太阳能是取之不尽用之不竭的清洁能源, 人类正致力开发高效的光催化剂, 以实现对太阳能的转化利用。目前, 已开发出的光催化剂大体可分为三种: 金属氧化物、硫化物(如TiO2 [1 ] 、ZnO[2 ] 、CdS[3 ] 等), 贵金属半导体(如Bi2 MoO6 [4 ] 、BiOBr[5 ] 、Ag3 PO4 [6 ] 等), 非金属半导体(如g-C3 N4 [7 ] , 红磷[8 ] 等)。ZnO(3.3 eV)和TiO2 (3.2 eV)带隙较宽, 仅能利用只占太阳能4%的紫外光。CdS(2.4 eV)带隙较窄, 但稳定性较差。Bi2 MoO6 (2.9 eV)和BiOBr(2.8 eV)带隙适中, 但含有贵金属元素, 价格较高。g-C3 N4 是一种非金属半导体, 由地球上含量较多的C、N元素组成, 带隙约2.7 eV, 对可见光有一定的吸收, 抗酸、碱、光的腐蚀, 稳定性好, 结构和性能易于调控, 具有较好的光催化性能, 因而成为光催化领域的研究热点。

[1]

TADA H JIN Q NISHIJIMA H et al . Titanium(IV) dioxide surface-modified with iron oxide as a visible light photocatalyst

. Angewandte Chemie International Edition , 2011 , 50 (15 ): 3501 -3505 .

[本文引用: 1]

[2]

XU T ZHANG L CHENG H et al . Significantly enhanced photocatalytic performance of ZnO via graphene hybridization and the mechanism study

. Applied Catalysis B: Environmental , 2011 , 101 (3/4 ): 382 -387 .

[本文引用: 1]

[3]

HE K LI M GUO L Preparation and photocatalytic activity of PANI-CdS composites for hydrogen evolution

. International Journal of Hydrogen Energy , 2012 , 37 (1 ): 755 -759 .

[本文引用: 1]

[4]

MIAO Y PAN G HUO Y et al . Aerosol-spraying preparation of Bi2 MoO6 : a visible photocatalyst in hollow microspheres with a porous outer shell and enhanced activity

. Dyes and Pigments , 2013 , 99 (2 ): 382 -389 .

[本文引用: 1]

[5]

WANG Y SHI Z FAN C et al . Synthesis, characterization, and photocatalytic properties of BiOBr catalyst

. Journal of Solid State Chemistry , 2013 , 199 : 224 -229 .

[本文引用: 1]

[6]

BAI S SHEN X LV H et al . Assembly of Ag3 PO4 nanocrystals on graphene-based nanosheets with enhanced photocatalytic performance

. Journal of Colloid and Interface Science , 2013 , 405 : 1 -9 .

[本文引用: 1]

[7]

WANG X BLECHERT S ANTONIETTI M Polymeric graphitic carbon nitride for heterogeneous photocatalysis

. ACS Catalysis , 2012 , 2 (8 ): 1596 -1606 .

[本文引用: 3]

[8]

WANG F NG W K H YU J C et al . Red phosphorus: an elemental photocatalyst for hydrogen formation from water

. Applied Catalysis B: Environmental , 2012 , 111-112 : 409 -414 .

[本文引用: 1]

[9]

LI C CAO C B ZHU H S Graphitic carbon nitride thin films deposited by electrodeposition

. Materials Letters , 2004 , 58 (12/13 ): 1903 -1906 .

[本文引用: 2]

[10]

LOTSCH B V SCHNICK W From triazines to heptazines: novel nonmetal tricyanomelaminates as precursors for graphitic carbon nitride materials

. Chemistry of Materials , 2006 , 18 (7 ): 1891 -1900 .

[11]

WIRNHIER E D BLINGER M GUNZELMANN D et al . Poly(triazine imide) with intercalation of lithium and chloride ions [(C3 N3 )2 (NHx Li1 -x )3 •LiCl]: a crystalline 2D carbon nitride network

. Chemistry - A European Journal , 2011 , 17 (11 ): 3213 -3221 .

[12]

ZHANG X XIE X WANG H et al . Enhanced photoresponsive ultrathin graphitic-phase C3 N4 nanosheets for bioimaging

. Journal of the American Chemical Society , 2013 , 135 (1 ): 18 -21 .

[本文引用: 3]

[13]

BOJDYS M J M LLER J O ANTONIETTI M et al . Ionothermal synthesis of crystalline, condensed, graphitic carbon nitride

. Chemistry - A European Journal , 2008 , 14 (27 ): 8177 -8182 .

[本文引用: 1]

[14]

WU F LIU Y YU G et al . Visible-light-absorption in graphitic C3 N4 bilayer: enhanced by interlayer coupling

. The Journal of Physical Chemistry Letters , 2012 , 3 (22 ): 3330 -3334 .

[本文引用: 1]

[15]

HUANG Z LI F CHEN B et al . Well-dispersed g-C3 N4 nanophases in mesoporous silica channels and their catalytic activity for carbon dioxide activation and conversion

. Applied Catalysis B: Environmental , 2013 , 136-137 : 269 -277 .

[本文引用: 4]

[16]

KROKE E SCHWARZ M HORATH-BORDON E et al . Tri-s-triazine derivatives. Part I. From trichloro-tri-s-triazine to graphitic C3 N4 structures

. New Journal of Chemistry , 2002 , 26 (5 ): 508 -512 .

[本文引用: 1]

[17]

MA H A JIA X P CHEN L X et al . High-pressure pyrolysis study of C3 NH6 : a route to preparing bulk C3 N4

. Journal of Physics: Condensed Matter , 2002 , 14 (44 ): 11269 -11273 .

[本文引用: 2]

[18]

GUO Q XIE Y WANG X et al . Characterization of well-crystal-lized graphitic carbon nitride nanocrystallites via a benzene-thermal route at low temperatures

. Chemical Physics Letters , 2003 , 380 (1/2 ): 84 -87 .

[本文引用: 1]

[19]

LI Y ZHANG J WANG Q et al . Nitrogen-rich carbon nitride hollow vessels: synthesis, characterization, and their properties

. The Journal of Physical Chemistry B , 2010 , 114 (29 ): 9429 -9434 .

[本文引用: 1]

[20]

DONG F WANG Z SUN Y et al . Engineering the nanoarchitecture and texture of polymeric carbon nitride semiconductor for enhanced visible light photocatalytic activity

. Journal of Colloid and Interface Science , 2013 , 401 : 70 -79 .

[本文引用: 4]

[21]

XIN G MENG Y Pyrolysis synthesized g-C3 N4 for photocatalytic degradation of methylene blue

. Journal of Chemistry , 2013 , 2013 : 1 -5 .

[本文引用: 5]

[22]

JI H CHANG F HU X et al . Photocatalytic degradation of 2,4,6-trichlorophenol over g-C3 N4 under visible light irradiation

. Chemical Engineering Journal , 2013 , 218 : 183 -190 .

[本文引用: 2]

[23]

LI X H ZHANG J CHEN X et al . Condensed graphitic carbon nitride nanorods by nanoconfinement: promotion of crystallinity on photocatalytic conversion

. Chemistry of Materials , 2011 , 23 (19 ): 4344 -4348 .

[本文引用: 5]

[24]

JORGE A B MARTIN D J DHANOA M T S et al . H2 and O2 evolution from water half-splitting reactions by graphitic carbon nitride materials

. The Journal of Physical Chemistry C , 2013 , 117 (14 ): 7178 -7185 .

[本文引用: 1]

[25]

DING G WANG W JIANG T et al . Highly selective synthesis of phenol from benzene over a vanadium-doped graphitic carbon nitride catalyst

. ChemCatChem , 2013 , 5 (1 ): 192 -200 .

[本文引用: 1]

[26]

ZHAI H S CAO L XIA X H Synthesis of graphitic carbon nitride through pyrolysis of melamine and its electrocatalysis for oxygen reduction reaction

. Chinese Chemical Letters , 2013 , 24 (2 ): 103 -106 .

[本文引用: 1]

[27]

ZHOU X JIN B CHEN R et al . Synthesis of porous Fe3 O4 /g- C3 N4 nanospheres as highly efficient and recyclable photocatalysts

. Materials Research Bulletin , 2013 , 48 (4 ): 1447 -1452 .

[本文引用: 6]

[28]

LIU W WANG M XU C et al . Significantly enhanced visible-light photocatalytic activity of g-C3 N4 via ZnO modification and the mechanism study

. Journal of Molecular Catalysis A: Chemical , 2013 , 368-369 : 9 -15 .

[本文引用: 4]

[29]

LIU G NIU P SUN C et al . Unique electronic structure induced high photoreactivity of sulfur-doped graphitic C3 N4

. Journal of the American Chemical Society , 2010 , 132 (33 ): 11642 -11648 .

[本文引用: 3]

[30]

ZHAO S CHEN S YU H et al . g-C3 N4 /TiO2 hybrid photocatalyst with wide absorption wavelength range and effective photogenerated charge separation

. Separation and Purification Technology , 2012 , 99 : 50 -54 .

[本文引用: 2]

[31]

MIRANDA C MANSILLA H Yan E Z J et al . Improved photocatalytic activity of g-C3 N4 /TiO2 composites prepared by a simple impregnation method

. Journal of Photochemistry and Photobiology A: Chemistry , 2013 , 253 : 16 -21 .

[本文引用: 1]

[32]

LIAO G CHEN S QUAN X et al . Graphene oxide modified g-C3 N4 hybrid with enhanced photocatalytic capability under visible light irradiation

. Journal of Materials Chemistry , 2012 , 22 (6 ): 2721 -2726 .

[本文引用: 2]

[33]

SUN C CHEN C MA W et al . Photocatalytic debromination of decabromodiphenyl ether by graphitic carbon nitride

. Science ChinaChemistry , 2012 , 55 (12 ): 2532 -2536 .

[本文引用: 1]

[34]

KATSUMATA K I MOTOYOSHI R MATSUSHITA N et al . Preparation of graphitic carbon nitride (g-C3 N4 )/WO3 composites and enhanced visible-light-driven photodegradation of acetaldehyde gas

. Journal of Hazardous Materials , 2013 , 260 : 475 -482 .

[本文引用: 1]

[35]

KONDO K MURAKAMI N YE C et al . Development of highly efficient sulfur-doped TiO2 photocatalysts hybridized with graphitic carbon nitride

. Applied Catalysis B: Environmental , 2013 , 142-143 : 362 -367 .

[本文引用: 2]

[36]

LIU W WANG M XU C et al . Facile synthesis of g-C3 N4 /ZnO composite with enhanced visible light photooxidation and photoreduction properties

. Chemical Engineering Journal , 2012 , 209 : 386 -393 .

[本文引用: 2]

[37]

DONG G ZHANG L Synthesis and enhanced Cr(VI) photoreduction property of formate anion containing graphitic carbon nitride

. The Journal of Physical Chemistry C , 2013 , 117 (8 ): 4062 -4068 .

[本文引用: 2]

[38]

SANO T TSUTSUI S KOIKE K et al . Activation of graphitic carbon nitride (g-C3 N4 ) by alkaline hydrothermal treatment for photocatalytic NO oxidation in gas phase

. Journal of Materials Chemistry A , 2013 , 1 (21 ): 6489 -6496 .

[本文引用: 4]

[39]

YANG S GONG Y ZHANG J et al . Exfoliated graphitic carbon nitride nanosheets as efficient catalysts for hydrogen evolution under visible light

. Advanced Materials , 2013 , 25 (17 ): 2452 -2456 .

[本文引用: 2]

[40]

SHAO-WEN C YU-PENG Y JUN F et al . In-situ growth of CdS quantum dots on g-C3 N4 nanosheets for highly efficient photocatalytic hydrogen generation under visible light irradiation

.International Journal of Hydrogen Energy , 2013 , 38 (3 ): 1258 -1266 .

[本文引用: 3]

[41]

GE L HAN C XIAO X et al . Synthesis and characterization of composite visible light active photocatalysts MoS2 -g-C3 N4 with enhanced hydrogen evolution activity

. International Journal of Hydrogen Energy , 2013 , 38 (17 ): 6960 -6969 .

[本文引用: 2]

[42]

WANG X MAEDA K THOMAS A et al . A metal-free polymeric photocatalyst for hydrogen production from water under visible light

. Nat. Mater. , 2009 , 8 (1 ): 76 -80 .

[本文引用: 4]

[43]

HONG J WANG Y WANG Y et al . Noble-metal-free NiS/C3 N4 for efficient photocatalytic hydrogen evolution from water

. ChemSusChem , 2013 : 1 -7 .

[本文引用: 1]

[44]

CHU S WANG Y GUO Y et al . Band structure engineering of carbon nitride: in search of a polymer photocatalyst with high photooxidation property

. ACS Catalysis , 2013 , 3 (5 ): 912 -919 .

[本文引用: 4]

[45]

SU F MATHEW S C LIPNER G et al . mpg-C3 N4 -catalyzed selective oxidation of alcohols using O2 and visible light

. Journal of the American Chemical Society , 2010 , 132 (46 ): 16299 -16301 .

[本文引用: 2]

[46]

LI X H CHEN J S WANG X et al . Metal-free activation of dioxygen by graphene/g-C3 N4 nanocomposites: functional dyads for selective oxidation of saturated hydrocarbons

. Journal of the American Chemical Society , 2011 , 133 (21 ): 8074 -8077 .

[本文引用: 1]

[47]

LI X H WANG X ANTONIETTI M Solvent-free and metal-free oxidation of toluene using O2 and g-C3 N4 with nanopores: nanostructure boosts the catalytic selectivity

. ACS Catalysis , 2012 , 2 (10 ): 2082 -2086 .

[本文引用: 2]

[48]

ZHANG P WANG Y YAO J et al . Visible-light-induced metal-free allylic oxidation utilizing a coupled photocatalytic system of g-C3 N4 and N-Hydroxy compounds

. Advanced Synthesis & Catalysis , 2011 , 353 (9 ): 1447 -1451 .

[本文引用: 1]

[49]

YUAN Y P CAO S W LIAO Y S et al . Red phosphor/g-C3 N4 heterojunction with enhanced photocatalytic activities for solar fuels production

. Applied Catalysis B: Environmental , 2013 , 140-141 : 164 -168 .

[本文引用: 1]

[50]

TAN B XU J XUE B et al . Mesoporous graphitic carbon nitride: synthesis and application towards knoevenagel condensation reactions

. Chemistry , 2013 , 76 (2 ): 150 -156 .

[本文引用: 1]

[51]

NIU P ZHANG L LIU G et al . Graphene-like carbon nitride nanosheets for improved photocatalytic activities

. Advanced Functional Materials , 2012 , 22 (22 ): 4763 -4770 .

[本文引用: 3]

[52]

JIN X BALASUBRAMANIAN V V SELVAN S T et al . Highly ordered mesoporous carbon nitride nanoparticles with high nitrogen content: a metal-free basic catalyst

. Angewandte Chemie , 2009 , 121 (42 ): 8024 -8027 .

[本文引用: 2]

[53]

GOETTMANN F FISCHER A ANTONIETTI M et al . Chemical synthesis of mesoporous carbon nitrides using hard templates and their use as a metal-free catalyst for friedel-crafts reaction of benzene

. Angewandte Chemie International Edition , 2006 , 45 (27 ): 4467 -4471 .

[本文引用: 2]

[54]

SONG L ZHANG S WU X et al . Graphitic C3 N4 photocatalyst for esterification of benzaldehyde and alcohol under visible light radiation

. Industrial & Engineering Chemistry Research , 2012 , 51 (28 ): 9510 -9514 .

[本文引用: 1]

[55]

SU F MATHEW S C M HLMANN L et al . Aerobic oxidative coupling of amines by carbon nitride photocatalysis with visible light

. Angewandte Chemie International Edition , 2011 , 50 (3 ): 657 -660 .

[本文引用: 1]

[56]

IKEDA T BOERO M HUANG S F et al . Carbon alloy catalysts: active sites for oxygen reduction reaction

. The Journal of Physical Chemistry C , 2008 , 112 (38 ): 14706 -14709 .

[本文引用: 1]

[57]

ZHENG Y LIU J LIANG J et al . Graphitic carbon nitride materials: controllable synthesis and applications in fuel cells and photocatalysis

. Energy & Environmental Science , 2012 , 5 (5 ): 6717 -6731 .

[本文引用: 1]

[58]

ASPERA S M KASAI H KAWAI H Density functional theory-based analysis on O2 molecular interaction with the tri-s- triazine-based graphitic carbon nitride

. Surface Science , 2012 , 606 (11-12 ): 892 -901 .

[本文引用: 1]

[59]

ZHENG Y JIAO Y JARONIEC M et al . Nanostructured metal-free electrochemical catalysts for highly efficient oxygen reduction

. Small , 2012 , 8 (23 ): 3550 -3566 .

[本文引用: 1]

[60]

JIN J FU X LIU Q et al . A highly active and stable electrocatalyst for the oxygen reduction reaction based on a graphene-supported g-C3 N4 @cobalt oxide core-shell hybrid in alkaline solution

. Journal of Materials Chemistry A , 2013 , 1 (35 ): 10538 -10545 .

[本文引用: 1]

[61]

LIU Q ZHANG J Graphene supported Co-g-C3 N4 as a novel metal-macrocyclic electrocatalyst for the oxygen reduction reaction in fuel cells

. Langmuir , 2013 , 29 (11 ): 3821 -3828 .

[本文引用: 1]

[62]

ZHENG Y JIAO Y CHEN J et al . Nanoporous graphitic- C3 N4 @carbon metal-free electrocatalysts for highly efficient oxygen reduction

. Journal of the American Chemical Society , 2011 , 133 (50 ): 20116 -20119 .

[本文引用: 1]

[63]

LI S WANG J T CHEN X Y et al . Catalytic performance of heat-treated Fe-melamine/C and Fe-g-C3 N4 /C electrocatalysts for oxygen reduction reaction

. Acta Phys. -Chim. Sin. , 2013 , 29 (4 ): 792 -798 .

[本文引用: 1]

[64]

BU Y CHEN Z YU J et al . A novel application of g-C3 N4 thin film in photoelectrochemical anticorrosion

. Electrochimica Acta, 2013 , 88 : 294 -300 .

[本文引用: 1]

[65]

LI X H KURASCH S KAISER U et al . Synthesis of monolayer- patched graphene from glucose

. Angewandte Chemie International Edition , 2012 , 51 (38 ): 9689 -9692 .

[本文引用: 1]

[66]

ZHANG Y ANTONIETTI M Phosphorus-doped carbon nitride solid enhanced electrical conductivity and photocurrent generation

. Chemistry - An Asian Journal , 2010 , 132 (18 ): 6294 -6295 .

[本文引用: 2]

[67]

XU L XIA J XU H et al . Reactable ionic liquid assisted solvothermal synthesis of graphite-like C3 N4 hybridized α-Fe2 O3 hollow microspheres with enhanced supercapacitive performance

. Journal of Power Sources , 2014 , 245 : 866 -874 .

[本文引用: 1]

[68]

TIAN J LIU Q ASIRI A M et al . Ultrathin graphitic carbon nitride nanosheet: a highly efficient fluorosensor for rapid, ultrasensitive detection of Cu2 +

. Analytical Chemistry , 2013 , 85 (11 ): 5595 -5599 .

[本文引用: 2]

[69]

CHENG C HUANG Y TIAN X et al . Electrogenerated chemiluminescence behavior of graphite-like carbon nitride and its application in selective sensing Cu2 +

. Analytical Chemistry , 2012 , 84 (11 ): 4754 -4759 .

[本文引用: 1]

[70]

XU H YAN J XU Y et al . Novel visible-light-driven AgX/graphite-like C3 N4 (X=Br, I) hybrid materials with synergistic photocatalytic activity

. Applied Catalysis B: Environmental , 2013 , 129 : 182 -193 .

[本文引用: 1]

[71]

YU J WANG S LOW J et al . Enhanced photocatalytic performance of direct Z-scheme g-C3 N4 -TiO2 photocatalysts for the decomposition of formaldehyde in air

. Physical Chemistry Chemical Physics , 2013 , 15 (39 ): 16883 -16890 .

[本文引用: 2]

[72]

LI T ZHAO L HE Y et al . Synthesis of g-C3 N4 /SmVO4 composite photocatalyst with improved visible light photocatalytic activities in RhB degradation

. Applied Catalysis B: Environmental , 2013 , 129 : 255 -263 .

[本文引用: 1]

[73]

GUI M S WANG P F YUAN D et al . Synthesis and visible-light photocatalytic activity of Bi2 WO6 /g-C3 N4 composite photocatalysts

. Chinese Journal of Inorganic Chemistry , 2013 , 29 (10 ): 2057 -2064 .

[本文引用: 1]

[74]

XIANG Q YU J JARONIEC M Preparation and enhanced visible-light photocatalytic H2 -production activity of graphene /C3 N4 composites

. The Journal of Physical Chemistry C , 2011 , 115 (15 ): 7355 -7363 .

[本文引用: 2]

[75]

SURYAWANSHI A DHANASEKARAN P MHAMANE D et al . Doubling of photocatalytic H2 evolution from g-C3 N4 via its nanocomposite formation with multiwall carbon nanotubes: electronic and morphological effects

. International Journal of Hydrogen Energy , 2012 , 37 (12 ): 9584 -9589 .

[本文引用: 1]

[76]

YAN H HUANG Y Polymer composites of carbon nitride and poly(3-hexylthiophene) to achieve enhanced hydrogen production from water under visible light

. Chemical Communications , 2011 , 47 (14 ): 4168 -4170 .

[本文引用: 1]

[77]

GE L HAN C LIU J In situ synthesis and enhanced visible light photocatalytic activities of novel PANI-g-C3 N4 composite photocatalysts

. Journal of Materials Chemistry , 2012 , 22 (23 ): 11843 -11850 .

[本文引用: 2]

[78]

MIN S LU G Enhanced electron transfer from the excited eosin Y to mpg-C3 N4 for highly efficient hydrogen evolution under 550 nm irradiation

. The Journal of Physical Chemistry C , 2012 , 116 (37 ): 19644 -19652 .

[本文引用: 1]

[79]

SUN A W CHEN H SONG C Y et al . Synthesis of Bi25 FeO40 - g-C3 N4 magnetic catalyst and its photocatalytic performance

.Environmental Chemistry , 2013 , 32 (5 ): 748 -754 .

[本文引用: 1]

[80]

HE Y CAI J LI T et al . Efficient degradation of RhB over GdVO4 /g-C3 N4 composites under visible-light irradiation

. Chemical Engineering Journal , 2013 , 215-216 : 721 -730 .

[81]

HE Y CAI J LI T et al . Synthesis, characterization, and activity evaluation of DyVO4 /g-C3 N4 composites under visible-light irradiation

. Industrial & Engineering Chemistry Research , 2012 , 51 (45 ): 14729 -14737 .

[82]

HOU Y WEN Z CUI S et al . Constructing 2D porous graphitic C3 N4 nanosheets/nitrogen-doped graphene/layered MoS2 ternary nanojunction with enhanced photoelectrochemical activity

. Advanced Materials , 2013 , 25 (43 ): 1 -7 .

[83]

ZHANG J ZHANG G CHEN X et al . Co-monomer control of carbon nitride semiconductors to optimize hydrogen evolution with visible light

. Angewandte Chemie International Edition , 2012 , 51 (13 ): 3183 -3187 .

[本文引用: 4]

[84]

ZHANG J CHEN X TAKANABE K et al . Synthesis of a carbon nitride structure for visible-light catalysis by copolymerization

. Angewandte Chemie International Edition , 2010 , 49 (2 ): 441 -444 .

[85]

ZHENG H R ZHANG J S WANG X C et al . Modification of carbon nitride phtocatalysts by copolymerization with diaminomaleonitrile

. Acta Phys. Chim. Sin. , 2012 , 28 (10 ): 2336 -2342 .

[本文引用: 1]

[86]

YAN S C LI Z S ZOU Z G Photodegradation of rhodamine B and methyl orange over boron-doped g-C3 N4 under visible light irradiation

. Langmuir , 2010 , 26 (6 ): 3894 -3901 .

[本文引用: 1]

[87]

WANG Y DI Y ANTONIETTI M et al . Excellent visible-light photocatalysis of fluorinated polymeric carbon nitride solids

. Chemistry of Materials , 2010 , 22 (18 ): 5119 -5121 .

[本文引用: 1]

[88]

GE L HAN C XIAO X et al . Enhanced visible light photocatalytic hydrogen evolution of sulfur-doped polymeric g-C3 N4 photocatalysts

. Materials Research Bulletin , 2013 , 48 (10 ): 3919 -3925 .

[本文引用: 1]

[89]

CHEN G GAO S P Structure and electronic structure of S-doped graphitic C3 N4 investigated by density functional theory

. Chinese Physics B , 2012 , 21 (10 ): 384 -390 .

[本文引用: 1]

[90]

DONG G ZHAO K ZHANG L Carbon self-doping induced high electronic conductivity and photoreactivity of g-C3 N4

. Chemical Communications , 2012 , 48 (49 ): 6178 -6180 .

[本文引用: 1]

[91]

WANG Y ZHANG J WANG X et al . Boron- and fluorine- containing mesoporous carbon nitride polymers: metal-free catalysts for cyclohexane oxidation

. Angewandte Chemie International Edition , 2010 , 49 (19 ): 3356 -3359 .

[92]

VINU A ARIGA K MORI T et al . Preparation and characterization of well-ordered hexagonal mesoporous carbon nitride

. Advanced Materials , 2005 , 17 (13 ): 1648 -1652 .

[本文引用: 2]

[93]

CHEN X JUN Y S TAKANABE K et al . Ordered mesoporous SBA-15 type graphitic carbon nitride: a semiconductor host structure for photocatalytic hydrogen evolution with visible light

. Chemistry of Materials , 2009 , 21 (18 ): 4093 -4095 .

[94]

DONG G ZHANG L Porous structure dependent photoreactivity of graphitic carbon nitride under visible light

. Journal of Materials Chemistry , 2012 , 22 (3 ): 1160 -1166 .

[本文引用: 4]

[95]

XU J WANG Y ZHU Y Nanoporous graphitic carbon nitride with enhanced photocatalytic performance

. Langmuir , 2013 , 29 (33 ): 10566 -10572 .

[本文引用: 1]

[96]

GROENEWOLT M ANTONIETTI M Synthesis of g-C3 N4 nanoparticles in mesoporous silica host matrices

. Advanced Materials , 2005 , 17 (14 ): 1789 -1792 .

[本文引用: 3]

[97]

BAI X WANG L ZONG R et al . Photocatalytic activity enhanced via g-C3 N4 nanoplates to nanorods

. The Journal of Physical Chemistry C , 2013 , 117 (19 ): 9952 -9961 .

[本文引用: 1]

[98]

CHANG F XIE Y LI C et al . A facile modification of g-C3 N4 with enhanced photocatalytic activity for degradation of methylene blue

. Applied Surface Science , 2013 , 280 : 967 -974 .

[本文引用: 1]

[99]

CHENG N TIAN J LIU Q et al . Au-nanoparticle-loaded graphitic carbon nitride nanosheets: green photocatalytic synthesis and application toward the degradation of organic pollutants

. ACS Applied Materials & Interfaces , 2013 , 5 (15 ): 6815 -6819 .

[本文引用: 1]

Titanium(IV) dioxide surface-modified with iron oxide as a visible light photocatalyst

1

2011

... 太阳能是取之不尽用之不竭的清洁能源, 人类正致力开发高效的光催化剂, 以实现对太阳能的转化利用.目前, 已开发出的光催化剂大体可分为三种: 金属氧化物、硫化物(如TiO2 [1 ] 、ZnO[2 ] 、CdS[3 ] 等), 贵金属半导体(如Bi2 MoO6 [4 ] 、BiOBr[5 ] 、Ag3 PO4 [6 ] 等), 非金属半导体(如g-C3 N4 [7 ] , 红磷[8 ] 等).ZnO(3.3 eV)和TiO2 (3.2 eV)带隙较宽, 仅能利用只占太阳能4%的紫外光.CdS(2.4 eV)带隙较窄, 但稳定性较差.Bi2 MoO6 (2.9 eV)和BiOBr(2.8 eV)带隙适中, 但含有贵金属元素, 价格较高.g-C3 N4 是一种非金属半导体, 由地球上含量较多的C、N元素组成, 带隙约2.7 eV, 对可见光有一定的吸收, 抗酸、碱、光的腐蚀, 稳定性好, 结构和性能易于调控, 具有较好的光催化性能, 因而成为光催化领域的研究热点. ...

Significantly enhanced photocatalytic performance of ZnO via graphene hybridization and the mechanism study

1

2011

... 太阳能是取之不尽用之不竭的清洁能源, 人类正致力开发高效的光催化剂, 以实现对太阳能的转化利用.目前, 已开发出的光催化剂大体可分为三种: 金属氧化物、硫化物(如TiO2 [1 ] 、ZnO[2 ] 、CdS[3 ] 等), 贵金属半导体(如Bi2 MoO6 [4 ] 、BiOBr[5 ] 、Ag3 PO4 [6 ] 等), 非金属半导体(如g-C3 N4 [7 ] , 红磷[8 ] 等).ZnO(3.3 eV)和TiO2 (3.2 eV)带隙较宽, 仅能利用只占太阳能4%的紫外光.CdS(2.4 eV)带隙较窄, 但稳定性较差.Bi2 MoO6 (2.9 eV)和BiOBr(2.8 eV)带隙适中, 但含有贵金属元素, 价格较高.g-C3 N4 是一种非金属半导体, 由地球上含量较多的C、N元素组成, 带隙约2.7 eV, 对可见光有一定的吸收, 抗酸、碱、光的腐蚀, 稳定性好, 结构和性能易于调控, 具有较好的光催化性能, 因而成为光催化领域的研究热点. ...

Preparation and photocatalytic activity of PANI-CdS composites for hydrogen evolution

1

2012

... 太阳能是取之不尽用之不竭的清洁能源, 人类正致力开发高效的光催化剂, 以实现对太阳能的转化利用.目前, 已开发出的光催化剂大体可分为三种: 金属氧化物、硫化物(如TiO2 [1 ] 、ZnO[2 ] 、CdS[3 ] 等), 贵金属半导体(如Bi2 MoO6 [4 ] 、BiOBr[5 ] 、Ag3 PO4 [6 ] 等), 非金属半导体(如g-C3 N4 [7 ] , 红磷[8 ] 等).ZnO(3.3 eV)和TiO2 (3.2 eV)带隙较宽, 仅能利用只占太阳能4%的紫外光.CdS(2.4 eV)带隙较窄, 但稳定性较差.Bi2 MoO6 (2.9 eV)和BiOBr(2.8 eV)带隙适中, 但含有贵金属元素, 价格较高.g-C3 N4 是一种非金属半导体, 由地球上含量较多的C、N元素组成, 带隙约2.7 eV, 对可见光有一定的吸收, 抗酸、碱、光的腐蚀, 稳定性好, 结构和性能易于调控, 具有较好的光催化性能, 因而成为光催化领域的研究热点. ...

Aerosol-spraying preparation of Bi2 MoO6 : a visible photocatalyst in hollow microspheres with a porous outer shell and enhanced activity

1

2013

... 太阳能是取之不尽用之不竭的清洁能源, 人类正致力开发高效的光催化剂, 以实现对太阳能的转化利用.目前, 已开发出的光催化剂大体可分为三种: 金属氧化物、硫化物(如TiO2 [1 ] 、ZnO[2 ] 、CdS[3 ] 等), 贵金属半导体(如Bi2 MoO6 [4 ] 、BiOBr[5 ] 、Ag3 PO4 [6 ] 等), 非金属半导体(如g-C3 N4 [7 ] , 红磷[8 ] 等).ZnO(3.3 eV)和TiO2 (3.2 eV)带隙较宽, 仅能利用只占太阳能4%的紫外光.CdS(2.4 eV)带隙较窄, 但稳定性较差.Bi2 MoO6 (2.9 eV)和BiOBr(2.8 eV)带隙适中, 但含有贵金属元素, 价格较高.g-C3 N4 是一种非金属半导体, 由地球上含量较多的C、N元素组成, 带隙约2.7 eV, 对可见光有一定的吸收, 抗酸、碱、光的腐蚀, 稳定性好, 结构和性能易于调控, 具有较好的光催化性能, 因而成为光催化领域的研究热点. ...

Synthesis, characterization, and photocatalytic properties of BiOBr catalyst

1

2013

... 太阳能是取之不尽用之不竭的清洁能源, 人类正致力开发高效的光催化剂, 以实现对太阳能的转化利用.目前, 已开发出的光催化剂大体可分为三种: 金属氧化物、硫化物(如TiO2 [1 ] 、ZnO[2 ] 、CdS[3 ] 等), 贵金属半导体(如Bi2 MoO6 [4 ] 、BiOBr[5 ] 、Ag3 PO4 [6 ] 等), 非金属半导体(如g-C3 N4 [7 ] , 红磷[8 ] 等).ZnO(3.3 eV)和TiO2 (3.2 eV)带隙较宽, 仅能利用只占太阳能4%的紫外光.CdS(2.4 eV)带隙较窄, 但稳定性较差.Bi2 MoO6 (2.9 eV)和BiOBr(2.8 eV)带隙适中, 但含有贵金属元素, 价格较高.g-C3 N4 是一种非金属半导体, 由地球上含量较多的C、N元素组成, 带隙约2.7 eV, 对可见光有一定的吸收, 抗酸、碱、光的腐蚀, 稳定性好, 结构和性能易于调控, 具有较好的光催化性能, 因而成为光催化领域的研究热点. ...

Assembly of Ag3 PO4 nanocrystals on graphene-based nanosheets with enhanced photocatalytic performance

1

2013

... 太阳能是取之不尽用之不竭的清洁能源, 人类正致力开发高效的光催化剂, 以实现对太阳能的转化利用.目前, 已开发出的光催化剂大体可分为三种: 金属氧化物、硫化物(如TiO2 [1 ] 、ZnO[2 ] 、CdS[3 ] 等), 贵金属半导体(如Bi2 MoO6 [4 ] 、BiOBr[5 ] 、Ag3 PO4 [6 ] 等), 非金属半导体(如g-C3 N4 [7 ] , 红磷[8 ] 等).ZnO(3.3 eV)和TiO2 (3.2 eV)带隙较宽, 仅能利用只占太阳能4%的紫外光.CdS(2.4 eV)带隙较窄, 但稳定性较差.Bi2 MoO6 (2.9 eV)和BiOBr(2.8 eV)带隙适中, 但含有贵金属元素, 价格较高.g-C3 N4 是一种非金属半导体, 由地球上含量较多的C、N元素组成, 带隙约2.7 eV, 对可见光有一定的吸收, 抗酸、碱、光的腐蚀, 稳定性好, 结构和性能易于调控, 具有较好的光催化性能, 因而成为光催化领域的研究热点. ...

Polymeric graphitic carbon nitride for heterogeneous photocatalysis

3

2012

... 太阳能是取之不尽用之不竭的清洁能源, 人类正致力开发高效的光催化剂, 以实现对太阳能的转化利用.目前, 已开发出的光催化剂大体可分为三种: 金属氧化物、硫化物(如TiO2 [1 ] 、ZnO[2 ] 、CdS[3 ] 等), 贵金属半导体(如Bi2 MoO6 [4 ] 、BiOBr[5 ] 、Ag3 PO4 [6 ] 等), 非金属半导体(如g-C3 N4 [7 ] , 红磷[8 ] 等).ZnO(3.3 eV)和TiO2 (3.2 eV)带隙较宽, 仅能利用只占太阳能4%的紫外光.CdS(2.4 eV)带隙较窄, 但稳定性较差.Bi2 MoO6 (2.9 eV)和BiOBr(2.8 eV)带隙适中, 但含有贵金属元素, 价格较高.g-C3 N4 是一种非金属半导体, 由地球上含量较多的C、N元素组成, 带隙约2.7 eV, 对可见光有一定的吸收, 抗酸、碱、光的腐蚀, 稳定性好, 结构和性能易于调控, 具有较好的光催化性能, 因而成为光催化领域的研究热点. ...

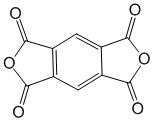

... (a) Crystal model[17 ] ; (b) S-triazine model[7 ] ; (c) 3-s-triazine model[7 ] ...

... [7 ] ...

Red phosphorus: an elemental photocatalyst for hydrogen formation from water

1

2012

... 太阳能是取之不尽用之不竭的清洁能源, 人类正致力开发高效的光催化剂, 以实现对太阳能的转化利用.目前, 已开发出的光催化剂大体可分为三种: 金属氧化物、硫化物(如TiO2 [1 ] 、ZnO[2 ] 、CdS[3 ] 等), 贵金属半导体(如Bi2 MoO6 [4 ] 、BiOBr[5 ] 、Ag3 PO4 [6 ] 等), 非金属半导体(如g-C3 N4 [7 ] , 红磷[8 ] 等).ZnO(3.3 eV)和TiO2 (3.2 eV)带隙较宽, 仅能利用只占太阳能4%的紫外光.CdS(2.4 eV)带隙较窄, 但稳定性较差.Bi2 MoO6 (2.9 eV)和BiOBr(2.8 eV)带隙适中, 但含有贵金属元素, 价格较高.g-C3 N4 是一种非金属半导体, 由地球上含量较多的C、N元素组成, 带隙约2.7 eV, 对可见光有一定的吸收, 抗酸、碱、光的腐蚀, 稳定性好, 结构和性能易于调控, 具有较好的光催化性能, 因而成为光催化领域的研究热点. ...

Graphitic carbon nitride thin films deposited by electrodeposition

2

2004

... g-C3 N4 , 即石墨相的C3 N4 , 是五种C3 N4 中最稳定的一种, 其结构如图1(a)所示.关于g-C3 N4 的单层结构, 人们主要有两种不同的看法: 一种认为单层g-C3 N4 以三嗪环(C3 N3 环)为结构单元(如图1(b))[9 -12 ] ; 另一种认为单层g-C3 N4 的基本结构单元是3-s-三嗪环(C6 N7 环)(如图1(c))[13 -15 ] .通过密度泛函(DFT)计算, 基于3-s-三嗪环的g-C3 N4 结构比基于三嗪环的g-C3 N4 结构稳定[16 ] , 近年来, 大多数对g-C3 N4 的研究都以3-s-三嗪环结构为理论模型. ...

... 在自然界中, 至今还没有发现存在天然的g-C3 N4 晶体.所以, g-C3 N4 的研究依赖于实验合成.合适的碳源和氮源在一定条件下反应可得到g-C3 N4 , 常用的反应物有三聚氰胺、三聚氰氯、氰胺、二氰二胺、尿素等.目前, g-C3 N4 的主要合成方法有: 高温高压法[17 ] 、溶剂热法[18 ] 、沉积法[9 , 19 ] 、热聚合法[15 , 20 ] 等.热聚合法可以方便地通过加入其他物质或改变反应条件来调节g-C3 N4 的结构, 从而提高g-C3 N4 的光催化性能, 是目前g-C3 N4 研究中常用的合成方法. ...

From triazines to heptazines: novel nonmetal tricyanomelaminates as precursors for graphitic carbon nitride materials

2006

Poly(triazine imide) with intercalation of lithium and chloride ions [(C3 N3 )2 (NHx Li1 -x )3 •LiCl]: a crystalline 2D carbon nitride network

2011

Enhanced photoresponsive ultrathin graphitic-phase C3 N4 nanosheets for bioimaging

3

2013

... g-C3 N4 , 即石墨相的C3 N4 , 是五种C3 N4 中最稳定的一种, 其结构如图1(a)所示.关于g-C3 N4 的单层结构, 人们主要有两种不同的看法: 一种认为单层g-C3 N4 以三嗪环(C3 N3 环)为结构单元(如图1(b))[9 -12 ] ; 另一种认为单层g-C3 N4 的基本结构单元是3-s-三嗪环(C6 N7 环)(如图1(c))[13 -15 ] .通过密度泛函(DFT)计算, 基于3-s-三嗪环的g-C3 N4 结构比基于三嗪环的g-C3 N4 结构稳定[16 ] , 近年来, 大多数对g-C3 N4 的研究都以3-s-三嗪环结构为理论模型. ...

... 除了上面几种在光催化领域的应用外, 科研人员还开发了g-C3 N4 的其他用途, 例如对钢材的电化学保护[64 ] 、合成石墨烯的模板[65 ] 、光生电[66 ] 、超级电容器[67 ] 、荧光探测和成像[12 , 68 -69 ] 等. ...

... g-C3 N4 具有类石墨烯的结构, 所以可以将g-C3 N4 做成纳米薄片甚至单层的结构(如图5(d)).目前, 制备g-C3 N4 纳米薄层结构主要采用剥离法, 包括热剥离和溶剂剥离.热剥离是将g-C3 N4 在空气中进行热处理, 块状结构逐渐分解, 最后留下纳米薄层[20 ,51 ] .对块状g-C3 N4 进行溶剂剥离常使用的溶剂为水[12 , 68 ] 和异丙醇(IPA)[39 ] 等.Wu等[14 ] 经计算得出, 双层g-C3 N4 具有很好的光吸收性能, 但目前难以精确控制g-C3 N4 的层数. ...

Ionothermal synthesis of crystalline, condensed, graphitic carbon nitride

1

2008

... g-C3 N4 , 即石墨相的C3 N4 , 是五种C3 N4 中最稳定的一种, 其结构如图1(a)所示.关于g-C3 N4 的单层结构, 人们主要有两种不同的看法: 一种认为单层g-C3 N4 以三嗪环(C3 N3 环)为结构单元(如图1(b))[9 -12 ] ; 另一种认为单层g-C3 N4 的基本结构单元是3-s-三嗪环(C6 N7 环)(如图1(c))[13 -15 ] .通过密度泛函(DFT)计算, 基于3-s-三嗪环的g-C3 N4 结构比基于三嗪环的g-C3 N4 结构稳定[16 ] , 近年来, 大多数对g-C3 N4 的研究都以3-s-三嗪环结构为理论模型. ...

Visible-light-absorption in graphitic C3 N4 bilayer: enhanced by interlayer coupling

1

2012

... g-C3 N4 具有类石墨烯的结构, 所以可以将g-C3 N4 做成纳米薄片甚至单层的结构(如图5(d)).目前, 制备g-C3 N4 纳米薄层结构主要采用剥离法, 包括热剥离和溶剂剥离.热剥离是将g-C3 N4 在空气中进行热处理, 块状结构逐渐分解, 最后留下纳米薄层[20 ,51 ] .对块状g-C3 N4 进行溶剂剥离常使用的溶剂为水[12 , 68 ] 和异丙醇(IPA)[39 ] 等.Wu等[14 ] 经计算得出, 双层g-C3 N4 具有很好的光吸收性能, 但目前难以精确控制g-C3 N4 的层数. ...

Well-dispersed g-C3 N4 nanophases in mesoporous silica channels and their catalytic activity for carbon dioxide activation and conversion

4

2013

... g-C3 N4 , 即石墨相的C3 N4 , 是五种C3 N4 中最稳定的一种, 其结构如图1(a)所示.关于g-C3 N4 的单层结构, 人们主要有两种不同的看法: 一种认为单层g-C3 N4 以三嗪环(C3 N3 环)为结构单元(如图1(b))[9 -12 ] ; 另一种认为单层g-C3 N4 的基本结构单元是3-s-三嗪环(C6 N7 环)(如图1(c))[13 -15 ] .通过密度泛函(DFT)计算, 基于3-s-三嗪环的g-C3 N4 结构比基于三嗪环的g-C3 N4 结构稳定[16 ] , 近年来, 大多数对g-C3 N4 的研究都以3-s-三嗪环结构为理论模型. ...

... 在自然界中, 至今还没有发现存在天然的g-C3 N4 晶体.所以, g-C3 N4 的研究依赖于实验合成.合适的碳源和氮源在一定条件下反应可得到g-C3 N4 , 常用的反应物有三聚氰胺、三聚氰氯、氰胺、二氰二胺、尿素等.目前, g-C3 N4 的主要合成方法有: 高温高压法[17 ] 、溶剂热法[18 ] 、沉积法[9 , 19 ] 、热聚合法[15 , 20 ] 等.热聚合法可以方便地通过加入其他物质或改变反应条件来调节g-C3 N4 的结构, 从而提高g-C3 N4 的光催化性能, 是目前g-C3 N4 研究中常用的合成方法. ...

... g-C3 N4 独特的结构决定了其独特的性质, 并赋予了其在光催化领域的广泛应用.目前, g-C3 N4 主要应用于光催化污染物分解[21 -22 ] 、光解水制氢制氧[23 -24 ] 、光催化有机合成[15 , 25 ] 和光催化氧气还原[26 ] 等. ...

... 在有机合成中, 利用O2 作为氧化剂制备某些有机物时, 由于O2 氧化能力较强, 不可避免地会产生大量的过度氧化产物, g-C3 N4 的加入可有效地解决这一问题, 实现精确性氧化[45 -46 ] .在反应体系中, 氧气在g-C3 N4 表面与光激发产生的电子结合形成•O2 - , 由于空穴静电作用, •O2 - 吸附在g-C3 N4 表面.附着在g-C3 N4 上的反应物经•O2 - 氧化后吸附能力减弱, 发生脱附, 因催化体系中没有游离的•O2 - 而避免了被过度氧化[47 ] .在羟胺化合物的帮助下, g-C3 N4 能很好地活化丙烯基位的碳氢键, 用于相应醛酮的合成[48 ] .CO2 的活化利用是有机合成的一个发展方向, Huang等[15 ] 在SBA-15的孔道中合成了g-C3 N4 , 经金属离子修饰后能够很好地活化CO2 用于环氧化合物和烯类化合物的合成.g-C3 N4 还能催化CO2 转化为CH4 [49 ] , 这将在燃料动力设备中发挥重要作用.g-C3 N4 中起桥连作用的N原子是Lewis碱活性位点, 可催化Knoevenagel缩合反应[50 ] .除此之外, g-C3 N4 可催化对苯二甲酸转化生成2-羟基对苯二甲酸[29 , 51 ] 、β-酮酯的酯交换反应[52 ] 、苯的傅-克酰基化反应[53 ] 、苯甲醛与醇的酯化反应[54 ] 和胺类的二聚反应[55 ] 等. ...

Tri-s-triazine derivatives. Part I. From trichloro-tri-s-triazine to graphitic C3 N4 structures

1

2002

... g-C3 N4 , 即石墨相的C3 N4 , 是五种C3 N4 中最稳定的一种, 其结构如图1(a)所示.关于g-C3 N4 的单层结构, 人们主要有两种不同的看法: 一种认为单层g-C3 N4 以三嗪环(C3 N3 环)为结构单元(如图1(b))[9 -12 ] ; 另一种认为单层g-C3 N4 的基本结构单元是3-s-三嗪环(C6 N7 环)(如图1(c))[13 -15 ] .通过密度泛函(DFT)计算, 基于3-s-三嗪环的g-C3 N4 结构比基于三嗪环的g-C3 N4 结构稳定[16 ] , 近年来, 大多数对g-C3 N4 的研究都以3-s-三嗪环结构为理论模型. ...

High-pressure pyrolysis study of C3 NH6 : a route to preparing bulk C3 N4

2

2002

... (a) Crystal model[17 ] ; (b) S-triazine model[7 ] ; (c) 3-s-triazine model[7 ] ...

... 在自然界中, 至今还没有发现存在天然的g-C3 N4 晶体.所以, g-C3 N4 的研究依赖于实验合成.合适的碳源和氮源在一定条件下反应可得到g-C3 N4 , 常用的反应物有三聚氰胺、三聚氰氯、氰胺、二氰二胺、尿素等.目前, g-C3 N4 的主要合成方法有: 高温高压法[17 ] 、溶剂热法[18 ] 、沉积法[9 , 19 ] 、热聚合法[15 , 20 ] 等.热聚合法可以方便地通过加入其他物质或改变反应条件来调节g-C3 N4 的结构, 从而提高g-C3 N4 的光催化性能, 是目前g-C3 N4 研究中常用的合成方法. ...

Characterization of well-crystal-lized graphitic carbon nitride nanocrystallites via a benzene-thermal route at low temperatures

1

2003

... 在自然界中, 至今还没有发现存在天然的g-C3 N4 晶体.所以, g-C3 N4 的研究依赖于实验合成.合适的碳源和氮源在一定条件下反应可得到g-C3 N4 , 常用的反应物有三聚氰胺、三聚氰氯、氰胺、二氰二胺、尿素等.目前, g-C3 N4 的主要合成方法有: 高温高压法[17 ] 、溶剂热法[18 ] 、沉积法[9 , 19 ] 、热聚合法[15 , 20 ] 等.热聚合法可以方便地通过加入其他物质或改变反应条件来调节g-C3 N4 的结构, 从而提高g-C3 N4 的光催化性能, 是目前g-C3 N4 研究中常用的合成方法. ...

Nitrogen-rich carbon nitride hollow vessels: synthesis, characterization, and their properties

1

2010

... 在自然界中, 至今还没有发现存在天然的g-C3 N4 晶体.所以, g-C3 N4 的研究依赖于实验合成.合适的碳源和氮源在一定条件下反应可得到g-C3 N4 , 常用的反应物有三聚氰胺、三聚氰氯、氰胺、二氰二胺、尿素等.目前, g-C3 N4 的主要合成方法有: 高温高压法[17 ] 、溶剂热法[18 ] 、沉积法[9 , 19 ] 、热聚合法[15 , 20 ] 等.热聚合法可以方便地通过加入其他物质或改变反应条件来调节g-C3 N4 的结构, 从而提高g-C3 N4 的光催化性能, 是目前g-C3 N4 研究中常用的合成方法. ...

Engineering the nanoarchitecture and texture of polymeric carbon nitride semiconductor for enhanced visible light photocatalytic activity

4

2013

... 在自然界中, 至今还没有发现存在天然的g-C3 N4 晶体.所以, g-C3 N4 的研究依赖于实验合成.合适的碳源和氮源在一定条件下反应可得到g-C3 N4 , 常用的反应物有三聚氰胺、三聚氰氯、氰胺、二氰二胺、尿素等.目前, g-C3 N4 的主要合成方法有: 高温高压法[17 ] 、溶剂热法[18 ] 、沉积法[9 , 19 ] 、热聚合法[15 , 20 ] 等.热聚合法可以方便地通过加入其他物质或改变反应条件来调节g-C3 N4 的结构, 从而提高g-C3 N4 的光催化性能, 是目前g-C3 N4 研究中常用的合成方法. ...

... 应用于g-C3 N4 光催化性能研究的主要污染物有两类, 即有机染料(亚甲基蓝(MB)[21 ] 、甲基橙(MO)[27 ] 和罗丹明B(RhB)[28 ] 等)和小分子化合物(苯酚[29 -31 ] 、2,4-二氯苯酚(2,4-DCP)[32 ] 、2,4,6-三氯苯酚(2,4,6,-TCP)[22 ] 、十溴联苯醚[33 ] 、乙醛[34 -35 ] 、NO[20 ] 和Cr(Ⅵ) [36 -37 ] 等).光照下, g-C3 N4 价带电子激发至导带形成电子-空穴对, 电子与氧气分子结合, 并进一步与水分子反应.上述三个过程促使三种活性粒子的生成, 即h+ 、•O2 - 和•OH[21 ] (图2(a)).这些活性粒子可促使有机染料(图2(b))和某些有机物分解.NO与活性粒子经一系列的反应可生成HNO3 、HNO2 (如图2(c)), 从而实现对含NO气体的净化[20 , 38 ] . ...

... [20 , 38 ]. ...

... g-C3 N4 具有类石墨烯的结构, 所以可以将g-C3 N4 做成纳米薄片甚至单层的结构(如图5(d)).目前, 制备g-C3 N4 纳米薄层结构主要采用剥离法, 包括热剥离和溶剂剥离.热剥离是将g-C3 N4 在空气中进行热处理, 块状结构逐渐分解, 最后留下纳米薄层[20 ,51 ] .对块状g-C3 N4 进行溶剂剥离常使用的溶剂为水[12 , 68 ] 和异丙醇(IPA)[39 ] 等.Wu等[14 ] 经计算得出, 双层g-C3 N4 具有很好的光吸收性能, 但目前难以精确控制g-C3 N4 的层数. ...

Pyrolysis synthesized g-C3 N4 for photocatalytic degradation of methylene blue

5

2013

... g-C3 N4 独特的结构决定了其独特的性质, 并赋予了其在光催化领域的广泛应用.目前, g-C3 N4 主要应用于光催化污染物分解[21 -22 ] 、光解水制氢制氧[23 -24 ] 、光催化有机合成[15 , 25 ] 和光催化氧气还原[26 ] 等. ...

... 应用于g-C3 N4 光催化性能研究的主要污染物有两类, 即有机染料(亚甲基蓝(MB)[21 ] 、甲基橙(MO)[27 ] 和罗丹明B(RhB)[28 ] 等)和小分子化合物(苯酚[29 -31 ] 、2,4-二氯苯酚(2,4-DCP)[32 ] 、2,4,6-三氯苯酚(2,4,6,-TCP)[22 ] 、十溴联苯醚[33 ] 、乙醛[34 -35 ] 、NO[20 ] 和Cr(Ⅵ) [36 -37 ] 等).光照下, g-C3 N4 价带电子激发至导带形成电子-空穴对, 电子与氧气分子结合, 并进一步与水分子反应.上述三个过程促使三种活性粒子的生成, 即h+ 、•O2 - 和•OH[21 ] (图2(a)).这些活性粒子可促使有机染料(图2(b))和某些有机物分解.NO与活性粒子经一系列的反应可生成HNO3 、HNO2 (如图2(c)), 从而实现对含NO气体的净化[20 , 38 ] . ...

... [21 ](图2(a)).这些活性粒子可促使有机染料(图2(b))和某些有机物分解.NO与活性粒子经一系列的反应可生成HNO3 、HNO2 (如图2(c)), 从而实现对含NO气体的净化[20 , 38 ] . ...

... 活性粒子的产生(a)[21 ] 与其催化有机染料降解(b)[27 -28 ] 和含NO气体净化的机理(c)[38 ] ...

... Generation of reactive species (a)[21 ] and action mechanism for degradation of organic dye (b)[27 -28 ] and purification of gas containing NO (c)[38 ] ...

Photocatalytic degradation of 2,4,6-trichlorophenol over g-C3 N4 under visible light irradiation

2

2013

... g-C3 N4 独特的结构决定了其独特的性质, 并赋予了其在光催化领域的广泛应用.目前, g-C3 N4 主要应用于光催化污染物分解[21 -22 ] 、光解水制氢制氧[23 -24 ] 、光催化有机合成[15 , 25 ] 和光催化氧气还原[26 ] 等. ...

... 应用于g-C3 N4 光催化性能研究的主要污染物有两类, 即有机染料(亚甲基蓝(MB)[21 ] 、甲基橙(MO)[27 ] 和罗丹明B(RhB)[28 ] 等)和小分子化合物(苯酚[29 -31 ] 、2,4-二氯苯酚(2,4-DCP)[32 ] 、2,4,6-三氯苯酚(2,4,6,-TCP)[22 ] 、十溴联苯醚[33 ] 、乙醛[34 -35 ] 、NO[20 ] 和Cr(Ⅵ) [36 -37 ] 等).光照下, g-C3 N4 价带电子激发至导带形成电子-空穴对, 电子与氧气分子结合, 并进一步与水分子反应.上述三个过程促使三种活性粒子的生成, 即h+ 、•O2 - 和•OH[21 ] (图2(a)).这些活性粒子可促使有机染料(图2(b))和某些有机物分解.NO与活性粒子经一系列的反应可生成HNO3 、HNO2 (如图2(c)), 从而实现对含NO气体的净化[20 , 38 ] . ...

Condensed graphitic carbon nitride nanorods by nanoconfinement: promotion of crystallinity on photocatalytic conversion

5

2011

... g-C3 N4 独特的结构决定了其独特的性质, 并赋予了其在光催化领域的广泛应用.目前, g-C3 N4 主要应用于光催化污染物分解[21 -22 ] 、光解水制氢制氧[23 -24 ] 、光催化有机合成[15 , 25 ] 和光催化氧气还原[26 ] 等. ...

... 在光解水制氧时, H2 O分子与光激发产生的空穴结合, 释放出氧气, 电子则需要加入AgNO3 [42 , 44 ] 等试剂去除.为了防止H+ 的积累导致pH的下降, 可使用缓冲试剂维持pH在8~9之间, 如La2 O3 [44 ] 等.由于N原子相对于O易被氧化, 光解水制氧可能会生成N2 [42 ] , 所有光解制氧时需要加入RuO2 等试剂及时将空穴从g-C3 N4 中导出.g-C3 N4 光解水制氧的能力较弱, 这可能是由于g-C3 N4 的价带(1.5V)与H2 O/O2 的电势(1.2V)较为接近, 热力学氧化驱动力不足造成的[42 ] , 因此可以通过降低价带的位置来提高水解制氧的速率[23 ] . ...

... 除了多孔结构外, 还可利用空间限制直接合成法[23 , 96 ] 或合成打碎法[97 ] 将g-C3 N4 做成纳米颗粒[96 ] (如图5(b))和纳米棒结构[23 ] (如图5(c)).这些纳米结构某些方向的尺寸较小, 减少了缺陷, 提高了结晶度, 缩短了光激发产生的电子和空穴转移至g-C3 N4 表面的距离, 使之较快地被利用, 降低了电子空穴的复合率. ...

... [23 ](如图5(c)).这些纳米结构某些方向的尺寸较小, 减少了缺陷, 提高了结晶度, 缩短了光激发产生的电子和空穴转移至g-C3 N4 表面的距离, 使之较快地被利用, 降低了电子空穴的复合率. ...

... (a) Porous structure [94 ] ; (b) Nanoparticle[96 ] ; (c) Nanorod[23 ] ; (d) Nanosheet[51 ] ...

H2 and O2 evolution from water half-splitting reactions by graphitic carbon nitride materials

1

2013

... g-C3 N4 独特的结构决定了其独特的性质, 并赋予了其在光催化领域的广泛应用.目前, g-C3 N4 主要应用于光催化污染物分解[21 -22 ] 、光解水制氢制氧[23 -24 ] 、光催化有机合成[15 , 25 ] 和光催化氧气还原[26 ] 等. ...

Highly selective synthesis of phenol from benzene over a vanadium-doped graphitic carbon nitride catalyst

1

2013

... g-C3 N4 独特的结构决定了其独特的性质, 并赋予了其在光催化领域的广泛应用.目前, g-C3 N4 主要应用于光催化污染物分解[21 -22 ] 、光解水制氢制氧[23 -24 ] 、光催化有机合成[15 , 25 ] 和光催化氧气还原[26 ] 等. ...

Synthesis of graphitic carbon nitride through pyrolysis of melamine and its electrocatalysis for oxygen reduction reaction

1

2013

... g-C3 N4 独特的结构决定了其独特的性质, 并赋予了其在光催化领域的广泛应用.目前, g-C3 N4 主要应用于光催化污染物分解[21 -22 ] 、光解水制氢制氧[23 -24 ] 、光催化有机合成[15 , 25 ] 和光催化氧气还原[26 ] 等. ...

Synthesis of porous Fe3 O4 /g- C3 N4 nanospheres as highly efficient and recyclable photocatalysts

6

2013

... 应用于g-C3 N4 光催化性能研究的主要污染物有两类, 即有机染料(亚甲基蓝(MB)[21 ] 、甲基橙(MO)[27 ] 和罗丹明B(RhB)[28 ] 等)和小分子化合物(苯酚[29 -31 ] 、2,4-二氯苯酚(2,4-DCP)[32 ] 、2,4,6-三氯苯酚(2,4,6,-TCP)[22 ] 、十溴联苯醚[33 ] 、乙醛[34 -35 ] 、NO[20 ] 和Cr(Ⅵ) [36 -37 ] 等).光照下, g-C3 N4 价带电子激发至导带形成电子-空穴对, 电子与氧气分子结合, 并进一步与水分子反应.上述三个过程促使三种活性粒子的生成, 即h+ 、•O2 - 和•OH[21 ] (图2(a)).这些活性粒子可促使有机染料(图2(b))和某些有机物分解.NO与活性粒子经一系列的反应可生成HNO3 、HNO2 (如图2(c)), 从而实现对含NO气体的净化[20 , 38 ] . ...

... 活性粒子的产生(a)[21 ] 与其催化有机染料降解(b)[27 -28 ] 和含NO气体净化的机理(c)[38 ] ...

... Generation of reactive species (a)[21 ] and action mechanism for degradation of organic dye (b)[27 -28 ] and purification of gas containing NO (c)[38 ] ...

... 物理复合改性是最方便的改进方法.目前, 选用的复合物主要有金属化合物(如CdS[40 ] 、Fe3 O4 [27 ] 、ZnO[28 ] 、AgX[70 ] (X= Br, I)、TiO2 [30 , 71 ] 、SmVO4 [72 ] 、MoS2 [41 ] 、Bi2 WO6 [73 ] 等)、类石墨烯材料(如石墨烯[74 ] 、氧化石墨烯[32 ] 、碳纳米管[75 ] 等), 高分子化合物(如P3HT[76 ] 、PANI[77 ] 等)和贵金属(如金[77 ] )等, 复合后g-C3 N4 的光催化性能都有一定提高(如表1).g-C3 N4 与复合物质之间并非简单的物理混合, 而是充分接触并形成异质结.由于二者导带和价带位置的差异, g-C3 N4 光激发产生的电子或空穴转移至复合物的导带或价带中, 电子空穴分离(如图3), 复合率降低, 从而可以更高效地利用光激发产生的活性粒子.经某些颜料(如曙红Y[78 ] )光敏化的g-C3 N4 对可见光的吸收增强, 光催化能力明显提高.复合物的加入还可赋予催化剂一些独特的优点, 例如g-C3 N4 与Fe3 O4 [27 ] 、Bi25 FeO40 [79 ] 复合后具有磁性, 方便了光催化剂的回收利用. ...

... [27 ]、Bi25 FeO40 [79 ] 复合后具有磁性, 方便了光催化剂的回收利用. ...

... (a) Convection-type charge transfer[30 , 40 ] (such as TiO2 , CdS); (b) Advection-type charge transfer[27 , 74 ] (such as Fe3 O4 , graphene); (c) Z-type charge transfer [35 , 71 ] ...

Significantly enhanced visible-light photocatalytic activity of g-C3 N4 via ZnO modification and the mechanism study

4

2013

... 应用于g-C3 N4 光催化性能研究的主要污染物有两类, 即有机染料(亚甲基蓝(MB)[21 ] 、甲基橙(MO)[27 ] 和罗丹明B(RhB)[28 ] 等)和小分子化合物(苯酚[29 -31 ] 、2,4-二氯苯酚(2,4-DCP)[32 ] 、2,4,6-三氯苯酚(2,4,6,-TCP)[22 ] 、十溴联苯醚[33 ] 、乙醛[34 -35 ] 、NO[20 ] 和Cr(Ⅵ) [36 -37 ] 等).光照下, g-C3 N4 价带电子激发至导带形成电子-空穴对, 电子与氧气分子结合, 并进一步与水分子反应.上述三个过程促使三种活性粒子的生成, 即h+ 、•O2 - 和•OH[21 ] (图2(a)).这些活性粒子可促使有机染料(图2(b))和某些有机物分解.NO与活性粒子经一系列的反应可生成HNO3 、HNO2 (如图2(c)), 从而实现对含NO气体的净化[20 , 38 ] . ...

... 活性粒子的产生(a)[21 ] 与其催化有机染料降解(b)[27 -28 ] 和含NO气体净化的机理(c)[38 ] ...

... Generation of reactive species (a)[21 ] and action mechanism for degradation of organic dye (b)[27 -28 ] and purification of gas containing NO (c)[38 ] ...

... 物理复合改性是最方便的改进方法.目前, 选用的复合物主要有金属化合物(如CdS[40 ] 、Fe3 O4 [27 ] 、ZnO[28 ] 、AgX[70 ] (X= Br, I)、TiO2 [30 , 71 ] 、SmVO4 [72 ] 、MoS2 [41 ] 、Bi2 WO6 [73 ] 等)、类石墨烯材料(如石墨烯[74 ] 、氧化石墨烯[32 ] 、碳纳米管[75 ] 等), 高分子化合物(如P3HT[76 ] 、PANI[77 ] 等)和贵金属(如金[77 ] )等, 复合后g-C3 N4 的光催化性能都有一定提高(如表1).g-C3 N4 与复合物质之间并非简单的物理混合, 而是充分接触并形成异质结.由于二者导带和价带位置的差异, g-C3 N4 光激发产生的电子或空穴转移至复合物的导带或价带中, 电子空穴分离(如图3), 复合率降低, 从而可以更高效地利用光激发产生的活性粒子.经某些颜料(如曙红Y[78 ] )光敏化的g-C3 N4 对可见光的吸收增强, 光催化能力明显提高.复合物的加入还可赋予催化剂一些独特的优点, 例如g-C3 N4 与Fe3 O4 [27 ] 、Bi25 FeO40 [79 ] 复合后具有磁性, 方便了光催化剂的回收利用. ...

Unique electronic structure induced high photoreactivity of sulfur-doped graphitic C3 N4

3

2010

... 应用于g-C3 N4 光催化性能研究的主要污染物有两类, 即有机染料(亚甲基蓝(MB)[21 ] 、甲基橙(MO)[27 ] 和罗丹明B(RhB)[28 ] 等)和小分子化合物(苯酚[29 -31 ] 、2,4-二氯苯酚(2,4-DCP)[32 ] 、2,4,6-三氯苯酚(2,4,6,-TCP)[22 ] 、十溴联苯醚[33 ] 、乙醛[34 -35 ] 、NO[20 ] 和Cr(Ⅵ) [36 -37 ] 等).光照下, g-C3 N4 价带电子激发至导带形成电子-空穴对, 电子与氧气分子结合, 并进一步与水分子反应.上述三个过程促使三种活性粒子的生成, 即h+ 、•O2 - 和•OH[21 ] (图2(a)).这些活性粒子可促使有机染料(图2(b))和某些有机物分解.NO与活性粒子经一系列的反应可生成HNO3 、HNO2 (如图2(c)), 从而实现对含NO气体的净化[20 , 38 ] . ...

... 在有机合成中, 利用O2 作为氧化剂制备某些有机物时, 由于O2 氧化能力较强, 不可避免地会产生大量的过度氧化产物, g-C3 N4 的加入可有效地解决这一问题, 实现精确性氧化[45 -46 ] .在反应体系中, 氧气在g-C3 N4 表面与光激发产生的电子结合形成•O2 - , 由于空穴静电作用, •O2 - 吸附在g-C3 N4 表面.附着在g-C3 N4 上的反应物经•O2 - 氧化后吸附能力减弱, 发生脱附, 因催化体系中没有游离的•O2 - 而避免了被过度氧化[47 ] .在羟胺化合物的帮助下, g-C3 N4 能很好地活化丙烯基位的碳氢键, 用于相应醛酮的合成[48 ] .CO2 的活化利用是有机合成的一个发展方向, Huang等[15 ] 在SBA-15的孔道中合成了g-C3 N4 , 经金属离子修饰后能够很好地活化CO2 用于环氧化合物和烯类化合物的合成.g-C3 N4 还能催化CO2 转化为CH4 [49 ] , 这将在燃料动力设备中发挥重要作用.g-C3 N4 中起桥连作用的N原子是Lewis碱活性位点, 可催化Knoevenagel缩合反应[50 ] .除此之外, g-C3 N4 可催化对苯二甲酸转化生成2-羟基对苯二甲酸[29 , 51 ] 、β-酮酯的酯交换反应[52 ] 、苯的傅-克酰基化反应[53 ] 、苯甲醛与醇的酯化反应[54 ] 和胺类的二聚反应[55 ] 等. ...

... 化学掺杂改性能够很好地改变g-C3 N4 的电子结构, 从而改善光催化性能.目前, 常采用杂环[44 , 83 -85 ] 和杂原子(如S[29 ] 、P[66 ] 、B[86 ] 、F[87 ] 等)进行掺杂.杂环的引入使g-C3 N4 的电子电势重新分配, 氧化还原位点分离[44 ] , 光催化性能提高(如图4、表2).S、P、B、F等杂原子与C、N原子的电负性不同, 它们的引入必然引起电子在整个网络中的不均匀, 导致电子结构的改变[88 -89 ] , 从而影响g-C3 N4 的光催化性能(如表2).异类元素的引入容易导致不对称掺杂或杂质, 这些都可以作为电子空穴的复合中心, 从而不利于光催化性能的提高, 故Dong等[90 ] 研究了C的自掺杂对g-C3 N4 光催化性能的影响, 发现掺杂的C取代了g-C3 N4 网络中起桥连作用的N, 扩大了电子的离域范围, 增加了电导率, 降低了带隙, 光催化性能得到了提高. ...

g-C3 N4 /TiO2 hybrid photocatalyst with wide absorption wavelength range and effective photogenerated charge separation

2

2012

... 物理复合改性是最方便的改进方法.目前, 选用的复合物主要有金属化合物(如CdS[40 ] 、Fe3 O4 [27 ] 、ZnO[28 ] 、AgX[70 ] (X= Br, I)、TiO2 [30 , 71 ] 、SmVO4 [72 ] 、MoS2 [41 ] 、Bi2 WO6 [73 ] 等)、类石墨烯材料(如石墨烯[74 ] 、氧化石墨烯[32 ] 、碳纳米管[75 ] 等), 高分子化合物(如P3HT[76 ] 、PANI[77 ] 等)和贵金属(如金[77 ] )等, 复合后g-C3 N4 的光催化性能都有一定提高(如表1).g-C3 N4 与复合物质之间并非简单的物理混合, 而是充分接触并形成异质结.由于二者导带和价带位置的差异, g-C3 N4 光激发产生的电子或空穴转移至复合物的导带或价带中, 电子空穴分离(如图3), 复合率降低, 从而可以更高效地利用光激发产生的活性粒子.经某些颜料(如曙红Y[78 ] )光敏化的g-C3 N4 对可见光的吸收增强, 光催化能力明显提高.复合物的加入还可赋予催化剂一些独特的优点, 例如g-C3 N4 与Fe3 O4 [27 ] 、Bi25 FeO40 [79 ] 复合后具有磁性, 方便了光催化剂的回收利用. ...

... (a) Convection-type charge transfer[30 , 40 ] (such as TiO2 , CdS); (b) Advection-type charge transfer[27 , 74 ] (such as Fe3 O4 , graphene); (c) Z-type charge transfer [35 , 71 ] ...

Improved photocatalytic activity of g-C3 N4 /TiO2 composites prepared by a simple impregnation method

1

2013

... 应用于g-C3 N4 光催化性能研究的主要污染物有两类, 即有机染料(亚甲基蓝(MB)[21 ] 、甲基橙(MO)[27 ] 和罗丹明B(RhB)[28 ] 等)和小分子化合物(苯酚[29 -31 ] 、2,4-二氯苯酚(2,4-DCP)[32 ] 、2,4,6-三氯苯酚(2,4,6,-TCP)[22 ] 、十溴联苯醚[33 ] 、乙醛[34 -35 ] 、NO[20 ] 和Cr(Ⅵ) [36 -37 ] 等).光照下, g-C3 N4 价带电子激发至导带形成电子-空穴对, 电子与氧气分子结合, 并进一步与水分子反应.上述三个过程促使三种活性粒子的生成, 即h+ 、•O2 - 和•OH[21 ] (图2(a)).这些活性粒子可促使有机染料(图2(b))和某些有机物分解.NO与活性粒子经一系列的反应可生成HNO3 、HNO2 (如图2(c)), 从而实现对含NO气体的净化[20 , 38 ] . ...

Graphene oxide modified g-C3 N4 hybrid with enhanced photocatalytic capability under visible light irradiation

2

2012

... 应用于g-C3 N4 光催化性能研究的主要污染物有两类, 即有机染料(亚甲基蓝(MB)[21 ] 、甲基橙(MO)[27 ] 和罗丹明B(RhB)[28 ] 等)和小分子化合物(苯酚[29 -31 ] 、2,4-二氯苯酚(2,4-DCP)[32 ] 、2,4,6-三氯苯酚(2,4,6,-TCP)[22 ] 、十溴联苯醚[33 ] 、乙醛[34 -35 ] 、NO[20 ] 和Cr(Ⅵ) [36 -37 ] 等).光照下, g-C3 N4 价带电子激发至导带形成电子-空穴对, 电子与氧气分子结合, 并进一步与水分子反应.上述三个过程促使三种活性粒子的生成, 即h+ 、•O2 - 和•OH[21 ] (图2(a)).这些活性粒子可促使有机染料(图2(b))和某些有机物分解.NO与活性粒子经一系列的反应可生成HNO3 、HNO2 (如图2(c)), 从而实现对含NO气体的净化[20 , 38 ] . ...

... 物理复合改性是最方便的改进方法.目前, 选用的复合物主要有金属化合物(如CdS[40 ] 、Fe3 O4 [27 ] 、ZnO[28 ] 、AgX[70 ] (X= Br, I)、TiO2 [30 , 71 ] 、SmVO4 [72 ] 、MoS2 [41 ] 、Bi2 WO6 [73 ] 等)、类石墨烯材料(如石墨烯[74 ] 、氧化石墨烯[32 ] 、碳纳米管[75 ] 等), 高分子化合物(如P3HT[76 ] 、PANI[77 ] 等)和贵金属(如金[77 ] )等, 复合后g-C3 N4 的光催化性能都有一定提高(如表1).g-C3 N4 与复合物质之间并非简单的物理混合, 而是充分接触并形成异质结.由于二者导带和价带位置的差异, g-C3 N4 光激发产生的电子或空穴转移至复合物的导带或价带中, 电子空穴分离(如图3), 复合率降低, 从而可以更高效地利用光激发产生的活性粒子.经某些颜料(如曙红Y[78 ] )光敏化的g-C3 N4 对可见光的吸收增强, 光催化能力明显提高.复合物的加入还可赋予催化剂一些独特的优点, 例如g-C3 N4 与Fe3 O4 [27 ] 、Bi25 FeO40 [79 ] 复合后具有磁性, 方便了光催化剂的回收利用. ...

Photocatalytic debromination of decabromodiphenyl ether by graphitic carbon nitride

1

2012

... 应用于g-C3 N4 光催化性能研究的主要污染物有两类, 即有机染料(亚甲基蓝(MB)[21 ] 、甲基橙(MO)[27 ] 和罗丹明B(RhB)[28 ] 等)和小分子化合物(苯酚[29 -31 ] 、2,4-二氯苯酚(2,4-DCP)[32 ] 、2,4,6-三氯苯酚(2,4,6,-TCP)[22 ] 、十溴联苯醚[33 ] 、乙醛[34 -35 ] 、NO[20 ] 和Cr(Ⅵ) [36 -37 ] 等).光照下, g-C3 N4 价带电子激发至导带形成电子-空穴对, 电子与氧气分子结合, 并进一步与水分子反应.上述三个过程促使三种活性粒子的生成, 即h+ 、•O2 - 和•OH[21 ] (图2(a)).这些活性粒子可促使有机染料(图2(b))和某些有机物分解.NO与活性粒子经一系列的反应可生成HNO3 、HNO2 (如图2(c)), 从而实现对含NO气体的净化[20 , 38 ] . ...

Preparation of graphitic carbon nitride (g-C3 N4 )/WO3 composites and enhanced visible-light-driven photodegradation of acetaldehyde gas

1

2013

... 应用于g-C3 N4 光催化性能研究的主要污染物有两类, 即有机染料(亚甲基蓝(MB)[21 ] 、甲基橙(MO)[27 ] 和罗丹明B(RhB)[28 ] 等)和小分子化合物(苯酚[29 -31 ] 、2,4-二氯苯酚(2,4-DCP)[32 ] 、2,4,6-三氯苯酚(2,4,6,-TCP)[22 ] 、十溴联苯醚[33 ] 、乙醛[34 -35 ] 、NO[20 ] 和Cr(Ⅵ) [36 -37 ] 等).光照下, g-C3 N4 价带电子激发至导带形成电子-空穴对, 电子与氧气分子结合, 并进一步与水分子反应.上述三个过程促使三种活性粒子的生成, 即h+ 、•O2 - 和•OH[21 ] (图2(a)).这些活性粒子可促使有机染料(图2(b))和某些有机物分解.NO与活性粒子经一系列的反应可生成HNO3 、HNO2 (如图2(c)), 从而实现对含NO气体的净化[20 , 38 ] . ...

Development of highly efficient sulfur-doped TiO2 photocatalysts hybridized with graphitic carbon nitride

2

2013

... 应用于g-C3 N4 光催化性能研究的主要污染物有两类, 即有机染料(亚甲基蓝(MB)[21 ] 、甲基橙(MO)[27 ] 和罗丹明B(RhB)[28 ] 等)和小分子化合物(苯酚[29 -31 ] 、2,4-二氯苯酚(2,4-DCP)[32 ] 、2,4,6-三氯苯酚(2,4,6,-TCP)[22 ] 、十溴联苯醚[33 ] 、乙醛[34 -35 ] 、NO[20 ] 和Cr(Ⅵ) [36 -37 ] 等).光照下, g-C3 N4 价带电子激发至导带形成电子-空穴对, 电子与氧气分子结合, 并进一步与水分子反应.上述三个过程促使三种活性粒子的生成, 即h+ 、•O2 - 和•OH[21 ] (图2(a)).这些活性粒子可促使有机染料(图2(b))和某些有机物分解.NO与活性粒子经一系列的反应可生成HNO3 、HNO2 (如图2(c)), 从而实现对含NO气体的净化[20 , 38 ] . ...

... (a) Convection-type charge transfer[30 , 40 ] (such as TiO2 , CdS); (b) Advection-type charge transfer[27 , 74 ] (such as Fe3 O4 , graphene); (c) Z-type charge transfer [35 , 71 ] ...

Facile synthesis of g-C3 N4 /ZnO composite with enhanced visible light photooxidation and photoreduction properties

2

2012

... 应用于g-C3 N4 光催化性能研究的主要污染物有两类, 即有机染料(亚甲基蓝(MB)[21 ] 、甲基橙(MO)[27 ] 和罗丹明B(RhB)[28 ] 等)和小分子化合物(苯酚[29 -31 ] 、2,4-二氯苯酚(2,4-DCP)[32 ] 、2,4,6-三氯苯酚(2,4,6,-TCP)[22 ] 、十溴联苯醚[33 ] 、乙醛[34 -35 ] 、NO[20 ] 和Cr(Ⅵ) [36 -37 ] 等).光照下, g-C3 N4 价带电子激发至导带形成电子-空穴对, 电子与氧气分子结合, 并进一步与水分子反应.上述三个过程促使三种活性粒子的生成, 即h+ 、•O2 - 和•OH[21 ] (图2(a)).这些活性粒子可促使有机染料(图2(b))和某些有机物分解.NO与活性粒子经一系列的反应可生成HNO3 、HNO2 (如图2(c)), 从而实现对含NO气体的净化[20 , 38 ] . ...

... Cr(Ⅵ)/Cr(Ⅲ)的还原电势为1.33 V, 而g-C3 N4 的价带(1.5 V)和导带(-1.2 V)跨立在其两端, 故g-C3 N4 在光激发产生的电子可将剧毒的Cr(Ⅵ)还原为低毒的Cr(Ⅲ)[36 -37 ] . ...

Synthesis and enhanced Cr(VI) photoreduction property of formate anion containing graphitic carbon nitride

2

2013

... 应用于g-C3 N4 光催化性能研究的主要污染物有两类, 即有机染料(亚甲基蓝(MB)[21 ] 、甲基橙(MO)[27 ] 和罗丹明B(RhB)[28 ] 等)和小分子化合物(苯酚[29 -31 ] 、2,4-二氯苯酚(2,4-DCP)[32 ] 、2,4,6-三氯苯酚(2,4,6,-TCP)[22 ] 、十溴联苯醚[33 ] 、乙醛[34 -35 ] 、NO[20 ] 和Cr(Ⅵ) [36 -37 ] 等).光照下, g-C3 N4 价带电子激发至导带形成电子-空穴对, 电子与氧气分子结合, 并进一步与水分子反应.上述三个过程促使三种活性粒子的生成, 即h+ 、•O2 - 和•OH[21 ] (图2(a)).这些活性粒子可促使有机染料(图2(b))和某些有机物分解.NO与活性粒子经一系列的反应可生成HNO3 、HNO2 (如图2(c)), 从而实现对含NO气体的净化[20 , 38 ] . ...

... Cr(Ⅵ)/Cr(Ⅲ)的还原电势为1.33 V, 而g-C3 N4 的价带(1.5 V)和导带(-1.2 V)跨立在其两端, 故g-C3 N4 在光激发产生的电子可将剧毒的Cr(Ⅵ)还原为低毒的Cr(Ⅲ)[36 -37 ] . ...

Activation of graphitic carbon nitride (g-C3 N4 ) by alkaline hydrothermal treatment for photocatalytic NO oxidation in gas phase

4

2013

... 应用于g-C3 N4 光催化性能研究的主要污染物有两类, 即有机染料(亚甲基蓝(MB)[21 ] 、甲基橙(MO)[27 ] 和罗丹明B(RhB)[28 ] 等)和小分子化合物(苯酚[29 -31 ] 、2,4-二氯苯酚(2,4-DCP)[32 ] 、2,4,6-三氯苯酚(2,4,6,-TCP)[22 ] 、十溴联苯醚[33 ] 、乙醛[34 -35 ] 、NO[20 ] 和Cr(Ⅵ) [36 -37 ] 等).光照下, g-C3 N4 价带电子激发至导带形成电子-空穴对, 电子与氧气分子结合, 并进一步与水分子反应.上述三个过程促使三种活性粒子的生成, 即h+ 、•O2 - 和•OH[21 ] (图2(a)).这些活性粒子可促使有机染料(图2(b))和某些有机物分解.NO与活性粒子经一系列的反应可生成HNO3 、HNO2 (如图2(c)), 从而实现对含NO气体的净化[20 , 38 ] . ...

... 活性粒子的产生(a)[21 ] 与其催化有机染料降解(b)[27 -28 ] 和含NO气体净化的机理(c)[38 ] ...

... Generation of reactive species (a)[21 ] and action mechanism for degradation of organic dye (b)[27 -28 ] and purification of gas containing NO (c)[38 ] ...

... 多孔g-C3 N4 合成后, 需要去除硬模板, 这往往需要使用剧毒的HF[92 ] 或NH4 HF2 [47 ] , 对人体的伤害较大.Xu等[95 ] 在前驱体中加入硫脲合成出多孔g-C3 N4 .同样, Dong等[94 ] 用三聚氰胺的盐酸季铵盐作为前驱体, 也合成出多孔的g-C3 N4 .硫脲和盐酸等软模板的加入, 不仅促使多孔结构的形成, 而且有效避免剧毒物质的使用.另外, 还可使用刻蚀液(如碱液[38 ] )将g-C3 N4 中不稳定的区域刻蚀掉, 得到多孔的g-C3 N4 . ...

Exfoliated graphitic carbon nitride nanosheets as efficient catalysts for hydrogen evolution under visible light

2

2013

... g-C3 N4 的导带和价带跨立在H+ /H2 和H2 O/O2 还原电势的两侧, 所以g-C3 N4 可用来催化水的分解.在g-C3 N4 光催化水解制氢时, 激发至导带的电子与氢离子结合, 留下的空穴由催化体系中加入的三乙醇胺[39 ] 、维C[40 ] 或甲醇[41 ] 及时移除.由于超电势的存在, g-C3 N4 光激发产生的电子不能快速地转移给氢离子, 影响了光解制氢的速率.在g-C3 N4 表面沉积一定量的Pt可以有效解决这个问题, 这是由于Pt可以和H形成Pt-H键, 有利于电子的迅速转移使H+ 转化为H2 [42 ] .金属Pt的使用增加了水解制氢的成本, Hong等[43 ] 使用NiS作为共催化剂, 取得了与使用Pt作为共催化剂相当的催化速率. ...

... g-C3 N4 具有类石墨烯的结构, 所以可以将g-C3 N4 做成纳米薄片甚至单层的结构(如图5(d)).目前, 制备g-C3 N4 纳米薄层结构主要采用剥离法, 包括热剥离和溶剂剥离.热剥离是将g-C3 N4 在空气中进行热处理, 块状结构逐渐分解, 最后留下纳米薄层[20 ,51 ] .对块状g-C3 N4 进行溶剂剥离常使用的溶剂为水[12 , 68 ] 和异丙醇(IPA)[39 ] 等.Wu等[14 ] 经计算得出, 双层g-C3 N4 具有很好的光吸收性能, 但目前难以精确控制g-C3 N4 的层数. ...

In-situ growth of CdS quantum dots on g-C3 N4 nanosheets for highly efficient photocatalytic hydrogen generation under visible light irradiation

3

2013

... g-C3 N4 的导带和价带跨立在H+ /H2 和H2 O/O2 还原电势的两侧, 所以g-C3 N4 可用来催化水的分解.在g-C3 N4 光催化水解制氢时, 激发至导带的电子与氢离子结合, 留下的空穴由催化体系中加入的三乙醇胺[39 ] 、维C[40 ] 或甲醇[41 ] 及时移除.由于超电势的存在, g-C3 N4 光激发产生的电子不能快速地转移给氢离子, 影响了光解制氢的速率.在g-C3 N4 表面沉积一定量的Pt可以有效解决这个问题, 这是由于Pt可以和H形成Pt-H键, 有利于电子的迅速转移使H+ 转化为H2 [42 ] .金属Pt的使用增加了水解制氢的成本, Hong等[43 ] 使用NiS作为共催化剂, 取得了与使用Pt作为共催化剂相当的催化速率. ...

... 物理复合改性是最方便的改进方法.目前, 选用的复合物主要有金属化合物(如CdS[40 ] 、Fe3 O4 [27 ] 、ZnO[28 ] 、AgX[70 ] (X= Br, I)、TiO2 [30 , 71 ] 、SmVO4 [72 ] 、MoS2 [41 ] 、Bi2 WO6 [73 ] 等)、类石墨烯材料(如石墨烯[74 ] 、氧化石墨烯[32 ] 、碳纳米管[75 ] 等), 高分子化合物(如P3HT[76 ] 、PANI[77 ] 等)和贵金属(如金[77 ] )等, 复合后g-C3 N4 的光催化性能都有一定提高(如表1).g-C3 N4 与复合物质之间并非简单的物理混合, 而是充分接触并形成异质结.由于二者导带和价带位置的差异, g-C3 N4 光激发产生的电子或空穴转移至复合物的导带或价带中, 电子空穴分离(如图3), 复合率降低, 从而可以更高效地利用光激发产生的活性粒子.经某些颜料(如曙红Y[78 ] )光敏化的g-C3 N4 对可见光的吸收增强, 光催化能力明显提高.复合物的加入还可赋予催化剂一些独特的优点, 例如g-C3 N4 与Fe3 O4 [27 ] 、Bi25 FeO40 [79 ] 复合后具有磁性, 方便了光催化剂的回收利用. ...

... (a) Convection-type charge transfer[30 , 40 ] (such as TiO2 , CdS); (b) Advection-type charge transfer[27 , 74 ] (such as Fe3 O4 , graphene); (c) Z-type charge transfer [35 , 71 ] ...

Synthesis and characterization of composite visible light active photocatalysts MoS2 -g-C3 N4 with enhanced hydrogen evolution activity

2

2013

... g-C3 N4 的导带和价带跨立在H+ /H2 和H2 O/O2 还原电势的两侧, 所以g-C3 N4 可用来催化水的分解.在g-C3 N4 光催化水解制氢时, 激发至导带的电子与氢离子结合, 留下的空穴由催化体系中加入的三乙醇胺[39 ] 、维C[40 ] 或甲醇[41 ] 及时移除.由于超电势的存在, g-C3 N4 光激发产生的电子不能快速地转移给氢离子, 影响了光解制氢的速率.在g-C3 N4 表面沉积一定量的Pt可以有效解决这个问题, 这是由于Pt可以和H形成Pt-H键, 有利于电子的迅速转移使H+ 转化为H2 [42 ] .金属Pt的使用增加了水解制氢的成本, Hong等[43 ] 使用NiS作为共催化剂, 取得了与使用Pt作为共催化剂相当的催化速率. ...

... 物理复合改性是最方便的改进方法.目前, 选用的复合物主要有金属化合物(如CdS[40 ] 、Fe3 O4 [27 ] 、ZnO[28 ] 、AgX[70 ] (X= Br, I)、TiO2 [30 , 71 ] 、SmVO4 [72 ] 、MoS2 [41 ] 、Bi2 WO6 [73 ] 等)、类石墨烯材料(如石墨烯[74 ] 、氧化石墨烯[32 ] 、碳纳米管[75 ] 等), 高分子化合物(如P3HT[76 ] 、PANI[77 ] 等)和贵金属(如金[77 ] )等, 复合后g-C3 N4 的光催化性能都有一定提高(如表1).g-C3 N4 与复合物质之间并非简单的物理混合, 而是充分接触并形成异质结.由于二者导带和价带位置的差异, g-C3 N4 光激发产生的电子或空穴转移至复合物的导带或价带中, 电子空穴分离(如图3), 复合率降低, 从而可以更高效地利用光激发产生的活性粒子.经某些颜料(如曙红Y[78 ] )光敏化的g-C3 N4 对可见光的吸收增强, 光催化能力明显提高.复合物的加入还可赋予催化剂一些独特的优点, 例如g-C3 N4 与Fe3 O4 [27 ] 、Bi25 FeO40 [79 ] 复合后具有磁性, 方便了光催化剂的回收利用. ...

A metal-free polymeric photocatalyst for hydrogen production from water under visible light

4

2009

... g-C3 N4 的导带和价带跨立在H+ /H2 和H2 O/O2 还原电势的两侧, 所以g-C3 N4 可用来催化水的分解.在g-C3 N4 光催化水解制氢时, 激发至导带的电子与氢离子结合, 留下的空穴由催化体系中加入的三乙醇胺[39 ] 、维C[40 ] 或甲醇[41 ] 及时移除.由于超电势的存在, g-C3 N4 光激发产生的电子不能快速地转移给氢离子, 影响了光解制氢的速率.在g-C3 N4 表面沉积一定量的Pt可以有效解决这个问题, 这是由于Pt可以和H形成Pt-H键, 有利于电子的迅速转移使H+ 转化为H2 [42 ] .金属Pt的使用增加了水解制氢的成本, Hong等[43 ] 使用NiS作为共催化剂, 取得了与使用Pt作为共催化剂相当的催化速率. ...

... 在光解水制氧时, H2 O分子与光激发产生的空穴结合, 释放出氧气, 电子则需要加入AgNO3 [42 , 44 ] 等试剂去除.为了防止H+ 的积累导致pH的下降, 可使用缓冲试剂维持pH在8~9之间, 如La2 O3 [44 ] 等.由于N原子相对于O易被氧化, 光解水制氧可能会生成N2 [42 ] , 所有光解制氧时需要加入RuO2 等试剂及时将空穴从g-C3 N4 中导出.g-C3 N4 光解水制氧的能力较弱, 这可能是由于g-C3 N4 的价带(1.5V)与H2 O/O2 的电势(1.2V)较为接近, 热力学氧化驱动力不足造成的[42 ] , 因此可以通过降低价带的位置来提高水解制氧的速率[23 ] . ...

... [42 ], 所有光解制氧时需要加入RuO2 等试剂及时将空穴从g-C3 N4 中导出.g-C3 N4 光解水制氧的能力较弱, 这可能是由于g-C3 N4 的价带(1.5V)与H2 O/O2 的电势(1.2V)较为接近, 热力学氧化驱动力不足造成的[42 ] , 因此可以通过降低价带的位置来提高水解制氧的速率[23 ] . ...

... [42 ], 因此可以通过降低价带的位置来提高水解制氧的速率[23 ] . ...

Noble-metal-free NiS/C3 N4 for efficient photocatalytic hydrogen evolution from water

1

2013

... g-C3 N4 的导带和价带跨立在H+ /H2 和H2 O/O2 还原电势的两侧, 所以g-C3 N4 可用来催化水的分解.在g-C3 N4 光催化水解制氢时, 激发至导带的电子与氢离子结合, 留下的空穴由催化体系中加入的三乙醇胺[39 ] 、维C[40 ] 或甲醇[41 ] 及时移除.由于超电势的存在, g-C3 N4 光激发产生的电子不能快速地转移给氢离子, 影响了光解制氢的速率.在g-C3 N4 表面沉积一定量的Pt可以有效解决这个问题, 这是由于Pt可以和H形成Pt-H键, 有利于电子的迅速转移使H+ 转化为H2 [42 ] .金属Pt的使用增加了水解制氢的成本, Hong等[43 ] 使用NiS作为共催化剂, 取得了与使用Pt作为共催化剂相当的催化速率. ...

Band structure engineering of carbon nitride: in search of a polymer photocatalyst with high photooxidation property

4

2013

... 在光解水制氧时, H2 O分子与光激发产生的空穴结合, 释放出氧气, 电子则需要加入AgNO3 [42 , 44 ] 等试剂去除.为了防止H+ 的积累导致pH的下降, 可使用缓冲试剂维持pH在8~9之间, 如La2 O3 [44 ] 等.由于N原子相对于O易被氧化, 光解水制氧可能会生成N2 [42 ] , 所有光解制氧时需要加入RuO2 等试剂及时将空穴从g-C3 N4 中导出.g-C3 N4 光解水制氧的能力较弱, 这可能是由于g-C3 N4 的价带(1.5V)与H2 O/O2 的电势(1.2V)较为接近, 热力学氧化驱动力不足造成的[42 ] , 因此可以通过降低价带的位置来提高水解制氧的速率[23 ] . ...

... [44 ]等.由于N原子相对于O易被氧化, 光解水制氧可能会生成N2 [42 ] , 所有光解制氧时需要加入RuO2 等试剂及时将空穴从g-C3 N4 中导出.g-C3 N4 光解水制氧的能力较弱, 这可能是由于g-C3 N4 的价带(1.5V)与H2 O/O2 的电势(1.2V)较为接近, 热力学氧化驱动力不足造成的[42 ] , 因此可以通过降低价带的位置来提高水解制氧的速率[23 ] . ...

... 化学掺杂改性能够很好地改变g-C3 N4 的电子结构, 从而改善光催化性能.目前, 常采用杂环[44 , 83 -85 ] 和杂原子(如S[29 ] 、P[66 ] 、B[86 ] 、F[87 ] 等)进行掺杂.杂环的引入使g-C3 N4 的电子电势重新分配, 氧化还原位点分离[44 ] , 光催化性能提高(如图4、表2).S、P、B、F等杂原子与C、N原子的电负性不同, 它们的引入必然引起电子在整个网络中的不均匀, 导致电子结构的改变[88 -89 ] , 从而影响g-C3 N4 的光催化性能(如表2).异类元素的引入容易导致不对称掺杂或杂质, 这些都可以作为电子空穴的复合中心, 从而不利于光催化性能的提高, 故Dong等[90 ] 研究了C的自掺杂对g-C3 N4 光催化性能的影响, 发现掺杂的C取代了g-C3 N4 网络中起桥连作用的N, 扩大了电子的离域范围, 增加了电导率, 降低了带隙, 光催化性能得到了提高. ...

... [44 ], 光催化性能提高(如图4、表2).S、P、B、F等杂原子与C、N原子的电负性不同, 它们的引入必然引起电子在整个网络中的不均匀, 导致电子结构的改变[88 -89 ] , 从而影响g-C3 N4 的光催化性能(如表2).异类元素的引入容易导致不对称掺杂或杂质, 这些都可以作为电子空穴的复合中心, 从而不利于光催化性能的提高, 故Dong等[90 ] 研究了C的自掺杂对g-C3 N4 光催化性能的影响, 发现掺杂的C取代了g-C3 N4 网络中起桥连作用的N, 扩大了电子的离域范围, 增加了电导率, 降低了带隙, 光催化性能得到了提高. ...

mpg-C3 N4 -catalyzed selective oxidation of alcohols using O2 and visible light

2

2010

... 在有机合成中, 利用O2 作为氧化剂制备某些有机物时, 由于O2 氧化能力较强, 不可避免地会产生大量的过度氧化产物, g-C3 N4 的加入可有效地解决这一问题, 实现精确性氧化[45 -46 ] .在反应体系中, 氧气在g-C3 N4 表面与光激发产生的电子结合形成•O2 - , 由于空穴静电作用, •O2 - 吸附在g-C3 N4 表面.附着在g-C3 N4 上的反应物经•O2 - 氧化后吸附能力减弱, 发生脱附, 因催化体系中没有游离的•O2 - 而避免了被过度氧化[47 ] .在羟胺化合物的帮助下, g-C3 N4 能很好地活化丙烯基位的碳氢键, 用于相应醛酮的合成[48 ] .CO2 的活化利用是有机合成的一个发展方向, Huang等[15 ] 在SBA-15的孔道中合成了g-C3 N4 , 经金属离子修饰后能够很好地活化CO2 用于环氧化合物和烯类化合物的合成.g-C3 N4 还能催化CO2 转化为CH4 [49 ] , 这将在燃料动力设备中发挥重要作用.g-C3 N4 中起桥连作用的N原子是Lewis碱活性位点, 可催化Knoevenagel缩合反应[50 ] .除此之外, g-C3 N4 可催化对苯二甲酸转化生成2-羟基对苯二甲酸[29 , 51 ] 、β-酮酯的酯交换反应[52 ] 、苯的傅-克酰基化反应[53 ] 、苯甲醛与醇的酯化反应[54 ] 和胺类的二聚反应[55 ] 等. ...

... 利用SiO2 作为硬模板, 可合成出多孔结构的g-C3 N4 [45 , 52 -53 , 92 -94 ] (如图5(a)), 其光催化苯的傅-克酰基化反应、光解水制氢和对醇的选择性氧化的能力明显提高.多孔结构使g-C3 N4 比表面积增加, 电子的捕捉位点增多, 减缓了电子空穴对的复合, 使其能克服带隙略微增加带来的不利影响而提高光催化性能[94 ] . ...

Metal-free activation of dioxygen by graphene/g-C3 N4 nanocomposites: functional dyads for selective oxidation of saturated hydrocarbons

1

2011

... 在有机合成中, 利用O2 作为氧化剂制备某些有机物时, 由于O2 氧化能力较强, 不可避免地会产生大量的过度氧化产物, g-C3 N4 的加入可有效地解决这一问题, 实现精确性氧化[45 -46 ] .在反应体系中, 氧气在g-C3 N4 表面与光激发产生的电子结合形成•O2 - , 由于空穴静电作用, •O2 - 吸附在g-C3 N4 表面.附着在g-C3 N4 上的反应物经•O2 - 氧化后吸附能力减弱, 发生脱附, 因催化体系中没有游离的•O2 - 而避免了被过度氧化[47 ] .在羟胺化合物的帮助下, g-C3 N4 能很好地活化丙烯基位的碳氢键, 用于相应醛酮的合成[48 ] .CO2 的活化利用是有机合成的一个发展方向, Huang等[15 ] 在SBA-15的孔道中合成了g-C3 N4 , 经金属离子修饰后能够很好地活化CO2 用于环氧化合物和烯类化合物的合成.g-C3 N4 还能催化CO2 转化为CH4 [49 ] , 这将在燃料动力设备中发挥重要作用.g-C3 N4 中起桥连作用的N原子是Lewis碱活性位点, 可催化Knoevenagel缩合反应[50 ] .除此之外, g-C3 N4 可催化对苯二甲酸转化生成2-羟基对苯二甲酸[29 , 51 ] 、β-酮酯的酯交换反应[52 ] 、苯的傅-克酰基化反应[53 ] 、苯甲醛与醇的酯化反应[54 ] 和胺类的二聚反应[55 ] 等. ...

Solvent-free and metal-free oxidation of toluene using O2 and g-C3 N4 with nanopores: nanostructure boosts the catalytic selectivity

2

2012

... 在有机合成中, 利用O2 作为氧化剂制备某些有机物时, 由于O2 氧化能力较强, 不可避免地会产生大量的过度氧化产物, g-C3 N4 的加入可有效地解决这一问题, 实现精确性氧化[45 -46 ] .在反应体系中, 氧气在g-C3 N4 表面与光激发产生的电子结合形成•O2 - , 由于空穴静电作用, •O2 - 吸附在g-C3 N4 表面.附着在g-C3 N4 上的反应物经•O2 - 氧化后吸附能力减弱, 发生脱附, 因催化体系中没有游离的•O2 - 而避免了被过度氧化[47 ] .在羟胺化合物的帮助下, g-C3 N4 能很好地活化丙烯基位的碳氢键, 用于相应醛酮的合成[48 ] .CO2 的活化利用是有机合成的一个发展方向, Huang等[15 ] 在SBA-15的孔道中合成了g-C3 N4 , 经金属离子修饰后能够很好地活化CO2 用于环氧化合物和烯类化合物的合成.g-C3 N4 还能催化CO2 转化为CH4 [49 ] , 这将在燃料动力设备中发挥重要作用.g-C3 N4 中起桥连作用的N原子是Lewis碱活性位点, 可催化Knoevenagel缩合反应[50 ] .除此之外, g-C3 N4 可催化对苯二甲酸转化生成2-羟基对苯二甲酸[29 , 51 ] 、β-酮酯的酯交换反应[52 ] 、苯的傅-克酰基化反应[53 ] 、苯甲醛与醇的酯化反应[54 ] 和胺类的二聚反应[55 ] 等. ...

... 多孔g-C3 N4 合成后, 需要去除硬模板, 这往往需要使用剧毒的HF[92 ] 或NH4 HF2 [47 ] , 对人体的伤害较大.Xu等[95 ] 在前驱体中加入硫脲合成出多孔g-C3 N4 .同样, Dong等[94 ] 用三聚氰胺的盐酸季铵盐作为前驱体, 也合成出多孔的g-C3 N4 .硫脲和盐酸等软模板的加入, 不仅促使多孔结构的形成, 而且有效避免剧毒物质的使用.另外, 还可使用刻蚀液(如碱液[38 ] )将g-C3 N4 中不稳定的区域刻蚀掉, 得到多孔的g-C3 N4 . ...

Visible-light-induced metal-free allylic oxidation utilizing a coupled photocatalytic system of g-C3 N4 and N-Hydroxy compounds

1

2011

... 在有机合成中, 利用O2 作为氧化剂制备某些有机物时, 由于O2 氧化能力较强, 不可避免地会产生大量的过度氧化产物, g-C3 N4 的加入可有效地解决这一问题, 实现精确性氧化[45 -46 ] .在反应体系中, 氧气在g-C3 N4 表面与光激发产生的电子结合形成•O2 - , 由于空穴静电作用, •O2 - 吸附在g-C3 N4 表面.附着在g-C3 N4 上的反应物经•O2 - 氧化后吸附能力减弱, 发生脱附, 因催化体系中没有游离的•O2 - 而避免了被过度氧化[47 ] .在羟胺化合物的帮助下, g-C3 N4 能很好地活化丙烯基位的碳氢键, 用于相应醛酮的合成[48 ] .CO2 的活化利用是有机合成的一个发展方向, Huang等[15 ] 在SBA-15的孔道中合成了g-C3 N4 , 经金属离子修饰后能够很好地活化CO2 用于环氧化合物和烯类化合物的合成.g-C3 N4 还能催化CO2 转化为CH4 [49 ] , 这将在燃料动力设备中发挥重要作用.g-C3 N4 中起桥连作用的N原子是Lewis碱活性位点, 可催化Knoevenagel缩合反应[50 ] .除此之外, g-C3 N4 可催化对苯二甲酸转化生成2-羟基对苯二甲酸[29 , 51 ] 、β-酮酯的酯交换反应[52 ] 、苯的傅-克酰基化反应[53 ] 、苯甲醛与醇的酯化反应[54 ] 和胺类的二聚反应[55 ] 等. ...

Red phosphor/g-C3 N4 heterojunction with enhanced photocatalytic activities for solar fuels production

1

2013

... 在有机合成中, 利用O2 作为氧化剂制备某些有机物时, 由于O2 氧化能力较强, 不可避免地会产生大量的过度氧化产物, g-C3 N4 的加入可有效地解决这一问题, 实现精确性氧化[45 -46 ] .在反应体系中, 氧气在g-C3 N4 表面与光激发产生的电子结合形成•O2 - , 由于空穴静电作用, •O2 - 吸附在g-C3 N4 表面.附着在g-C3 N4 上的反应物经•O2 - 氧化后吸附能力减弱, 发生脱附, 因催化体系中没有游离的•O2 - 而避免了被过度氧化[47 ] .在羟胺化合物的帮助下, g-C3 N4 能很好地活化丙烯基位的碳氢键, 用于相应醛酮的合成[48 ] .CO2 的活化利用是有机合成的一个发展方向, Huang等[15 ] 在SBA-15的孔道中合成了g-C3 N4 , 经金属离子修饰后能够很好地活化CO2 用于环氧化合物和烯类化合物的合成.g-C3 N4 还能催化CO2 转化为CH4 [49 ] , 这将在燃料动力设备中发挥重要作用.g-C3 N4 中起桥连作用的N原子是Lewis碱活性位点, 可催化Knoevenagel缩合反应[50 ] .除此之外, g-C3 N4 可催化对苯二甲酸转化生成2-羟基对苯二甲酸[29 , 51 ] 、β-酮酯的酯交换反应[52 ] 、苯的傅-克酰基化反应[53 ] 、苯甲醛与醇的酯化反应[54 ] 和胺类的二聚反应[55 ] 等. ...

Mesoporous graphitic carbon nitride: synthesis and application towards knoevenagel condensation reactions

1

2013

... 在有机合成中, 利用O2 作为氧化剂制备某些有机物时, 由于O2 氧化能力较强, 不可避免地会产生大量的过度氧化产物, g-C3 N4 的加入可有效地解决这一问题, 实现精确性氧化[45 -46 ] .在反应体系中, 氧气在g-C3 N4 表面与光激发产生的电子结合形成•O2 - , 由于空穴静电作用, •O2 - 吸附在g-C3 N4 表面.附着在g-C3 N4 上的反应物经•O2 - 氧化后吸附能力减弱, 发生脱附, 因催化体系中没有游离的•O2 - 而避免了被过度氧化[47 ] .在羟胺化合物的帮助下, g-C3 N4 能很好地活化丙烯基位的碳氢键, 用于相应醛酮的合成[48 ] .CO2 的活化利用是有机合成的一个发展方向, Huang等[15 ] 在SBA-15的孔道中合成了g-C3 N4 , 经金属离子修饰后能够很好地活化CO2 用于环氧化合物和烯类化合物的合成.g-C3 N4 还能催化CO2 转化为CH4 [49 ] , 这将在燃料动力设备中发挥重要作用.g-C3 N4 中起桥连作用的N原子是Lewis碱活性位点, 可催化Knoevenagel缩合反应[50 ] .除此之外, g-C3 N4 可催化对苯二甲酸转化生成2-羟基对苯二甲酸[29 , 51 ] 、β-酮酯的酯交换反应[52 ] 、苯的傅-克酰基化反应[53 ] 、苯甲醛与醇的酯化反应[54 ] 和胺类的二聚反应[55 ] 等. ...

Graphene-like carbon nitride nanosheets for improved photocatalytic activities

3

2012

... 在有机合成中, 利用O2 作为氧化剂制备某些有机物时, 由于O2 氧化能力较强, 不可避免地会产生大量的过度氧化产物, g-C3 N4 的加入可有效地解决这一问题, 实现精确性氧化[45 -46 ] .在反应体系中, 氧气在g-C3 N4 表面与光激发产生的电子结合形成•O2 - , 由于空穴静电作用, •O2 - 吸附在g-C3 N4 表面.附着在g-C3 N4 上的反应物经•O2 - 氧化后吸附能力减弱, 发生脱附, 因催化体系中没有游离的•O2 - 而避免了被过度氧化[47 ] .在羟胺化合物的帮助下, g-C3 N4 能很好地活化丙烯基位的碳氢键, 用于相应醛酮的合成[48 ] .CO2 的活化利用是有机合成的一个发展方向, Huang等[15 ] 在SBA-15的孔道中合成了g-C3 N4 , 经金属离子修饰后能够很好地活化CO2 用于环氧化合物和烯类化合物的合成.g-C3 N4 还能催化CO2 转化为CH4 [49 ] , 这将在燃料动力设备中发挥重要作用.g-C3 N4 中起桥连作用的N原子是Lewis碱活性位点, 可催化Knoevenagel缩合反应[50 ] .除此之外, g-C3 N4 可催化对苯二甲酸转化生成2-羟基对苯二甲酸[29 , 51 ] 、β-酮酯的酯交换反应[52 ] 、苯的傅-克酰基化反应[53 ] 、苯甲醛与醇的酯化反应[54 ] 和胺类的二聚反应[55 ] 等. ...

... g-C3 N4 具有类石墨烯的结构, 所以可以将g-C3 N4 做成纳米薄片甚至单层的结构(如图5(d)).目前, 制备g-C3 N4 纳米薄层结构主要采用剥离法, 包括热剥离和溶剂剥离.热剥离是将g-C3 N4 在空气中进行热处理, 块状结构逐渐分解, 最后留下纳米薄层[20 ,51 ] .对块状g-C3 N4 进行溶剂剥离常使用的溶剂为水[12 , 68 ] 和异丙醇(IPA)[39 ] 等.Wu等[14 ] 经计算得出, 双层g-C3 N4 具有很好的光吸收性能, 但目前难以精确控制g-C3 N4 的层数. ...

... (a) Porous structure [94 ] ; (b) Nanoparticle[96 ] ; (c) Nanorod[23 ] ; (d) Nanosheet[51 ] ...

Highly ordered mesoporous carbon nitride nanoparticles with high nitrogen content: a metal-free basic catalyst

2

2009

... 在有机合成中, 利用O2 作为氧化剂制备某些有机物时, 由于O2 氧化能力较强, 不可避免地会产生大量的过度氧化产物, g-C3 N4 的加入可有效地解决这一问题, 实现精确性氧化[45 -46 ] .在反应体系中, 氧气在g-C3 N4 表面与光激发产生的电子结合形成•O2 - , 由于空穴静电作用, •O2 - 吸附在g-C3 N4 表面.附着在g-C3 N4 上的反应物经•O2 - 氧化后吸附能力减弱, 发生脱附, 因催化体系中没有游离的•O2 - 而避免了被过度氧化[47 ] .在羟胺化合物的帮助下, g-C3 N4 能很好地活化丙烯基位的碳氢键, 用于相应醛酮的合成[48 ] .CO2 的活化利用是有机合成的一个发展方向, Huang等[15 ] 在SBA-15的孔道中合成了g-C3 N4 , 经金属离子修饰后能够很好地活化CO2 用于环氧化合物和烯类化合物的合成.g-C3 N4 还能催化CO2 转化为CH4 [49 ] , 这将在燃料动力设备中发挥重要作用.g-C3 N4 中起桥连作用的N原子是Lewis碱活性位点, 可催化Knoevenagel缩合反应[50 ] .除此之外, g-C3 N4 可催化对苯二甲酸转化生成2-羟基对苯二甲酸[29 , 51 ] 、β-酮酯的酯交换反应[52 ] 、苯的傅-克酰基化反应[53 ] 、苯甲醛与醇的酯化反应[54 ] 和胺类的二聚反应[55 ] 等. ...

... 利用SiO2 作为硬模板, 可合成出多孔结构的g-C3 N4 [45 , 52 -53 , 92 -94 ] (如图5(a)), 其光催化苯的傅-克酰基化反应、光解水制氢和对醇的选择性氧化的能力明显提高.多孔结构使g-C3 N4 比表面积增加, 电子的捕捉位点增多, 减缓了电子空穴对的复合, 使其能克服带隙略微增加带来的不利影响而提高光催化性能[94 ] . ...

Chemical synthesis of mesoporous carbon nitrides using hard templates and their use as a metal-free catalyst for friedel-crafts reaction of benzene

2

2006

... 在有机合成中, 利用O2 作为氧化剂制备某些有机物时, 由于O2 氧化能力较强, 不可避免地会产生大量的过度氧化产物, g-C3 N4 的加入可有效地解决这一问题, 实现精确性氧化[45 -46 ] .在反应体系中, 氧气在g-C3 N4 表面与光激发产生的电子结合形成•O2 - , 由于空穴静电作用, •O2 - 吸附在g-C3 N4 表面.附着在g-C3 N4 上的反应物经•O2 - 氧化后吸附能力减弱, 发生脱附, 因催化体系中没有游离的•O2 - 而避免了被过度氧化[47 ] .在羟胺化合物的帮助下, g-C3 N4 能很好地活化丙烯基位的碳氢键, 用于相应醛酮的合成[48 ] .CO2 的活化利用是有机合成的一个发展方向, Huang等[15 ] 在SBA-15的孔道中合成了g-C3 N4 , 经金属离子修饰后能够很好地活化CO2 用于环氧化合物和烯类化合物的合成.g-C3 N4 还能催化CO2 转化为CH4 [49 ] , 这将在燃料动力设备中发挥重要作用.g-C3 N4 中起桥连作用的N原子是Lewis碱活性位点, 可催化Knoevenagel缩合反应[50 ] .除此之外, g-C3 N4 可催化对苯二甲酸转化生成2-羟基对苯二甲酸[29 , 51 ] 、β-酮酯的酯交换反应[52 ] 、苯的傅-克酰基化反应[53 ] 、苯甲醛与醇的酯化反应[54 ] 和胺类的二聚反应[55 ] 等. ...

... 利用SiO2 作为硬模板, 可合成出多孔结构的g-C3 N4 [45 , 52 -53 , 92 -94 ] (如图5(a)), 其光催化苯的傅-克酰基化反应、光解水制氢和对醇的选择性氧化的能力明显提高.多孔结构使g-C3 N4 比表面积增加, 电子的捕捉位点增多, 减缓了电子空穴对的复合, 使其能克服带隙略微增加带来的不利影响而提高光催化性能[94 ] . ...

Graphitic C3 N4 photocatalyst for esterification of benzaldehyde and alcohol under visible light radiation

1

2012

... 在有机合成中, 利用O2 作为氧化剂制备某些有机物时, 由于O2 氧化能力较强, 不可避免地会产生大量的过度氧化产物, g-C3 N4 的加入可有效地解决这一问题, 实现精确性氧化[45 -46 ] .在反应体系中, 氧气在g-C3 N4 表面与光激发产生的电子结合形成•O2 - , 由于空穴静电作用, •O2 - 吸附在g-C3 N4 表面.附着在g-C3 N4 上的反应物经•O2 - 氧化后吸附能力减弱, 发生脱附, 因催化体系中没有游离的•O2 - 而避免了被过度氧化[47 ] .在羟胺化合物的帮助下, g-C3 N4 能很好地活化丙烯基位的碳氢键, 用于相应醛酮的合成[48 ] .CO2 的活化利用是有机合成的一个发展方向, Huang等[15 ] 在SBA-15的孔道中合成了g-C3 N4 , 经金属离子修饰后能够很好地活化CO2 用于环氧化合物和烯类化合物的合成.g-C3 N4 还能催化CO2 转化为CH4 [49 ] , 这将在燃料动力设备中发挥重要作用.g-C3 N4 中起桥连作用的N原子是Lewis碱活性位点, 可催化Knoevenagel缩合反应[50 ] .除此之外, g-C3 N4 可催化对苯二甲酸转化生成2-羟基对苯二甲酸[29 , 51 ] 、β-酮酯的酯交换反应[52 ] 、苯的傅-克酰基化反应[53 ] 、苯甲醛与醇的酯化反应[54 ] 和胺类的二聚反应[55 ] 等. ...

Aerobic oxidative coupling of amines by carbon nitride photocatalysis with visible light

1

2011

... 在有机合成中, 利用O2 作为氧化剂制备某些有机物时, 由于O2 氧化能力较强, 不可避免地会产生大量的过度氧化产物, g-C3 N4 的加入可有效地解决这一问题, 实现精确性氧化[45 -46 ] .在反应体系中, 氧气在g-C3 N4 表面与光激发产生的电子结合形成•O2 - , 由于空穴静电作用, •O2 - 吸附在g-C3 N4 表面.附着在g-C3 N4 上的反应物经•O2 - 氧化后吸附能力减弱, 发生脱附, 因催化体系中没有游离的•O2 - 而避免了被过度氧化[47 ] .在羟胺化合物的帮助下, g-C3 N4 能很好地活化丙烯基位的碳氢键, 用于相应醛酮的合成[48 ] .CO2 的活化利用是有机合成的一个发展方向, Huang等[15 ] 在SBA-15的孔道中合成了g-C3 N4 , 经金属离子修饰后能够很好地活化CO2 用于环氧化合物和烯类化合物的合成.g-C3 N4 还能催化CO2 转化为CH4 [49 ] , 这将在燃料动力设备中发挥重要作用.g-C3 N4 中起桥连作用的N原子是Lewis碱活性位点, 可催化Knoevenagel缩合反应[50 ] .除此之外, g-C3 N4 可催化对苯二甲酸转化生成2-羟基对苯二甲酸[29 , 51 ] 、β-酮酯的酯交换反应[52 ] 、苯的傅-克酰基化反应[53 ] 、苯甲醛与醇的酯化反应[54 ] 和胺类的二聚反应[55 ] 等. ...

Carbon alloy catalysts: active sites for oxygen reduction reaction

1

2008

... 氧气的还原反应(ORR)是燃料电池的一个重要的半反应.碳材料中共轭的N原子可以有效地催化ORR[56 ] , 故对ORR的催化已成为g-C3 N4 应用研究的一个方向[57 ] .O2 的最低空轨道(LUMO)与g-C3 N4 中的共轭氮原子相互作用, 发生电荷的转移, 从而促进氧气的还原[58 ] .研究表明, g-C3 N4 对ORR的光催化是一个较为复杂的过程, 其可分为四电子还原 ...

Graphitic carbon nitride materials: controllable synthesis and applications in fuel cells and photocatalysis

1

2012

... 氧气的还原反应(ORR)是燃料电池的一个重要的半反应.碳材料中共轭的N原子可以有效地催化ORR[56 ] , 故对ORR的催化已成为g-C3 N4 应用研究的一个方向[57 ] .O2 的最低空轨道(LUMO)与g-C3 N4 中的共轭氮原子相互作用, 发生电荷的转移, 从而促进氧气的还原[58 ] .研究表明, g-C3 N4 对ORR的光催化是一个较为复杂的过程, 其可分为四电子还原 ...

Density functional theory-based analysis on O2 molecular interaction with the tri-s- triazine-based graphitic carbon nitride

1

2012

... 氧气的还原反应(ORR)是燃料电池的一个重要的半反应.碳材料中共轭的N原子可以有效地催化ORR[56 ] , 故对ORR的催化已成为g-C3 N4 应用研究的一个方向[57 ] .O2 的最低空轨道(LUMO)与g-C3 N4 中的共轭氮原子相互作用, 发生电荷的转移, 从而促进氧气的还原[58 ] .研究表明, g-C3 N4 对ORR的光催化是一个较为复杂的过程, 其可分为四电子还原 ...

Nanostructured metal-free electrochemical catalysts for highly efficient oxygen reduction

1

2012

... 两种[59 ] .经石墨烯/CoO[60 ] 、石墨烯/Co[61 ] 、C[62 ] 、Fe[63 ] 修饰的g-C3 N4 对ORR具有较好的催化活性, 具有较好的应用前景. ...

A highly active and stable electrocatalyst for the oxygen reduction reaction based on a graphene-supported g-C3 N4 @cobalt oxide core-shell hybrid in alkaline solution

1

2013

... 两种[59 ] .经石墨烯/CoO[60 ] 、石墨烯/Co[61 ] 、C[62 ] 、Fe[63 ] 修饰的g-C3 N4 对ORR具有较好的催化活性, 具有较好的应用前景. ...

Graphene supported Co-g-C3 N4 as a novel metal-macrocyclic electrocatalyst for the oxygen reduction reaction in fuel cells

1

2013

... 两种[59 ] .经石墨烯/CoO[60 ] 、石墨烯/Co[61 ] 、C[62 ] 、Fe[63 ] 修饰的g-C3 N4 对ORR具有较好的催化活性, 具有较好的应用前景. ...

Nanoporous graphitic- C3 N4 @carbon metal-free electrocatalysts for highly efficient oxygen reduction

1

2011

... 两种[59 ] .经石墨烯/CoO[60 ] 、石墨烯/Co[61 ] 、C[62 ] 、Fe[63 ] 修饰的g-C3 N4 对ORR具有较好的催化活性, 具有较好的应用前景. ...

Catalytic performance of heat-treated Fe-melamine/C and Fe-g-C3 N4 /C electrocatalysts for oxygen reduction reaction

1

2013

... 两种[59 ] .经石墨烯/CoO[60 ] 、石墨烯/Co[61 ] 、C[62 ] 、Fe[63 ] 修饰的g-C3 N4 对ORR具有较好的催化活性, 具有较好的应用前景. ...

A novel application of g-C3 N4 thin film in photoelectrochemical anticorrosion

1

... 除了上面几种在光催化领域的应用外, 科研人员还开发了g-C3 N4 的其他用途, 例如对钢材的电化学保护[64 ] 、合成石墨烯的模板[65 ] 、光生电[66 ] 、超级电容器[67 ] 、荧光探测和成像[12 , 68 -69 ] 等. ...

Synthesis of monolayer- patched graphene from glucose

1

2012

... 除了上面几种在光催化领域的应用外, 科研人员还开发了g-C3 N4 的其他用途, 例如对钢材的电化学保护[64 ] 、合成石墨烯的模板[65 ] 、光生电[66 ] 、超级电容器[67 ] 、荧光探测和成像[12 , 68 -69 ] 等. ...

Phosphorus-doped carbon nitride solid enhanced electrical conductivity and photocurrent generation

2

2010

... 除了上面几种在光催化领域的应用外, 科研人员还开发了g-C3 N4 的其他用途, 例如对钢材的电化学保护[64 ] 、合成石墨烯的模板[65 ] 、光生电[66 ] 、超级电容器[67 ] 、荧光探测和成像[12 , 68 -69 ] 等. ...

... 化学掺杂改性能够很好地改变g-C3 N4 的电子结构, 从而改善光催化性能.目前, 常采用杂环[44 , 83 -85 ] 和杂原子(如S[29 ] 、P[66 ] 、B[86 ] 、F[87 ] 等)进行掺杂.杂环的引入使g-C3 N4 的电子电势重新分配, 氧化还原位点分离[44 ] , 光催化性能提高(如图4、表2).S、P、B、F等杂原子与C、N原子的电负性不同, 它们的引入必然引起电子在整个网络中的不均匀, 导致电子结构的改变[88 -89 ] , 从而影响g-C3 N4 的光催化性能(如表2).异类元素的引入容易导致不对称掺杂或杂质, 这些都可以作为电子空穴的复合中心, 从而不利于光催化性能的提高, 故Dong等[90 ] 研究了C的自掺杂对g-C3 N4 光催化性能的影响, 发现掺杂的C取代了g-C3 N4 网络中起桥连作用的N, 扩大了电子的离域范围, 增加了电导率, 降低了带隙, 光催化性能得到了提高. ...

Reactable ionic liquid assisted solvothermal synthesis of graphite-like C3 N4 hybridized α-Fe2 O3 hollow microspheres with enhanced supercapacitive performance

1

2014

... 除了上面几种在光催化领域的应用外, 科研人员还开发了g-C3 N4 的其他用途, 例如对钢材的电化学保护[64 ] 、合成石墨烯的模板[65 ] 、光生电[66 ] 、超级电容器[67 ] 、荧光探测和成像[12 , 68 -69 ] 等. ...

Ultrathin graphitic carbon nitride nanosheet: a highly efficient fluorosensor for rapid, ultrasensitive detection of Cu2 +

2

2013

... 除了上面几种在光催化领域的应用外, 科研人员还开发了g-C3 N4 的其他用途, 例如对钢材的电化学保护[64 ] 、合成石墨烯的模板[65 ] 、光生电[66 ] 、超级电容器[67 ] 、荧光探测和成像[12 , 68 -69 ] 等. ...

... g-C3 N4 具有类石墨烯的结构, 所以可以将g-C3 N4 做成纳米薄片甚至单层的结构(如图5(d)).目前, 制备g-C3 N4 纳米薄层结构主要采用剥离法, 包括热剥离和溶剂剥离.热剥离是将g-C3 N4 在空气中进行热处理, 块状结构逐渐分解, 最后留下纳米薄层[20 ,51 ] .对块状g-C3 N4 进行溶剂剥离常使用的溶剂为水[12 , 68 ] 和异丙醇(IPA)[39 ] 等.Wu等[14 ] 经计算得出, 双层g-C3 N4 具有很好的光吸收性能, 但目前难以精确控制g-C3 N4 的层数. ...

Electrogenerated chemiluminescence behavior of graphite-like carbon nitride and its application in selective sensing Cu2 +

1

2012

... 除了上面几种在光催化领域的应用外, 科研人员还开发了g-C3 N4 的其他用途, 例如对钢材的电化学保护[64 ] 、合成石墨烯的模板[65 ] 、光生电[66 ] 、超级电容器[67 ] 、荧光探测和成像[12 , 68 -69 ] 等. ...

Novel visible-light-driven AgX/graphite-like C3 N4 (X=Br, I) hybrid materials with synergistic photocatalytic activity

1

2013

... 物理复合改性是最方便的改进方法.目前, 选用的复合物主要有金属化合物(如CdS[40 ] 、Fe3 O4 [27 ] 、ZnO[28 ] 、AgX[70 ] (X= Br, I)、TiO2 [30 , 71 ] 、SmVO4 [72 ] 、MoS2 [41 ] 、Bi2 WO6 [73 ] 等)、类石墨烯材料(如石墨烯[74 ] 、氧化石墨烯[32 ] 、碳纳米管[75 ] 等), 高分子化合物(如P3HT[76 ] 、PANI[77 ] 等)和贵金属(如金[77 ] )等, 复合后g-C3 N4 的光催化性能都有一定提高(如表1).g-C3 N4 与复合物质之间并非简单的物理混合, 而是充分接触并形成异质结.由于二者导带和价带位置的差异, g-C3 N4 光激发产生的电子或空穴转移至复合物的导带或价带中, 电子空穴分离(如图3), 复合率降低, 从而可以更高效地利用光激发产生的活性粒子.经某些颜料(如曙红Y[78 ] )光敏化的g-C3 N4 对可见光的吸收增强, 光催化能力明显提高.复合物的加入还可赋予催化剂一些独特的优点, 例如g-C3 N4 与Fe3 O4 [27 ] 、Bi25 FeO40 [79 ] 复合后具有磁性, 方便了光催化剂的回收利用. ...

Enhanced photocatalytic performance of direct Z-scheme g-C3 N4 -TiO2 photocatalysts for the decomposition of formaldehyde in air

2

2013

... 物理复合改性是最方便的改进方法.目前, 选用的复合物主要有金属化合物(如CdS[40 ] 、Fe3 O4 [27 ] 、ZnO[28 ] 、AgX[70 ] (X= Br, I)、TiO2 [30 , 71 ] 、SmVO4 [72 ] 、MoS2 [41 ] 、Bi2 WO6 [73 ] 等)、类石墨烯材料(如石墨烯[74 ] 、氧化石墨烯[32 ] 、碳纳米管[75 ] 等), 高分子化合物(如P3HT[76 ] 、PANI[77 ] 等)和贵金属(如金[77 ] )等, 复合后g-C3 N4 的光催化性能都有一定提高(如表1).g-C3 N4 与复合物质之间并非简单的物理混合, 而是充分接触并形成异质结.由于二者导带和价带位置的差异, g-C3 N4 光激发产生的电子或空穴转移至复合物的导带或价带中, 电子空穴分离(如图3), 复合率降低, 从而可以更高效地利用光激发产生的活性粒子.经某些颜料(如曙红Y[78 ] )光敏化的g-C3 N4 对可见光的吸收增强, 光催化能力明显提高.复合物的加入还可赋予催化剂一些独特的优点, 例如g-C3 N4 与Fe3 O4 [27 ] 、Bi25 FeO40 [79 ] 复合后具有磁性, 方便了光催化剂的回收利用. ...

... (a) Convection-type charge transfer[30 , 40 ] (such as TiO2 , CdS); (b) Advection-type charge transfer[27 , 74 ] (such as Fe3 O4 , graphene); (c) Z-type charge transfer [35 , 71 ] ...

Synthesis of g-C3 N4 /SmVO4 composite photocatalyst with improved visible light photocatalytic activities in RhB degradation

1

2013

... 物理复合改性是最方便的改进方法.目前, 选用的复合物主要有金属化合物(如CdS[40 ] 、Fe3 O4 [27 ] 、ZnO[28 ] 、AgX[70 ] (X= Br, I)、TiO2 [30 , 71 ] 、SmVO4 [72 ] 、MoS2 [41 ] 、Bi2 WO6 [73 ] 等)、类石墨烯材料(如石墨烯[74 ] 、氧化石墨烯[32 ] 、碳纳米管[75 ] 等), 高分子化合物(如P3HT[76 ] 、PANI[77 ] 等)和贵金属(如金[77 ] )等, 复合后g-C3 N4 的光催化性能都有一定提高(如表1).g-C3 N4 与复合物质之间并非简单的物理混合, 而是充分接触并形成异质结.由于二者导带和价带位置的差异, g-C3 N4 光激发产生的电子或空穴转移至复合物的导带或价带中, 电子空穴分离(如图3), 复合率降低, 从而可以更高效地利用光激发产生的活性粒子.经某些颜料(如曙红Y[78 ] )光敏化的g-C3 N4 对可见光的吸收增强, 光催化能力明显提高.复合物的加入还可赋予催化剂一些独特的优点, 例如g-C3 N4 与Fe3 O4 [27 ] 、Bi25 FeO40 [79 ] 复合后具有磁性, 方便了光催化剂的回收利用. ...

Synthesis and visible-light photocatalytic activity of Bi2 WO6 /g-C3 N4 composite photocatalysts

1

2013

... 物理复合改性是最方便的改进方法.目前, 选用的复合物主要有金属化合物(如CdS[40 ] 、Fe3 O4 [27 ] 、ZnO[28 ] 、AgX[70 ] (X= Br, I)、TiO2 [30 , 71 ] 、SmVO4 [72 ] 、MoS2 [41 ] 、Bi2 WO6 [73 ] 等)、类石墨烯材料(如石墨烯[74 ] 、氧化石墨烯[32 ] 、碳纳米管[75 ] 等), 高分子化合物(如P3HT[76 ] 、PANI[77 ] 等)和贵金属(如金[77 ] )等, 复合后g-C3 N4 的光催化性能都有一定提高(如表1).g-C3 N4 与复合物质之间并非简单的物理混合, 而是充分接触并形成异质结.由于二者导带和价带位置的差异, g-C3 N4 光激发产生的电子或空穴转移至复合物的导带或价带中, 电子空穴分离(如图3), 复合率降低, 从而可以更高效地利用光激发产生的活性粒子.经某些颜料(如曙红Y[78 ] )光敏化的g-C3 N4 对可见光的吸收增强, 光催化能力明显提高.复合物的加入还可赋予催化剂一些独特的优点, 例如g-C3 N4 与Fe3 O4 [27 ] 、Bi25 FeO40 [79 ] 复合后具有磁性, 方便了光催化剂的回收利用. ...

Preparation and enhanced visible-light photocatalytic H2 -production activity of graphene /C3 N4 composites

2

2011

... 物理复合改性是最方便的改进方法.目前, 选用的复合物主要有金属化合物(如CdS[40 ] 、Fe3 O4 [27 ] 、ZnO[28 ] 、AgX[70 ] (X= Br, I)、TiO2 [30 , 71 ] 、SmVO4 [72 ] 、MoS2 [41 ] 、Bi2 WO6 [73 ] 等)、类石墨烯材料(如石墨烯[74 ] 、氧化石墨烯[32 ] 、碳纳米管[75 ] 等), 高分子化合物(如P3HT[76 ] 、PANI[77 ] 等)和贵金属(如金[77 ] )等, 复合后g-C3 N4 的光催化性能都有一定提高(如表1).g-C3 N4 与复合物质之间并非简单的物理混合, 而是充分接触并形成异质结.由于二者导带和价带位置的差异, g-C3 N4 光激发产生的电子或空穴转移至复合物的导带或价带中, 电子空穴分离(如图3), 复合率降低, 从而可以更高效地利用光激发产生的活性粒子.经某些颜料(如曙红Y[78 ] )光敏化的g-C3 N4 对可见光的吸收增强, 光催化能力明显提高.复合物的加入还可赋予催化剂一些独特的优点, 例如g-C3 N4 与Fe3 O4 [27 ] 、Bi25 FeO40 [79 ] 复合后具有磁性, 方便了光催化剂的回收利用. ...

... (a) Convection-type charge transfer[30 , 40 ] (such as TiO2 , CdS); (b) Advection-type charge transfer[27 , 74 ] (such as Fe3 O4 , graphene); (c) Z-type charge transfer [35 , 71 ] ...

Doubling of photocatalytic H2 evolution from g-C3 N4 via its nanocomposite formation with multiwall carbon nanotubes: electronic and morphological effects

1

2012

... 物理复合改性是最方便的改进方法.目前, 选用的复合物主要有金属化合物(如CdS[40 ] 、Fe3 O4 [27 ] 、ZnO[28 ] 、AgX[70 ] (X= Br, I)、TiO2 [30 , 71 ] 、SmVO4 [72 ] 、MoS2 [41 ] 、Bi2 WO6 [73 ] 等)、类石墨烯材料(如石墨烯[74 ] 、氧化石墨烯[32 ] 、碳纳米管[75 ] 等), 高分子化合物(如P3HT[76 ] 、PANI[77 ] 等)和贵金属(如金[77 ] )等, 复合后g-C3 N4 的光催化性能都有一定提高(如表1).g-C3 N4 与复合物质之间并非简单的物理混合, 而是充分接触并形成异质结.由于二者导带和价带位置的差异, g-C3 N4 光激发产生的电子或空穴转移至复合物的导带或价带中, 电子空穴分离(如图3), 复合率降低, 从而可以更高效地利用光激发产生的活性粒子.经某些颜料(如曙红Y[78 ] )光敏化的g-C3 N4 对可见光的吸收增强, 光催化能力明显提高.复合物的加入还可赋予催化剂一些独特的优点, 例如g-C3 N4 与Fe3 O4 [27 ] 、Bi25 FeO40 [79 ] 复合后具有磁性, 方便了光催化剂的回收利用. ...

Polymer composites of carbon nitride and poly(3-hexylthiophene) to achieve enhanced hydrogen production from water under visible light

1

2011

... 物理复合改性是最方便的改进方法.目前, 选用的复合物主要有金属化合物(如CdS[40 ] 、Fe3 O4 [27 ] 、ZnO[28 ] 、AgX[70 ] (X= Br, I)、TiO2 [30 , 71 ] 、SmVO4 [72 ] 、MoS2 [41 ] 、Bi2 WO6 [73 ] 等)、类石墨烯材料(如石墨烯[74 ] 、氧化石墨烯[32 ] 、碳纳米管[75 ] 等), 高分子化合物(如P3HT[76 ] 、PANI[77 ] 等)和贵金属(如金[77 ] )等, 复合后g-C3 N4 的光催化性能都有一定提高(如表1).g-C3 N4 与复合物质之间并非简单的物理混合, 而是充分接触并形成异质结.由于二者导带和价带位置的差异, g-C3 N4 光激发产生的电子或空穴转移至复合物的导带或价带中, 电子空穴分离(如图3), 复合率降低, 从而可以更高效地利用光激发产生的活性粒子.经某些颜料(如曙红Y[78 ] )光敏化的g-C3 N4 对可见光的吸收增强, 光催化能力明显提高.复合物的加入还可赋予催化剂一些独特的优点, 例如g-C3 N4 与Fe3 O4 [27 ] 、Bi25 FeO40 [79 ] 复合后具有磁性, 方便了光催化剂的回收利用. ...

In situ synthesis and enhanced visible light photocatalytic activities of novel PANI-g-C3 N4 composite photocatalysts

2

2012

... 物理复合改性是最方便的改进方法.目前, 选用的复合物主要有金属化合物(如CdS[40 ] 、Fe3 O4 [27 ] 、ZnO[28 ] 、AgX[70 ] (X= Br, I)、TiO2 [30 , 71 ] 、SmVO4 [72 ] 、MoS2 [41 ] 、Bi2 WO6 [73 ] 等)、类石墨烯材料(如石墨烯[74 ] 、氧化石墨烯[32 ] 、碳纳米管[75 ] 等), 高分子化合物(如P3HT[76 ] 、PANI[77 ] 等)和贵金属(如金[77 ] )等, 复合后g-C3 N4 的光催化性能都有一定提高(如表1).g-C3 N4 与复合物质之间并非简单的物理混合, 而是充分接触并形成异质结.由于二者导带和价带位置的差异, g-C3 N4 光激发产生的电子或空穴转移至复合物的导带或价带中, 电子空穴分离(如图3), 复合率降低, 从而可以更高效地利用光激发产生的活性粒子.经某些颜料(如曙红Y[78 ] )光敏化的g-C3 N4 对可见光的吸收增强, 光催化能力明显提高.复合物的加入还可赋予催化剂一些独特的优点, 例如g-C3 N4 与Fe3 O4 [27 ] 、Bi25 FeO40 [79 ] 复合后具有磁性, 方便了光催化剂的回收利用. ...

... [77 ])等, 复合后g-C3 N4 的光催化性能都有一定提高(如表1).g-C3 N4 与复合物质之间并非简单的物理混合, 而是充分接触并形成异质结.由于二者导带和价带位置的差异, g-C3 N4 光激发产生的电子或空穴转移至复合物的导带或价带中, 电子空穴分离(如图3), 复合率降低, 从而可以更高效地利用光激发产生的活性粒子.经某些颜料(如曙红Y[78 ] )光敏化的g-C3 N4 对可见光的吸收增强, 光催化能力明显提高.复合物的加入还可赋予催化剂一些独特的优点, 例如g-C3 N4 与Fe3 O4 [27 ] 、Bi25 FeO40 [79 ] 复合后具有磁性, 方便了光催化剂的回收利用. ...

Enhanced electron transfer from the excited eosin Y to mpg-C3 N4 for highly efficient hydrogen evolution under 550 nm irradiation

1

2012

... 物理复合改性是最方便的改进方法.目前, 选用的复合物主要有金属化合物(如CdS[40 ] 、Fe3 O4 [27 ] 、ZnO[28 ] 、AgX[70 ] (X= Br, I)、TiO2 [30 , 71 ] 、SmVO4 [72 ] 、MoS2 [41 ] 、Bi2 WO6 [73 ] 等)、类石墨烯材料(如石墨烯[74 ] 、氧化石墨烯[32 ] 、碳纳米管[75 ] 等), 高分子化合物(如P3HT[76 ] 、PANI[77 ] 等)和贵金属(如金[77 ] )等, 复合后g-C3 N4 的光催化性能都有一定提高(如表1).g-C3 N4 与复合物质之间并非简单的物理混合, 而是充分接触并形成异质结.由于二者导带和价带位置的差异, g-C3 N4 光激发产生的电子或空穴转移至复合物的导带或价带中, 电子空穴分离(如图3), 复合率降低, 从而可以更高效地利用光激发产生的活性粒子.经某些颜料(如曙红Y[78 ] )光敏化的g-C3 N4 对可见光的吸收增强, 光催化能力明显提高.复合物的加入还可赋予催化剂一些独特的优点, 例如g-C3 N4 与Fe3 O4 [27 ] 、Bi25 FeO40 [79 ] 复合后具有磁性, 方便了光催化剂的回收利用. ...

Synthesis of Bi25 FeO40 - g-C3 N4 magnetic catalyst and its photocatalytic performance

1

2013

... 物理复合改性是最方便的改进方法.目前, 选用的复合物主要有金属化合物(如CdS[40 ] 、Fe3 O4 [27 ] 、ZnO[28 ] 、AgX[70 ] (X= Br, I)、TiO2 [30 , 71 ] 、SmVO4 [72 ] 、MoS2 [41 ] 、Bi2 WO6 [73 ] 等)、类石墨烯材料(如石墨烯[74 ] 、氧化石墨烯[32 ] 、碳纳米管[75 ] 等), 高分子化合物(如P3HT[76 ] 、PANI[77 ] 等)和贵金属(如金[77 ] )等, 复合后g-C3 N4 的光催化性能都有一定提高(如表1).g-C3 N4 与复合物质之间并非简单的物理混合, 而是充分接触并形成异质结.由于二者导带和价带位置的差异, g-C3 N4 光激发产生的电子或空穴转移至复合物的导带或价带中, 电子空穴分离(如图3), 复合率降低, 从而可以更高效地利用光激发产生的活性粒子.经某些颜料(如曙红Y[78 ] )光敏化的g-C3 N4 对可见光的吸收增强, 光催化能力明显提高.复合物的加入还可赋予催化剂一些独特的优点, 例如g-C3 N4 与Fe3 O4 [27 ] 、Bi25 FeO40 [79 ] 复合后具有磁性, 方便了光催化剂的回收利用. ...

Efficient degradation of RhB over GdVO4 /g-C3 N4 composites under visible-light irradiation

2013

Synthesis, characterization, and activity evaluation of DyVO4 /g-C3 N4 composites under visible-light irradiation

2012

Constructing 2D porous graphitic C3 N4 nanosheets/nitrogen-doped graphene/layered MoS2 ternary nanojunction with enhanced photoelectrochemical activity

2013

Co-monomer control of carbon nitride semiconductors to optimize hydrogen evolution with visible light

4

2012

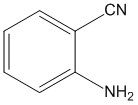

... 化学掺杂改性能够很好地改变g-C3 N4 的电子结构, 从而改善光催化性能.目前, 常采用杂环[44 , 83 -85 ] 和杂原子(如S[29 ] 、P[66 ] 、B[86 ] 、F[87 ] 等)进行掺杂.杂环的引入使g-C3 N4 的电子电势重新分配, 氧化还原位点分离[44 ] , 光催化性能提高(如图4、表2).S、P、B、F等杂原子与C、N原子的电负性不同, 它们的引入必然引起电子在整个网络中的不均匀, 导致电子结构的改变[88 -89 ] , 从而影响g-C3 N4 的光催化性能(如表2).异类元素的引入容易导致不对称掺杂或杂质, 这些都可以作为电子空穴的复合中心, 从而不利于光催化性能的提高, 故Dong等[90 ] 研究了C的自掺杂对g-C3 N4 光催化性能的影响, 发现掺杂的C取代了g-C3 N4 网络中起桥连作用的N, 扩大了电子的离域范围, 增加了电导率, 降低了带隙, 光催化性能得到了提高. ...

... 引入不同的杂环对g-C3 N4 水解制氢速率的影响[83 ] ...

... Influence of different heterocycles introduced into g-C3 N4 on the rate of hydrogen production[83 ] ...

... 除了上述方法外, 还有一些其他的改性手段, 例如利用NaNO3 引入活性缺陷[98 ] 等.单一的改性方法对光催化性能的提高都是有限的, 同时应用多种改性方法[83 , 99 ] 有望获得更好的效果. ...

Synthesis of a carbon nitride structure for visible-light catalysis by copolymerization

2010

Modification of carbon nitride phtocatalysts by copolymerization with diaminomaleonitrile

1

2012

... 化学掺杂改性能够很好地改变g-C3 N4 的电子结构, 从而改善光催化性能.目前, 常采用杂环[44 , 83 -85 ] 和杂原子(如S[29 ] 、P[66 ] 、B[86 ] 、F[87 ] 等)进行掺杂.杂环的引入使g-C3 N4 的电子电势重新分配, 氧化还原位点分离[44 ] , 光催化性能提高(如图4、表2).S、P、B、F等杂原子与C、N原子的电负性不同, 它们的引入必然引起电子在整个网络中的不均匀, 导致电子结构的改变[88 -89 ] , 从而影响g-C3 N4 的光催化性能(如表2).异类元素的引入容易导致不对称掺杂或杂质, 这些都可以作为电子空穴的复合中心, 从而不利于光催化性能的提高, 故Dong等[90 ] 研究了C的自掺杂对g-C3 N4 光催化性能的影响, 发现掺杂的C取代了g-C3 N4 网络中起桥连作用的N, 扩大了电子的离域范围, 增加了电导率, 降低了带隙, 光催化性能得到了提高. ...

Photodegradation of rhodamine B and methyl orange over boron-doped g-C3 N4 under visible light irradiation

1

2010