目前, 有关NN陶瓷晶相组成调控的研究报道很多[8,9], 如利用压力、温度、外置电场、晶粒尺寸和化学组成等方法调控, 普遍认为, NN陶瓷在室温下的主晶相为AFE(P相)和亚稳相为FE(Q相)[4], 尺寸效应和外加电场可以诱导NN陶瓷出现亚稳FE相[8], 所以NN陶瓷很难在室温下观察到双电滞回线, 从而限制了NN陶瓷在储能领域的应用。美国宾夕法尼亚州立大学CLIVE课题组[4,9-13]通过掺杂(BiScO3(BS)、SrZrO3(SZ)、CaZrO3(CZ)、CaHfO3(CH))使NN出现了双电滞回线, 但是没有对储能性能进行评价。Liu等[2]研究了CZ掺杂对NN微观结构、相组成和电学性能的影响, 成功获得了双电滞回线, 当CZ掺杂量(摩尔分数)为0.04%时, NN-0.04CZ陶瓷晶粒平均粒径最小, 击穿强度(Breakdown strength, BDS)约141 kV/cm, 有效储能密度(Wrec)只有0.55 J/cm3, 储能效率(η)仅为63%, 与其它AFE材料的储能性能相差较大, 且BDS较低。Qi等[14]研究了(0.94-x)NaNbO3-0.06BaZrO3-xCaZrO3陶瓷的储能性能, 当x=0.04时, 在0.1 Hz下, 样品的Wrec为1.59 J/cm3, 但η只有30%。Wang课题组[15,16]通过掺杂CaSnO3(CS), 在室温下成功获得了双电滞回线, 并研究了稀土La、Sm和Lu对0.96NN-0.04CS储能性能的影响。

储能密度(W)、有效储能密度(Wrec)和储能效率(η)是储能材料的主要参数, 计算公式如下[1]:

其中, P, Pmax, Pr和E分别代表极化强度、最大极化强度、剩余极化强度和外加电场强度。为了提高W和Wrec, 需要同时增加Pmax, 减小Pr并提高BDS。

变价离子价态丰富, 可以占据A位、B位或者同时占据A位和B位, 能够很好地调控材料的性能。如Mn离子在煅烧过程中可能出现Mn2+/Mn3+/Mn4+, 对应的离子半径为0.083、0.064和0.053 nm, 可以取代A位的Ag或者B位的Nb, 对AgNbO3的储能性能起到很好的调控作用[17]。掺杂Mn减少了NN陶瓷的氧空位, 电学性能得到改善[18]。本工作采用固相法制备了NNCZ-xFe陶瓷, 通过掺杂可变价的过渡金属元素Fe来调控0.96NaNbO3-0.04CaZrO3(NNCZ)陶瓷性能, 以降低NNCZ的烧结温度, 减小样品的晶粒尺寸, 抑制氧空位的迁移速率,提高其BDS, 从而最终提高NNCZ陶瓷的Wrec和η。

1 实验方法

采用固相法制备(0.96NaNbO3-0.04CaZrO3)- xFe2O3 (x=0, 0.005, 0.01, 0.015, 0.02, 0.025)陶瓷, 简写NNCZ-xFe。Nb2O5(99.5%)、Na2CO3(99.8%)、CaCO3(99%)、ZrO2(99%)、Fe2O3(99%)称量前充分干燥, 以无水乙醇为分散剂, 氧化锆球为介质, 球磨24 h, 料浆烘干后压成直径为5 cm的圆片, 在800 ℃下预烧6 h。二次球磨后的泥浆干燥过筛得到预合成的粉体, 加入PVA(质量分数5%)造粒, 在340 MPa下压制成直径为13 mm, 厚度~1 mm圆片生坯。在600 ℃排胶2 h, 采用埋烧的方式, NNCZ和NNCZ-xFe 分别在1370和1230 ℃下煅烧2 h得到陶瓷。陶瓷样品两面经过抛光, 使用丝网印刷, 根据测试需要刷不同直径的银浆, 在550 ℃下保温30 min制备银电极, 用于电学性能测试。

采用X射线衍射仪(XRD, D8-Advance A25, Bruker)和扫描电子显微镜(SEM, SU8010, Hitachi)对样品相组成和微观形貌进行表征, 采用介电温谱测试系统(HP4294A, Agilent)测试介电温谱, 采用铁电综合测试系统(Trek model 609B, Radiant)获得陶瓷的电滞回线, 采用X射线光电子能谱仪(XPS, EscaLab250Xi, Thermo Fisher Scientific)对样品表面的化学元素价态及含量进行表征, 采用绝缘电阻仪测得直流电阻(TH2684, Tonghui)。

2 结果与讨论

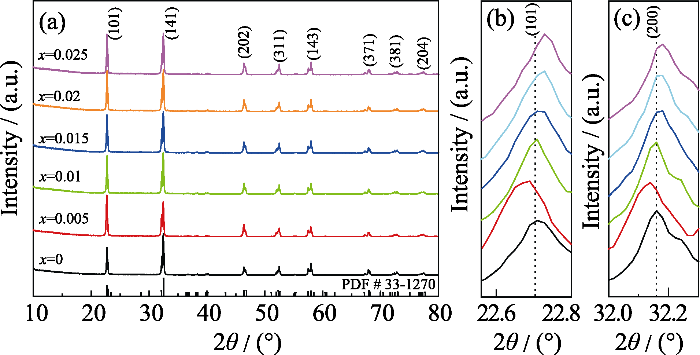

图1为NNCZ-xFe陶瓷的XRD图谱。由图1(a)可见, NNCZ-xFe陶瓷呈现单一的钙钛矿相, 没有出现明显的第二相, 且结晶度较好, 说明Fe3+成功固溶进入NNCZ晶格。从局部放大的图1(b, c)可见, 随着Fe2O3掺杂量增大, 衍射峰先向低角度再向高角度移动, 表明NNCZ-xFe陶瓷晶胞体积随着Fe2O3掺杂量的增加, 先变大后减小。NNCZ的烧结温度为1370 ℃, 在较高温度下Na+会挥发, 从而导致化学计量偏离和晶粒异常长大及晶胞体积减小[19]。掺杂Fe2O3使NNCZ陶瓷的烧结温度降到1230 ℃, 烧结温度降低使钠离子挥发量减少, 与NNCZ相比, 晶胞体积变大。所以少量离子半径较小的Fe3+(0.0645 nm)置换离子半径较大的Zr4+ (0.072 nm), NNCZ-0.005Fe陶瓷的晶胞体积仍然比NNCZ大, XRD衍射峰向低角度偏移[20]。

图1

图1

NNCZ-xFe陶瓷的XRD图谱

(a), 22.5º~22.8º放大图谱(b)和31.8º~33.0º放大图谱(c)

Fig. 1

XRD patterns of NNCZ-xFe ceramics

(a), enlarged XRD patterns from 22.5° to 22.8° (b), and from 31.8° to 33.0° (c) of NNCZ-xFe ceramics

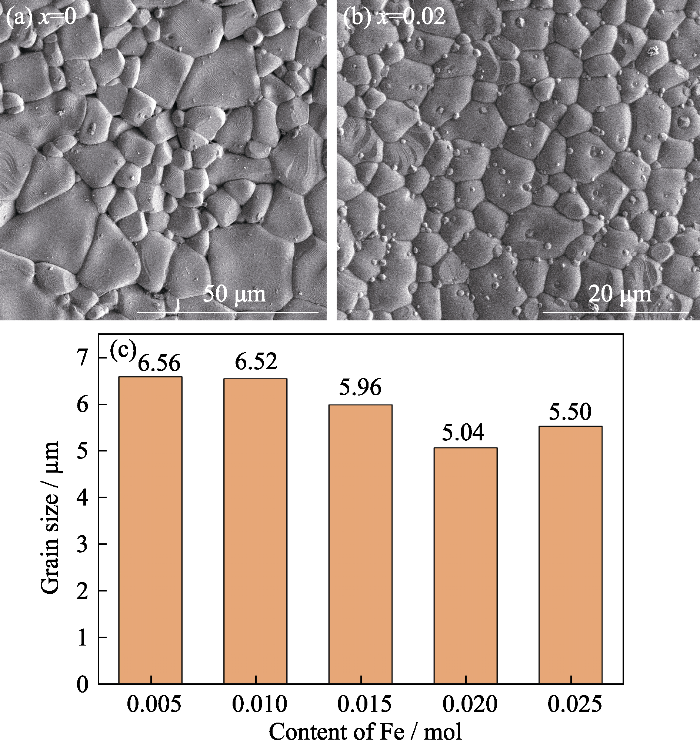

图2

图2

NNCZ-xFe陶瓷的表面形貌照片及其平均粒径

Fig. 2

Surface morphologies of NNCZ-xFe ceramics and corresponding average grain size

(a) x=0; (b) x=0.02; (c) Average grain size

NNCZ陶瓷的氧空位主要来源于高温煅烧时Na+的挥发, 为了平衡价态, 产生了氧空位, 大量的氧空位为离子迁移提供了通道, 促进了晶粒的生长[2]。NNCZ-xFe的氧空位一部分来源于Na+挥发, 另外一部分来源于低价态的Fe3+置换了高价态的Zr4+和Nb5+。掺杂Fe2O3使煅烧温度明显降低, Na+的挥发量减少, 与NNCZ相比, 该部分氧空位数量下降。Fe2O3在高温情况下容易还原成FeO, 产生游离的氧[O], 见式(4)[20], 产生的[O]会消耗一部分氧空位, 所以适量掺杂Fe2O3不会引起NNCZ陶瓷氧空位数量发生较大变化。当掺入过量Fe2O3时, 氧空位数量进一步增加, 促进晶粒生长。所以当掺杂量增加到0.025%时, 晶粒平均尺寸有上升趋势, 见图2(c)。

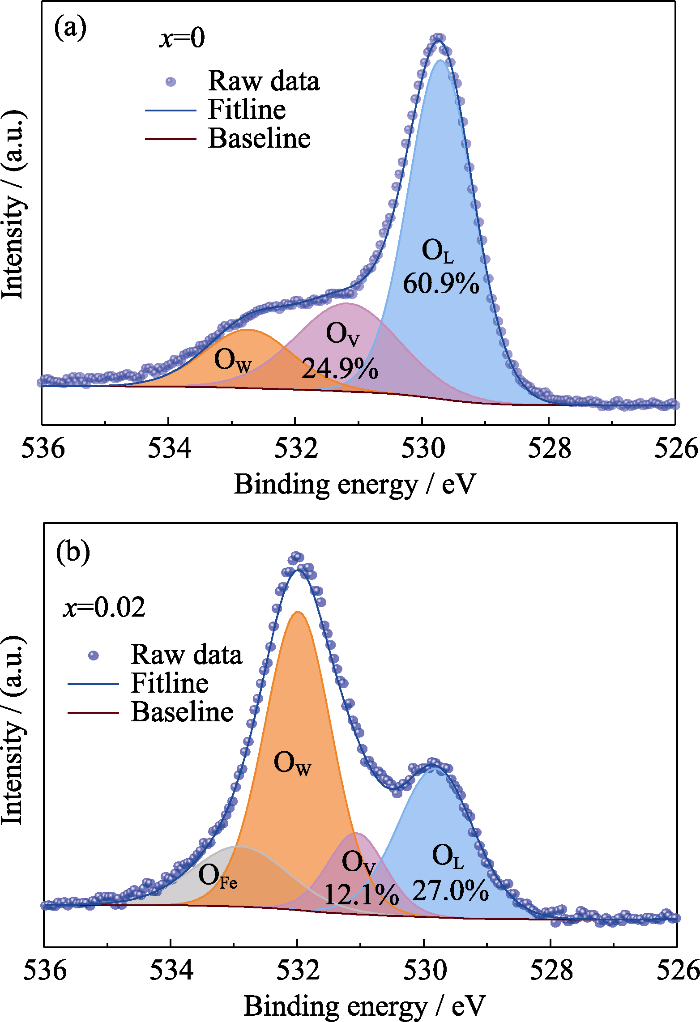

进一步研究Fe2O3掺杂对NNCZ陶瓷氧空位数量的影响, 对NNCZ和NNCZ-0.02Fe陶瓷样品的O1s进行了XPS分析, 如图3所示。NNCZ可以拟合出3个Gauss峰, OL在529 eV附近, 对应的是钙钛矿结构的晶格氧。图中其它峰是与OH基相关的吸附氧, 一般通过检测陶瓷表面OH含量, 可以间接表征氧空位浓度[22]。OV在531 eV附近, 对应氧空位; OW在533 eV附近, 对应吸附水[22,23]。掺杂Fe2O3使NNCZ陶瓷表面O的形态多样化, 拟合出了第四个峰(OFe), 这个峰与Fe3+有关[24]。一般通过氧空位与晶格氧之间的面积比(OV/OL)可以间接判断氧空位浓度的变化, 由图3可知, NNCZ和NNCZ-0.02Fe的OV/OL分别为0.41和0.45, 因此NNCZ和NNCZ-0.02Fe氧空位溶度比较接近。

图3

图3

NNCZ-xFe陶瓷的O1s XPS图谱

Fig. 3

XPS spectra of O1s peak for NNCZ-xFe

(a) x=0; (b) x=0.02

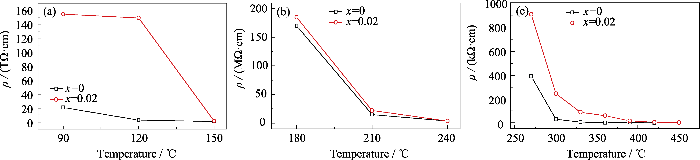

就压电陶瓷而言, 中低温条件下最可能发生迁移的是氧空位, 氧空位浓度和迁移速率是影响其电学性能的重要因素。NNCZ和NNCZ-0.02Fe陶瓷氧空位浓度接近, 故氧空位的迁移速率是影响其电学性能的主要因素, 可以间接通过氧空位激活能(Ea)和电阻率(ρ)来表征。对NNCZ和NNCZ-0.02Fe陶瓷晶粒和晶界的Ea分别进行拟合计算[25,26], Ea在0.74~1.14 eV范围, 表明在350~470 ℃范围内NNCZ和NNCZ-0.02Fe陶瓷均以氧空位电导为主[27]。NNCZ和NNCZ-0.02Fe晶粒的Ea接近但是低于晶界, 说明晶界是影响氧空位迁移速率的主要因素。NNCZ-0.02Fe陶瓷的晶界Ea高于NNCZ陶瓷, 表明氧空位在NNCZ-0.02Fe陶瓷内的迁移速率低于NNCZ陶瓷。根据以上分析可知NNCZ-0.02Fe陶瓷的ρ应高于NNCZ陶瓷, NNCZ-0.02Fe的实测ρ确实高于NNCZ, 如图4所示。90~150 ℃范围内两者电阻率相差较大, 随着温度升高, 两者差距逐渐缩小。氧空位容易与缺陷形成缺陷偶极子对(Fe’zr-V··o-或Fe”Nb-V··o)限制氧空位的迁移[21], 使ρ升高, 另外, NNCZ-0.02Fe陶瓷晶粒尺寸较小, 晶界密度大, 使氧空位迁移变得更困难。

图4

图4

NNCZ-xFe陶瓷的电阻率(ρ)随温度的变化曲线

Fig. 4

Temperature dependence of electrical resistivity (ρ) for NNCZ-xFe in the different temperature range

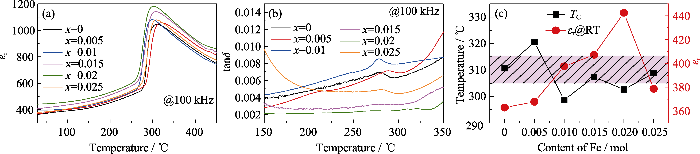

图5(a, b)为NNCZ-xFe陶瓷在100 kHz频率下测得的介电常数εr和介电损耗tand随温度变化的曲线图, 图5(c)为NNCZ-xFe的居里温度(TC)及室温下的介电常数与Fe2O3掺杂量的关系曲线。在300 ℃左右出现的介电异常峰, 对应于AFE的P相向R相(Pnmm)转变[15], 如图5(a)所示。随着Fe2O3掺杂量变化, NNCZ的介电损耗也发生变化, 由图5(b)可知, x=0.02样品的介电损耗最低, 这是由于NNCZ-0.02Fe氧空位的迁移速率较低, 晶界较多, 损耗相应减小。从图5(c)可知, NNCZ-xFe陶瓷的TC比较接近。随着Fe2O3掺杂量增大, 介电常数先增大后减小。这是由于较大离子极化率的Fe3+(2.14×10-3 nm3)置换了离子极化率较小的Zr4+(2.023×10-3 nm3), 所以介电常数上升; 当过量掺杂时, Fe3+置换了离子极化率较高的Nb5+(3.1×10-3 nm3), 介电常数又随之下降[28]。

图5

图5

NNCZ-xFe陶瓷的介电性能

Fig. 5

Dielectric property of NNCZ-xFe ceramics

(a) Temperature dependence of relative permittivity of NNCZ-xFe ceramics; (b) Loss tangent of NNCZ-xFe ceramics; (c) Change of Curie temperature (TC) and dielectric constant at room temperature (RT) with the content of Fe3+colorful figures are available on website

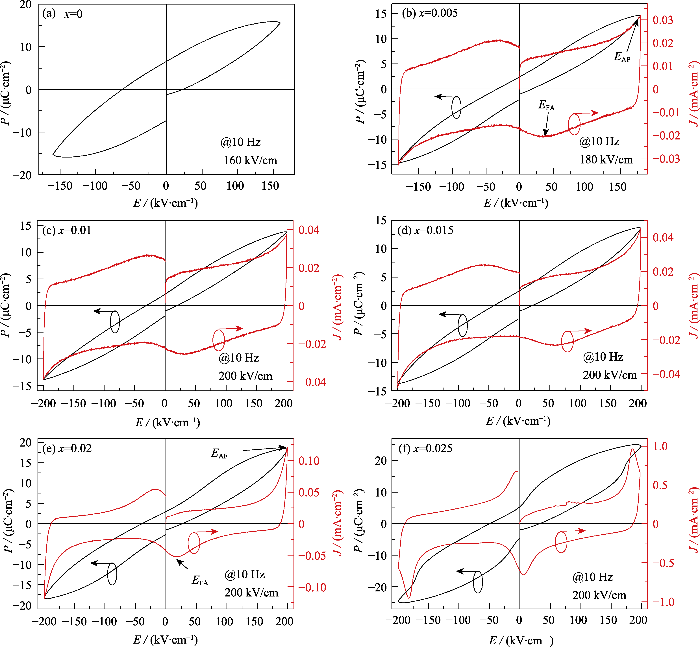

NNCZ-xFe陶瓷在室温下测得的电滞回线如图6所示, 样品均表现出双电滞回线。x=0.005~0.02样品均表现出夹紧状双电滞回线, 当掺杂量增加到x=0.025时, 出现哑铃状的双电滞回线, 且Pmax明显增大。从NNCZ-xFe陶瓷的电流回线可以看到, 掺杂后的样品均出现了4个电流峰, 且AFE®FE对应的电流峰明显, 表明NNCZ-xFe陶瓷均以AFE的微米畴为主[16]。且随着掺杂量增大, AFE®FE对应的电流峰逐渐明显, 表明样品中FE相增多, 所以Pmax逐渐增大。x=0.01、0.015、0.02和0.025样品对应的AFE®FE翻转电场强度(EAF)分别为: 202.2、200.1、198.9、198.4和185.2 kV/cm, 过量的Fe2O3使EAF减小。

图6

图6

NNCZ-xFe陶瓷室温下测得的电滞回线

Fig. 6

P-E loops of NNCZ-xFe ceramics at room temperature

(a) x=0; (b) x=0.005; (c) x=0.01; (d) x=0.015; (e) x=0.02; (f) x=0.025

氧空位对铁电畴能起到钉扎作用, 但是钉扎效应与氧空位数量存在最优配比。掺杂过量Fe2O3使NNCZ陶瓷氧空位进一步增加, 钉扎效应减弱, 使得NNCZ-0.025Fe陶瓷中大量的AFE向FE转变, 出现如图6(f)所示的哑铃状双电滞回线, Pmax明显增大。

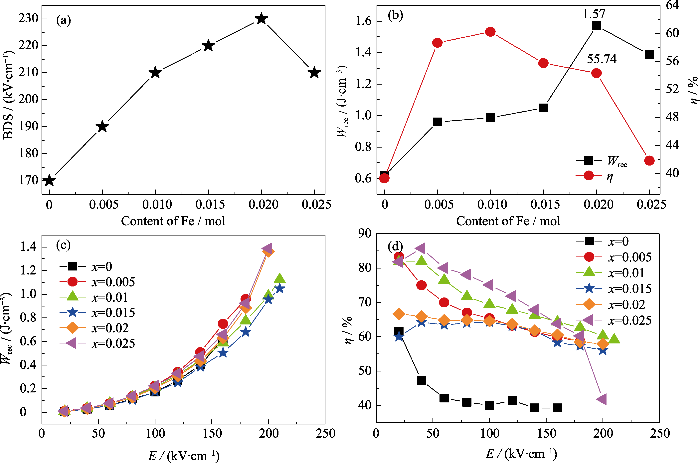

图7

图7

NNCZ-xFe陶瓷的击穿强度和储能性能

Fig. 7

Breakdown strength and energy storage property of NNCZ-xFe ceramics

(a) Breakdown strength; (b) Energy storage property before breakdown; (c, d) Energy storage property at different electric fields

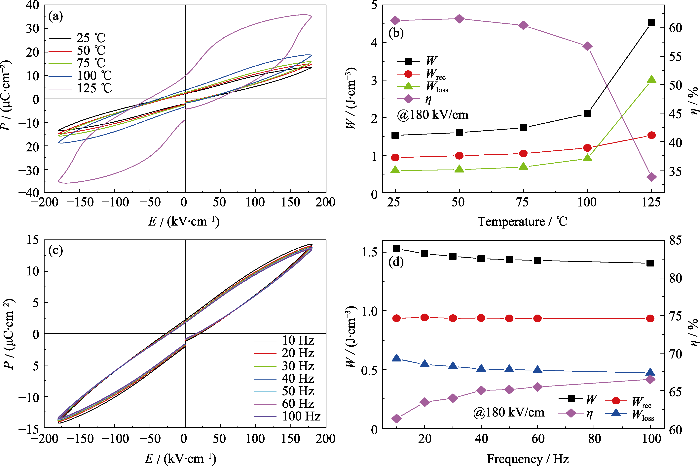

图8

图8

NNCZ-0.02Fe陶瓷在不同温度和频率下的电滞回线储能性能

Fig. 8

P-E loops and energy storage properties of NNCZ-0.02Fe ceramics at different temperatures and different frequencies

(a) P-E loops of different temperatures; (b) Energy storage properties of different temperatures; (c) P-E loops of different frequencies; (b) Energy storage properties of different frequency

NNCZ-0.02Fe陶瓷的储能性能在10~100 Hz范围内表现出良好的稳定性, 随着频率增加, η由63.5%增大到66.5%, η变化率为4.7%, 这是由于NNCZ-0.02Fe陶瓷内的畴翻转跟不上外部电场, 所以W稍微减小, Wrec基本保持不变, η有上升趋势[31]。

3 结论

通过传统固相法制备,的(0.96NaNbO3- 0.04CaZrO3)-xFe2O3(NNCZ-xFe)陶瓷, 呈现单一钙钛矿结构, 无明显的第二相。掺杂Fe2O3能明显降低NNCZ陶瓷的烧结温度, 且随着掺杂量增大, 晶粒的平均尺寸和介电常数先减小后增大, x=0.02时, 样品的平均晶粒尺寸最小(5.04 mm), 击穿强度最大(230 kV/cm), 介电常数最高。室温下, NNCZ-0.02Fe陶瓷击穿前的有效储能密度(Wrec)和储能效率(η)分别为1.57 J/cm3和55.74%。在电场强度为180 kV/cm下, 室温至100 ℃, NNCZ-0.02Fe表现出良好的温度稳定性, η变化率为7.3%, 在125 ℃下, 储能密度为4.53 J/cm3; 在测试频率为10~100 Hz时, 表现较高且稳定的储能效率, 储能效率维持63.5%以上, η变化率为4.7%。本研究表明: NNCZ-0.02Fe在电介质储能领域具有较好的潜在应用价值。

参考文献

Linear-like lead-free relaxor antiferroelectric (Bi0.5Na0.5)TiO3-NaNbO3 with giant energy-storage density/efficiency and super stability against temperature and frequency

Energy storage properties of NaNbO3-CaZrO3 ceramics with coexistence of ferroelectric and antiferroelectric phases

Energy-storage performance of NaNbO3 based multilayered capacitors

Lead-free antiferroelectric: xCaZrO3-(1-x)NaNbO3 system (0≤x≤0.10)

Research progress of antiferroelectric energy storage ceramics

Isolation of a ferroelectric intermediate phase in antiferroelectric dense sodium niobate ceramics

Microstructural evolution in NaNbO3-based antiferroelectrics

Direct evidence of an incommensurate phase in NaNbO3 and its implication in NaNbO3-based lead-free antiferroelectrics

Stabilized antiferroelectricity in xBiScO3-(1-x)NaNbO3 lead-free ceramics with established double hysteresis loops

Strategy for stabilization of the antiferroelectric phase (Pbma) over the metastable ferroelectric phase (P21ma) to establish double loop hysteresis in lead-free (1-x)NaNbO3-xSrZrO3 solid solution

1-x) NaNbO3 with induced double hysteresis loops at room temperature

Excellent energy-storage properties of NaNbO3-based lead-free antiferroelectric orthorhombic P-phase (Pbma) ceramics with repeatable double polarization-field loops

Enhanced antiferroelectricity and double hysteresis loop observed in lead-free (1-x)NaNbO3-xCaSnO3 ceramics

Effect of rare-earth doping on the dielectric property and polarization behavior of antiferroelectric sodium niobate-based ceramics

Lead-free AgNbO3 anti-ferroelectric ceramics with an enhanced energy storage performance using MnO2 modification

XANES Mn K edge in NaNbO3 based ceramics doped with Mn and Bi ions

NaNbO3 nanoparticles: Rapid mechanochemical synthesis and high densification behavior

Dielectric properties of Fe2O3-doped MgTiO3-CaTiO3 microwave ceramics

B-site acceptor doped AgNbO3 lead-free antiferroelectric ceramics: The role of dopant on microstructure and breakdown strength

High quality Mn-doped (Na,K)NbO3 nanofibers for flexible piezoelectric nanogenerators

Enhanced photocatalytic activity of perovskite NaNbO3 by oxygen vacancy engineering

Characterization of ferrocene and (η 6-benzene) tricarbonylchromium complexes by X-ray photoelectron spectroscopy

Enhanced electrical resistivity and mechanical properties in BCTZ-based composite ceramic

Piezoelectric and ferroelectric properties of Na0.5Bi4.5Ti4O15-BaTiO3 composite ceramics with Mg doping

Influence of Ce 3+ substitution on the structure and electrical characteristics of bismuth-layer Na0.5Bi8.5Ti7O27 ceramics

Empirical electronic polarizabilities in oxides, hydroxides, oxyfluorides, and oxychlorides

Perovskite lead-free dielectrics for energy storage applications

Dielectric and energy storage property of BaTiO3-ZnNb2O6 ceramics

Dielectric, ferroelectric and high energy storage behavior of (1-x)K0.5Na0.5NbO3-xBi(Mg0.5Ti0.5)O3 lead free relaxor ferroelectric ceramics