO3-BaTiO3 ceramics.J. Am. Ceram. Soc., 2013, 96(10): 3163-3168. |

| [22] | ZAK A K, MAJID W H ABD, ABRISHAMI M E, et al. X-ray analysis of ZnO nanoparticles by Williamson-Hall and size-strain plot methods.Solid. State. Sci., 2011, 13: 251-256. |

| [23] | LUO L L, JIANG N, LEI F Y, et al.Phase transition, ferroelectric and piezoelectric properties of Bi(Mg0.5Zr0.5)O3-modified BiFeO3- BaTiO3 lead-free ceramics.J. Mater. Sci.: Mater. Electron., 2014, 25(4): 1736-1744. |

| [24] | TAN Y Q, ZHANG J L, WANG C L.High piezoelectric properties and good temperature stabilities of CuO-modified Ba(Ti0.96SnxZr0.04-x)O3 ceramics.J. Adv. Dielect., 2013, 03(02): 1350014. |

| [25] | WEI Y, WANG X, JIA J, et al.Multiferroic and piezoelectric properties of 0.65BiFeO3-0.35BaTiO3 ceramic with pseudo-cubic symmetry.Ceram. Int., 2012, 38(4): 3499-3502. |

| [26] | YAO Z, XU C, WANG Z, et al.Microstructure, ferro-piezoelectric and thermal stability of SiO2 modified BiFeO3-BaTiO3 high temperature piezoceramics.J. Mater. Sci., 2015, 26(1): 479-484. |

| [1] | 康文烁, 郭晓杰, 邹凯, 赵祥永, 周志勇, 梁瑞虹. 层状结构第二相增强BiFeO3-BaTiO3陶瓷电阻率研究[J]. 无机材料学报, 2023, 38(12): 1420-1426. |

| [2] | 程玮杰, 王明磊, 林国强. 电弧离子镀CrAlN-DLC硬质复合薄膜的成分、结构与性能[J]. 无机材料学报, 2022, 37(7): 764-772. |

| [3] | 莫亚杰,王明磊,程玮杰,林国强. 电弧离子镀Cr1-xAlxN硬质薄膜的成分、结构与性能[J]. 无机材料学报, 2020, 35(6): 675-681. |

| [4] | 陈宇方, 李宇杰, 郑春满, 谢 凯, 陈重学. 富锂层状氧化物正极材料研究进展[J]. 无机材料学报, 2017, 32(8): 792-800. |

| [5] | 鲁媛媛, 李贺军, 杨冠军. 氢稀释比对氢化硅薄膜两相结构和电学性能的影响[J]. 无机材料学报, 2015, 30(5): 474-478. |

| [6] | 程羽佳, 张晓虹, 周雪冬, 郭 宁, 成如如, 张天旭. 冷却方式对MMT/LDPE介电性能的影响[J]. 无机材料学报, 2015, 30(12): 1295-1302. |

| [7] | 梅兴志, 罗永春, 张国庆, 康 龙. 稀土系A2B7型La1-xScxNi2.6Co0.3Mn0.5Al0.1(x = 0~0.5)储氢合金相结构和电化学性能研究[J]. 无机材料学报, 2015, 30(10): 1049-1055. |

| [8] | 王孝笑, 杨 琳, 刘 洪, 陈 强, 肖定全, 朱建国. 低温水热法制备ZnS:Co+Cr纳米晶及其光学性能研究[J]. 无机材料学报, 2014, 29(10): 1049-1054. |

| [9] | 兰春锋, 聂恒昌, 陈学锋, 王军霞, 王根水, 董显林, 刘雨生, 贺红亮. 致密PZT95/5铁电陶瓷低温相结构与电性能研究[J]. 无机材料学报, 2013, 28(5): 502-506. |

| [10] | 杨文冬, 黄剑锋, 曹丽云, 夏昌奎. AlPO4晶相结构对复合涂层显微结构及抗氧化性能的影响[J]. 无机材料学报, 2010, 25(5): 527-531. |

| [11] | 吴汉华,于凤荣,李俊杰,吕宪义,金曾孙. 铝合金微弧氧化陶瓷膜形成过程中的特性研究[J]. 无机材料学报, 2004, 19(3): 617-622. |

| [12] | 董辉,邵宗平,熊国兴,杨维慎. 钴掺杂Sr4Fe6O13混合导体氧化物结构及透氧测定[J]. 无机材料学报, 2001, 16(2): 311-318. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||