Journal of Inorganic Materials ›› 2019, Vol. 34 ›› Issue (6): 646-652.DOI: 10.15541/jim20180394

Previous Articles Next Articles

Yan-Zhe ZHOU1,2,Min LIU2( ),Kun YANG2,Wei ZENG2,Jin-Bing SONG2,Chun-Ming DENG2,Chang-Guang DENG2

),Kun YANG2,Wei ZENG2,Jin-Bing SONG2,Chun-Ming DENG2,Chang-Guang DENG2

Received:2018-09-03

Revised:2018-10-31

Published:2019-06-20

Online:2019-05-23

Supported by:CLC Number:

Yan-Zhe ZHOU, Min LIU, Kun YANG, Wei ZENG, Jin-Bing SONG, Chun-Ming DENG, Chang-Guang DENG. Microstructure and Property of MoSi2-30Al2O3 Electrothermal Coating Prepared by Atmospheric Plasma Spraying[J]. Journal of Inorganic Materials, 2019, 34(6): 646-652.

| Sample | Current/A | Voltage/V | Distance/mm | Flux of Ar/(L?min-1) | Flux of H2/(L?min-1) | Powder feed rate/(g?min-1) |

|---|---|---|---|---|---|---|

| NiAl | 600 | 70 | 110 | 45 | 8 | 20 |

| MgAl2O4 | 630 | 75 | 110 | 40 | 11 | 19 |

| MoSi-Al2O3 | 600 | 76 | 110 | 41 | 12 | 24 |

Table 1 Atmospheric plasma spraying parameters

| Sample | Current/A | Voltage/V | Distance/mm | Flux of Ar/(L?min-1) | Flux of H2/(L?min-1) | Powder feed rate/(g?min-1) |

|---|---|---|---|---|---|---|

| NiAl | 600 | 70 | 110 | 45 | 8 | 20 |

| MgAl2O4 | 630 | 75 | 110 | 40 | 11 | 19 |

| MoSi-Al2O3 | 600 | 76 | 110 | 41 | 12 | 24 |

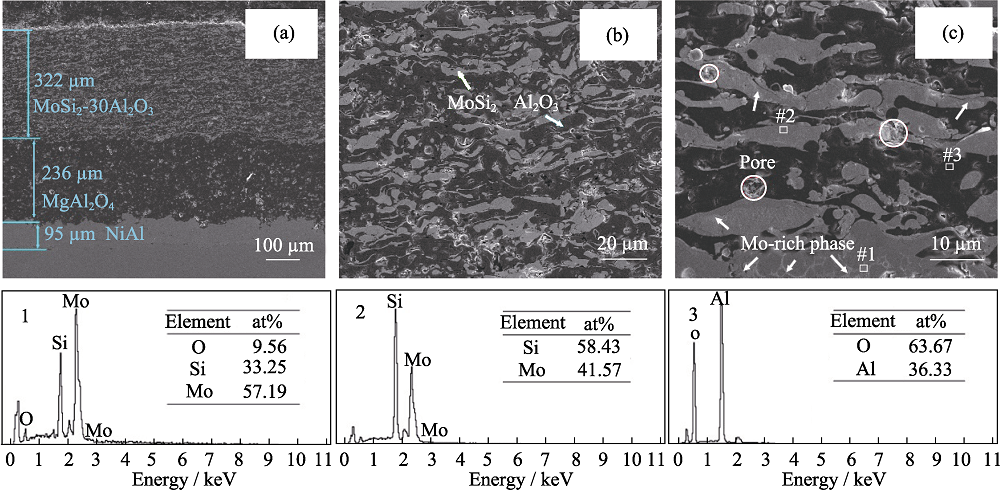

Fig. 3 Polished cross-section morphologies of electrothermal coating system (a) and MoSi2-30Al2O3 coating (b, c); EDS analysis of corresponding points (1,2,3)

| [1] |

PRUDENZIATI M . Development and the implementation of high-temperature reliable heaters in plasma spray technology. Journal of Thermal Spray Technology, 2008,17(2):234-243.

DOI URL |

| [2] |

GADOW R, KILLINGER A, LI C . Product development with thermally sprayed functional coatings on glass and glass-ceramics substrates. International Journal of Applied Ceramic Technology, 2005,2(6):493-503.

DOI URL |

| [3] |

PRUDENZIATI M, GUALTIERI M L . Electrical properties of thermally sprayed Ni- and Ni20Cr-based resistors. Journal of Thermal Spray Technology, 2008,17(3):385-394.

DOI URL |

| [4] | CHANG C, CHEN C Z, SUN W C , et al. Microstructure and electrothermal properties of SiC/55MoSi2 materials. Journal of Silicate, 2003,231:862-866. |

| [5] | SCHEITZ S, TOMA F L, BERGER L M , et al. Thermisch gespritzte keramische Schichtheizelemente. Thermally Sprayed Multilayer Ceramic Heating Elements, 2011,4:88-92. |

| [6] |

ZHANG Y, LI Y, BAI C . Microstructure and oxidation behavior of Si-MoSi2 functionally graded coating on Mo substrate. Ceramics International, 2017,43(8):6250-6256.

DOI URL |

| [7] | FENG P Z, QU X H . Progress in the research and application of MoSi2 heating element. China Molybdenum Indusry, 2005,29(2):38-42. |

| [8] | BERZTISS D A, CERCHIARA R R, GULBRANSEN E A , et al. Oxidation of MoSi2 and comparison with other silicide materials. Materials Science & Engineering A, 1992,155(1/2):165-181. |

| [9] |

CHOU T C, NIEH T G . Mechanism of MoSi2 pest during low temperature oxidation. Journal of Materials Research, 1993,8(1):214-226.

DOI URL |

| [10] |

FEI X, NIU Y, JI H , et al. Oxidation behavior of Al2O3 reinforced MoSi2 composite coatings fabricated by vacuum plasma spraying. Ceramics International, 2010,36:2235-2239.

DOI URL |

| [11] | HUANG H H, LIU Y S, CHEN Y M , et al. Effect of oxygen pressure on the microstructure and properties of the Al2O3-SiO2 thin films deposited by E-beam evaporation. Surface & Coatings Technology, 2006,200(10):3309-3313. |

| [12] |

KÖBEL S, PLÜSCHKE J, VOGT U , et al. MoSi2-Al2O3 electroconductive ceramic composites. Ceramics International, 2004,30(8):2105-2110.

DOI URL |

| [13] |

TOMA F L, SCHEITZ S, BERGER L M , et al. Comparative study of the electrical properties and characteristics of thermally sprayed alumina and spinel coatings. Journal of Thermal Spray Technology, 2011,20(1/2):195-204.

DOI URL |

| [14] |

MAO J Y, LIU M, MAO J , et al. Oxidation-resistance of ZrB2-MoSi2 composite coatings prepared by atmospheric plasma spraying. Journal of Inorganic Materials, 2015,30(3):282-286.

DOI URL |

| [15] |

WANG L, FU Q, ZHAO F . Improving oxidation resistance of MoSi2 coating by reinforced with Al2O3 whiskers. Intermetallics, 2018,94:106-113.

DOI URL |

| [16] | LIU X Z, DENG C M, DENG C G , et al. Mullite-modified ZrB2-MoSi2 coating for carbon/carbon composites to withstand long term ablation. Ceramics International, 2017,44(4):4330-4337. |

| [17] | NEWMAN A, SAMPATH S, HERMAN H . Processing and properties of MoSi2-SiC and MoSi2-Al2O3. Materials Science & Engineering A, 1999,261(1/2):252-260. |

| [18] | WANG D Z, LIU X Y, ZUO T Y . MoSi2-Mo5Si3 low temperature behavior of MoSi2-Mo5Si3 composites. Journal of Rare Metal materials and Engineering, 2002,31(1):48-51. |

| [19] |

ZHOU H M, LIU G Q, XIAO L R , et al. Low temperature oxidation behavior of MoSi2 composeties strengthened and toughened by Si3N4 particles and SiC whiskers. Journal of Inorganic Materials, 2009,24(5):929-933.

DOI URL |

| [20] |

MESCHTER P J . Oxidation of MoSi2/TiB2 and MoSi2/Al2O3 mixtures. Scripta Metallurgica Et Materialia, 1991,25(5):1065-1069.

DOI URL |

| [21] | MARUYAMA T, YANAGIHARA MK . High temperature oxidation and pesting ofo(Si,A)2. Materials Science & Engineering A, 1997, 239-240:828-841. |

| [22] | WANG G, ZHAO S K, JIANG W . Progress in the low temperature oxidation of MoSi2. Journal of Inorganic Materials, 2001,16(6):1041-1048. |

| [1] | LI Jie, LUO Zhixin, CUI Yang, ZHANG Guangheng, SUN Luchao, WANG Jingyang. CMAS Corrosion Resistance of Y3Al5O12/Al2O3 Ceramic Coating Deposited by Atmospheric Plasma Spraying [J]. Journal of Inorganic Materials, 2024, 39(6): 671-680. |

| [2] | LI Da-Chuan, ZHAO Hua-Yu, ZHONG Xing-Hua, TAO Shun-Yan. Research Progresses of Atmospheric Plasma Sprayed Splat [J]. Journal of Inorganic Materials, 2017, 32(6): 571-580. |

| [3] | SUN Xu-Xuan, CHEN Hong-Fei, YANG Guang, LIU Bin, GAO Yan-Feng. YSZ- Ti3AlC2 Thermal Barrier Coating and Its Self-healing Behavior under High Temperatures [J]. Journal of Inorganic Materials, 2017, 32(12): 1269-1274. |

| [4] | YU Fang-Li, BAI Yu, WU Xiu-Ying, Wang Hai-Jun, WU Jiu-Hui. Corrosion Resistance and Anti-wear Property of Nickel Based Abradable Sealing Coating Deposited by Plasma Spraying [J]. Journal of Inorganic Materials, 2016, 31(7): 687-693. |

| [5] | MAO Jin-Yuan, LIU Min, MAO Jie, DENG Chun-Min, ZENG De-Chang, XU Lin. Oxidation-resistance of ZrB2-MoSi2 Composite Coatings Prepared by Atmospheric Plasma Spraying [J]. Journal of Inorganic Materials, 2015, 30(3): 282-286. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||