无机材料学报 ›› 2023, Vol. 38 ›› Issue (3): 288-295.DOI: 10.15541/jim20220485 CSTR: 32189.14.10.15541/jim20220485

穆宏赫1( ), 王鹏飞1(

), 王鹏飞1( ), 施宇峰1, 张中晗1(

), 施宇峰1, 张中晗1( ), 武安华1,2, 苏良碧1,2

), 武安华1,2, 苏良碧1,2

收稿日期:2022-08-15

修回日期:2022-09-08

出版日期:2023-03-20

网络出版日期:2022-11-20

通讯作者:

王鹏飞, 助理研究员. Email: wangpengfei@mail.sic.ac.cn;作者简介:穆宏赫(1997-), 女, 硕士研究生. E-mail: muhonghe@mails.ucas.ac.cn

基金资助:

MU Honghe1( ), WANG Pengfei1(

), WANG Pengfei1( ), SHI Yufeng1, ZHANG Zhonghan1(

), SHI Yufeng1, ZHANG Zhonghan1( ), WU Anhua1,2, SU Liangbi1,2

), WU Anhua1,2, SU Liangbi1,2

Received:2022-08-15

Revised:2022-09-08

Published:2023-03-20

Online:2022-11-20

Contact:

WANG Pengfei, lecturer. E-mail: wangpengfei@mail.sic.ac.cn;About author:About author: MU Honghe (1997-), female, Master candidate. E-mail: muhonghe@mails.ucas.ac.cn

Supported by:摘要:

随着CeF3晶体在激光和磁光领域应用的持续发展, 大尺寸、高光学质量的CeF3单晶的需求日益急迫, 而CeF3熔体的高黏度和低热导率的特性给晶体生长工艺带来了较大挑战。为研究CeF3熔体低导热性引发的生长问题, 探究其生长过程中炉体结构和工艺参数对温度分布和结晶界面的影响机制, 本工作对热交换坩埚下降法(Heat Exchanger-Bridgman method, HEB)生长大尺寸(ϕ80 mm)CeF3晶体中炉体结构与晶体/熔体温度分布关系、不同生长阶段界面的变化规律以及热场结构对生长界面的作用机制开展了数值模拟研究。研究结果表明:当发热体长度与坩埚长度相适应时,更有利于构建合理的温度梯度场, 而放肩和等径生长阶段的凹界面问题则可以通过改变隔板形状和加反射屏调节坩埚壁温度分布得到有效解决。本研究成果不仅可以加深对CeF3晶体结晶习性的理解, 炉体结构和生长界面的优化思路对坩埚下降法制备其他晶体同样有实际指导意义。

中图分类号:

穆宏赫, 王鹏飞, 施宇峰, 张中晗, 武安华, 苏良碧. 热交换坩埚下降法制备大尺寸氟化铈晶体的热场设计与优化[J]. 无机材料学报, 2023, 38(3): 288-295.

MU Honghe, WANG Pengfei, SHI Yufeng, ZHANG Zhonghan, WU Anhua, SU Liangbi. Large-size CeF3 Crystal Growth by Heat Exchanger-Bridgman Method: Thermal Field Design and Optimization[J]. Journal of Inorganic Materials, 2023, 38(3): 288-295.

| Physical properties | Thermal conductivity/ (W·m-1·K-1) | Density/(kg·m-3) | Heat capacity/(J·kg-1·K-1) | Emissivity | Absorption coefficient |

|---|---|---|---|---|---|

| Vacuum | 2.4×10-4 | 2.9×10-3 | 150 | - | - |

| Molybdenum | 163.7-0.062T+9.72×10-6T2 | 10200 | 250.78 | 0.4 | - |

| Graphite | exp(-5.7×10-4T+4.5) | 1950 | 710 | 0.8 | - |

| Stainless Steel | 9.2+0.0175T-2×10-6T2 | 7930 | 500 | 0.66 | - |

| CeF3 melt | 0.5 | 3200 | 1470.8 | - | 900 |

| CeF3 crystal | 1.72 | 5800 | 1064.52+0.198T+9.29×10-5T2 | - | 10 |

表1 材料热物性参数

Table 1 Thermophysical parameters of materials

| Physical properties | Thermal conductivity/ (W·m-1·K-1) | Density/(kg·m-3) | Heat capacity/(J·kg-1·K-1) | Emissivity | Absorption coefficient |

|---|---|---|---|---|---|

| Vacuum | 2.4×10-4 | 2.9×10-3 | 150 | - | - |

| Molybdenum | 163.7-0.062T+9.72×10-6T2 | 10200 | 250.78 | 0.4 | - |

| Graphite | exp(-5.7×10-4T+4.5) | 1950 | 710 | 0.8 | - |

| Stainless Steel | 9.2+0.0175T-2×10-6T2 | 7930 | 500 | 0.66 | - |

| CeF3 melt | 0.5 | 3200 | 1470.8 | - | 900 |

| CeF3 crystal | 1.72 | 5800 | 1064.52+0.198T+9.29×10-5T2 | - | 10 |

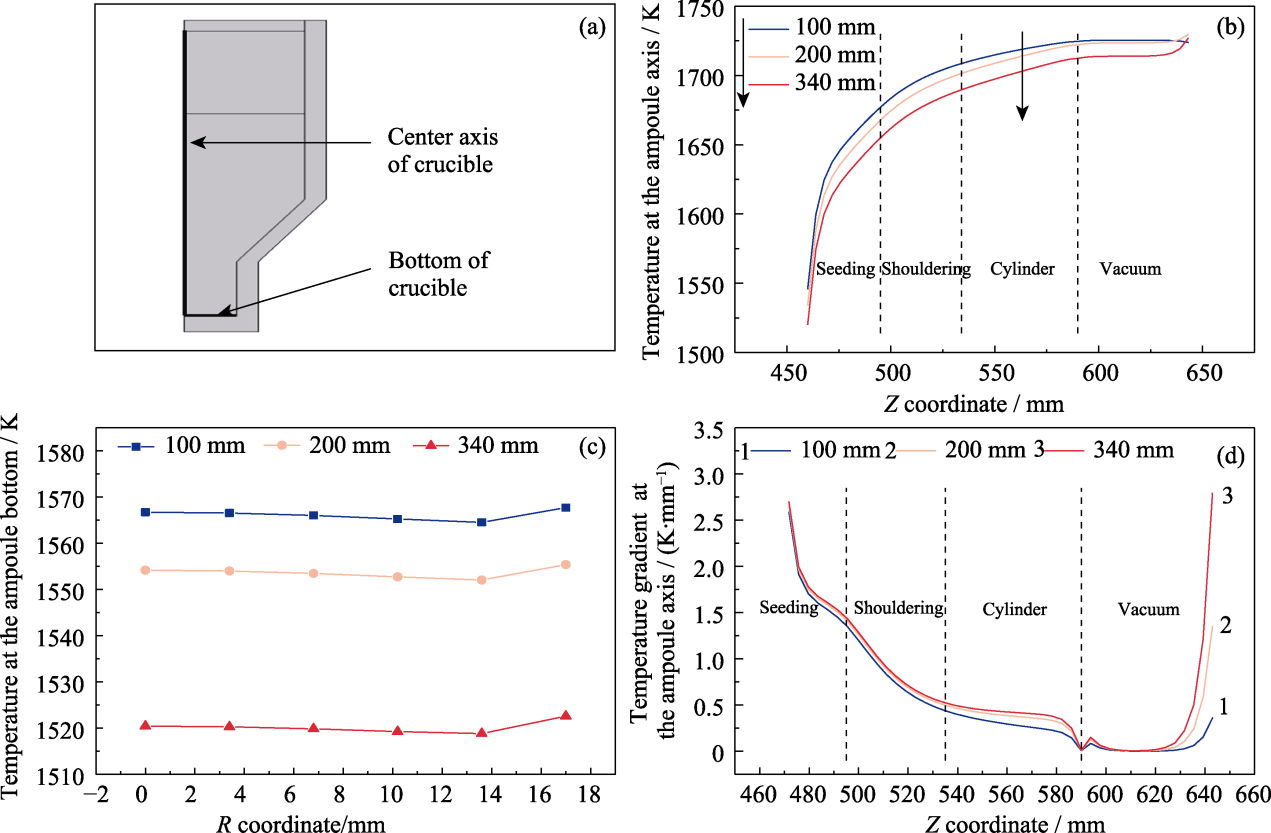

图3 不同长度发热体对应的坩埚内部温度分布

Fig. 3 Internal temperature distribution of the crucible corresponding to the heating elements of different lengths (a) Specific location schematic; (b) Longitudinal temperature at the central axis; (c) Radial temperature at the bottom of the crucible; (d) Longitudinal temperature gradient at the central axis; Colorful figures are available on website

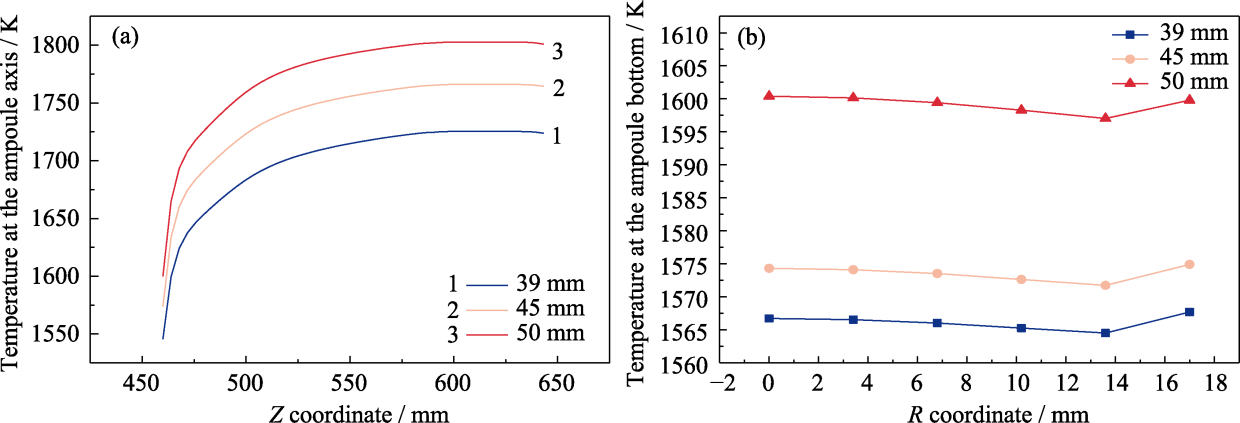

图4 不同宽度隔板对应的坩埚内部温度分布

Fig. 4 Temperature distributions inside the crucible corresponding to the partitions of different widths (a) Longitudinal temperature at the central axis; (b) Radial temperature at the bottom of the crucible; Colorful figures are available on website

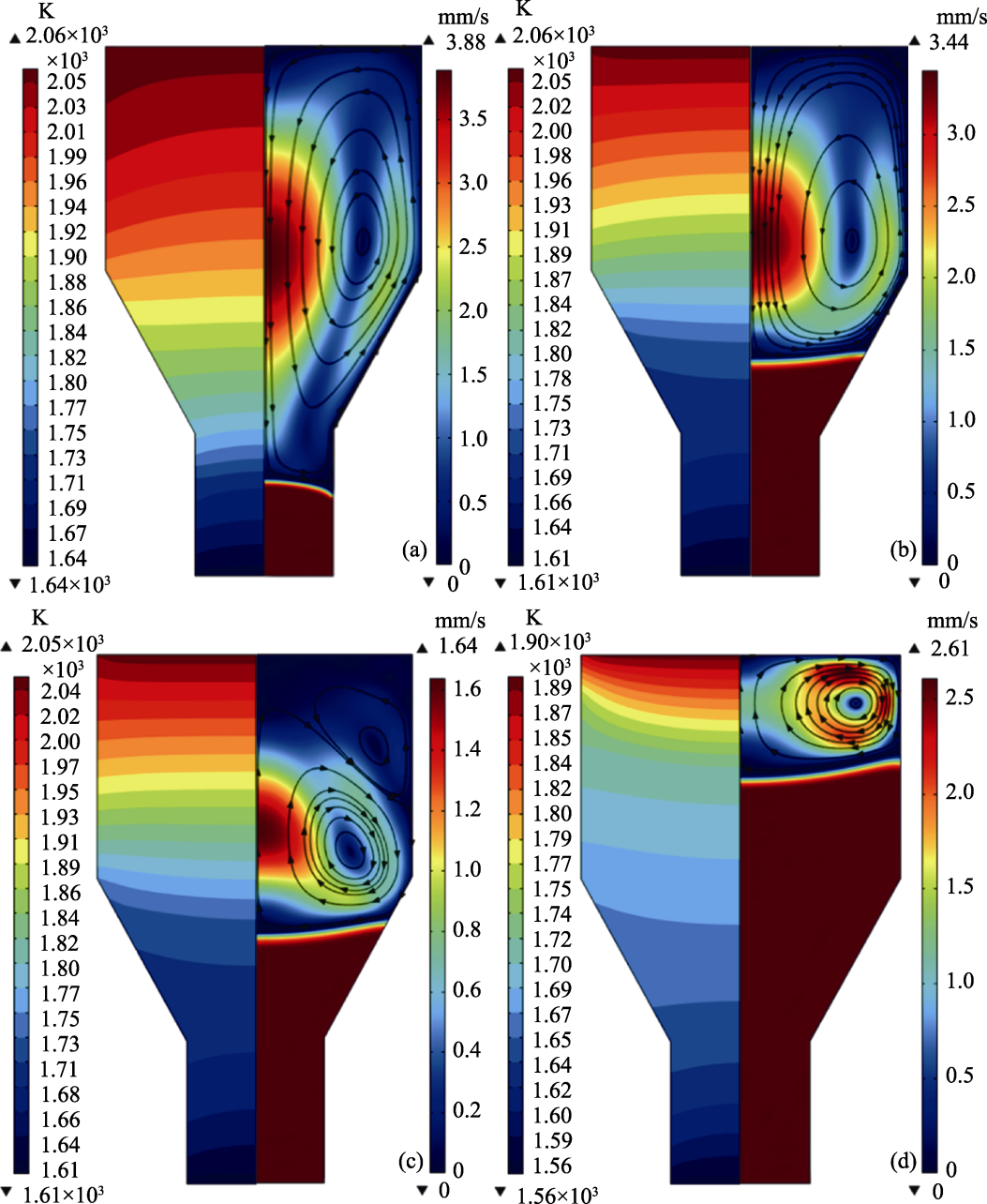

图5 不同生长阶段的温场分布(左)和流场分布及界面形状(右)

Fig. 5 Thermal field distribution (left) and flow field distribution, interface shape (right) at different growth stages (a) Seeding stage; (b) Beginning of shouldering stage; (c) End of shouldering stage; (d) Cylinder stage

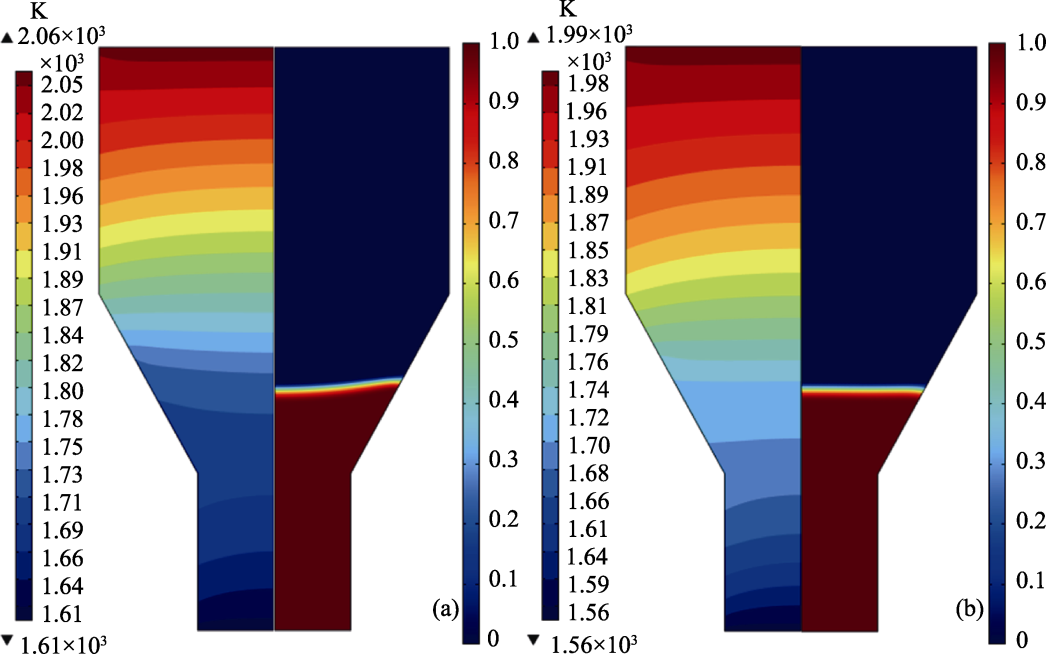

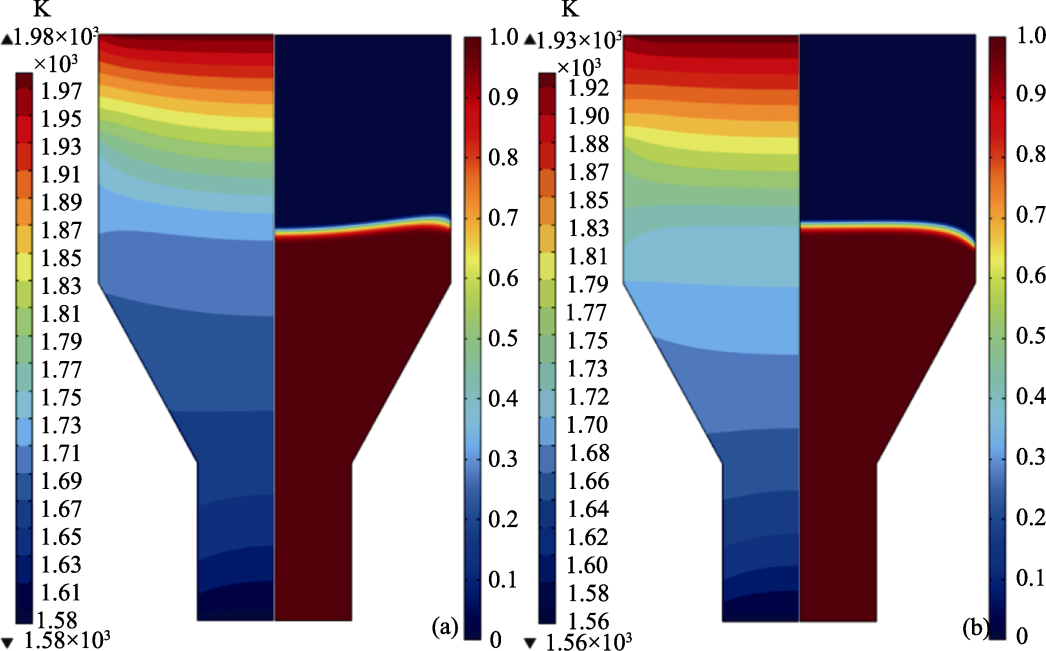

图7 放肩阶段温场分布(左)和界面形状(右)

Fig. 7 Thermal field distribution (left) and interface shape (right) in the shouldering stage (a) Original separator; (b) Trapezoidal separator

图8 等径阶段温场分布(左)和界面形状(右)

Fig. 8 Thermal field distribution (left) and interface shape (right) in the cylinder stage (a) Original partition without reflective screen; (b) Reflective screen without partition

| [1] |

STAROBOR A, MIRONOV E, PALASHOV O. High-power Faraday isolator on a uniaxial CeF3 crystal. Optics Letters, 2019, 44(6): 1297.

DOI URL |

| [2] |

LI H F, WANG J Y, CHEN J F, et al. Bridgman growth and magneto-optical properties of CeF3 crystal as Faraday Rotator. Optical Materials, 2020, 100: 109675.

DOI URL |

| [3] |

MOLINA P, VASYLIEV V, VILLORA E G, et al. CeF3 and PrF3 as UV-Visible Faraday rotators. Optics Express, 2011, 19(12): 11786.

DOI URL |

| [4] |

VOJNA D, SLEZAK O, YASUHARA R, et al. Faraday rotation of Dy2O3, CeF3 and Y3Fe5O12 at the mid-infrared wavelengths. Materials, 2020, 13(23): 5324.

DOI URL |

| [5] |

ZHAO G, ZHAO C C, YANG Y L, et al. Magneto-optical performances of novel neodymium-doped CeF3 crystal. Materials Letters, 2021, 300: 130134.

DOI URL |

| [6] |

KARIMOV D N, LISOVENKO D S, IVANOVA A G, et al. Bridgman growth and physical properties anisotropy of CeF3 single crystals. Crystals, 2021, 11(7): 793.

DOI URL |

| [7] |

YOSHIKAWA A, SATONAGA T, KAMADA K, et al. Crystal growth of Ce: PrF3 by micro-pulling-down method. Journal of Crystal Growth, 2004, 270(3/4): 427.

DOI URL |

| [8] | INAGAKI T, YOSHIMURA Y, KANDA Y, et al. Development of CeF3 crystal for high-energy electromagnetic calorimetry. Nuclear Instruments & Methods in Physics Research Section A-Accelerators Spectrometers Detectors and Associated Equipment, 2000, 443(1): 126. |

| [9] |

KUPPURAO S, DERBY J J. Designing thermal environments to promote convex interface shapes during the vertical Bridgman growth of cadmium zinc telluride. Journal of Crystal Growth, 1997, 172(3/4): 350.

DOI URL |

| [10] |

HAHN S H, YOON J K. Numerical analysis for the application of radiative reflectors to vertical Bridgman growth configurations. Journal of Crystal Growth, 1997, 177: 296.

DOI URL |

| [11] |

EPURE S, DUFFAR T, BRAESCU L. Comparison between analytical and numeric determination of the interface curvature during dewetted Bridgman crystal growth. Journal of Crystal Growth, 2008, 310(7/8/9): 1559.

DOI URL |

| [12] |

ZAPPETTINI A, ZhA M, MARCHINI L, et al. Control of the interface shape in vertical Bridgman grown CdZnTe crystals for X- ray detector applications. CrystEngComm, 2012, 14(18): 5992.

DOI URL |

| [13] |

YANG X, LV G, MA W, et al. The effect of radiative heat transfer characteristics on vacuum directional solidification process of multicrystalline silicon in the vertical Bridgman system. Applied Thermal Engineering, 2016, 93: 731.

DOI URL |

| [14] |

ZHAO W, LIU L. Control of heat transfer in continuous-feeding Czochralski-silicon crystal growth with a water-cooled jacket. Journal of Crystal Growth, 2017, 458: 31.

DOI URL |

| [15] |

ZHANG C, GAO B, TREMSIN A S, et al. Analysis of chemical stress and the propensity for cracking during the vertical Bridgman growth of BaBrCl:Eu. Journal of Crystal Growth, 2020, 546: 125794.

DOI URL |

| [16] | FEDYUSHKIN A I, BURAGO N G, PUNTUS A A. Convective heat and mass transfer modeling under crystal growth by vertical Bridgman method. Journal of Physics: Conference Series, 2020, 1479(1): 012029. |

| [17] |

KUPPURAO S, BRANDON S, DERBY J J. Modeling the vertical Bridgman growth of cadmium zinc telluride I. Quasi-steady analysis of heat transfer and convection. Journal of Crystal Growth, 1995, 155(1/2): 93.

DOI URL |

| [18] |

HONG B, ZHANG S, ZHENG L, et al. Studies on thermal and interface optimization for CdZnTe crystals by unseeded traveling heater method. Journal of Crystal Growth, 2020, 546: 125776.

DOI URL |

| [19] |

VOLLER V R, PRAKASH C. A fixed grid numerical modelling methodology for convection-diffusion mushy region phase-change problems. International Journal of Heat and Mass Transfer, 1987, 30(8): 1709.

DOI URL |

| [20] |

SPEDDING F H, BEAUDRY B J, HENDERSON D C, et al. High-temperature enthalpies and related thermodynamic functions of trifluorides of Sc, Ce, Sm, Eu, Gd, Tb, Dy, Er, Tm, and Yb. Journal of Chemical Physics, 1974, 60(4): 1578.

DOI URL |

| [21] |

HU K, ZHENG L, ZHANG H. Control of interface shape during high melting sesquioxide crystal growth by HEM technique. Journal of Crystal Growth, 2018, 483: 175.

DOI URL |

| [22] | HAO P, ZHU J, LIAO J, et al. Quality control and process optimization of ingot crystalline silicon based on neural network and genetic algorithm. Journal of Synthetic Crystals, 2022, 51(3): 385. |

| [1] | 郝永鑫, 秦娟, 孙军, 杨金凤, 李清连, 黄贵军, 许京军. 坩埚底角形状对提拉法生长同成分铌酸锂晶体的影响[J]. 无机材料学报, 2024, 39(10): 1167-1174. |

| [2] | 史艳磊, 孙聂枫, 徐成彦, 王书杰, 林朋, 马春雷, 徐森锋, 王维, 陈春梅, 付莉杰, 邵会民, 李晓岚, 王阳, 秦敬凯. 半密封直拉法生长6英寸磷化铟单晶热场研究[J]. 无机材料学报, 2023, 38(3): 335-342. |

| [3] | 孙晗, 李文俊, 贾子璇, 张岩, 殷利迎, 介万奇, 徐亚东. ACRT技术对大尺寸ZnTe晶体溶液法制备及其性能影响[J]. 无机材料学报, 2023, 38(3): 310-315. |

| [4] | 陈文波, 陈伦江, 刘川东, 程昌明, 童洪辉, 朱海龙. 射频热等离子体制备球形氧化铝粉末的数值模拟及实验研究[J]. 无机材料学报, 2018, 33(5): 550-556. |

| [5] | 王晓媛, 闫亚宾, 嶋田隆広, 北村隆行. 纳米铁电材料铁电性及其力电耦合特性的原子尺度模拟研究[J]. 无机材料学报, 2015, 30(6): 561-570. |

| [6] | 刘光霞, 王圣来, 丁建旭, 孙 云, 刘文洁, 朱胜军. 转速对KDP晶体成帽影响的数值模拟研究[J]. 无机材料学报, 2013, 28(06): 665-670. |

| [7] | 孙天拓, 林 健, 魏恒勇, 冯昭彬. 银纳米晶掺杂玻璃基片对Er3+/Yb3+共掺碲酸盐薄膜的荧光增强及其数值模拟[J]. 无机材料学报, 2011, 26(11): 1215-1220. |

| [8] | 魏玺,成来飞,张立同,徐永东. C/SiC复合材料等温化学气相浸渗过程的数值模拟研究[J]. 无机材料学报, 2006, 21(5): 1179-1184. |

| [9] | 常旭,唐春安,张后全,张永彬,张亚芳. 层状复合陶瓷增韧机理的数值模拟[J]. 无机材料学报, 2005, 20(2): 459-464. |

| [10] | 宇慧平,隋允康,张峰翊,常新安,安国平. φ300mm的大直径直拉单晶硅勾形磁场下生长的数值模拟[J]. 无机材料学报, 2005, 20(2): 453-458. |

| [11] | 张海斌,沈定中,任国浩,宫波. 坩埚下降法晶体生长中输运过程的数值模拟的研究进展[J]. 无机材料学报, 2002, 17(5): 910-914. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||