无机材料学报 ›› 2020, Vol. 35 ›› Issue (12): 1333-1339.DOI: 10.15541/jim20200182 CSTR: 32189.14.10.15541/jim20200182

所属专题: 结构陶瓷论文精选(2020)

收稿日期:2020-04-07

修回日期:2020-06-12

出版日期:2020-12-20

网络出版日期:2020-07-10

作者简介:刘金云(1994–), 女, 硕士研究生. E-mail: 1158381254@qq.com

基金资助:

LIU Jinyun( ),ZHANG Yuting,HONG Zhou,LIU Hua,WANG Shengxian,GU Xuehong(

),ZHANG Yuting,HONG Zhou,LIU Hua,WANG Shengxian,GU Xuehong( )

)

Received:2020-04-07

Revised:2020-06-12

Published:2020-12-20

Online:2020-07-10

About author:LIU Jinyun(1994–), female, Master candidate. E-mail: 1158381254@qq.com

Supported by:摘要:

中空纤维陶瓷膜具有装填密度高, 传质阻力低, 使用寿命长等优点, 被广泛用于膜分离领域。高度非对称结构的中空纤维膜有利于同时实现高通量与高截留率, 本研究采用共挤出法制备双层中空纤维陶瓷复合膜, 内外层纺丝液分别掺杂平均粒径为1 μm和300 nm的α-Al2O3粉体。系统考察了内层纺丝液TiO2掺杂量、外层纺丝液Al2O3/聚醚砜(PESf)质量比和煅烧温度对膜的结构与性能的影响。结果表明, 在内层纺丝液TiO2掺杂量为2wt%, 外层纺丝液Al2O3/PESf质量比为5.60, 烧结温度为1350 ℃的最优条件下, 中空纤维膜断裂负荷为24 N、平均孔径为0.15 μm、去油率为97.5%。

中图分类号:

刘金云, 张玉亭, 洪周, 刘华, 王圣贤, 顾学红. 共挤出法制备双层中空纤维陶瓷复合膜[J]. 无机材料学报, 2020, 35(12): 1333-1339.

LIU Jinyun, ZHANG Yuting, HONG Zhou, LIU Hua, WANG Shengxian, GU Xuehong. Fabrication of Dual-layer Hollow Fiber Ceramic Composite Membranes by Co-extrusion[J]. Journal of Inorganic Materials, 2020, 35(12): 1333-1339.

| Suspension composition | Inner layer | Outer layer |

|---|---|---|

| Solvent (NMP) | 33.34 | 37.81 |

| Al2O3 (1 μm) | 55.35 | / |

| Al2O3 (300 nm) | / | 49.15 |

| Polymer (PESf) | 9.77 | 11.34 |

| Additive (PVP) | 1.54 | 1.70 |

表1 双层中空纤维膜纺丝液组成/wt%

Table 1 Suspension composition of dual-layer hollow fiber membrane/wt%

| Suspension composition | Inner layer | Outer layer |

|---|---|---|

| Solvent (NMP) | 33.34 | 37.81 |

| Al2O3 (1 μm) | 55.35 | / |

| Al2O3 (300 nm) | / | 49.15 |

| Polymer (PESf) | 9.77 | 11.34 |

| Additive (PVP) | 1.54 | 1.70 |

图1 双层中空纤维膜和单层中空纤维膜SEM照片

Fig. 1 SEM images of dual-layer hollow fiber and single-layer hollow fiber Cross-section morphologies of (a, b) dual-layer hollow fiber precursor, (c, d) dual-layer hollow fiber, (e, f) 1 μm single-layer hollow fiber; SEM images of the surface morphology: (g) dual-layer hollow fiber, (h) 1 μm single-layer hollow fiber

| Property | η/% | Fracture load/N | Pure water flux/(m3?m-2?h-1) | Porosity/% | Average pore size/μm | RTOC/% |

|---|---|---|---|---|---|---|

| Single-layer (1 μm) | 13.0 | 9 | 3.52 | 51.57 | 0.70 | 95.4 |

| Single-layer (300 nm) | 16.9 | 19 | 0.86 | 48.20 | 0.13 | 98.4 |

| Dual-layer (1 μm/300 nm) | 14.3 | 12 | 2.30 | 50.89 | 0.24 | 97 |

表2 单层与双层中空纤维膜的性能比较

Table 2 Comparison of properties between single-layer and dual-layer hollow fiber membranes

| Property | η/% | Fracture load/N | Pure water flux/(m3?m-2?h-1) | Porosity/% | Average pore size/μm | RTOC/% |

|---|---|---|---|---|---|---|

| Single-layer (1 μm) | 13.0 | 9 | 3.52 | 51.57 | 0.70 | 95.4 |

| Single-layer (300 nm) | 16.9 | 19 | 0.86 | 48.20 | 0.13 | 98.4 |

| Dual-layer (1 μm/300 nm) | 14.3 | 12 | 2.30 | 50.89 | 0.24 | 97 |

| TiO2 content/wt% | η/% | Fracture load/N | Pure water flux/ (m3?m-2?h-1) | Porosity/% | Average pore size/μm |

|---|---|---|---|---|---|

| 0 | 14.3 | 12 | 2.30 | 50.89 | 0.240 |

| 2 | 14.9 | 24 | 1.65 | 48.05 | 0.152 |

| 5 | 14.9 | 22 | 1.32 | 49.97 | 0.147 |

| 10 | 15.2 | 20 | 1.21 | 46.43 | 0.150 |

| 15 | 15.3 | 19 | 1.12 | 45.68 | 0.145 |

| 20 | 16.3 | 17 | 0.91 | 43.90 | 0.141 |

表3 TiO2掺杂量对双层中空纤维膜性能的影响

Table 3 Influence of TiO2 content on properties of dual-layer hollow fiber membranes

| TiO2 content/wt% | η/% | Fracture load/N | Pure water flux/ (m3?m-2?h-1) | Porosity/% | Average pore size/μm |

|---|---|---|---|---|---|

| 0 | 14.3 | 12 | 2.30 | 50.89 | 0.240 |

| 2 | 14.9 | 24 | 1.65 | 48.05 | 0.152 |

| 5 | 14.9 | 22 | 1.32 | 49.97 | 0.147 |

| 10 | 15.2 | 20 | 1.21 | 46.43 | 0.150 |

| 15 | 15.3 | 19 | 1.12 | 45.68 | 0.145 |

| 20 | 16.3 | 17 | 0.91 | 43.90 | 0.141 |

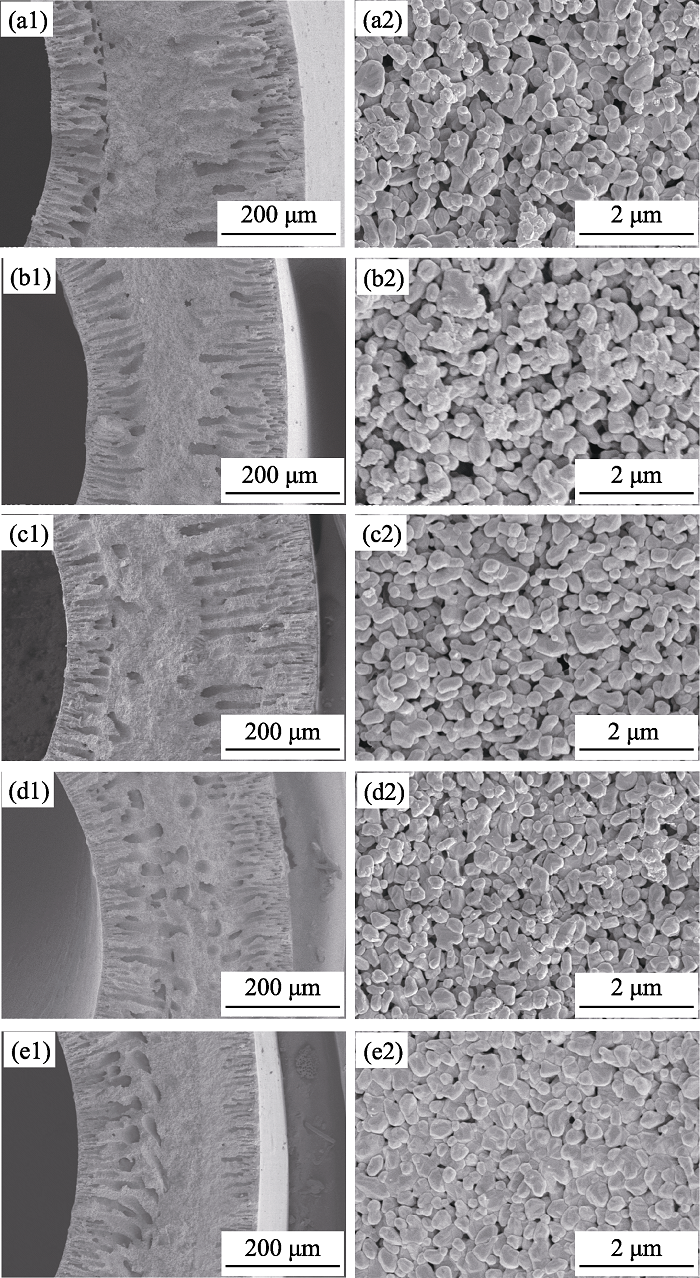

图3 不同外层纺丝液Al2O3/PESf质量比的双层中空纤维膜SEM照片

Fig. 3 SEM images of dual-layer hollow fiber membranes with different Al2O3/PESf mass ratios in outer suspension (a) 2.75; (b) 4.33; (c) 5.60; (d) 7.50; (e) 13.3

| Al2O3/PESf | Outer suspension viscosity/cP | Fracture load/N | Pure water flux/ (m3?m-2?h-1) | Porosity/ % | Mean pore size/μm | RTOC/% |

|---|---|---|---|---|---|---|

| 2.75 | 7320 | 21 | 1.99 | 49.90 | 0.180 | 97.3 |

| 4.33 | 8580 | 22 | 1.10 | 52.26 | 0.175 | 97.5 |

| 5.60 | 9720 | 23 | 1.41 | 53.91 | 0.130 | 97.5 |

| 7.50 | 11020 | 25 | 1.08 | 53.31 | 0.125 | 97.6 |

| 13.30 | 58300 | 23 | 0.48 | 52.54 | 0.115 | 97.8 |

表4 外层纺丝液Al2O3/PESf质量比对双层中空纤维膜性能的影响

Table 4 Influence of Al2O3/PESf mass ratio in outer suspension on properties of dual-layer hollow fiber membranes

| Al2O3/PESf | Outer suspension viscosity/cP | Fracture load/N | Pure water flux/ (m3?m-2?h-1) | Porosity/ % | Mean pore size/μm | RTOC/% |

|---|---|---|---|---|---|---|

| 2.75 | 7320 | 21 | 1.99 | 49.90 | 0.180 | 97.3 |

| 4.33 | 8580 | 22 | 1.10 | 52.26 | 0.175 | 97.5 |

| 5.60 | 9720 | 23 | 1.41 | 53.91 | 0.130 | 97.5 |

| 7.50 | 11020 | 25 | 1.08 | 53.31 | 0.125 | 97.6 |

| 13.30 | 58300 | 23 | 0.48 | 52.54 | 0.115 | 97.8 |

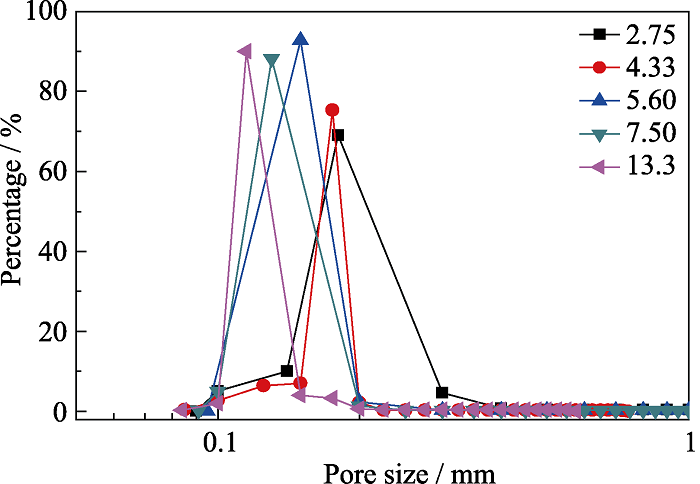

图4 外层纺丝液Al2O3/PESf质量比对双层中空纤维膜孔径分布的影响

Fig. 4 Influence of Al2O3/PESf mass ratio in outer suspension on pore size distribution of dual-layer hollow fiber membranes

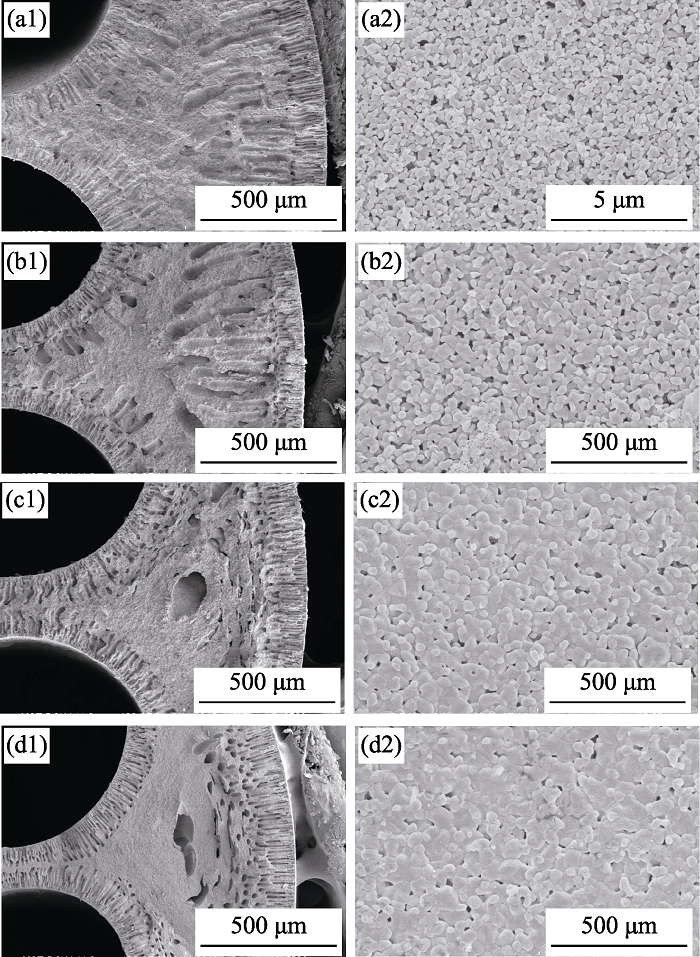

图5 不同温度烧结的双层氧化铝中空纤维膜的SEM照片

Fig. 5 SEM images of dual-layer hollow fiber membrane of alumina sintered at different temperatures (a)1250 ℃, (b)1300 ℃, (c) 1350 ℃, (d)1400 ℃

| Temperature/℃ | Fracture load/N | Pure water flux/(m3?m-2?h-1) | Porosity/% | Average pore size/μm | RTOC/% |

|---|---|---|---|---|---|

| 1250 | 11 | 3.23 | 61.97 | 0.235 | 96.7 |

| 1300 | 15 | 2.34 | 55.62 | 0.199 | 97.4 |

| 1350 | 24 | 1.20 | 48.88 | 0.150 | 97.5 |

| 1400 | 37 | 0.26 | 40.33 | 0.126 | 98.3 |

表5 不同烧结温度对双层中空纤维性能的影响

Table 5 Influence of sintering temperature on the properties of dual-layer hollow fiber membranes

| Temperature/℃ | Fracture load/N | Pure water flux/(m3?m-2?h-1) | Porosity/% | Average pore size/μm | RTOC/% |

|---|---|---|---|---|---|

| 1250 | 11 | 3.23 | 61.97 | 0.235 | 96.7 |

| 1300 | 15 | 2.34 | 55.62 | 0.199 | 97.4 |

| 1350 | 24 | 1.20 | 48.88 | 0.150 | 97.5 |

| 1400 | 37 | 0.26 | 40.33 | 0.126 | 98.3 |

| Membranes | Sintering temperature/℃ | Average pore size/μm | Pure water flux/ (m3?m-2?h-1) | Bending strength/MPa | Fracture load/N | Ref. |

|---|---|---|---|---|---|---|

| Single-Channel Al2O3 hollow fiber | 1455 | 0.10 | 0.664 | 88.2 | - | [ |

| Single-Channel Al2O3 hollow fiber | 1500 | 0.75 | 1.280 | 85.8 | - | [ |

| 4-Channel Al2O3 hollow fiber | 1500 | 1.20 | 2.710 | - | 22 | [ |

| 7-Channel Al2O3 hollow fiber | 1350 | 0.183 | 1.070 | - | 14 | [ |

| 7-Channel YSZ/Al2O3 hollow fiber | 1400 | 230.00 | 1.640 | - | 14 | [ |

| 4-Channel 1 μm/300 nm Al2O3 hollow fiber | 1350 | 0.15 | 1.260 | - | 24 | This work |

表6 不同中空纤维陶瓷膜性能比较

Table 6 Comparison in properties of different hollow fiber ceramic membranes

| Membranes | Sintering temperature/℃ | Average pore size/μm | Pure water flux/ (m3?m-2?h-1) | Bending strength/MPa | Fracture load/N | Ref. |

|---|---|---|---|---|---|---|

| Single-Channel Al2O3 hollow fiber | 1455 | 0.10 | 0.664 | 88.2 | - | [ |

| Single-Channel Al2O3 hollow fiber | 1500 | 0.75 | 1.280 | 85.8 | - | [ |

| 4-Channel Al2O3 hollow fiber | 1500 | 1.20 | 2.710 | - | 22 | [ |

| 7-Channel Al2O3 hollow fiber | 1350 | 0.183 | 1.070 | - | 14 | [ |

| 7-Channel YSZ/Al2O3 hollow fiber | 1400 | 230.00 | 1.640 | - | 14 | [ |

| 4-Channel 1 μm/300 nm Al2O3 hollow fiber | 1350 | 0.15 | 1.260 | - | 24 | This work |

| [1] | WANG S X, TIAN J Y, WANG Q, et al. Low-temperature sintered high-strength CuO doped ceramic hollow fiber membrane: preparation, characterization and catalytic activity. Journal of Membrane Science, 2019,570-571:333-342. |

| [2] | LEE M, WU Z T, WANG R, et al. Micro-structured alumina hollow fibre membranes- potential applications in wastewater treatment. Journal of Membrane Science, 2014,461:39-48. |

| [3] | HONG J L, MIN K K, JUNG H P. Decompression stripping of carbon dioxide from rich monoethanolamine through porous hydrophobic modified ceramic hollow fiber membrane contactor. Separation and Purification Technology, 2020,236:1-8. |

| [4] | YANG N T, TAN X Y, MA Z F, et al. Fabrication and characterization of Ce0.8Sm0.2O1.9 microtubular dual-structured electrolyte membranes for application in solid oxide fuel cell technology. Journal of the American Ceramic Society, 2009,92(11):2544-2550. |

| [5] | KINGSBURY B F K, LI K. A morphological study of ceramic hollow fibre membranes. Journal of Membrane Science, 2009,328(1/2):134-140. |

| [6] | AZIZ M H A, OTHMAN M H D, HASHIM N A, et al. Fabrication and characterization of mullite ceramic hollow fiber membrane from natural occurring ball clay. Applied Clay Science, 2019,177:51-62. |

| [7] | HUBADILLAH S K, OTHMAN M H D, ISMAIL A F, et al. Fabrication of low cost, green silica based ceramic hollow fibre membrane prepared from waste rice husk for water filtration application. Ceramics International, 2018,44(9):10498-10509. |

| [8] | HENNE W, DUNWEG G, SCHMITZ W, et al. Method of Producing Dialyzing Membrane. US, D01F1/08, US04164437, 1979.08.14. |

| [9] | XIA Q C, LIU M L, CAO X L, et al. Structure design and applications of dual-layer polymeric membranes. Journal of Membrane Science, 2018,562:85-111. |

| [10] | ONG Y K, CHUNG T S. Pushing the limits of high performance dual-layer hollow fiber fabricated via (IPS)-P-2 process in dehydration of ethanol. AIChE Journal, 2013,59(8):3006-3018. |

| [11] | LI D F, CHUNG T S, WANG R. Morphological aspects and structure control of dual-layer asymmetric hollow fiber membranes formed by a simultaneous co-extrusion approach. Journal of Membrane Science, 2004,243(1-2):155-175. |

| [12] | SETIAWAN L, SHI L, KRANTZ W B, et al. Explorations of delamination and irregular structure in poly(amide-imide)-polyethersulfone dual layer hollow fiber membranes. Journal of Membrane Science, 2012,423:73-84. |

| [13] | KHAN I U, OTHMAN M H D, ISMAIL A F, et al. Status and improvement of dual-layer hollow fiber membranes via co-extrusion process for gas separation: a review. Journal of Natural Gas Science and Engineering, 2018,52:215-234. |

| [14] | SHI G M, WANG Y, CHUNG T S. Dual-layer PBI/P84 hollow fibers for pervaporation dehydration of acetone. AIChE Journal, 2012,58(4):1133-1145. |

| [15] | BONYADI S, CHUNG T S. Flux enhancement in membrane distillation by fabrication of dual layer hydrophilic-hydrophobic hollow fiber membranes. Journal of Membrane Science, 2007,306(1/2):134-146. |

| [16] | JONG J D, BENES N E, KOOPS G H, et al. Towards single step production of multi-layer inorganic hollow fibers. Journal of Membrane Science, 2004,239(2):265-269. |

| [17] | DROUSHIOTIS N, OTHMAN M H D, DORASWAMI U, et al. Novel co-extruded electrolyte-anode hollow fibres for solid oxide fuel cells. Electrochemistry Communications, 2009,11(9):1799-1802. |

| [18] | OTHMAN M H D, WU Z T, DROUSHIOTIS N, et al. Single-step fabrication and characterisations of electrolyte/anode dual-layer hollow fibres for micro-tubular solid oxide fuel cells. Journal of Membrane Science, 2010,351(1/2):196-204. |

| [19] | JAMIL S M, OTHMAN M H D, RAHMAN M A, et al. Properties and performance evaluation of dual-layer ceramic hollow fiber with modified electrolyte for MT-SOFC. Renewable Energy, 2019,134:1423-1433. |

| [20] | GONG X, MENG X X, YANG N T, et al. Electrolyte thickness control and its effect on YSZ/Ni-YSZ dual-layer hollow fibres. Journal of Inorganic Materials, 2013,28(10):1108-1114. |

| [21] | WU Z T, WANG B, LI K. A novel dual-layer ceramic hollow fibre membrane reactor for methane conversion. Journal of Membrane Science, 2010,352(1-2):63-70. |

| [22] | CHENG H D, WANG X B, MENG X, et al. Dual-layer BaCe0.8Y0.2O3-δ-Ce0.8Y0.2O2-δ/BaCe0.8Y0.2O3-δ-Ni hollow fiber membranes for H2 separation. Journal of Membrane Science, 2020,:117801-1-9. |

| [23] | CHONG J Y, WANG B, LI K. High performance stainless steel- ceramic composite hollow fibres for microfiltration. Journal of Membrane Science, 2017,541:425-433. |

| [24] | SHI Z Z, ZHANG Y T, CAI C, et al. Preparation and characterization of α-Al2O3 hollow fiber membranes with four-channel configuration. Ceramics International, 2015,41(1):1333-1339. |

| [25] | CAI C, ZHANG Y T, ZHANG C, et al. Microstructure modulation of α-Al2O3 hollow fiber membranes with four-channel geometric configuration. Asia-Pacific Journal of Chemical Engineering, 2016,11(6):949-957. |

| [26] | KALITA S J, SOMANI V. Al2TiO5-Al2O3-TiO2 nanocomposite: Structure, mechanical property and bioactivity studies. Materials Research Bulletin, 2010,45(12):1803-1810. |

| [27] | STANCIU L, GROZA J R, STOICA L, et al. Influence of powder precursors on reaction sintering of Al2TiO5. Scripta Materialia, 2004,50(9):1259-1262. |

| [28] | LEE M, WU Z, WANG R, et al. Micro-structured alumina hollow fibre membranes-potential applications in wastewater treatment. Journal of Membrane Science, 2014,461:39-48. |

| [29] |

ZHU L, JI J, WANG S, et al. Removal of Pb(II) from wastewater using Al2O3-NaA zeolite composite hollow fiber membranes synthesized from solid waste coal fly ash. Chemosphere, 2018,206:278-284.

DOI URL PMID |

| [30] | LEE M, WU Z, WANG B, et al. Micro-structured alumina multi- channel capillary tubes and monoliths. Journal of Membrane Science, 2015,489:64-72. |

| [31] | WANG B, LEE M, LI K. YSZ-reinforced alumina multi-channel capillary membranes for micro-filtration. Membranes, 2016,6:5. |

| [1] | 杨燕, 张发强, 马名生, 王墉哲, 欧阳琪, 刘志甫. 基于CuO-TiO2-Nb2O5复合氧化物烧结助剂的ZnAl2O4陶瓷低温烧结研究[J]. 无机材料学报, 2025, 40(6): 711-718. |

| [2] | 马彬彬, 钟婉菱, 韩涧, 陈椋煜, 孙婧婧, 雷彩霞. ZIF-8/TiO2复合介观晶体的制备及光催化活性[J]. 无机材料学报, 2024, 39(8): 937-944. |

| [3] | 贾鑫, 李晋宇, 丁世豪, 申倩倩, 贾虎生, 薛晋波. Pd纳米颗粒协同氧空位增强TiO2光催化CO2还原性能[J]. 无机材料学报, 2023, 38(11): 1301-1308. |

| [4] | 安琳, 吴淏, 韩鑫, 李耀刚, 王宏志, 张青红. 非贵金属Co5.47N/N-rGO助催化剂增强TiO2光催化制氢性能[J]. 无机材料学报, 2022, 37(5): 534-540. |

| [5] | 吕庆洋, 张玉亭, 顾学红. 超声辅助溶胶-凝胶法制备中空纤维TiO2超滤膜[J]. 无机材料学报, 2022, 37(10): 1051-1057. |

| [6] | 肖翔, 郭少柯, 丁成, 张志洁, 黄海瑞, 徐家跃. CsPbBr3@TiO2核壳结构纳米复合材料用作水稳高效可见光催化剂[J]. 无机材料学报, 2021, 36(5): 507-512. |

| [7] | 席文, 李海波. TiO2/Ti3C2Tx复合材料的制备及其杂化电容脱盐特性的研究[J]. 无机材料学报, 2021, 36(3): 283-291. |

| [8] | 刘彩, 刘芳, 黄方, 王晓娟. 海藻基CDs-Cu-TiO2复合材料的制备及其光催化性能[J]. 无机材料学报, 2021, 36(11): 1154-1162. |

| [9] | 李翠霞, 孙会珍, 金海泽, 史晓, 李文生, 孔文慧. 3D多级孔rGO/TiO2复合材料的构筑及其光催化性能研究[J]. 无机材料学报, 2021, 36(10): 1039-1046. |

| [10] | 王苹,李心宇,时占领,李海涛. Ag与Ag2O协同增强TiO2光催化制氢性能的研究[J]. 无机材料学报, 2020, 35(7): 781-788. |

| [11] | 季邦, 赵文锋, 段洁利, 马立哲, 付兰慧, 杨洲. 泡沫镍网负载TiO2/WO3薄膜对乙烯的光催化降解[J]. 无机材料学报, 2020, 35(5): 581-588. |

| [12] | 王旭聪, 邓浩, 姜忠义, 袁立永. 不同N源无定形TiO2/g-C3N4光催化还原Re(VII)性能[J]. 无机材料学报, 2020, 35(12): 1340-1348. |

| [13] | 陈浩禹, 张亦文, 吴忠, 秦真波, 吴姗姗, 胡文彬. 强磁靶共溅射法制备具有室温磁电阻特性的Co-TiO2纳米复合薄膜[J]. 无机材料学报, 2020, 35(11): 1263-1267. |

| [14] | 吕喜庆, 张环宇, 李瑞, 张梅, 郭敏. Nb2O5包覆对TiO2纳米阵列/上转换发光复合结构柔性染料敏化太阳能电池性能的影响[J]. 无机材料学报, 2019, 34(6): 590-598. |

| [15] | 简刚, 刘美瑞, 张晨, 邵辉. 用于高介电复合材料的全包裹Ag@TiO2填充颗粒的制备[J]. 无机材料学报, 2019, 34(6): 641-645. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||