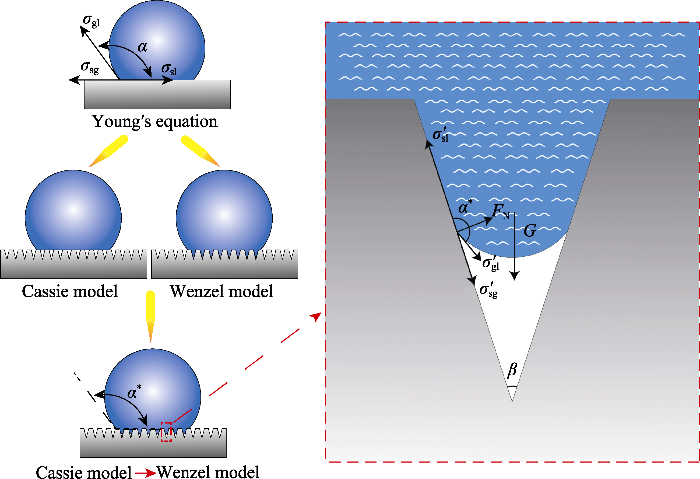

已有研究表明, 微织构可以改善碳化硅表面的疏水效果。马春红团队[15]应用激光加工各种微织构的加工沟槽具有不同的高度、宽度和间距, 并且碳化硅表面的疏水性随着表面粗糙度的增加而增大。赵美云团队[16]对不同种类的微织构做了更详细的研究, 他们采用激光雕刻机在陶瓷表面加工了一系列的微织构, 发现不同种类的微织构对表面性能的影响不同。相比之下, 柱状纹理不仅可以改善陶瓷表面的疏水性, 而且可以提高陶瓷的抗冻性和耐磨性。此外, 在理论研究方面, 王树涛团队[17]根据固体和液体的接触状态, 总结了五种固液接触的模型。Wenzel模型是指液体完全填满沟槽的状态, 而Cassie模型则是指沟槽中没有液体的状态。还有一种模型介于Cassie模型和Wenzel模型之间, 即只有一部分液体进入凹槽。除了这三个模型之外, 还有两个模型是特殊的固液接触状态: 一个是“莲花”状态, 因与莲花表面接触相似而得名; 另一个是“壁虎”状态, 液体交错填满凹槽, 这种形态经常出现在纳米管表面。在Wenzel模型和Cassie模型的基础上, Bico等[18]做了很多计算和对比实验, 他们将影响接触角的因素分为两个无量纲参数, 即表面粗糙度和沟槽比, 沟槽比指的是沟槽面积和接触面面积之间的比率。目前有许多理论模型用于计算疏水角, 并用来解释微织构对接触角的影响, 但没有模型研究形态特征参数和疏水角之间的关系, 无法从微织构对疏水角进行预测并对改善微织构提出建议。

本研究利用皮秒激光在碳化硅上加工一系列的微织构, 探讨了影响润湿性能的表面形态学参数, 并研究了皮秒激光对碳化硅表面的烧蚀作用原理和氟硅烷(FAS)对碳化硅表面润湿性改性的作用原理。并且实验还分析了沟槽形态和沟槽比例对疏水性的影响, 并提出涉及具体形貌参数的接触角模型, 在对接触性能改良原理做出解释的同时进一步预测了其它形貌的接触角, 从而指导微织构的改良方向。

1 实验方法

1.1 碳化硅样品准备

实验选择在2020 ℃下常压烧结的碳化硅块作为样品, 块体材料的纯度为98.5%, 密度为3.12 g/cm³。为了消除原始平面形状和附着杂质的影响, 使用300目(48 μm)的金刚砂纸将碳化硅块平面打磨平整, 并清洗干燥。

1.2 微织构制备及形貌表征

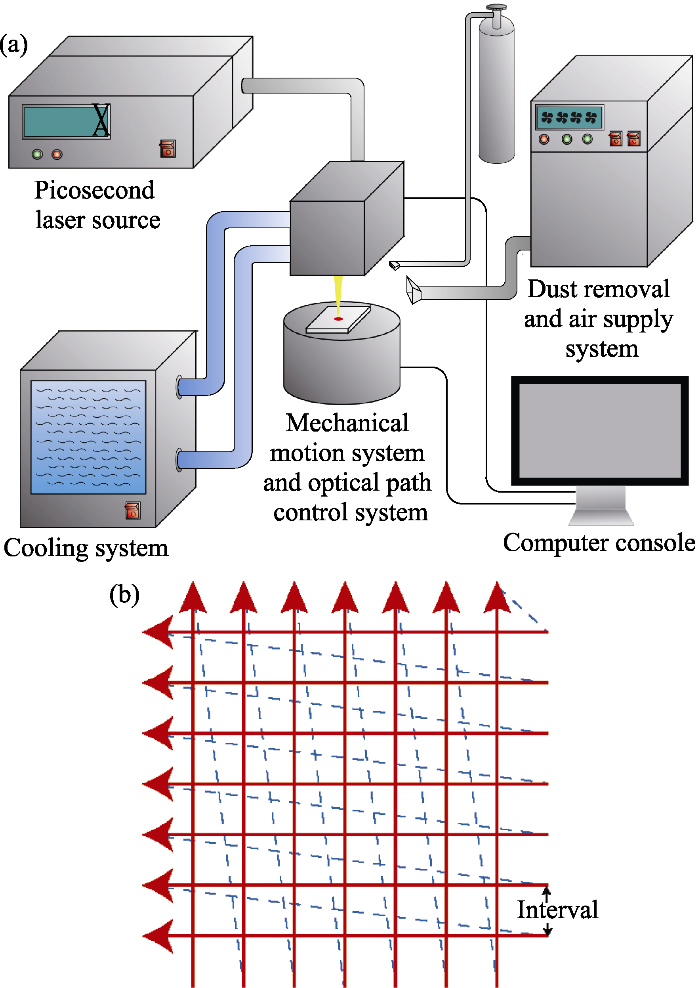

图1

图1

激光加工系统(a)及其加工路径(b)

Fig. 1

Laser processing system (a) and corresponding processing paths (b)

表1 皮秒激光加工参数

Table 1

| Serial number | Power/ W | Speed/ (mm·s-1) | Interval/ μm |

|---|---|---|---|

| A-1~A-10 | 9 | 125 | 64/80/100/125/150/ |

| 200/250/300/400/500 | |||

| B-1~B-10 | 6 | 100 | 64/80/100/125/150/ |

| 200/250/300/400/500 | |||

| C-1~C-10 | 3 | 50 | 64/80/100/125/150/ |

| 200/250/300/400/500 |

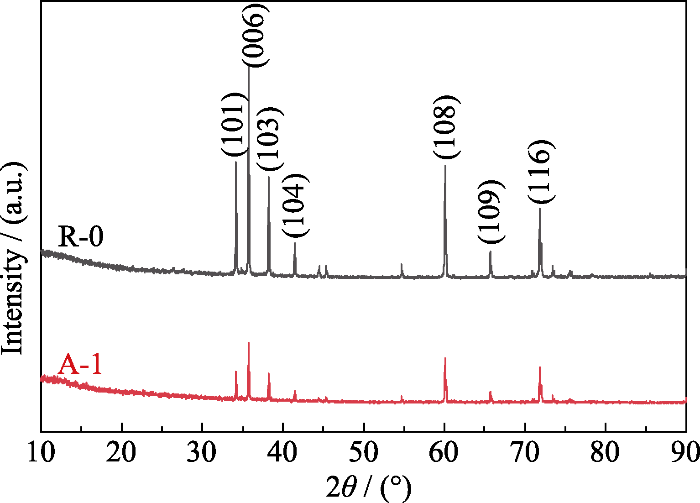

利用BRUKER D8 ADVANCE型X射线衍射仪(XRD)检测激光加工后碳化硅表面的相组成变化情况, 检测范围为2θ=10°~90°, 对应的检测速度为5 (°)/min。此外, 采用VK-X250型激光共聚焦显微镜分析微观形态, 通过其配备的多文件分析软件 (VK-X系列)可以获得特定区域的三维形态学信息, 进而得到微观形态的具体形状和参数。

1.3 表面化学修饰及润湿性表征

实验选择氟硅烷(FAS)溶液作为改性剂, FAS全称为十七氟癸基三乙氧基硅烷(C8F17C2H4-Si(OC2H5)3), 使用时用无水乙醇稀释到1%[19], 并加入两滴盐酸作为催化剂。将三组经过微织构加工的样品以及一个原始样品R-1放入FAS溶液中浸泡24 h进行化学修饰, 随后在120 ℃下干燥4 h, 最终获得表面被氟硅烷包覆的碳化硅块。

碳化硅表面的固液接触角是用来表征表面性能变化的指标, 测量中使用蒸馏水作为接触液体以避免固液间的反应性接触。实验使用JCY-1型接触角测量仪器, 它可以记录接触图像, 并有多种接触角测量方法。为了保证测量结果的准确性, 实验采用小尺寸的34G针作为滴液的针头, 并采用几何法来测定接触角。

2 结果与讨论

2.1 表面形貌分析

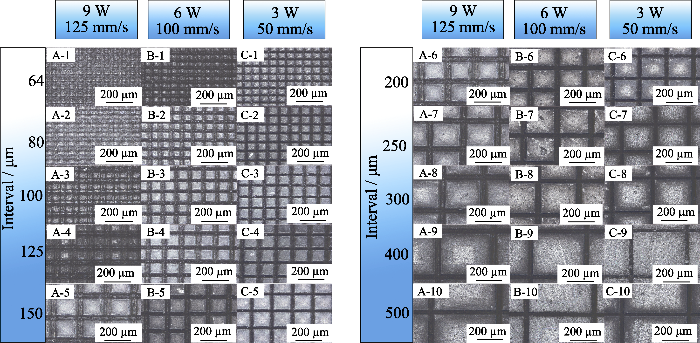

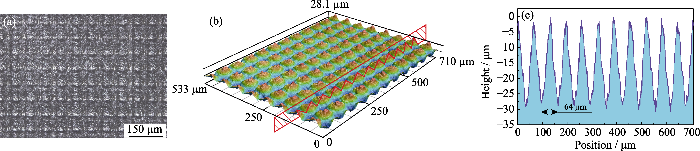

图2

图3

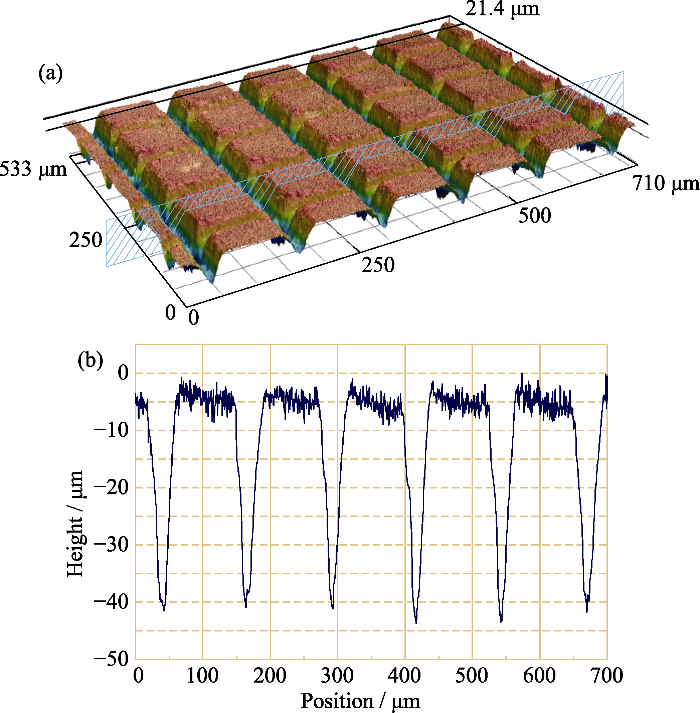

在激光加工过程中, 碳化硅吸收激光能量在烧蚀过程中分解升华。实验中使用的皮秒激光能量密度在光斑中按高斯分布, 当激光能量从光斑中心向外传递时, 光斑形状则会保持原有的激光密度分布。同时, 在激光加工过程中, 碳化硅存在一个烧蚀阈值, 只有当能量密度高于烧蚀阈值时, 碳化硅才会被烧蚀, 从而导致激光加工后的沟槽呈现出倒三角形的不完整的高斯分布形状, 如图4(a, b)所示。因此, 实验中选择凹槽深度和凹槽宽度作为微织构研究的特征参数。

图4

图4

样品C-4表面形貌的3D图(a)及其对应的横截面形状(b)

Fig. 4

Surface morphology of laser confocal 3D model (a) and corresponding cross-sectional shape (b) of sample C-4

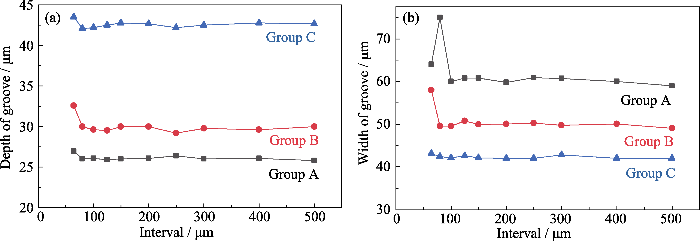

图5

图5

表面形貌特征的参数分析

Fig. 5

Parametric analyses of morphological features

(a) Depth of groove; (b) Width of groove

图6

图6

样品A-1表面形貌的图像、3d图和对应横截面

Fig. 6

Surface morphologies of A-1

(a) Photograph of laser machined reticular micro-texture; (b) Laser confocal 3D model; (c) Cross-sectional shape of (b)

2.2 表面接触角分析

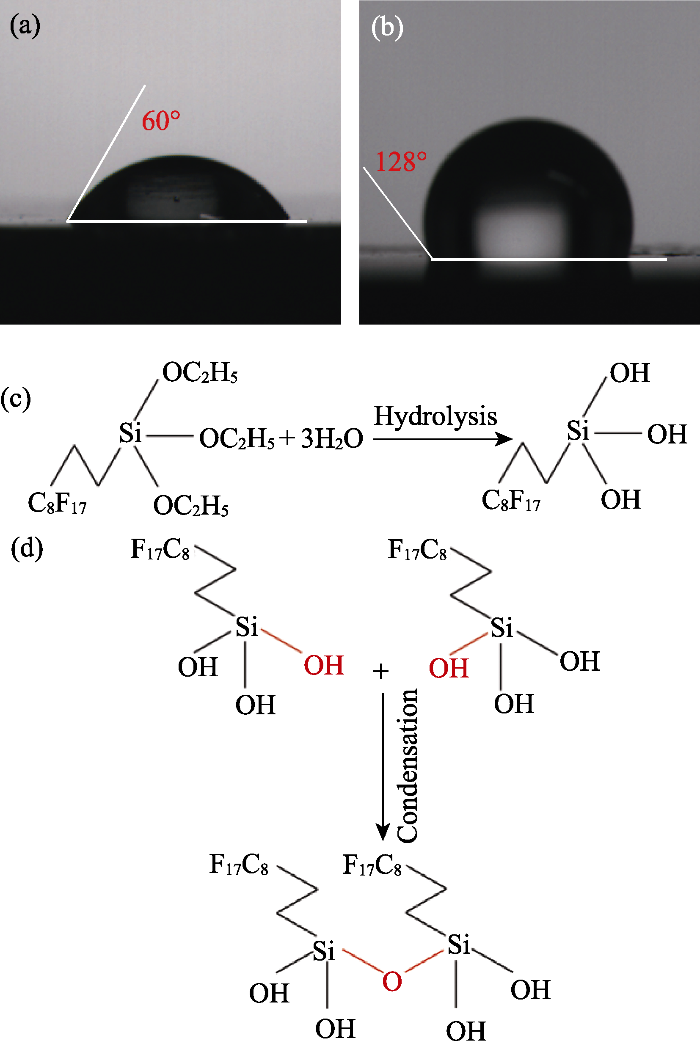

比较R-0和R-1的接触角(图7(a, b)), 原始碳化硅表面具有较高的表面能使其表现出亲水性, 而FAS改性使碳化硅表面的接触角从60°增大到128°。在化学改性过程中, 十七氟癸基三乙氧基硅烷(C8F17C2H4Si(OC2H5)3)中的官能团-OC2H5通过水解和脱水缩合相互连接[25], 同时, 基团-OH可以与Si连接(如图7(c, d)所示), 这意味着FAS可以稳定地附着在SiC的表面并形成涂层[26]。另一方面, 硅原子另一侧的基团-CF3和-CF2沿着碳化硅的外侧表面分布, 而这两个基团的亲油和疏水特性, 使碳化硅表面获得了较低的表面能, 从亲水表面转变为疏水表面[27-28]。

图7

图7

修饰对接触角的影响及修饰过程中的水解缩合

Fig. 7

Effect of modification on contact angle and its modification principle

(a) Contact angle of R-0; (b) Contact angle of R-1; (c) Hydrolysis of FAS; (d) Dehydration condensation

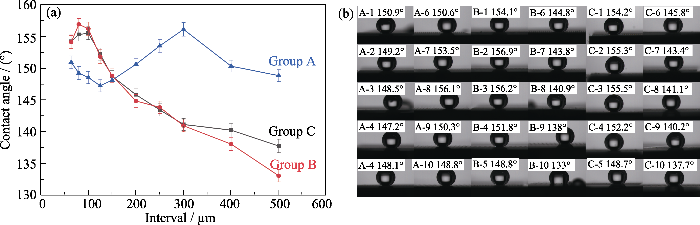

从图8中可以看出, 微织构样品表面的最小固液接触角为133°, 依旧大于没有微织构原始表面的128°, 证明碳化硅表面的微织构可以提高其疏水性能。实验中A、B和C组的最大接触角分别为156°、157°和155°, 这些接触角并没有出现在加工间隔最小、微织构最密的情况下。在其他条件不变的情况下, 微织构纹理密度随着加工间隔增加而降低, 导致接触角大小逐渐趋向于原始表面的接触角。但从图8中还可以看出, 接触角随着加工间隔增大呈现先增后减的趋势, 只有当各组的加工间隔大于一个特定值时, 接触角才会持续减小并向原始表面接触角靠拢。为了探究这一现象, 本文引入了杨氏方程、Wenzel模型和Cassie模型从理论上进行分析。

图8

图8

三组样品的接触角变化和图像

Fig. 8

Statistics and photographs of contact angle for samples

(a) Contact angles of three groups with processing intervals; (b) Contact angle photographs of three groups

杨氏方程研究的是表面影响接触角的因素, 在液体与固体表面接触时, 固、液、气之间的界面力相互平衡, 形成了杨氏接触角α, 如图9所示[29]。在接触面存在微织构的条件下, 根据水是否渗入微织构, 对杨氏方程进行改良, 得到Cassie模型和Wenzel模型。在Cassie模型中, 水完全不渗入微织构, 在杨氏方程中引入了一个修正量fs, 即固液接触面积占总接触面积中的比例。与此相对的Wenzel模型中, 水充满了微织构, 在杨氏方程中引入了一个粗糙度变量Rw, 即实际固液接触面积与微织构投影到平面上面积的比例[30-31]。本研究采用介于Cassie模型和Wenzel模型之间的过渡模型, 并在综合考虑了两种模型的影响因素基础上, 提出了过渡模型的修正杨氏方程(公式(1))[32⇓-34]。

图9

图9

接触角模型的改良方法和沟槽内渗入水的受力分析

Fig. 9

Improvement of contact angle model and its force analysis of infiltrated water in the groove

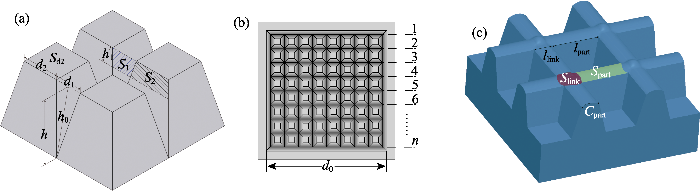

分析微织构形貌, 如图10(a~c), 计算气液接触面积Sgl、固液接触面积Ssl和它们的投影面积Sp:

图10

图10

微观纹理的形态特征参数

Fig. 10

Morphological parameters of micro-texture

(a) Micro grooves; (b) Micro-texture area; (c) Solid-liquid contact area of infiltrated water

其中, c是渗透率:

同时, 公式(1)可以转化为以下形式:

在充分考虑所有参数关系的条件下, 通过合并常数得到一个更简单的公式, 即公式(7)。

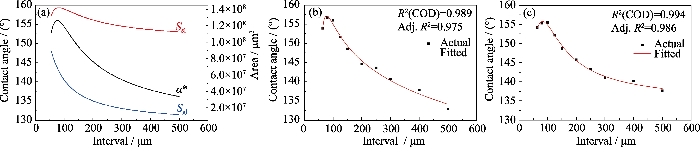

图11

图11

理论接触角变化和两组样品的拟合预测曲线

Fig. 11

Theoretical contact angle variation and fitted curves

(a) Theoretical variation of contact angle; (b) Fitted curve of variation of contact angle of group B; (c) Fitted curve of variation of contact angle of group C

通过对该疏水角模型的分析可知, 气液接触面积和固液接触面积增大使疏水性随着加工间隔减小而持续增强。然而, 当加工间隔小于某一定值时, 固液接触面积开始减少。而当固液接触面积减小对疏水性的减弱效果大于固气接触面积增大对疏水性的增强效果时, 表面疏水性开始下降, 这就产生了接触角随着加工间隔减小而先增大后减小的现象。

3 结论

皮秒激光加工可以精确控制SiC上加工的微织构的形态, 同时, 合适的加工参数可以获得更精细的微织构。

1)激光加工过程以激光烧蚀为主, 重熔为辅。激光能量的高斯分布, 使烧蚀沟槽呈现倒三角形。同时, 过窄的加工间隔引起的激光重熔效应会增加织构凹槽的宽度, 而过高的激光功率引起的重熔效应又会减少织构凹槽的深度;

2)氟硅烷是修饰碳化硅表面的理想修饰剂, 它能牢固地覆盖在碳化硅表面, 使其从亲水表面转变为固液接触角达128°的疏水表面。同时, 微织构可以进一步提高疏水性能, 使固液接触角增加到157°, 达到超疏水的效果;

3)文中提出的固液接触角模型很好地解释接触角的实际变化规律。微织构通过改变固、气、液两两之间的接触面积来影响接触角的大小。从模型来看, 相同凹槽存在一个特定的微织构密度, 使接触角达到最大。该模型对如何改良微织构来提高疏水性能提供了理论指导。

参考文献

Characterization of a silicon nitride ceramic material for ceramic springs

Thermal and corrosion properties of silicon nitride for copper die casting components

All-SiC telescope technology: recent progress and achievements

Thermal and environmental barrier coatings for SiC/SiC CMCs in aircraft engine applications

Evaluation of aggregates surface micro-texture using spectral analysis

Analysis of the research status of surface texture technology

Characterization and distribution of water-repellent, self-cleaning plant surfaces

Superhydrophobic nanocomposite surface topography and ice adhesion

Electrochemical micromachining of micro-dimple arrays on cylindrical inner surfaces using a dry-film photoresist

Experimental evaluation of surface generation and force time-varying characteristics of curvilinear grooved micro end mills fabricated by EDM

Applying micro-texture to cast iron surfaces to reduce the friction coefficient under lubricated conditions

Micro-texture at the coated tool face for high performance cutting

Friction properties of lubricated laser-microtextured-surfaces: an experimental study from boundary-to hydrodynamic-lubrication

Fractal characterization of surface microtexture of Ti6Al4V subjected to ultrasonic vibration assisted milling

Improving hydrophobicity of laser textured SiC surface with micro-square convexes

Preparation of ceramic superhydrophobic surface based on laser engraving technology

Definition of superhydrophobic states

Wetting of textured surfaces

Superhydrophilicity/superhydrophobicity of nickel micro-arrays fabricated by electroless deposition on an etched porous aluminum template

Investigations on the oxidation phenomenon of SiC/SiC fabricated by high repetition frequency femtosecond laser

Investigation on the laser ablation of SiC ceramics using micro-Raman mapping technique

Research on the laser ablation behavior of SiC ceramics has great significance for the improvement of their anti-laser ability as high-performance mirrors in space and lasers, or the laser surface micro-machining technology as electronic components in micro-electron mechanical systems (MEMS). In this work, the laser ablation of SiC ceramics has been performed by using laser pulses of 12 ns duration at 1064 nm. The laser induced damage threshold (LIDT) below 0.1 J/cm2 was obtained by 1-on-1 mode and its damage morphology appeared in the form of “burning crater” with a clear boundary. Micro-Raman mapping technique was first introduced in our study on the laser ablation mechanisms of SiC surface by identifying physical and chemical changes between uninjured and laser-ablated areas. It has been concluded that during the ablation process, SiC surface mainly underwent decomposition to the elemental Si and C, accompanied by some transformation of crystal orientation. The oxidation of SiC also took place but only in small amount on the edges of target region, while there was no hint of SiO2 in the center with higher energy density, maybe because of deficiency of O2 atmosphere in the ablated area, elimination of SiO2 by carbon at 1505 °C, or evaporating at 2230 °C.

Experimental investigation on laser micromilling of SiC microchannels

Surface structuring by laser remelting of metals

Influence of surface morphology on processing of C/SiC composites via femtosecond laser

Surface hydrophobic modification of biochar by silane coupling agent KH-570

Biochar-amended soil cover (BSC) in landfills can improve the oxidation of methane. However, adding biochar can cause a larger amount of rainwater to enter the soil cover and landfill because it increases the permeability of the soil cover, which increases leachate production. Improving the hydrophobicity and waterproof ability of BSC is expected to reduce rainwater that goes into landfills. Silane coupling agent KH-570 is used to modify biochar to improve its hydrophobicity and waterproof ability after being added to the soil cover. The waterproofness of hydrophobic biochar-amended soil cover (HBSC) was studied by conducting a precipitation simulation test. Results showed that the optimum hydrophobicity of the surface-modified biochar was obtained when the mass fraction of KH-570 was 7%, the biochar dosage was 7 g, and the modification temperature was 60 °C. In these conditions, the contact angle was 143.99° and the moisture absorption rate was 0.10%. The analysis results of thermogravimetric, X-ray diffractometer and scanning electron microscopy before and after the biochar modification showed that KH-570 formed a hydrophobic organic coating layer on the biochar surface, indicating that the surface hydrophobic modification of biochar was successfully carried out by silane coupling agent. The waterproof ability of HBSC was significantly better than that of BSC in the simulated precipitation test.

Identification of surface structures on 3C-SiC nanocrystals with hydrogen and hydroxyl bonding by photoluminescence

Approaching super-hydrophobicity from cellulosic materials: a review

Definitions for hydrophilicity, hydrophobicity, and superhydrophobicity: getting the basics right

Surface tension, interfacial tension and contact angles of ionic liquids

Preparation and characterisation of super-hydrophobic surfaces

A modified Wenzel model for hydrophobic behavior of nanostructured surfaces

Apparent contact angles on rough surfaces: the Wenzel equation revisited

Hybrid Cassie-Wenzel model for droplets on surfaces with nanoscale roughness

Derivation of the Wenzel and Cassie equations from a phase field model for two phase flow on rough surface